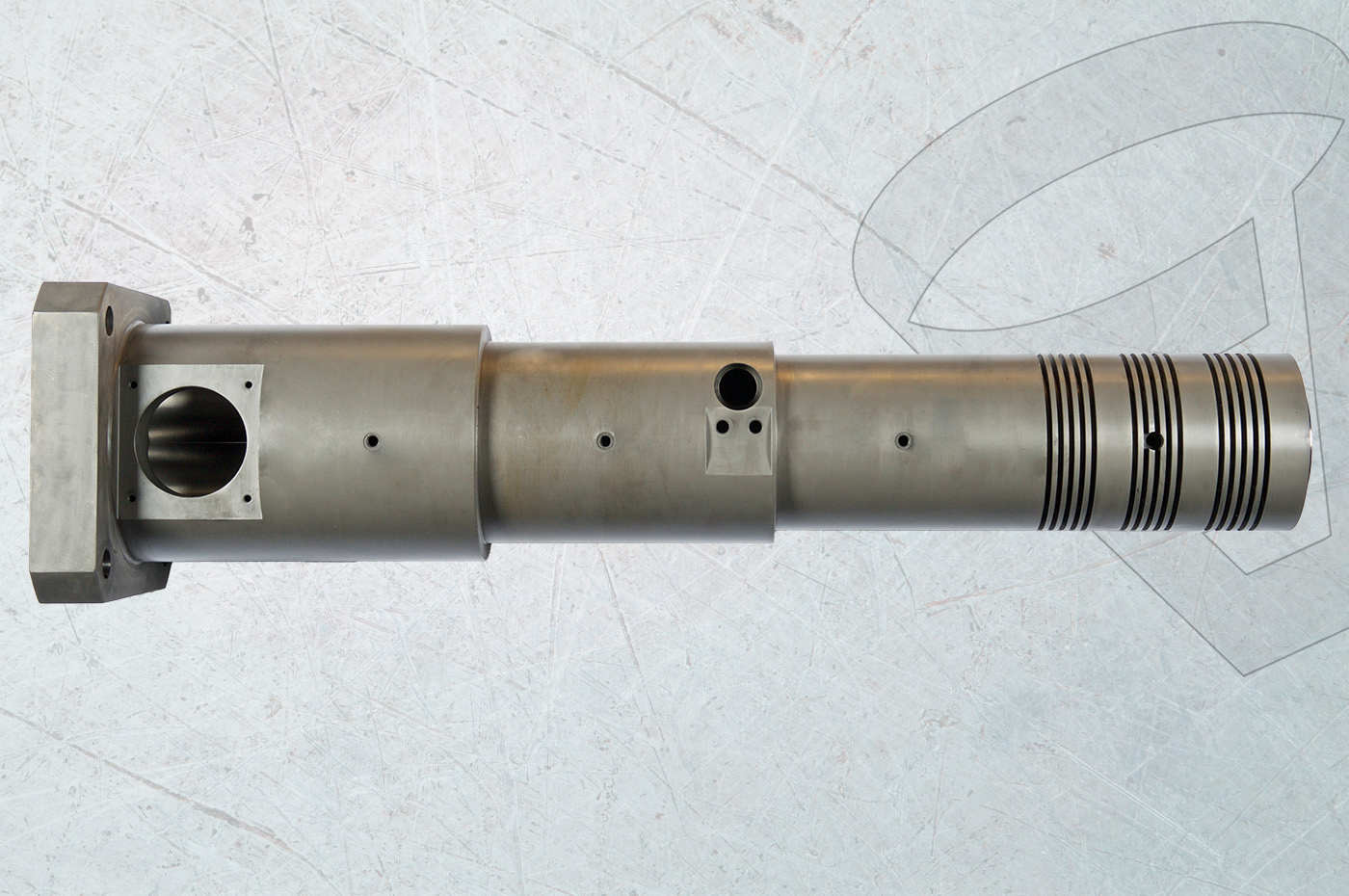

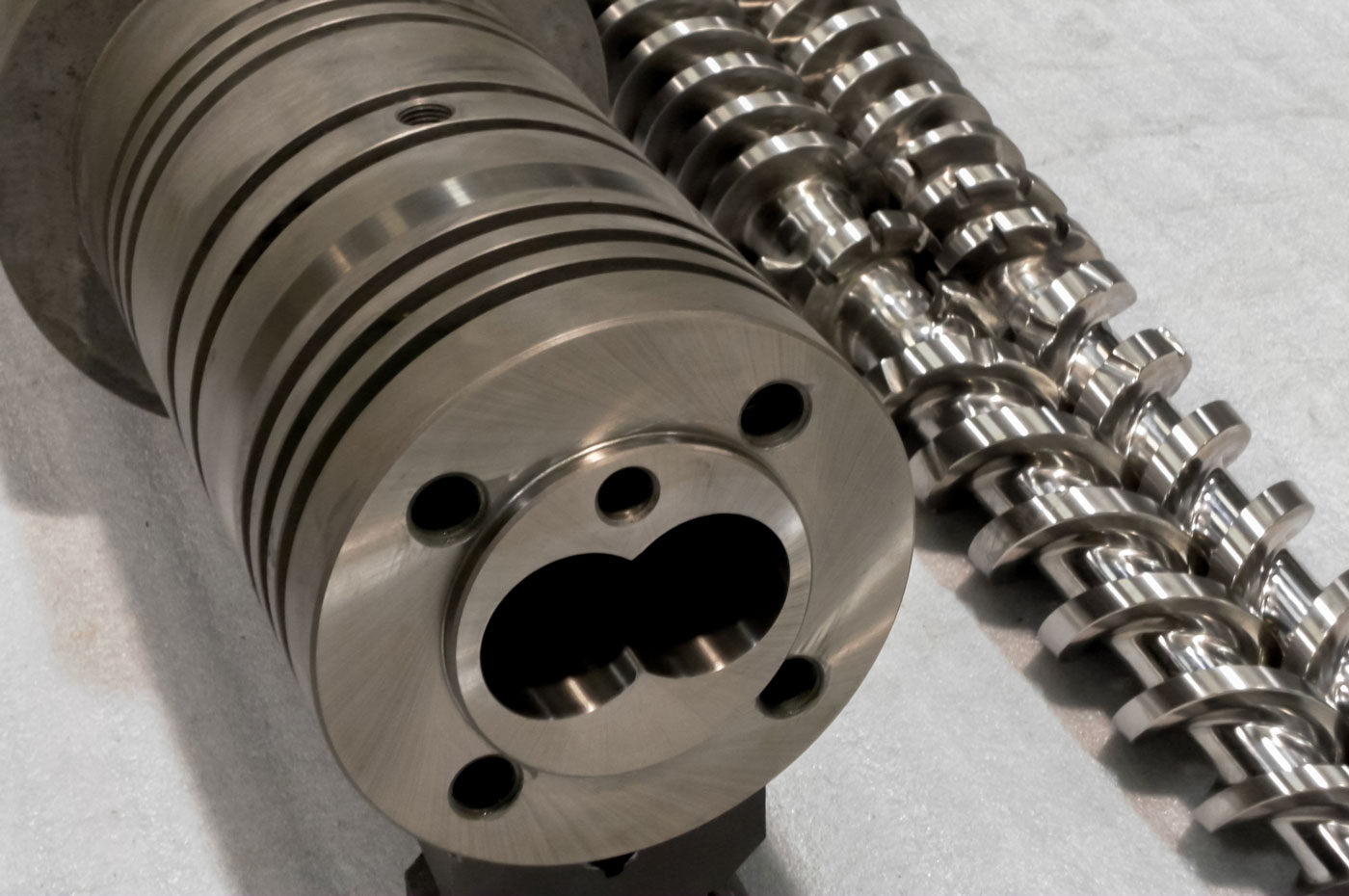

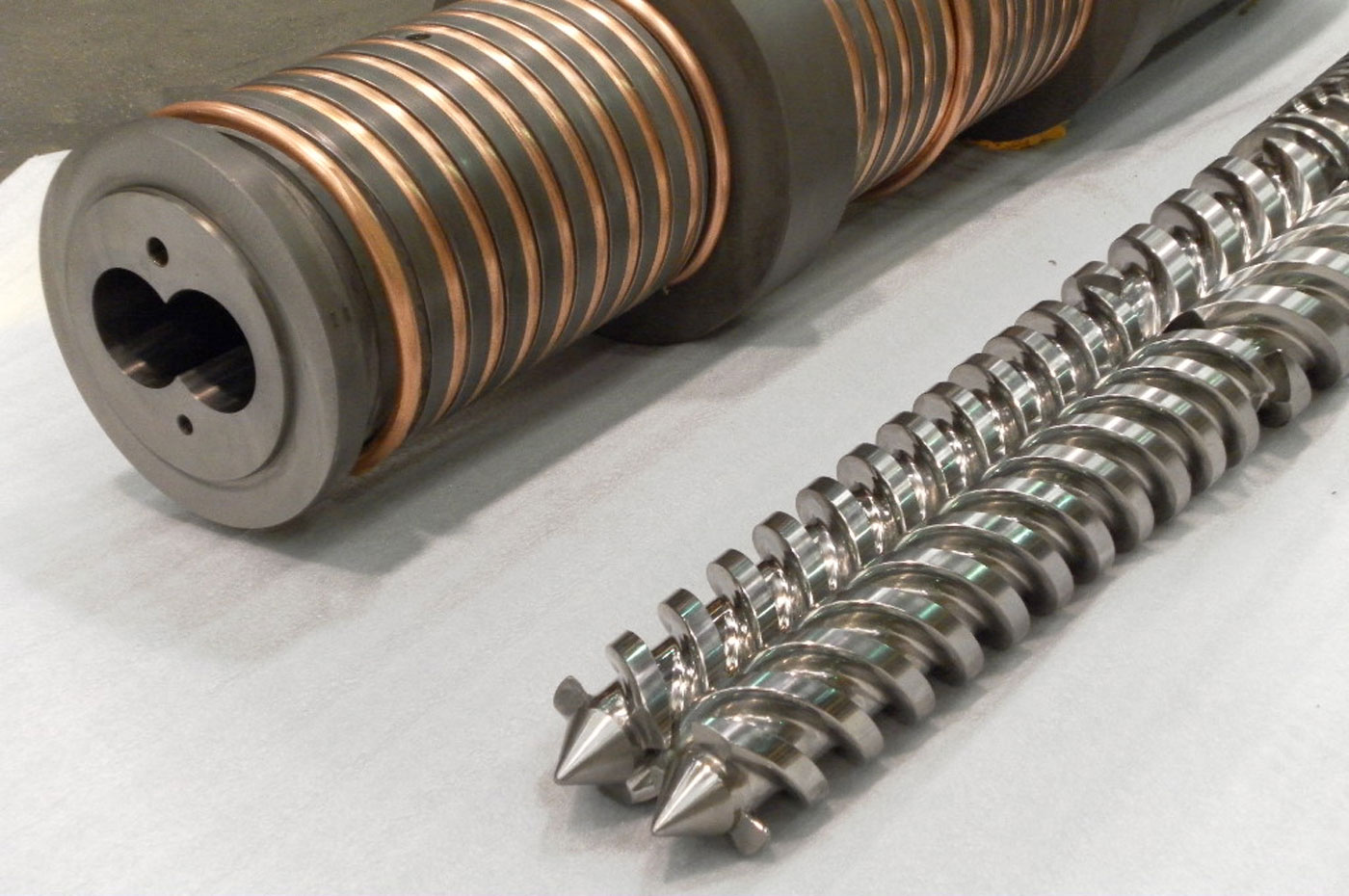

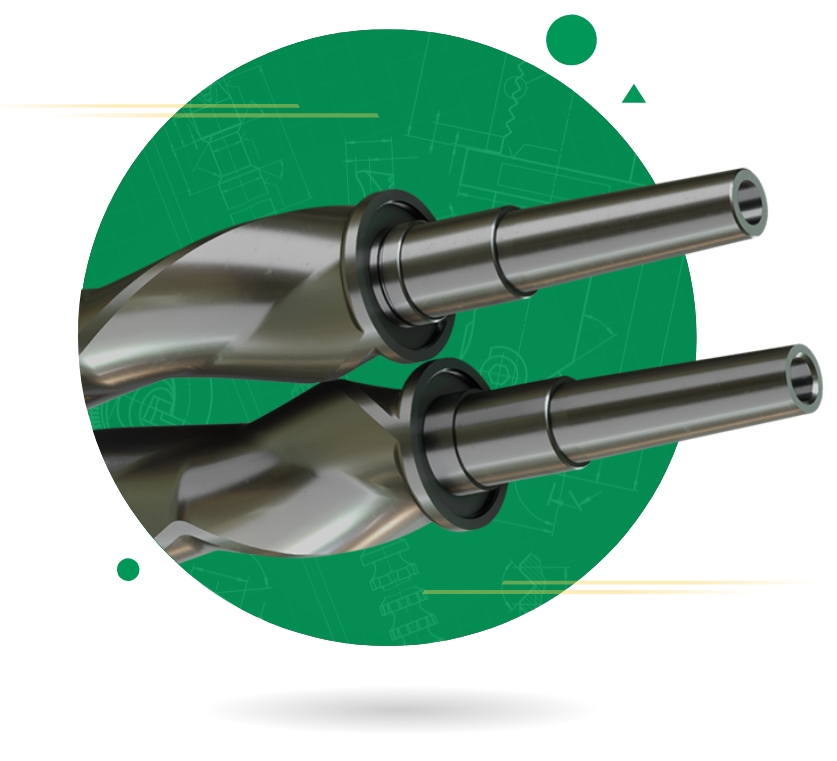

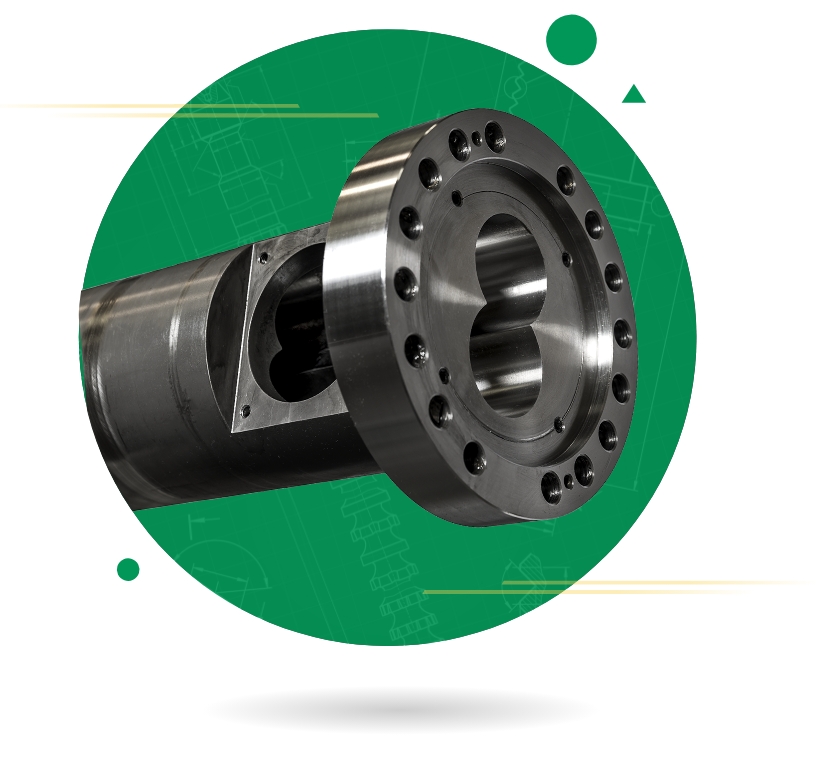

The conical twin-hole barrel is characterized by a diameter that progressively narrows from the inlet to the outlet, forming what is known as the nominal diameter of the conical extruder.

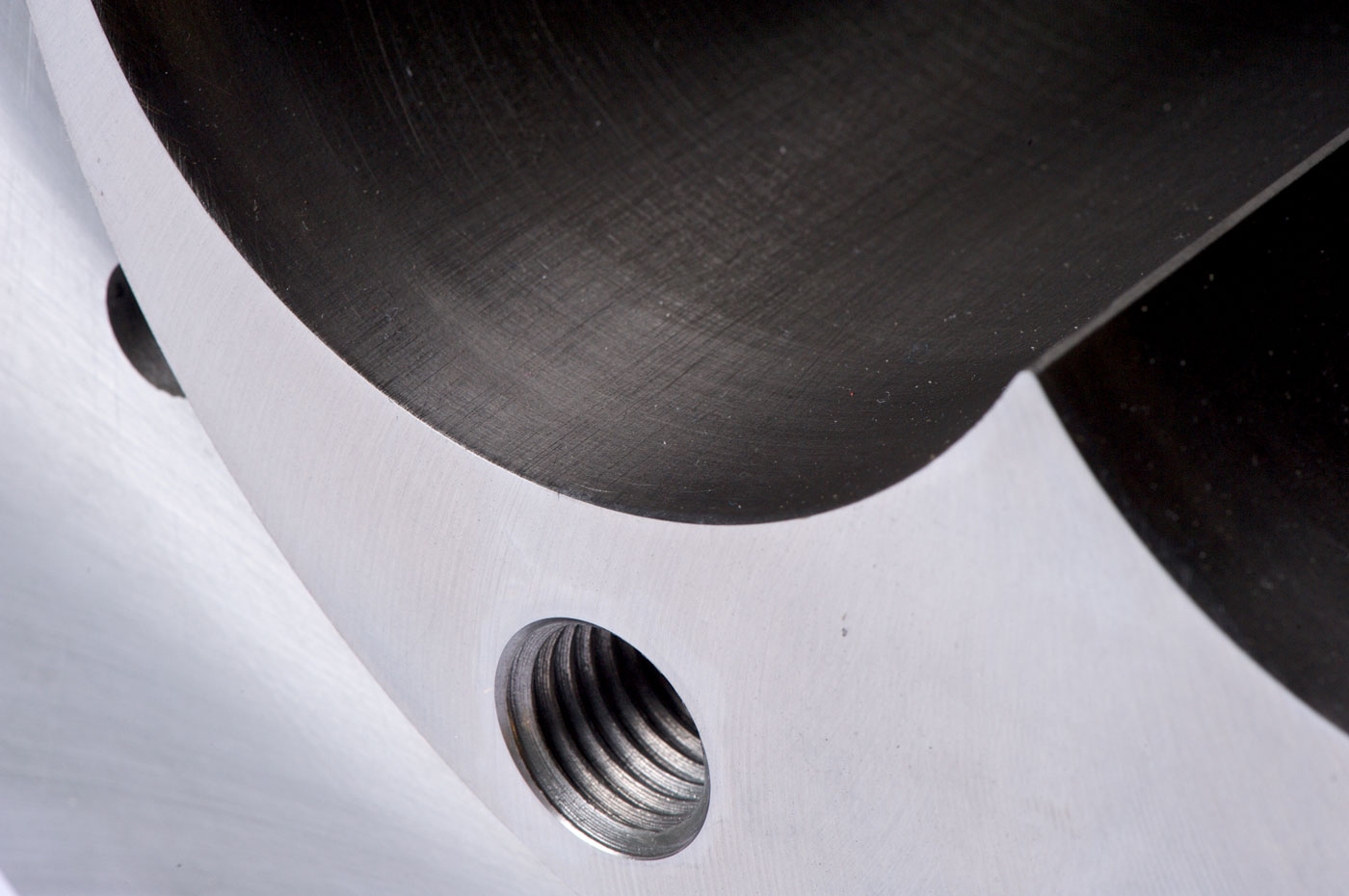

The creation of this type of barrel presents a significant challenge: maintaining the correct distance and angle between the holes.

This is crucial since the barrel must not only have a conical shape but also precise alignment of the holes, making it one of the most complex to produce in its category.

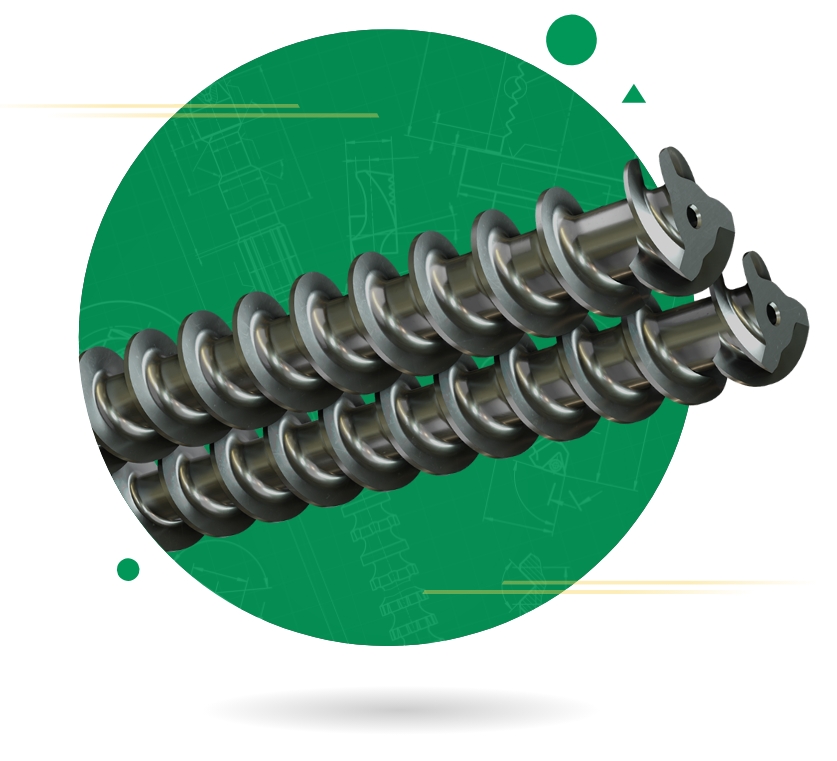

Conical barrels can have a smooth or grooved external diameter, depending on the specific application. In the case of external grooves, they play a functional role beyond aesthetics, ideal for supporting the positioning of the cooling circuit tube, usually made of stainless steel or copper.

Gallery

Discover the technical information about

Barrel

| EUV CODES | TYPE | INLAY BASE ALLOY | TREATMENT | HARDNESS |

|---|---|---|---|---|

| EUV34 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV |

| EUV41 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV |

Related Products

CONTACT US

Tell us what you need

Follow us