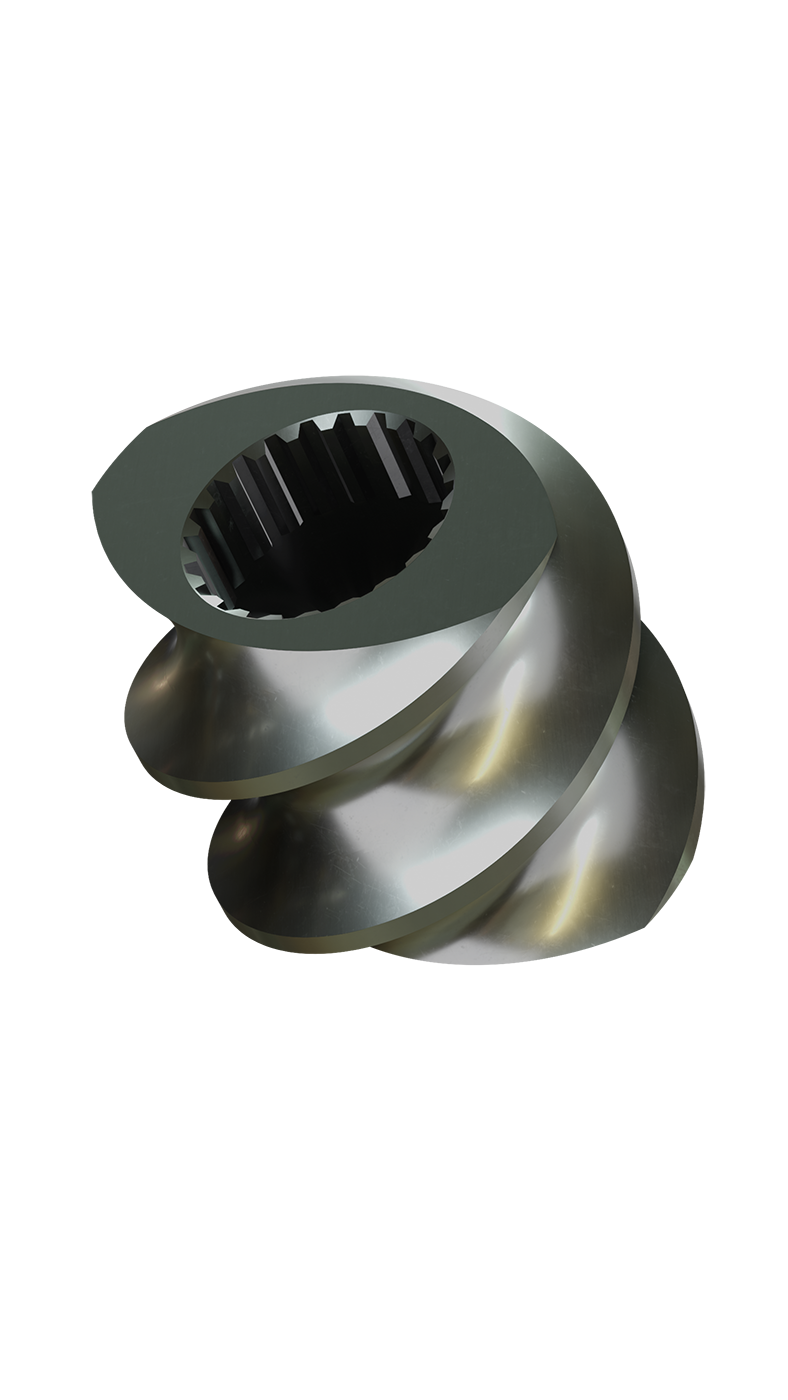

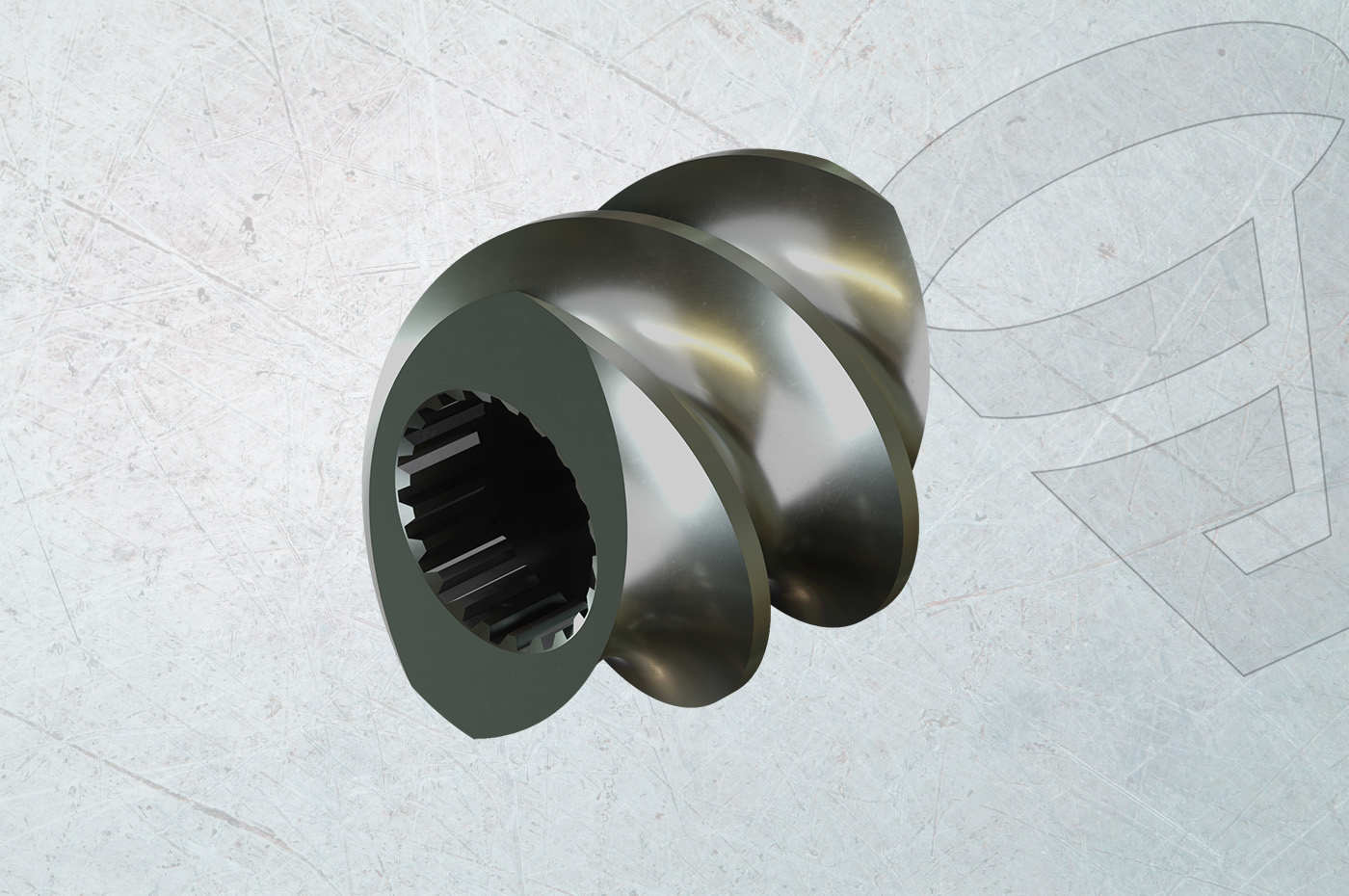

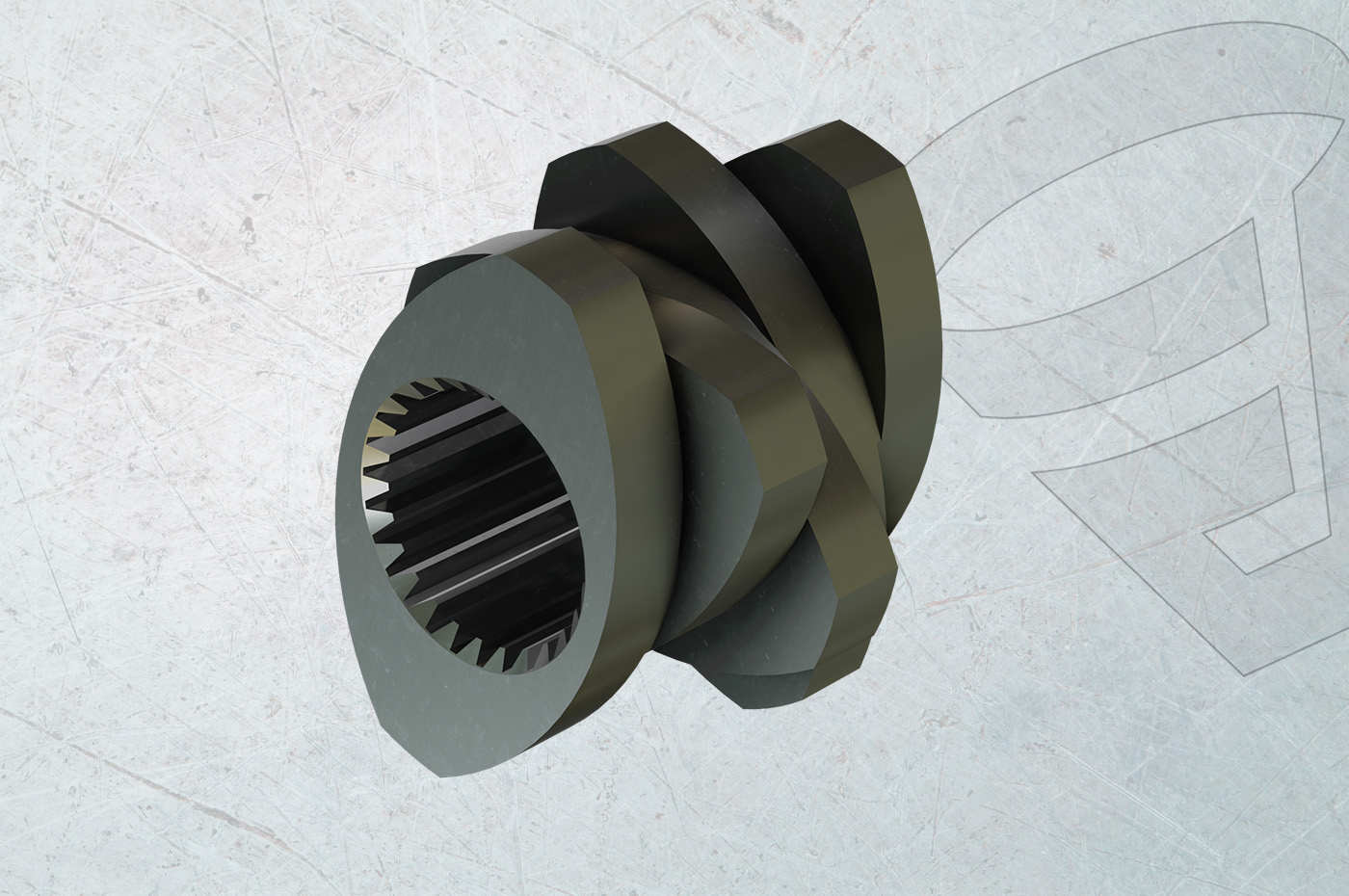

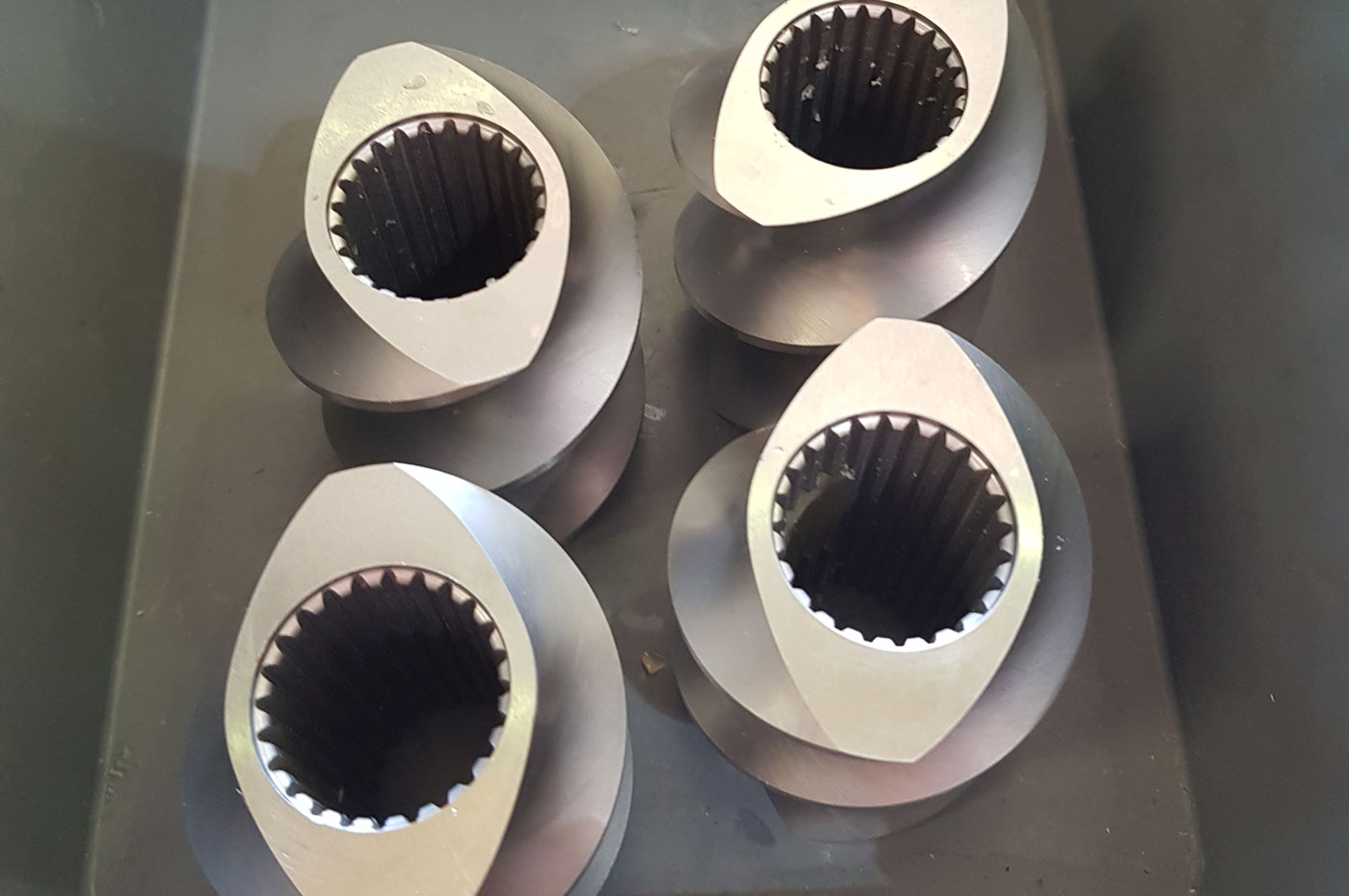

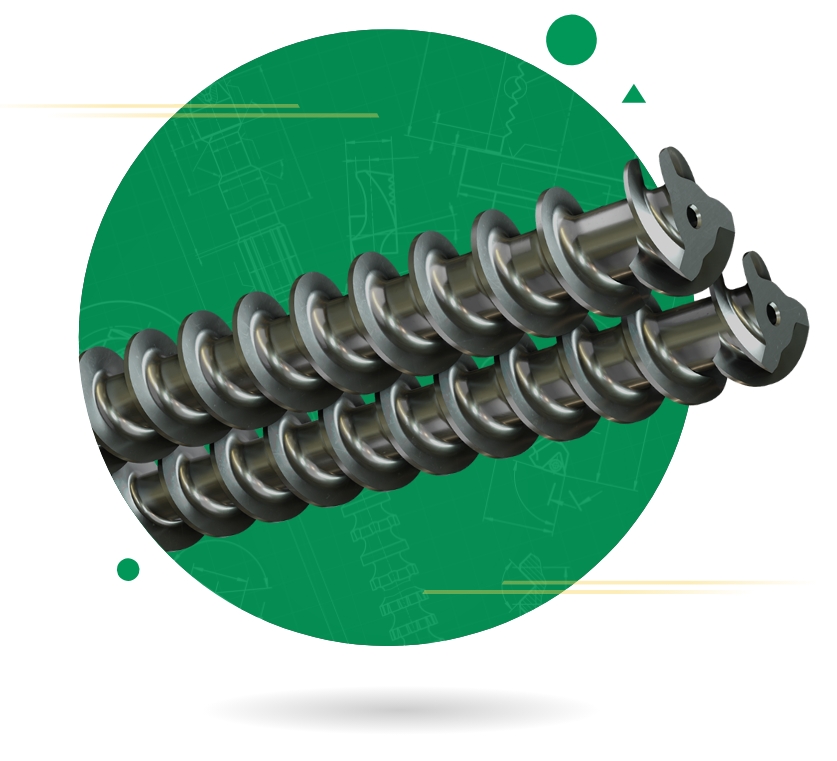

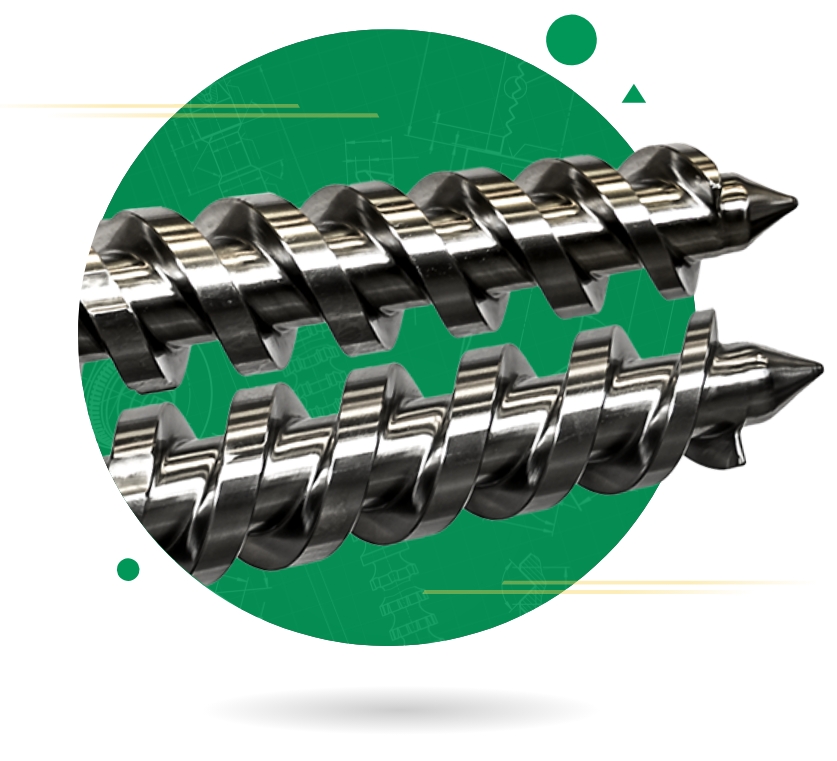

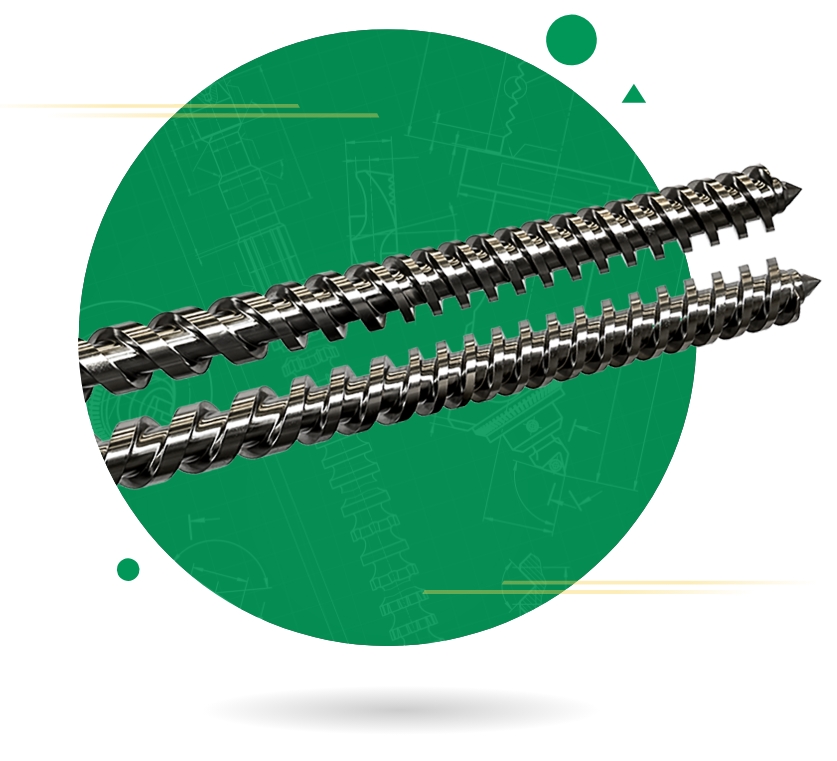

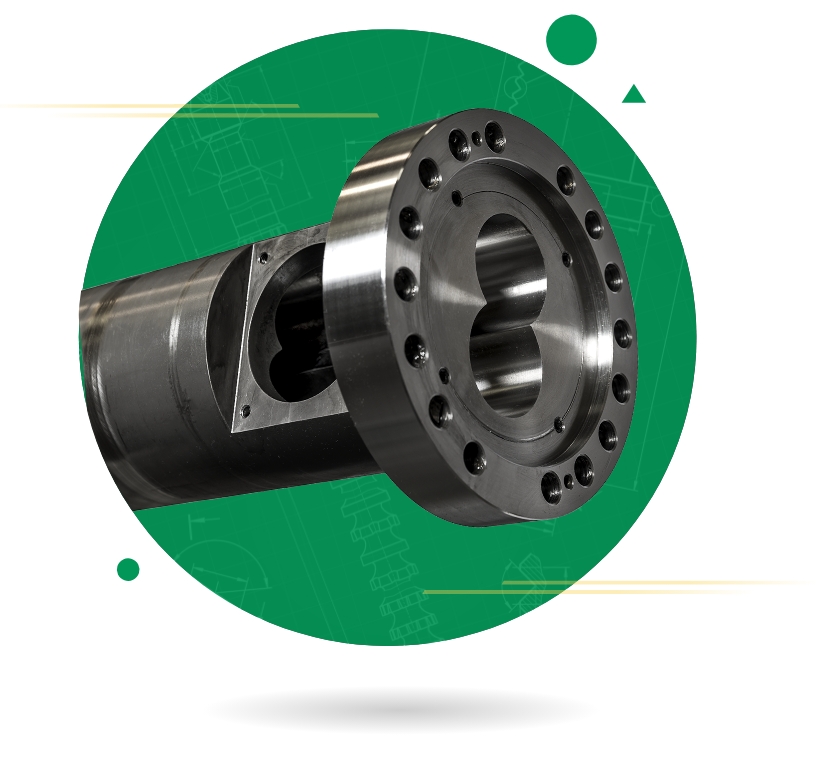

Co-rotating screws, key components in an extrusion system, are designed as modular segments. This structure offers not only significant flexibility in construction but also a self-cleaning profile that helps to prevent the accumulation of residual material along the extrusion path, eliminating potential stagnation zones.

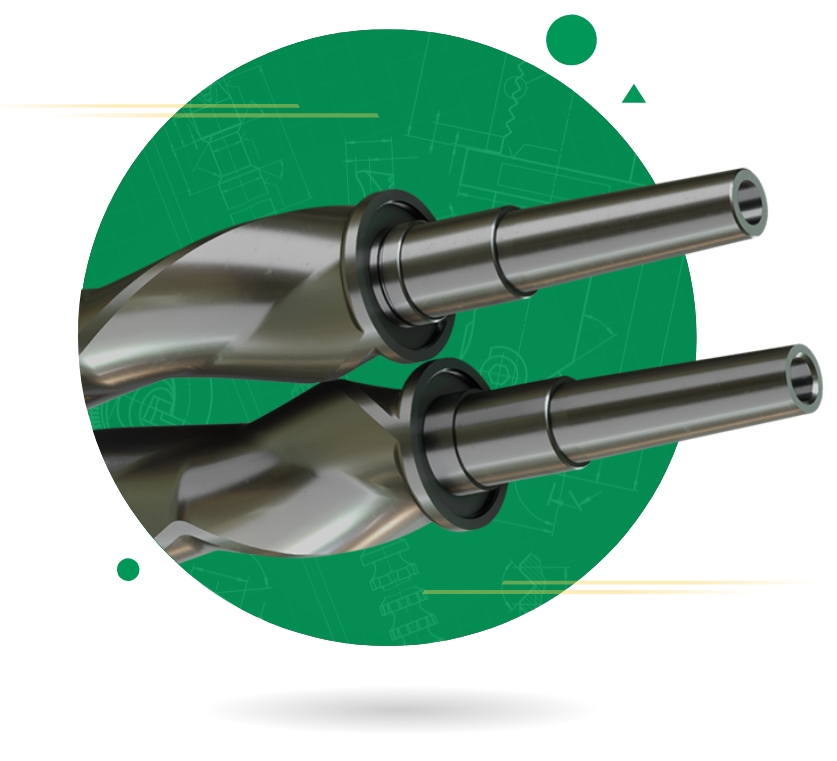

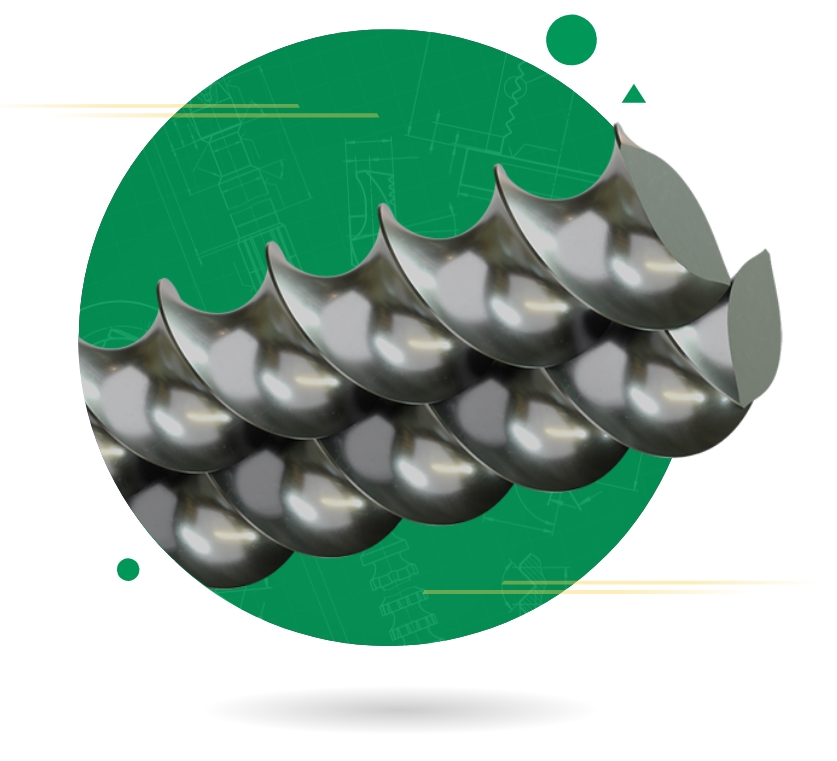

Each screw segment, mounted on a dedicated shaft, can have different types of geometry based on its specific function. Generally, these segments are divided into two main categories: the conveying segments, which move the material along the extrusion path, and the kneading blocks, which work the material preparing it for extrusion.

The real strength of the modular structure of co-rotating screws lies in their customizability. It allows for combining the screws with different types of profiles, each ideal for a particular type of material to be extruded. This versatility makes co-rotating extruders extremely adaptable to a wide variety of applications and materials, giving them an indispensable role in material processing.

Gallery

Discover the technical information about

Segments

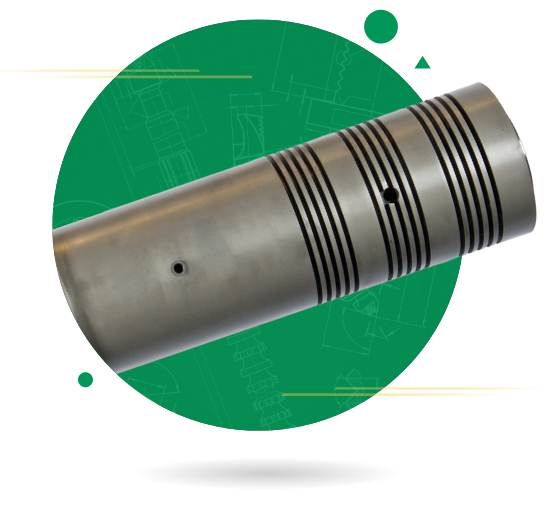

| EUV CODES | STEEL TYPE | TREATMENT | TYPE | HARDNESS |

|---|---|---|---|---|

| EUV41 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV |

| EUV79 | Cold Work Tool Steel | Hardening & Tempering | Total Hardening | 58÷62HRC |

| EUV10 | Powder Metallurgy Steel - Protection from Abrasion | Hardening & Tempering | Total Hardening | 58÷64HRC |

| EUV90 | Powder Metallurgy Tool Steels | Special Hardening & Tempering | Total Hardening | 57÷63HRC |

| EUV50 | Stainless Steels | Special Hardening & Tempering / Induction Hardening / Blank | Total or Partial Hardening or Blank | 44÷60HRC |

Related Products

CONTACT US

Tell us what you need

Follow us