30 years

of experience

Dedicated R&D

office

Euroviti boasts over thirty years of experience in the construction and development of plasticizing screws and barrels for a wide range of plastic materials.

Born creating components based on technical drawings or samples, Euroviti can now claim to be one of the few companies in the sector, at a global level, capable of providing customized solutions for both injection and extrusion plasticing units.

Designing suitable for the client’s needs and the materials processed, ensuring high-quality standards in plasticizing, mastering, and mixing. Euroviti’s R&D department has the expertise necessary to study and, if possible, design a customized profile to improve production capacity and quality. We offer a tailor-made service that optimizes the production process, ensuring high performance, energy savings, and a significant reduction in production costs. Some of our works are exposed in our success story page.

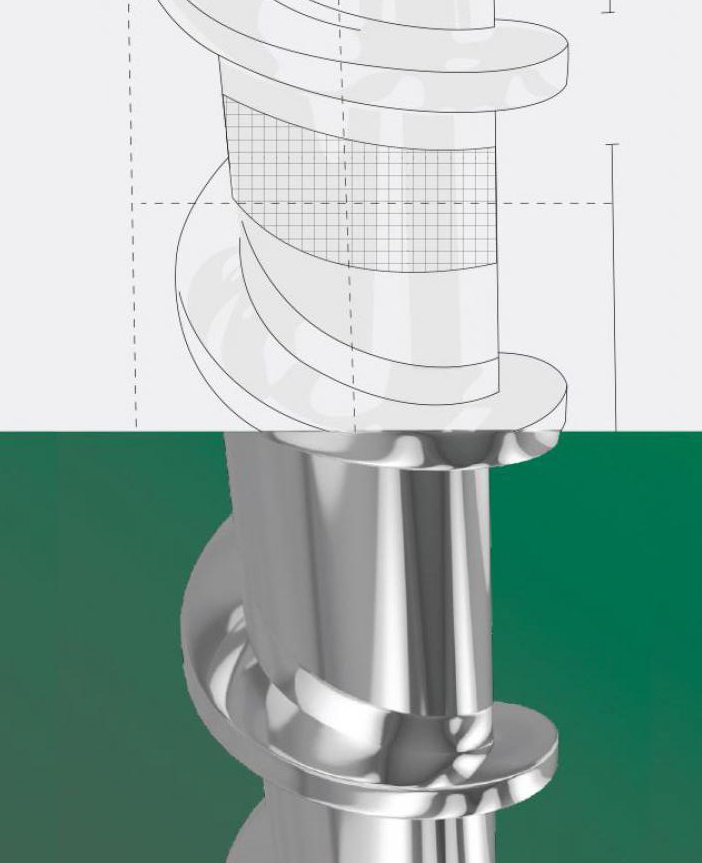

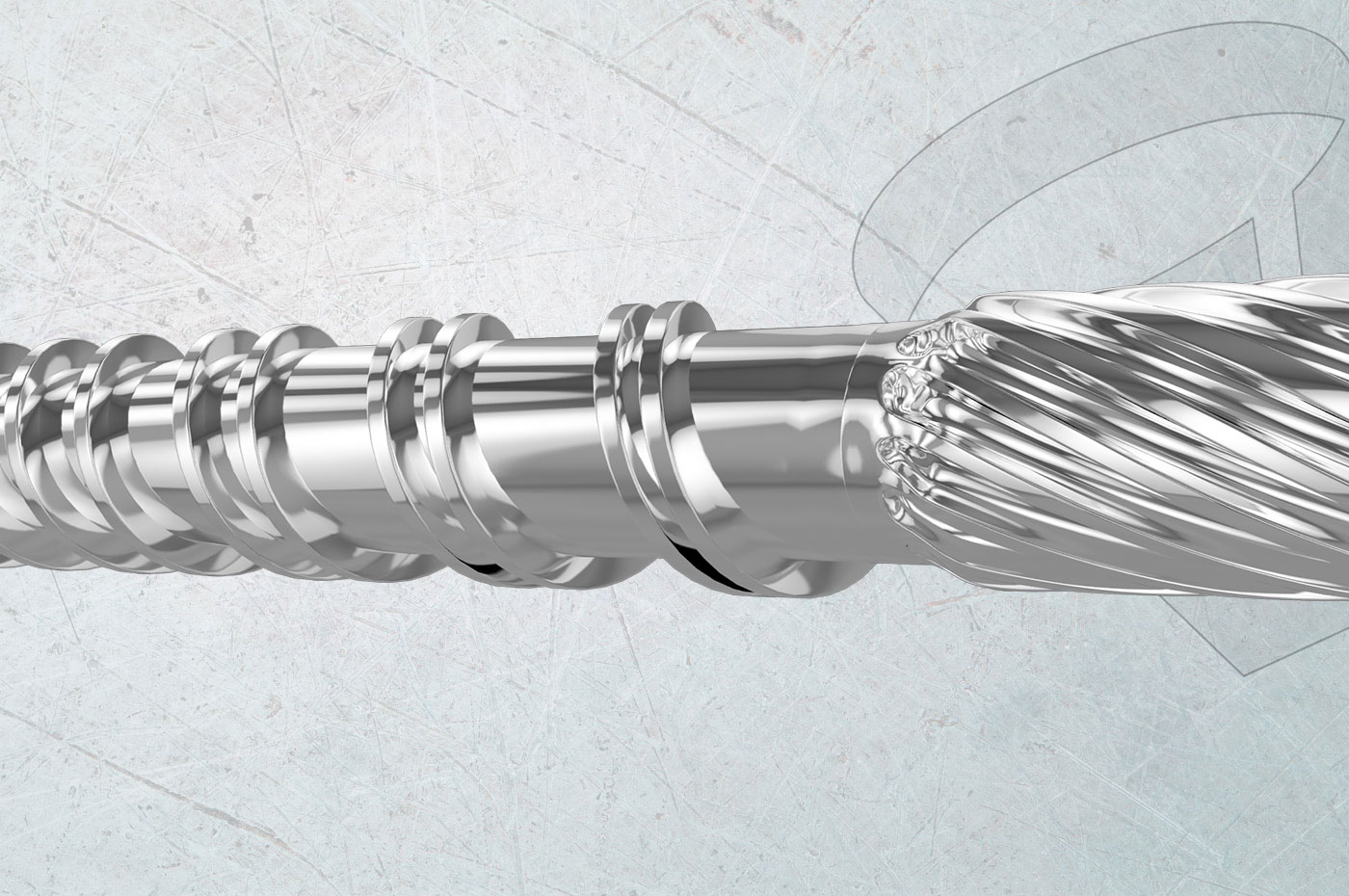

SCREW DESIGN

Customized single-screw profiles, grouped in the HPS, HPB, and HPE versions, bring numerous benefits, including tangible improvements in production thanks to high efficiency and melt quality. Benefits include significant reductions in pressure, a lower melting temperature requirement, reduced peripheral speed for less fiber stress, and, thanks to the balance between profile and process, a longer life for the screws. Additionally, a more fluid geometry and fewer stagnation points allow for faster color changes. We also offer a range of surface coatings for better glide and a reduction in the coefficient of friction.

HPS (High Performance Screw)

High Performance Screw include a three-zone profile (feed, compression, metering) revolutionized by customized variable pitch and TC (compression rate). Focused on the injection moulding plasticizing process its characteristics vary depending on the material to be processed, the available L/Ds, and the features of the IMM – when possible mixing areas can be added to improve specific performance.

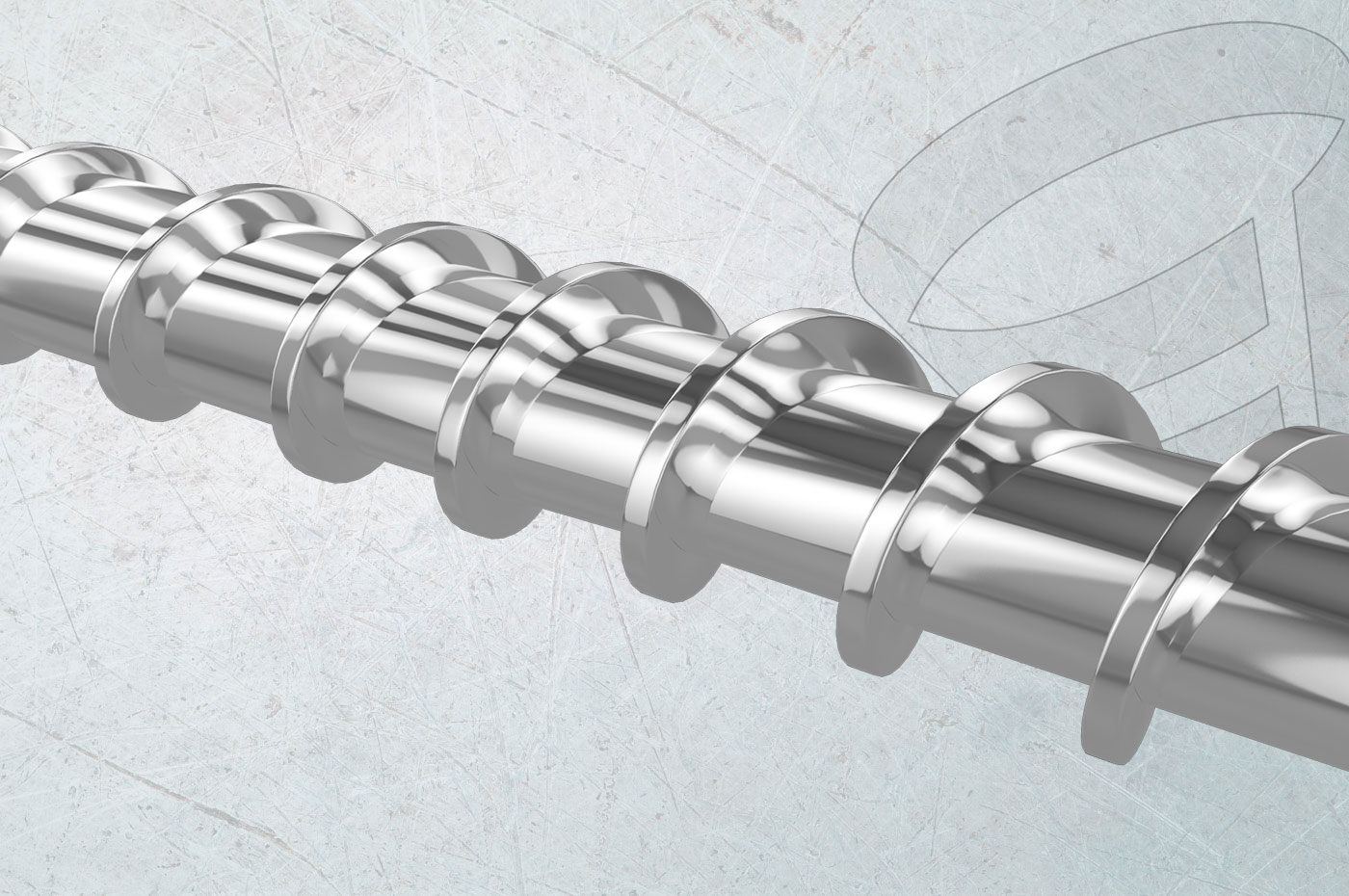

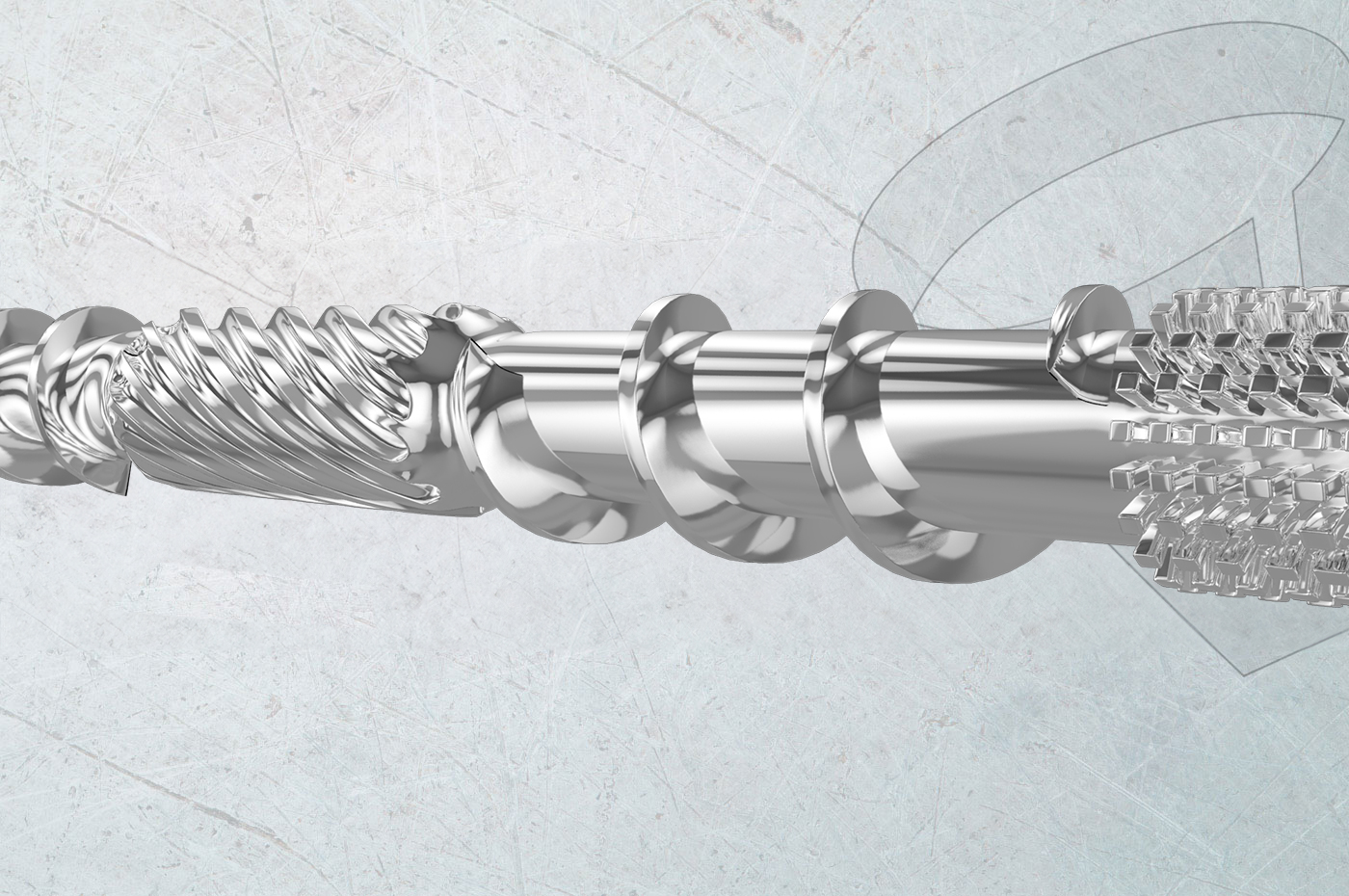

HPB (High Performance Barrier)

High-performance barrier screws improve both the mixing and homogenization of the granule featuring a high shearing effect that prevents not melted granules from passing the “barrier zone”. They can include a mixer with various geometric shapes, and even maddocks to further increase mastering performance, even up to 50% more compared to traditional three-zone screws. In their “recycling” variation they become particularly suitable for uses with regrind materials up to 100%.

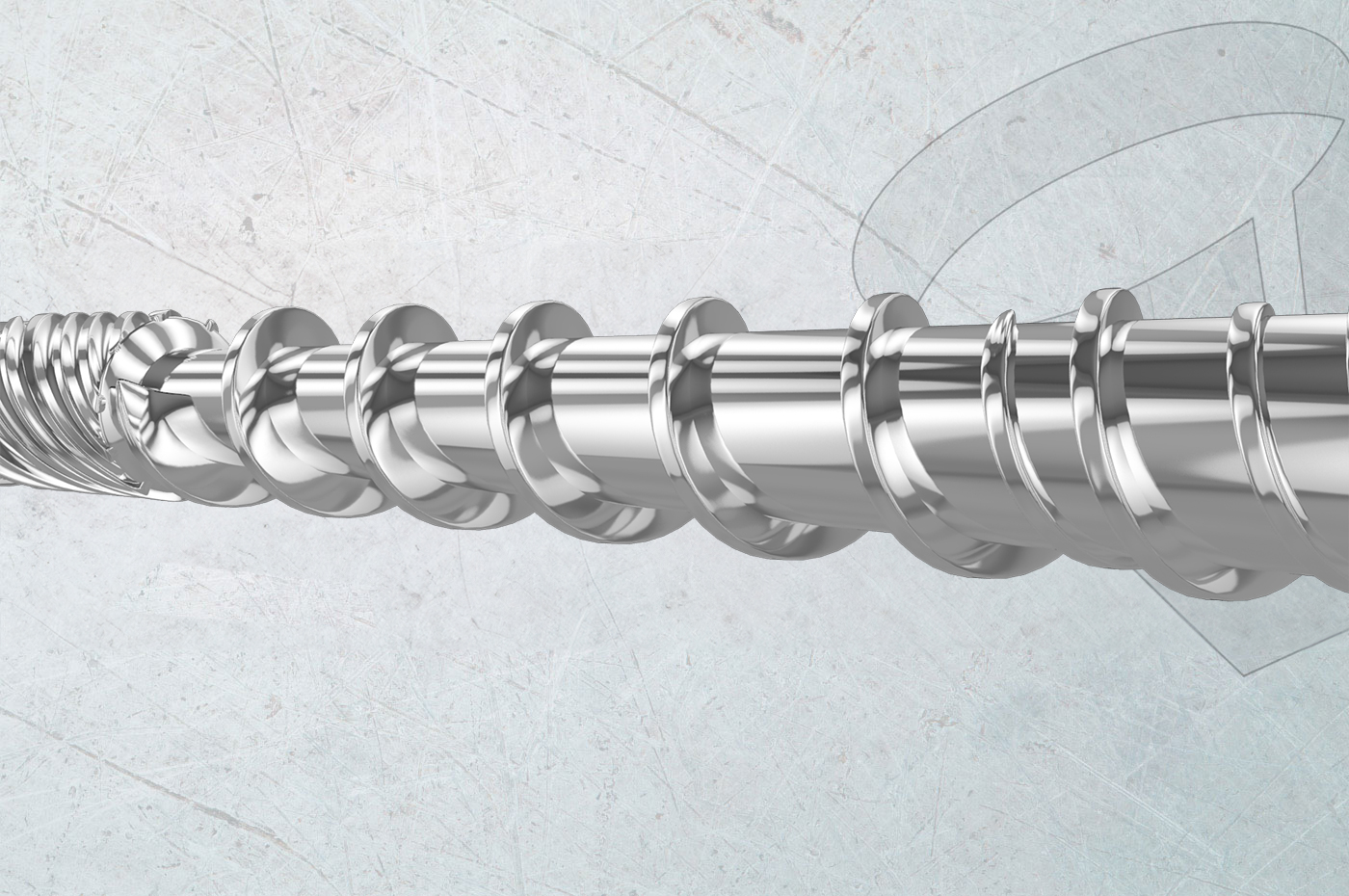

HPE (High Performance Extrusion)

High-performance screws for extrusion, with different profiles depending on the application area. Tied to the world of extrusion, with extruders that have important L/Ds, they allow for the inclusion of specific features on the screw profile depending on the processed granule, achieving improvements in various aspects.

HPR (High Performance Recycling)

High-performance screws for recycling were born as a versatile solution for all types of material, focusing on tackling significant issues with homogenisation, plasticising, and mixing of heterogeneous recycled, leaf or trims materials. Particularly suited for plastic recycling and processing plastic waste they have become during year of research and development with our customers and partners a great solution from plastic recycling itself till injection and extrusion of the recycled materials.

SOLUTIONS FOR RECYCLING

During over three decades in the sector and constant collaboration with end users or original equipment manufacturers, our team has been transforming plastic waste into profit for years. Euroviti’s solutions represent an ideal choice for the recycling market, aiming to increase the efficiency of the extruder and the quality of plasticization. We try to contribute to waste reduction and promote the responsible reuse of plastic resources. The recycling of post-industrial or post-consumer plastic waste materials is motivated not only by economic reasons but also by ethical, environmental, and sustainability considerations. This synergy between advanced solutions and environmental responsibility is fundamental to addressing global challenges related to the use of plastic resources and promoting a more sustainable future. Then, once we’ve done our part cooperating with plastic recycling companies, we are alongside those who process both regrind and recycled plastic, whether with a twin-screw or a single-screw plasticizing units, our customized design can expertly manage all recycled plastic related challenges.

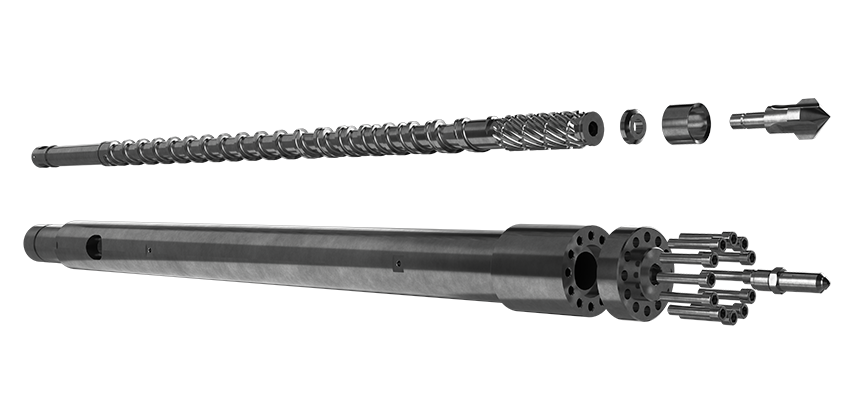

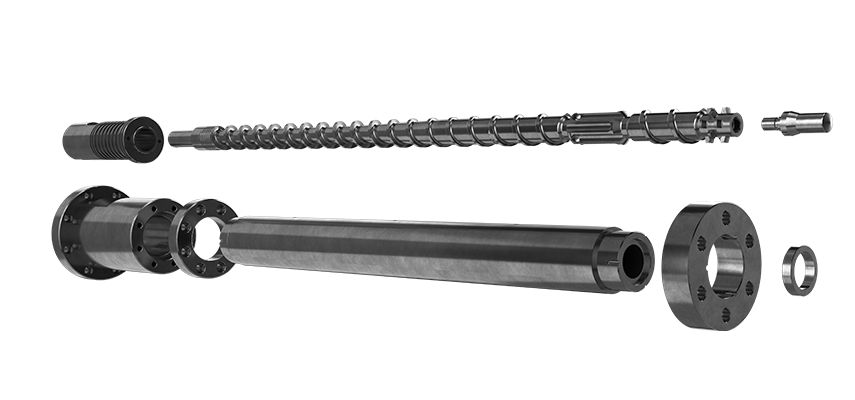

COMPLETE UNITS

Providing complete plasticizing units with accessories is not a central part of Euroviti’s core business. However, sometimes this step is necessary to be able to fully realize and develop our customized solutions as in the case of special units dedicated to specific materials or final products to be made by injection or extrusion; in these cases our technical department, after the study and design, continues to identify all the necessary elements also with the support of specialized partners in each product sector and leaves to the customer the possibility of continuing independently with the purchase of all the necessary accessories or if they prefer a complete supply including all elements such as heater-bands, fans, thermocouples, protective casings, gearboxes, bases and many more.

CONTACT US

Tell us what you need

Follow us