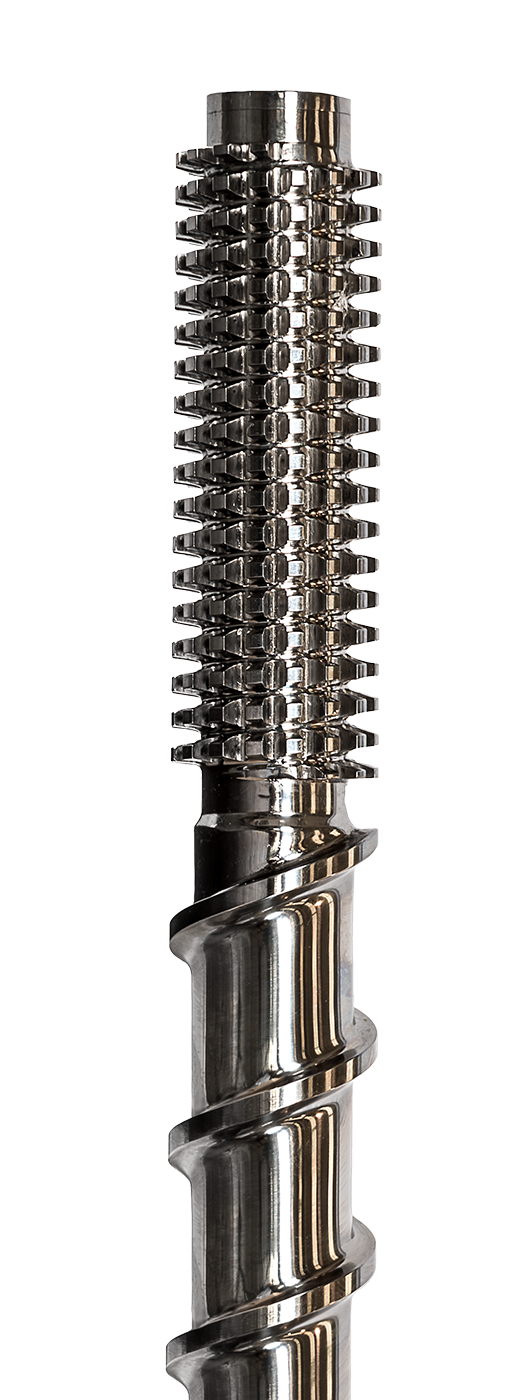

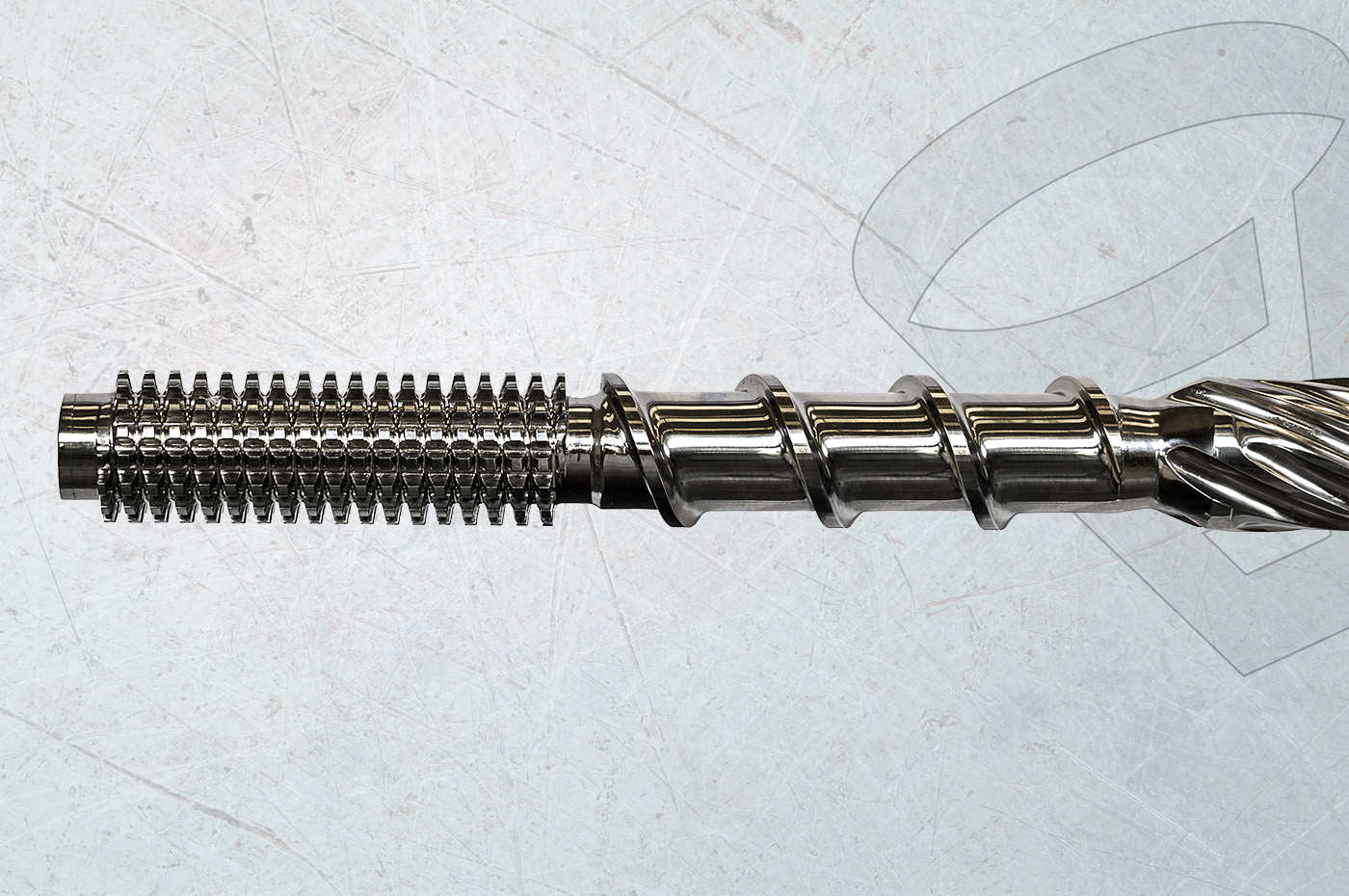

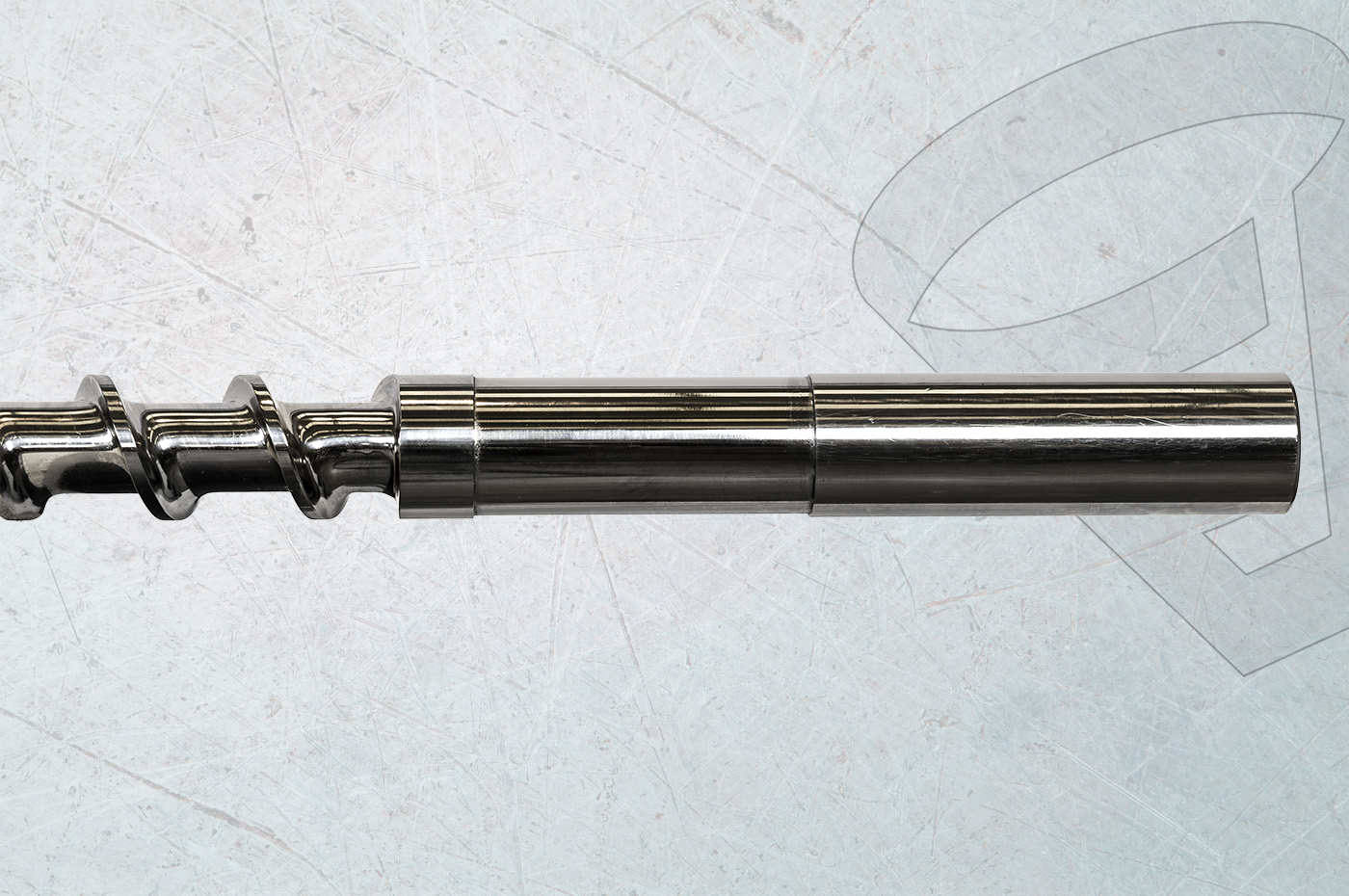

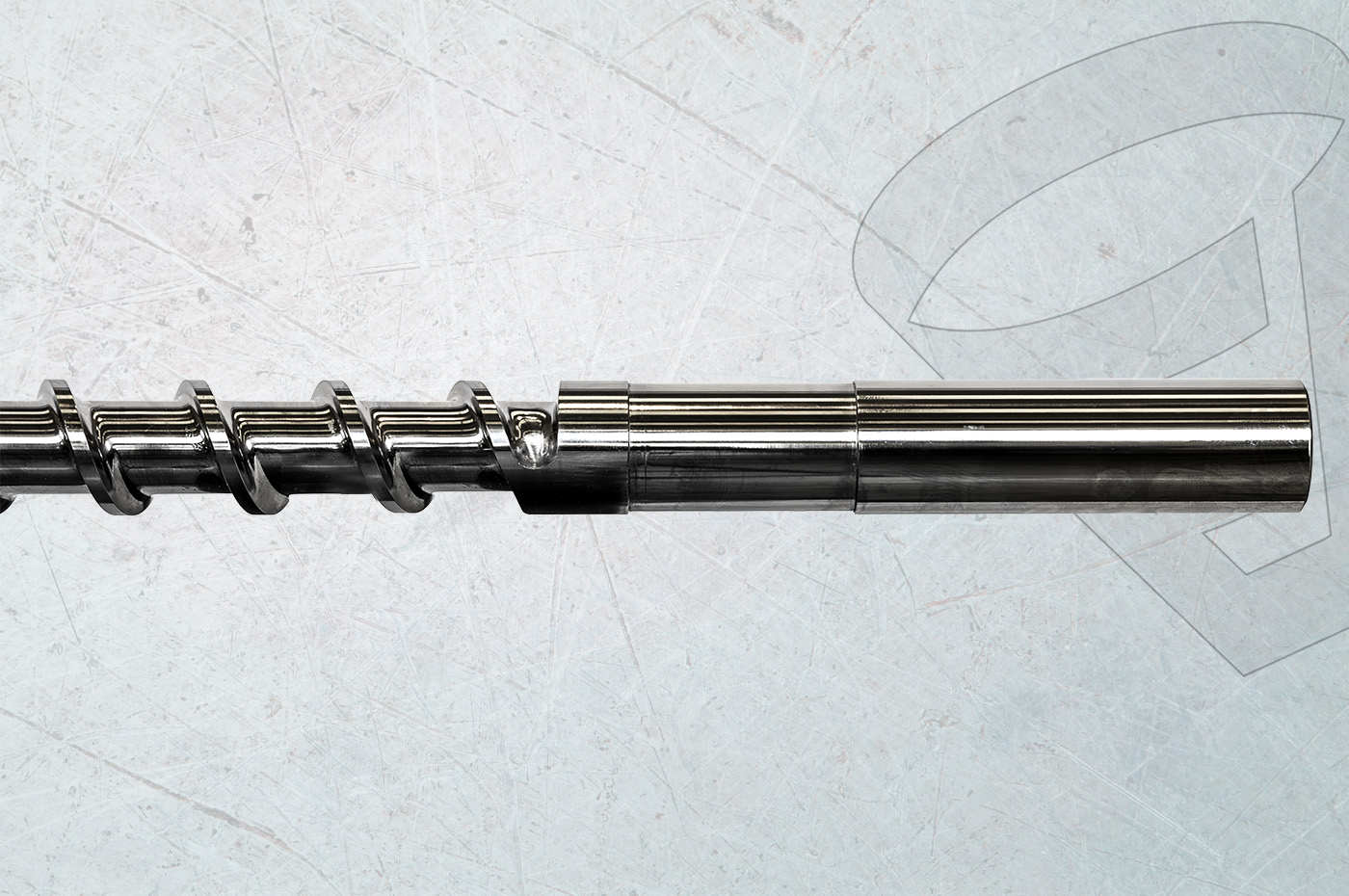

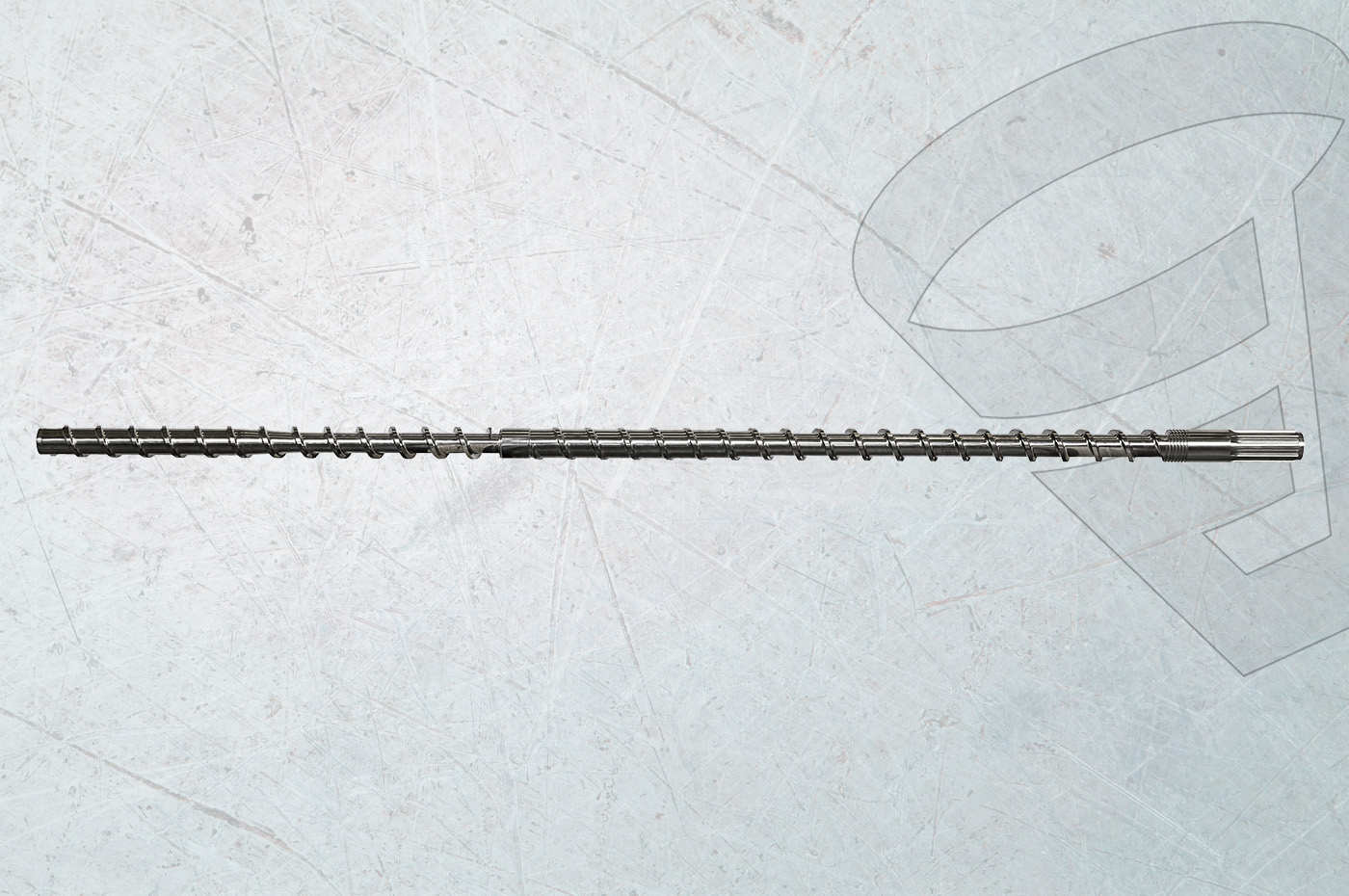

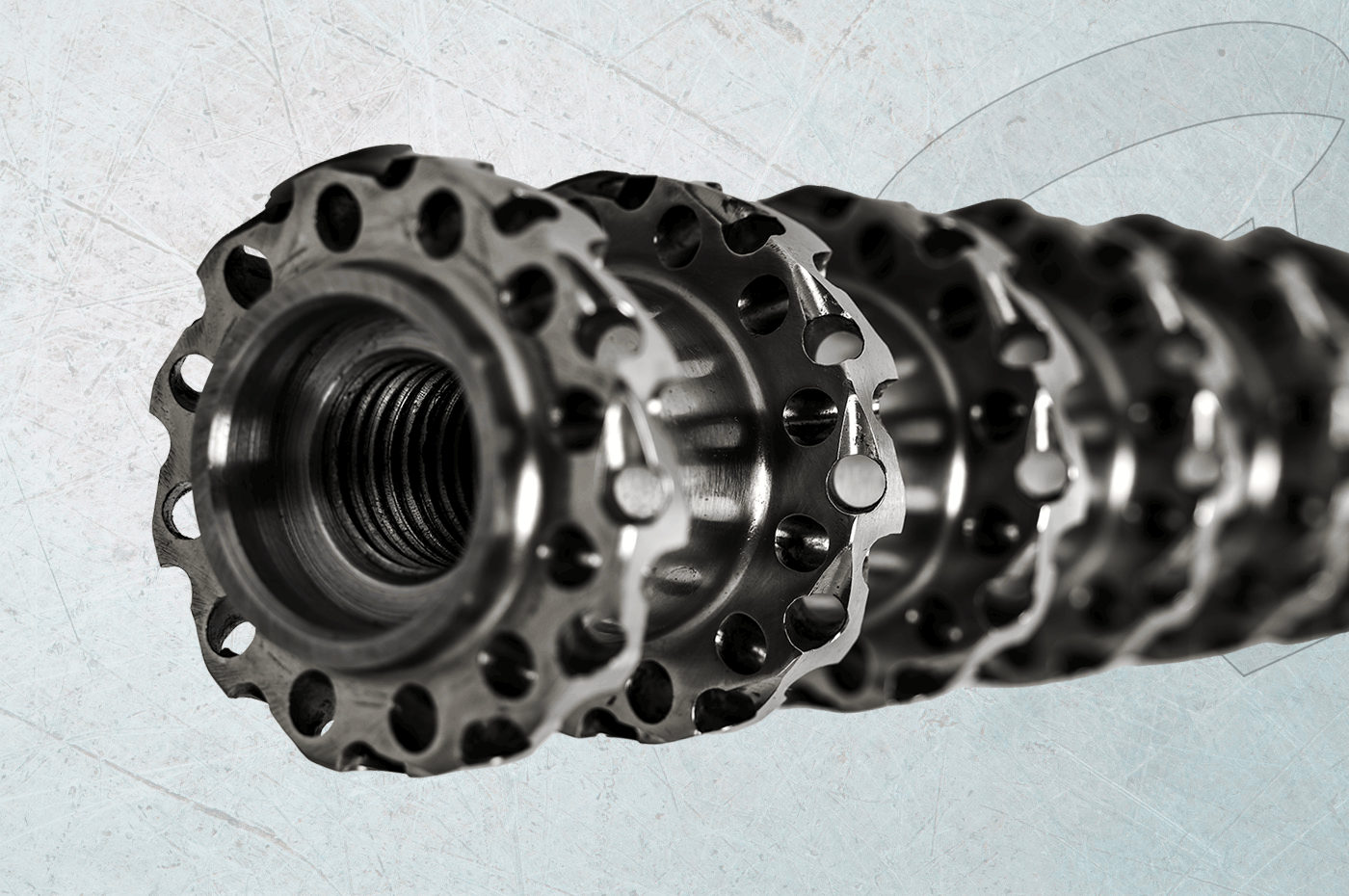

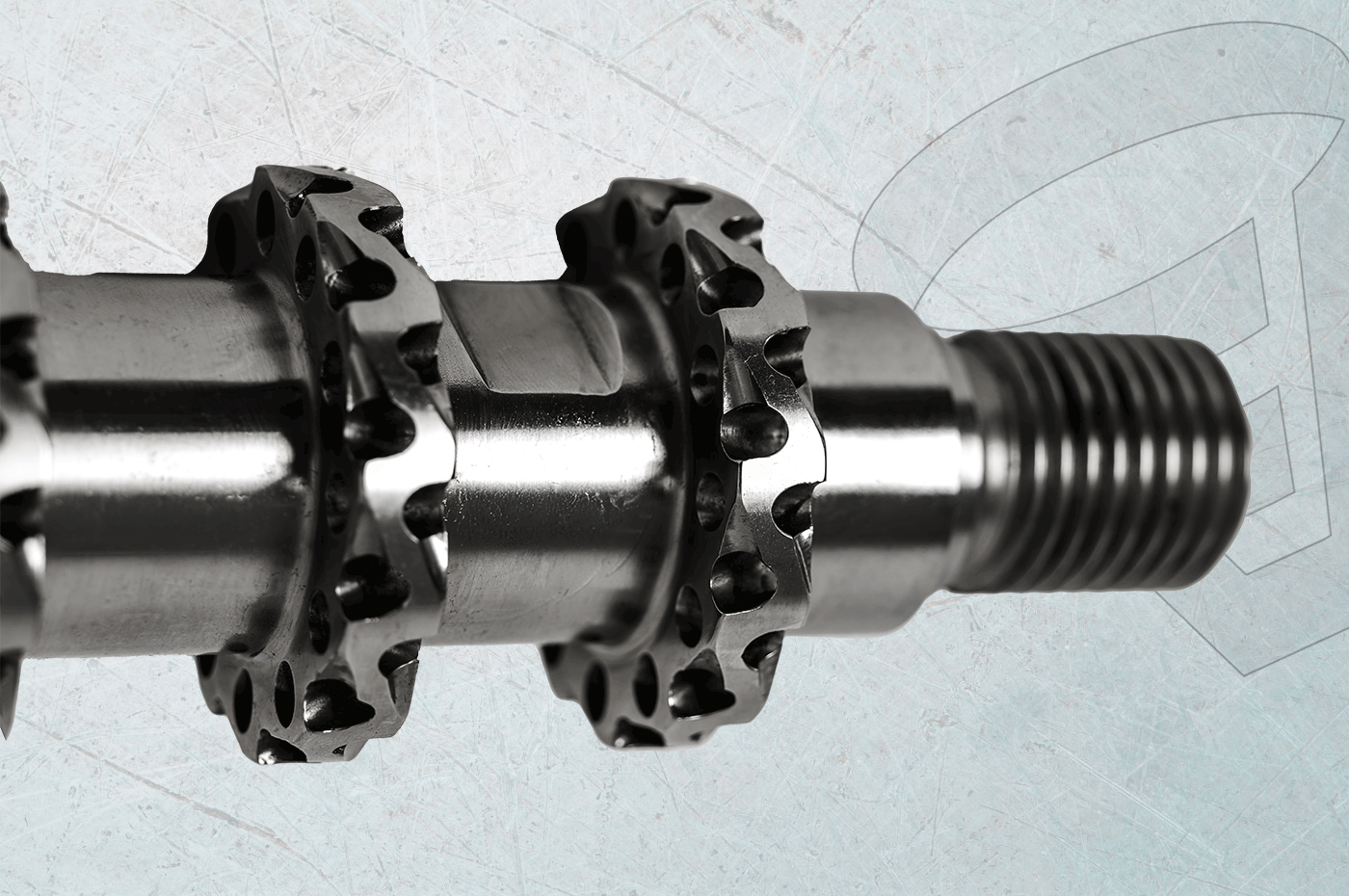

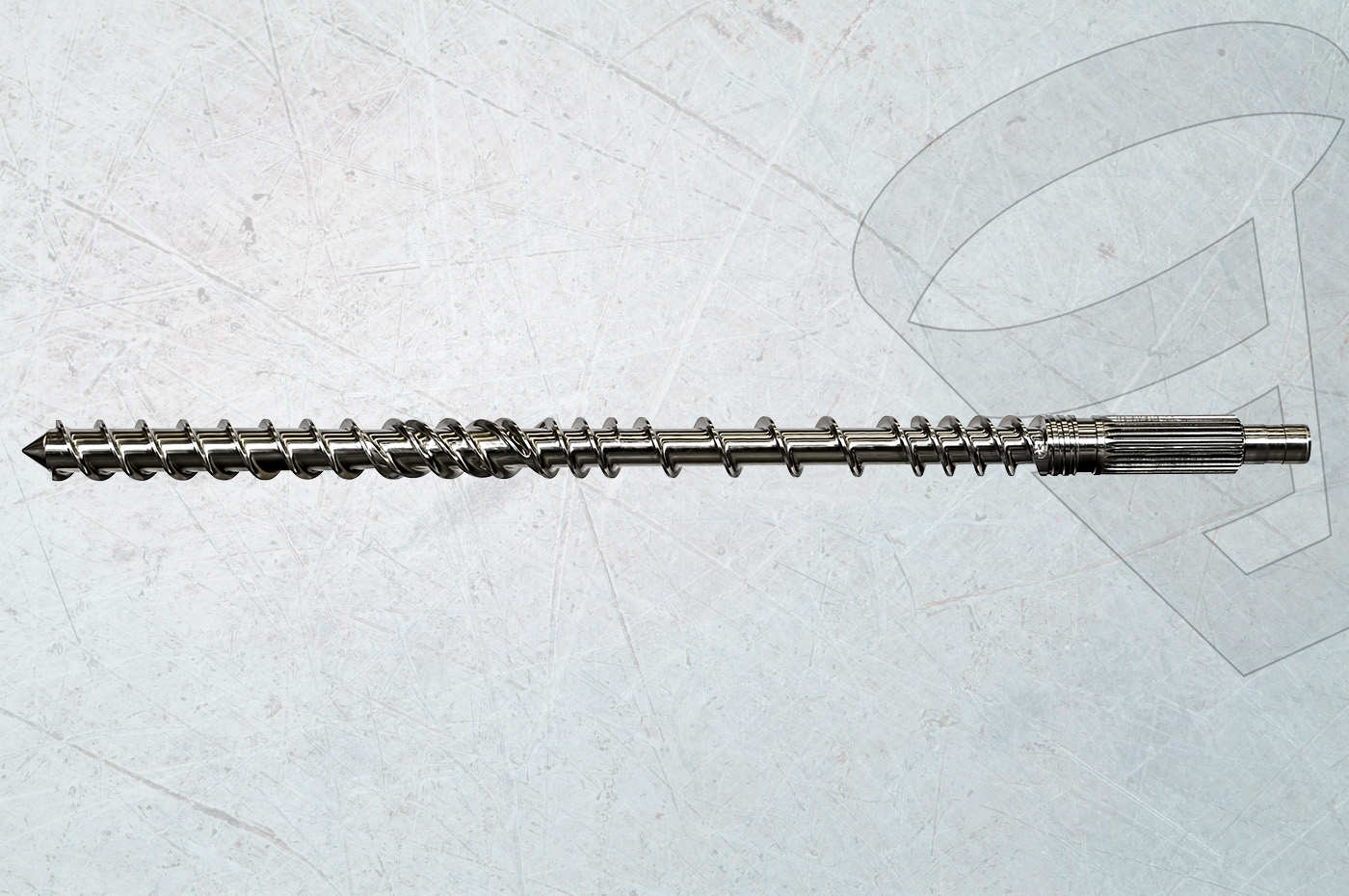

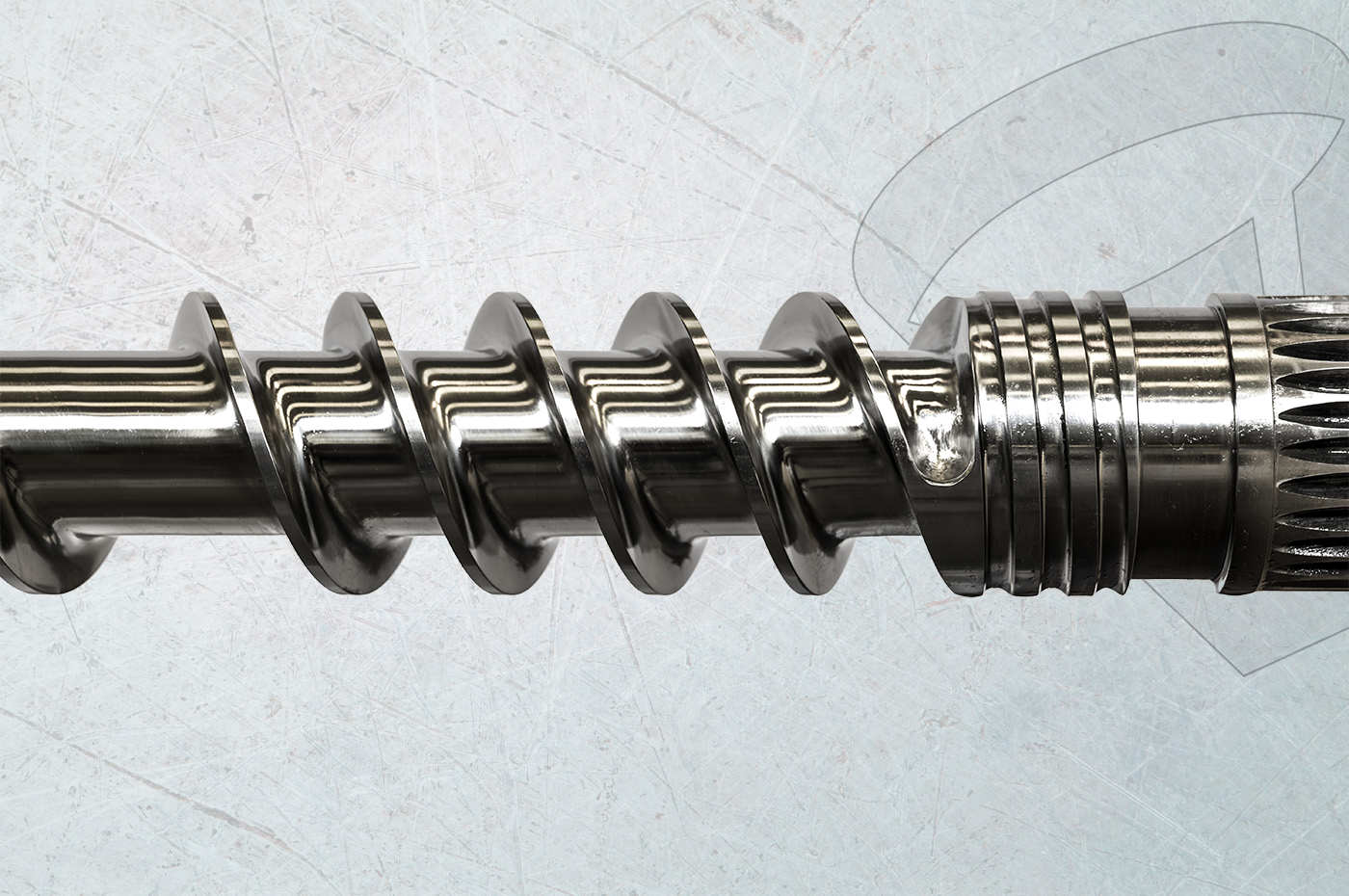

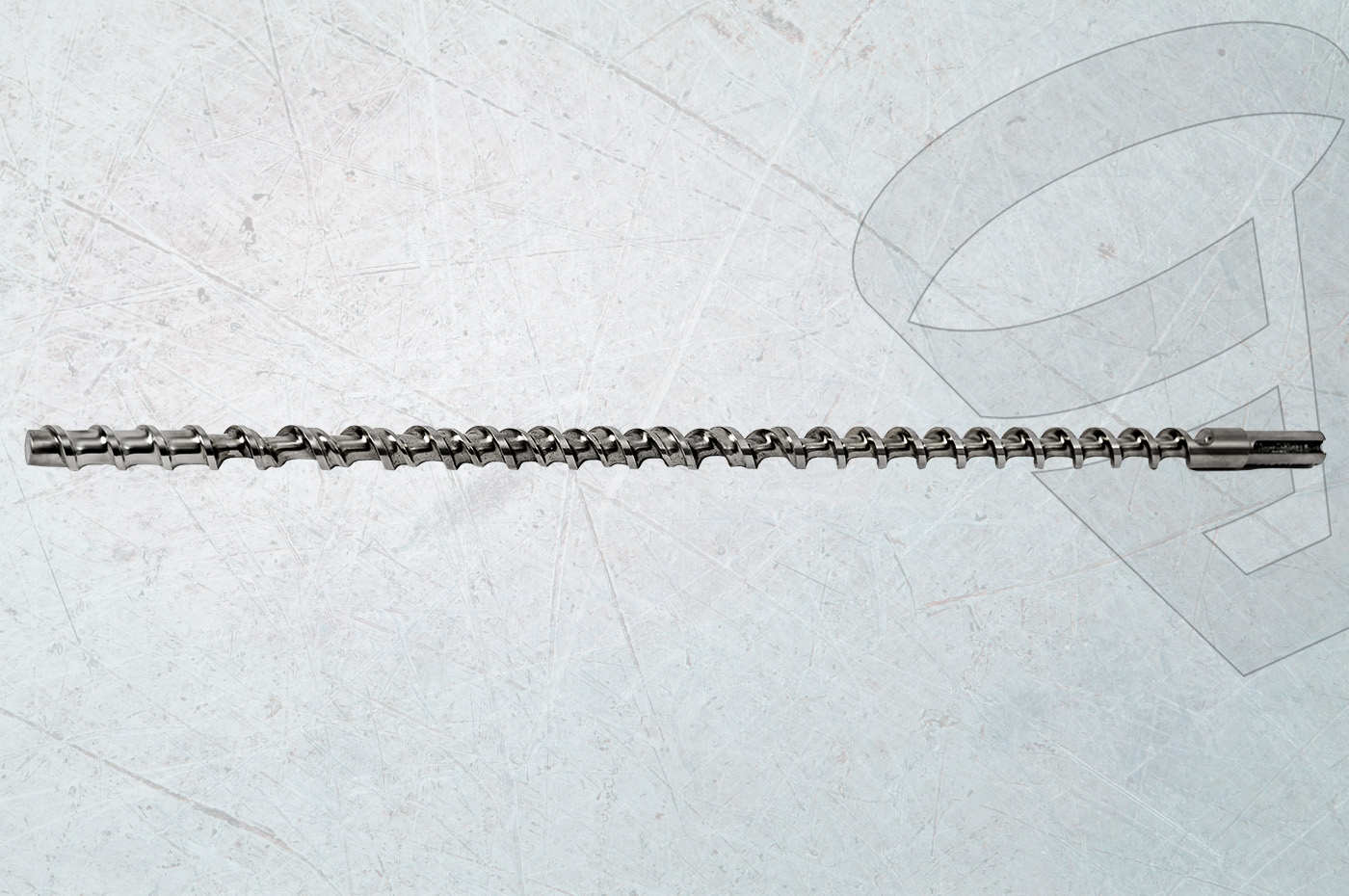

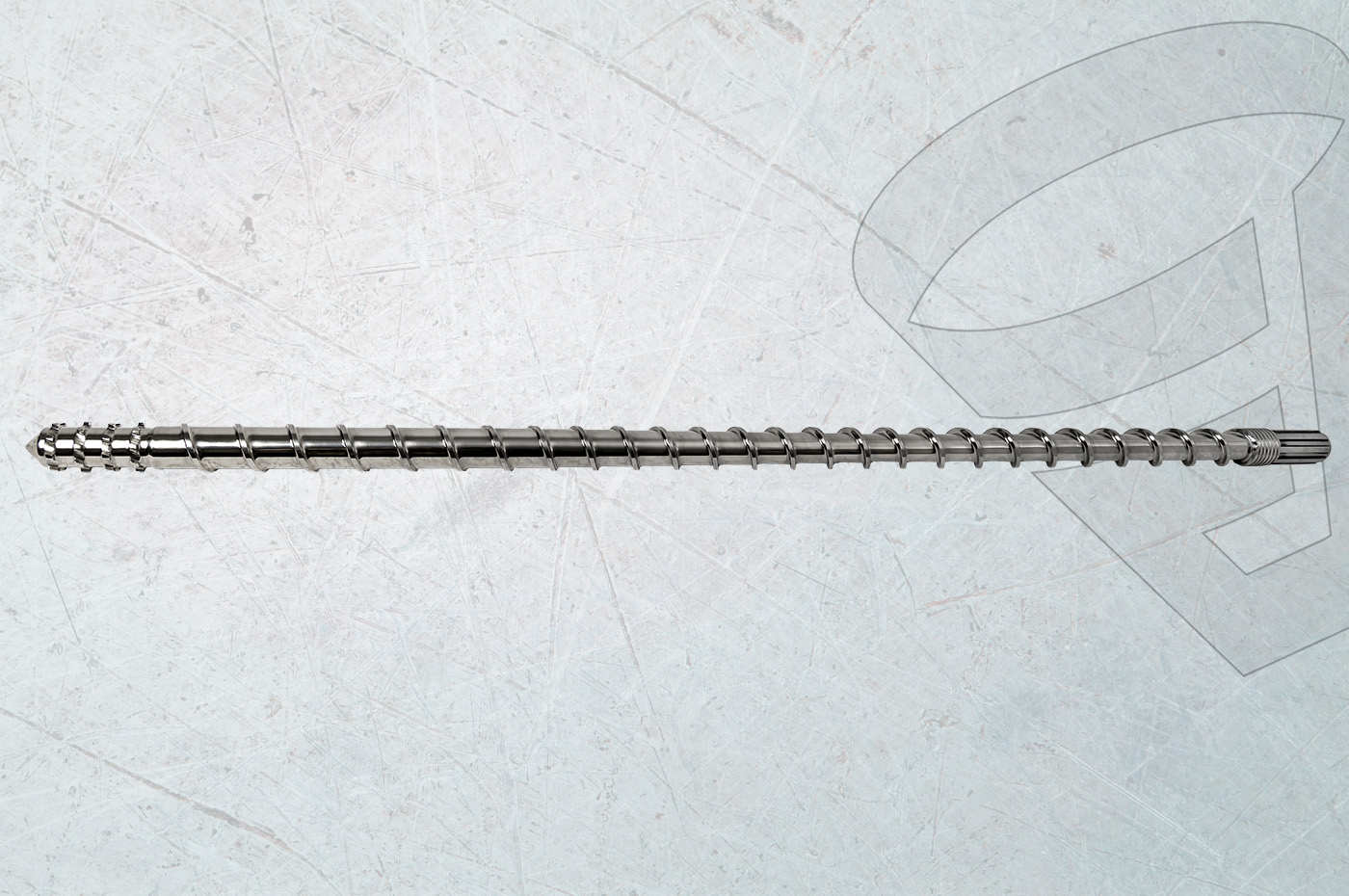

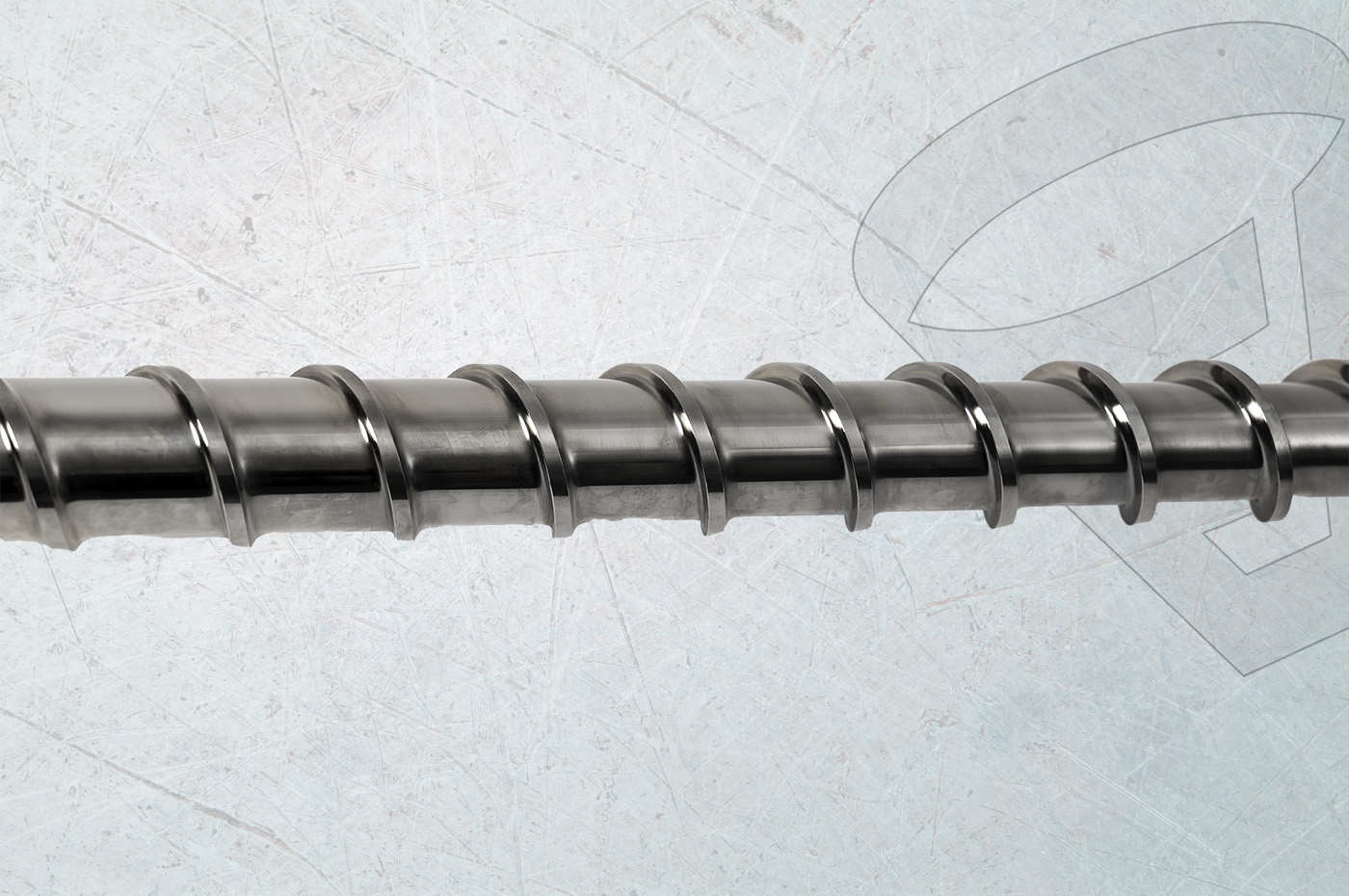

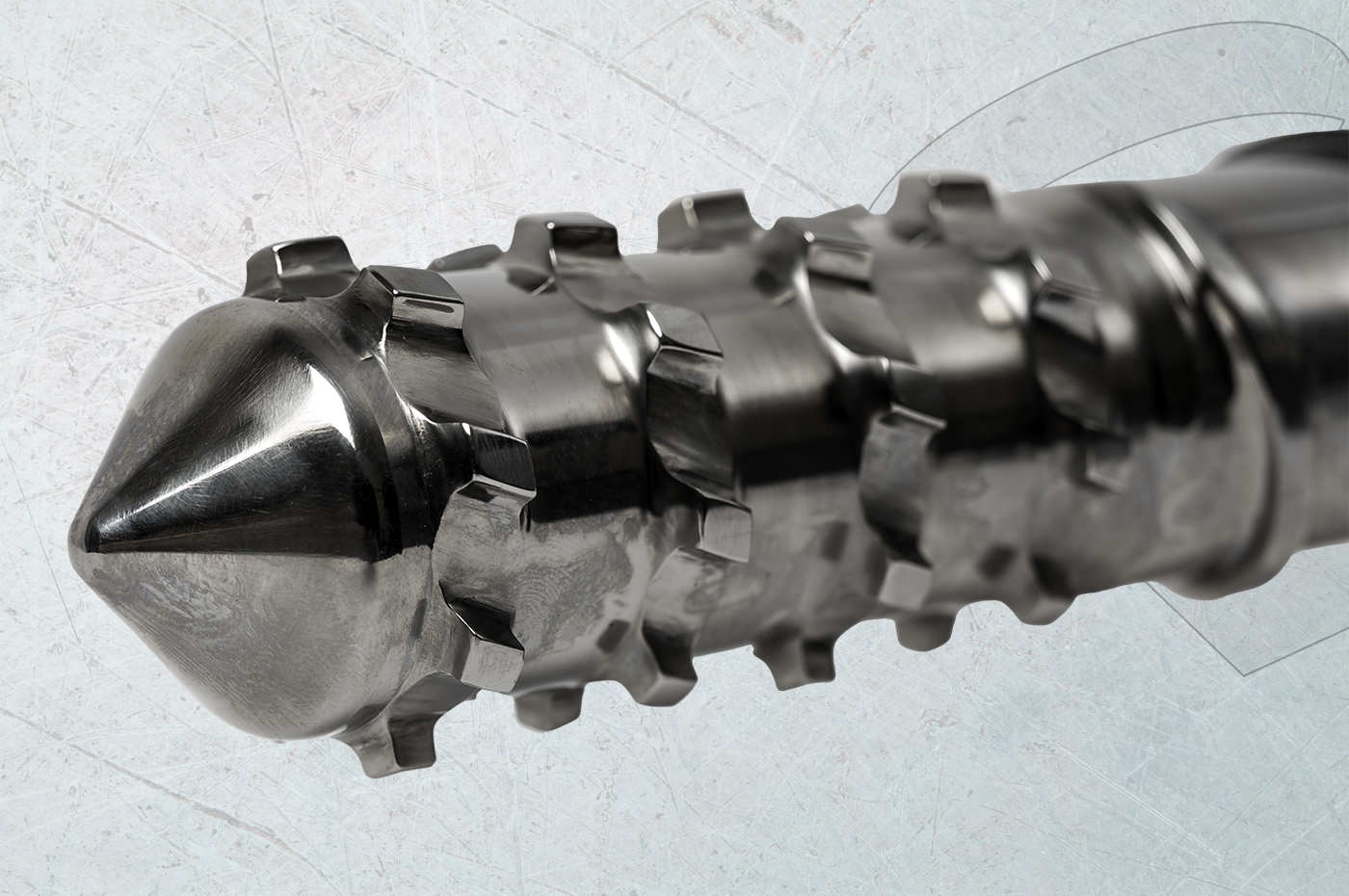

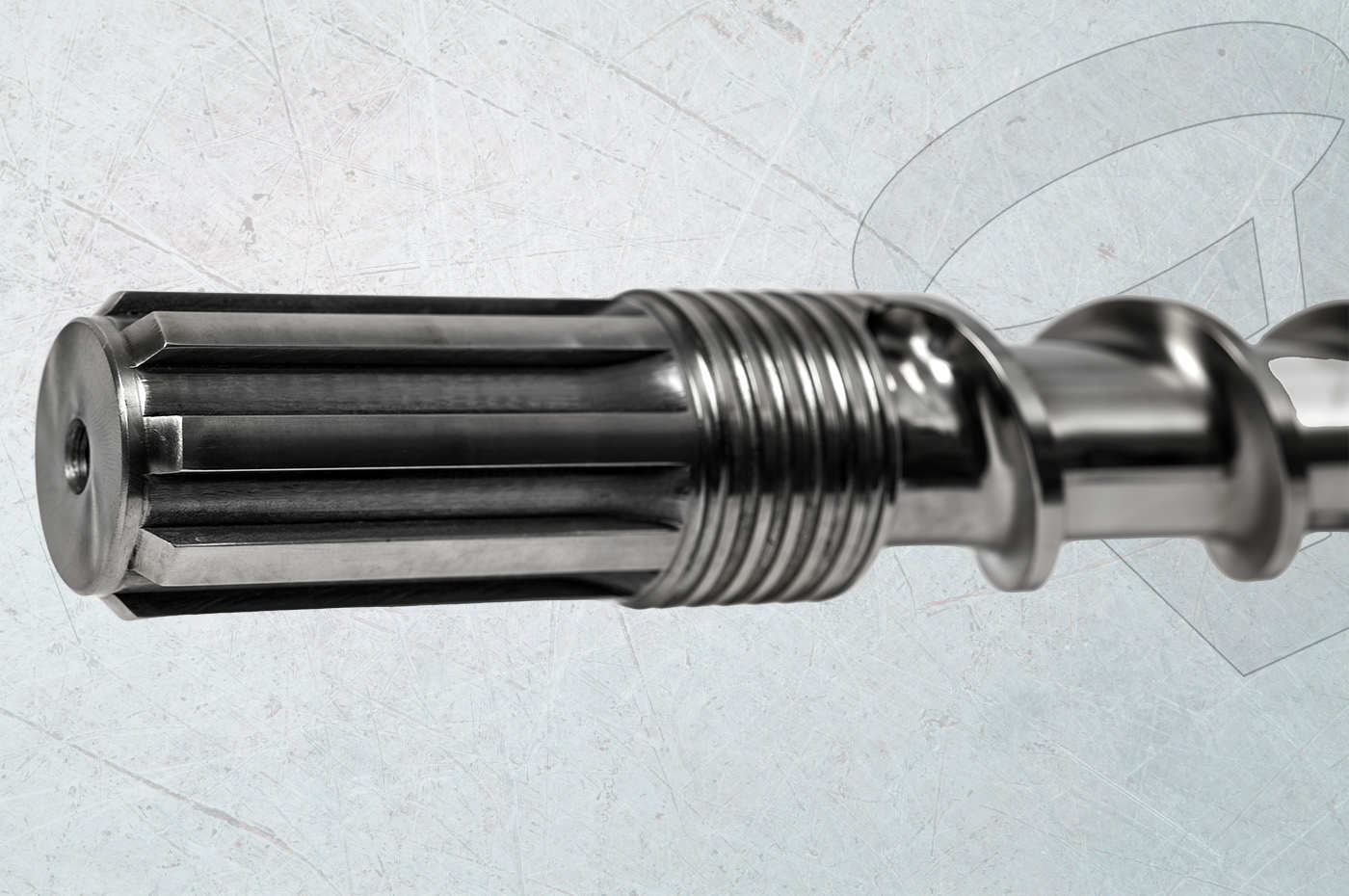

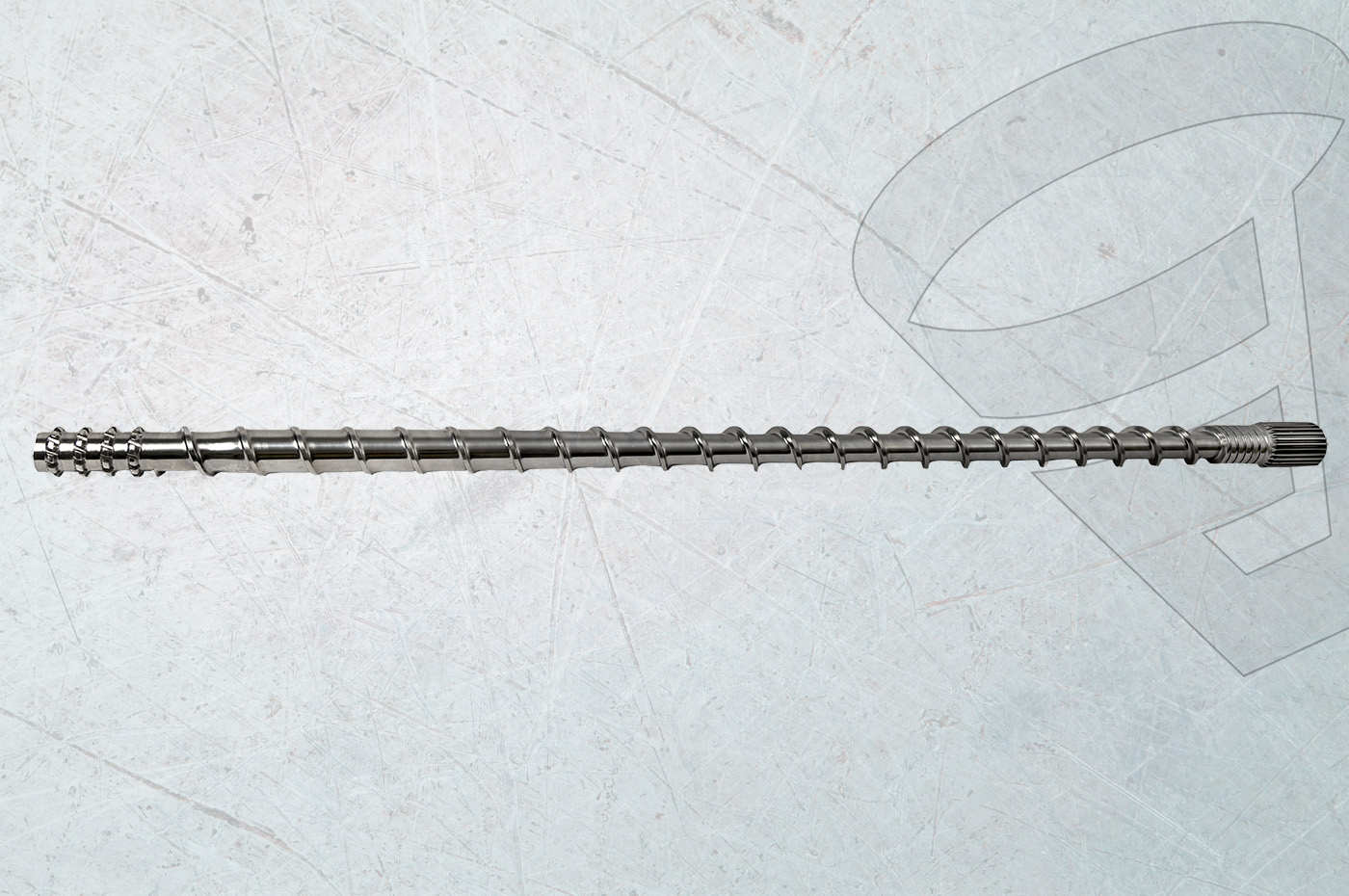

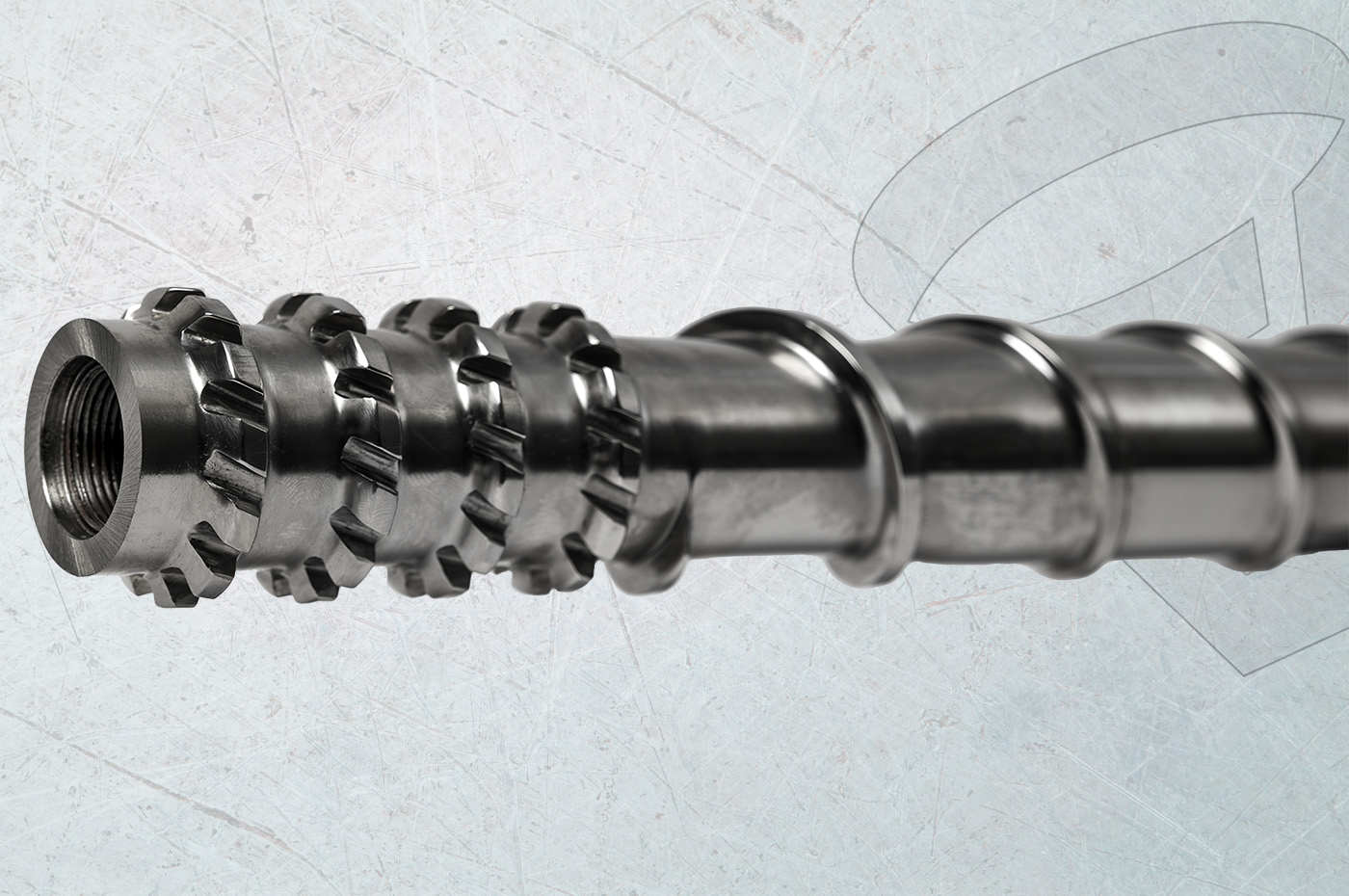

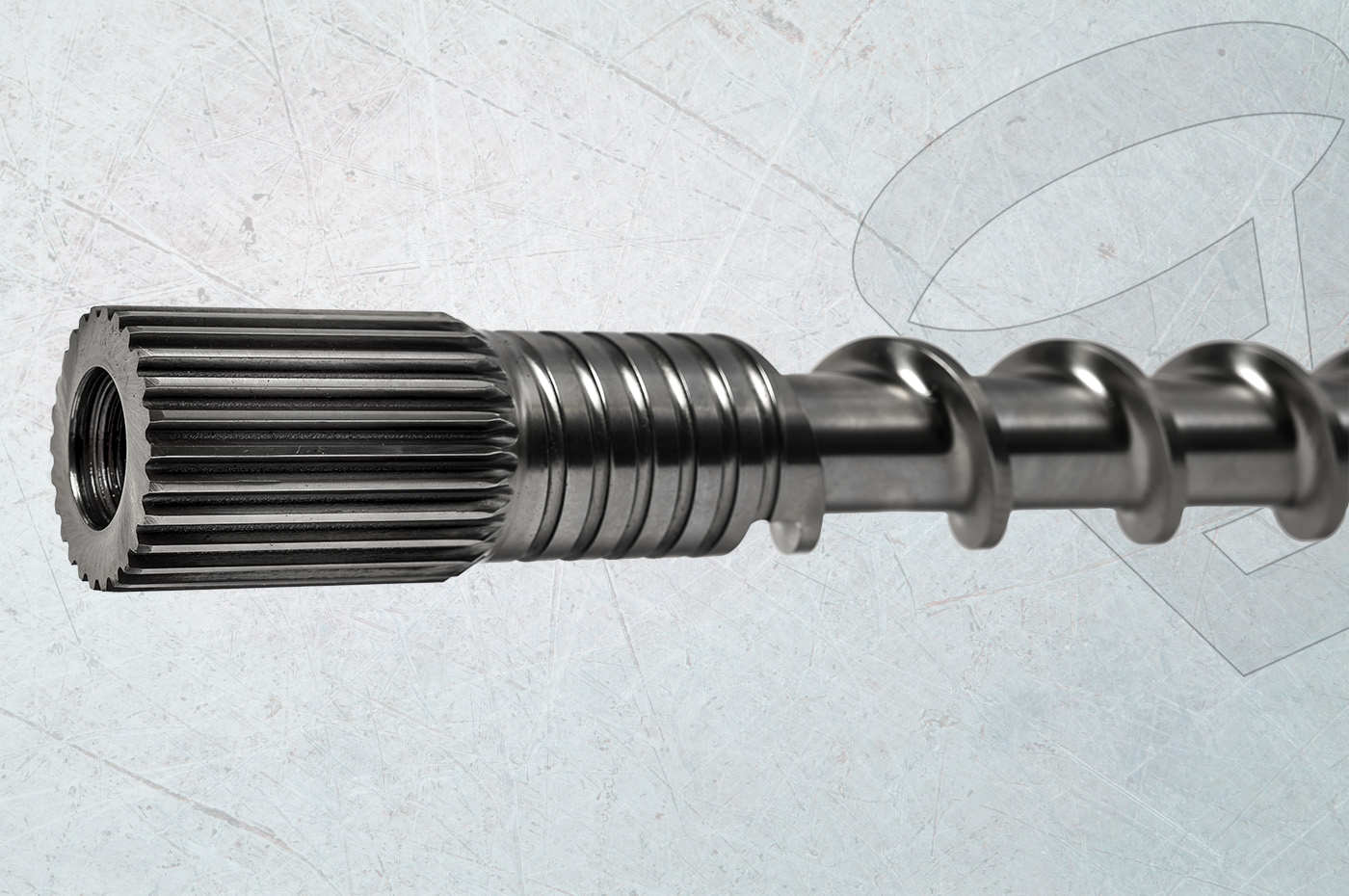

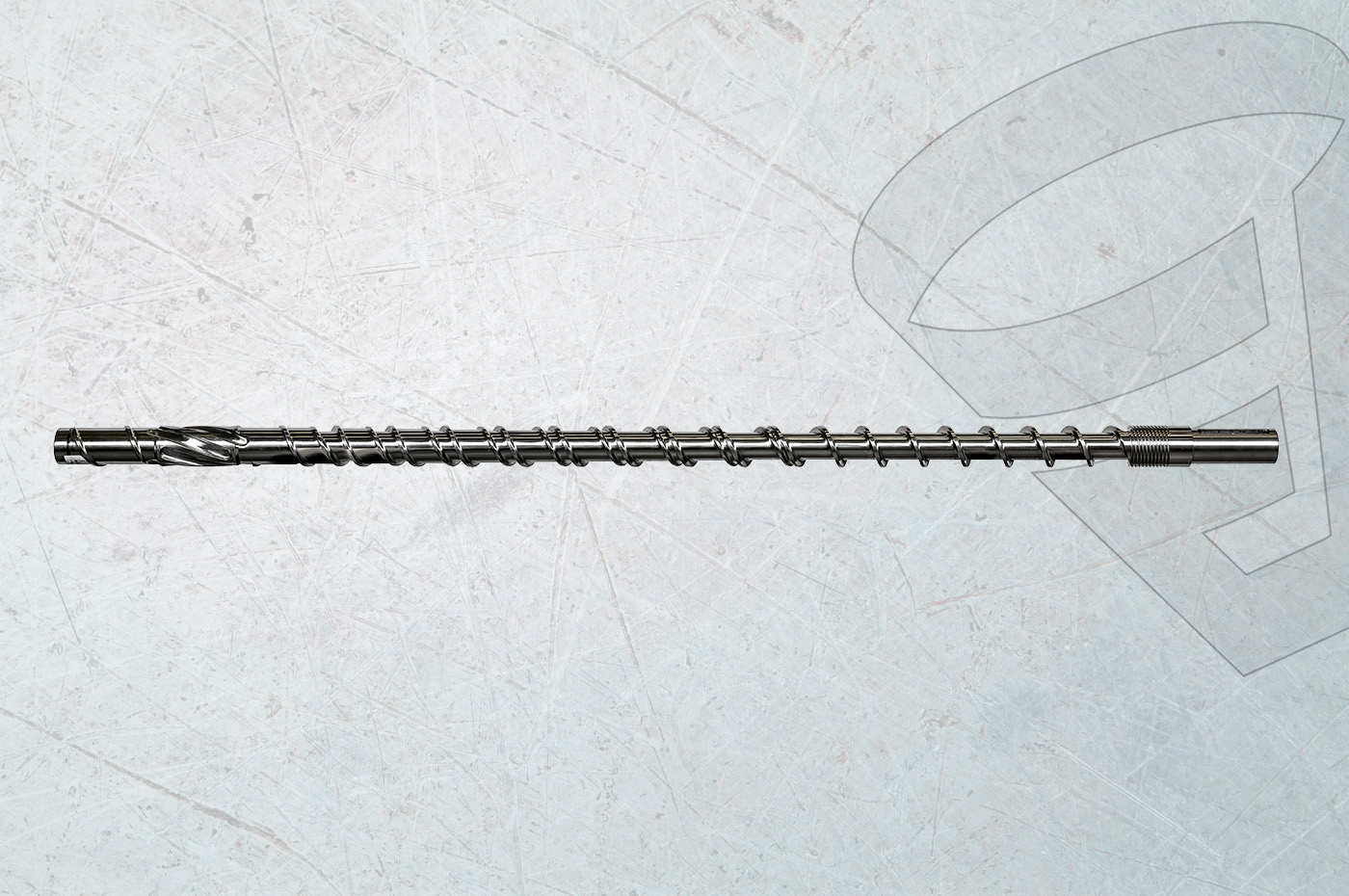

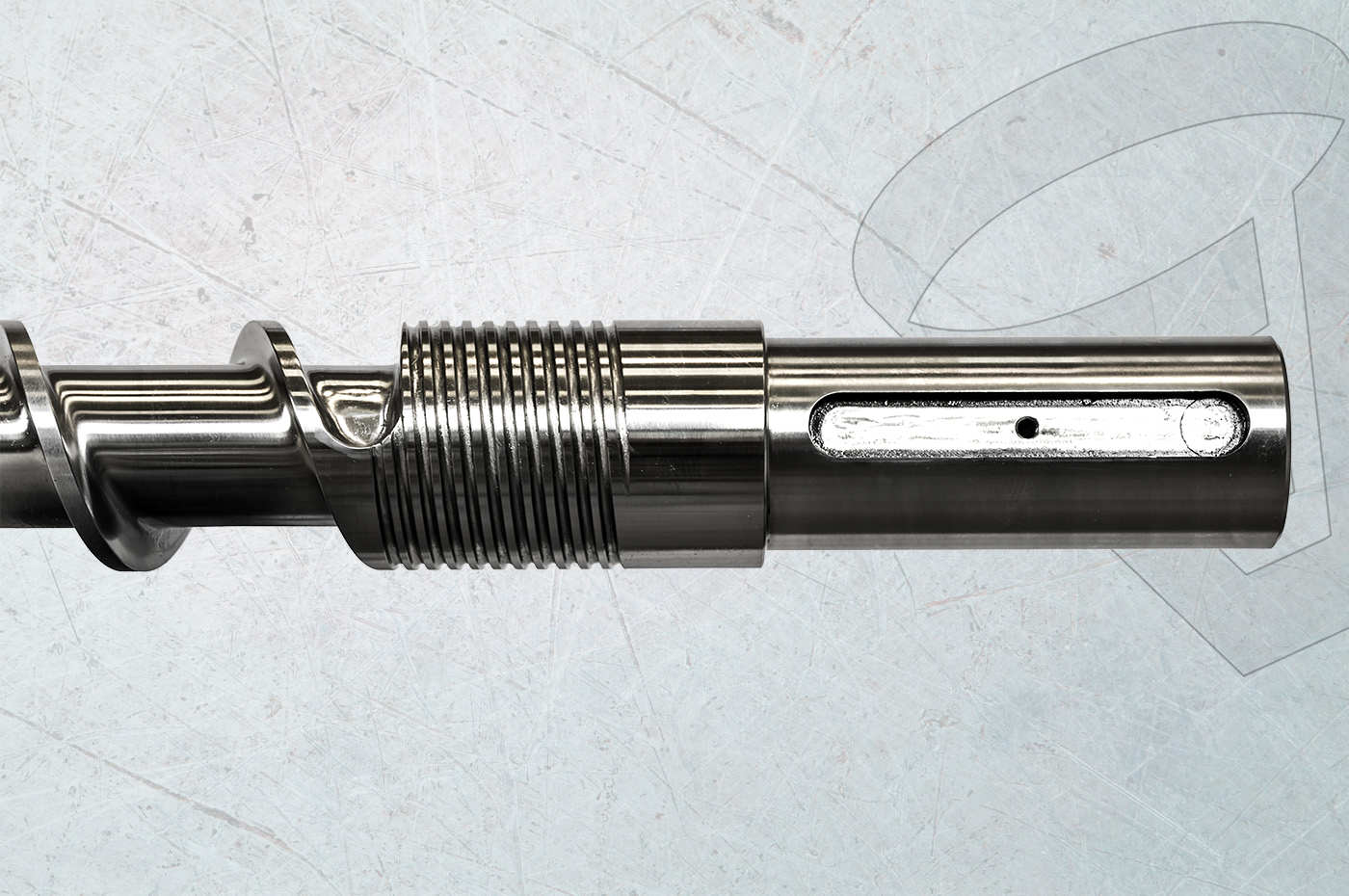

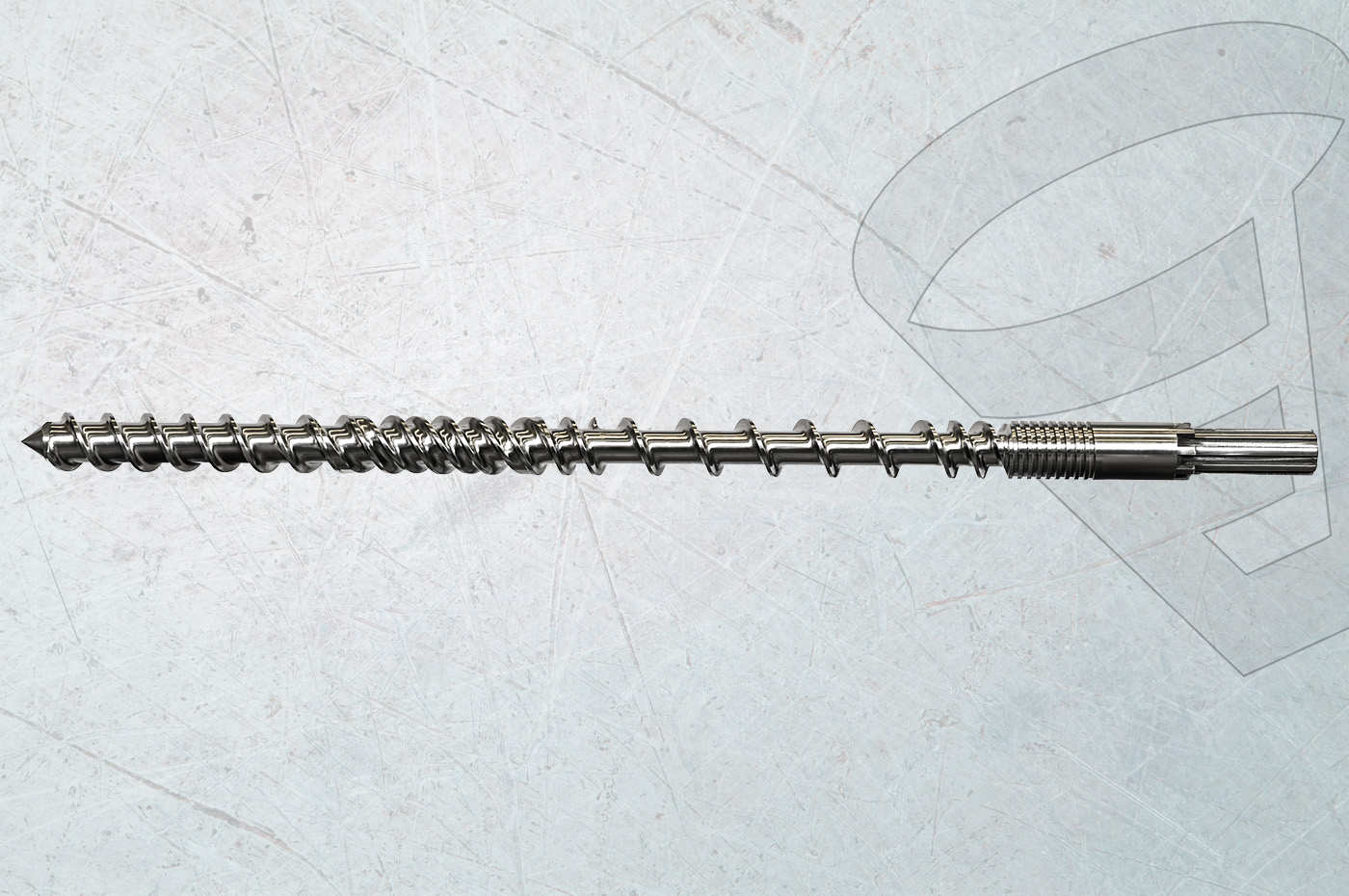

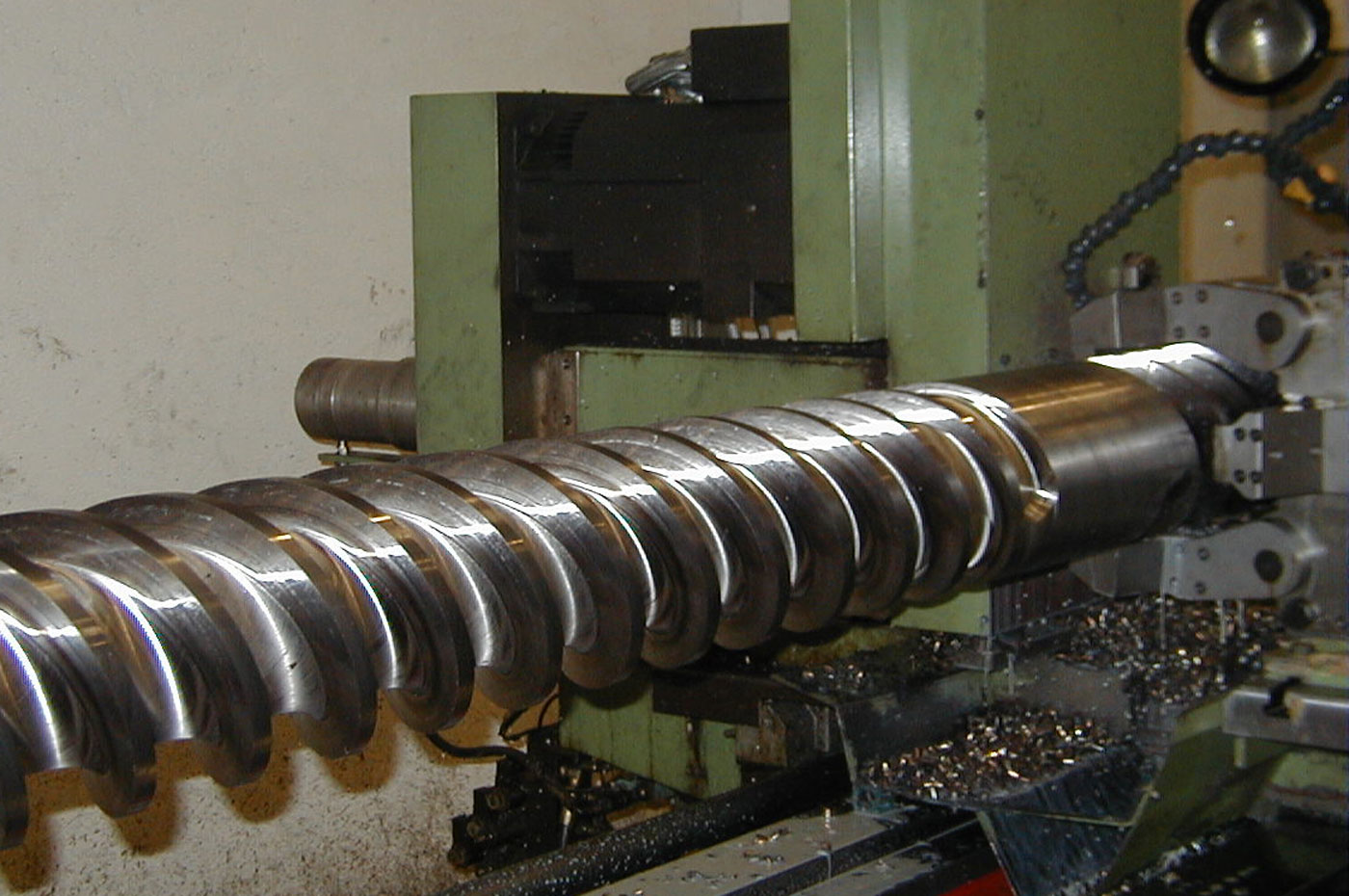

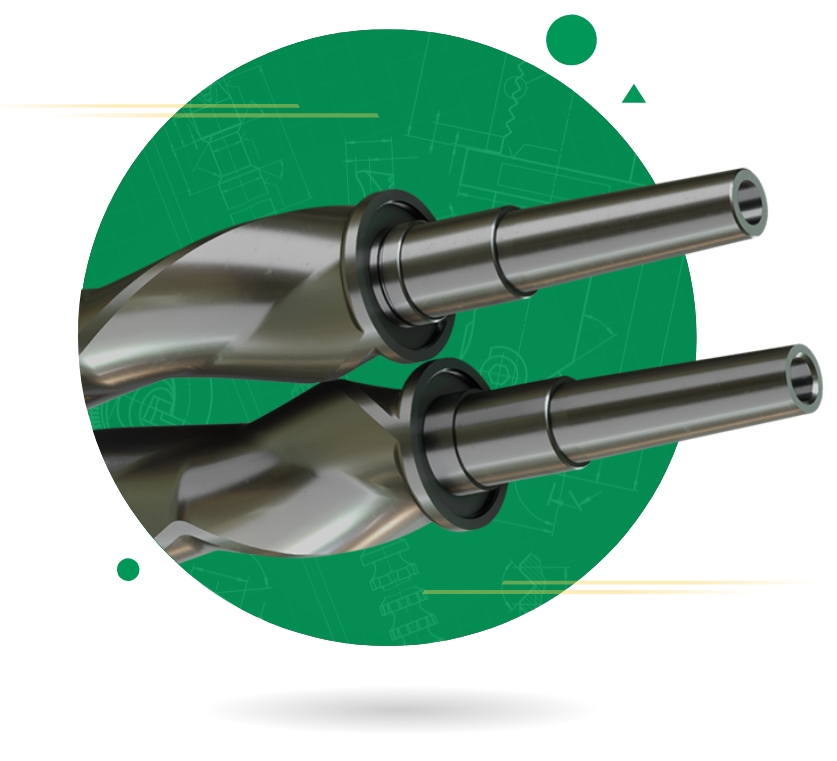

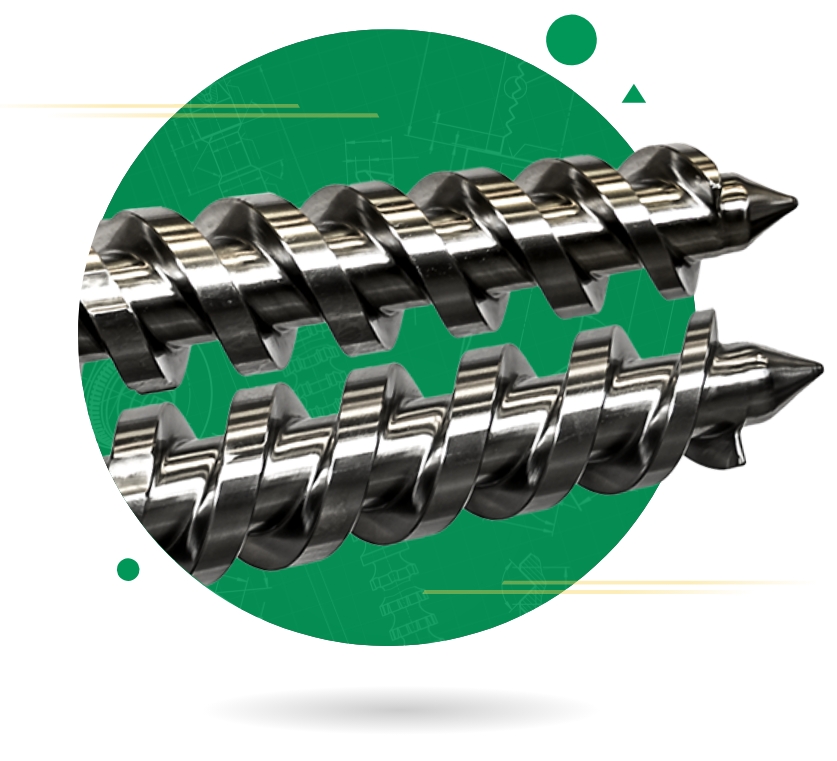

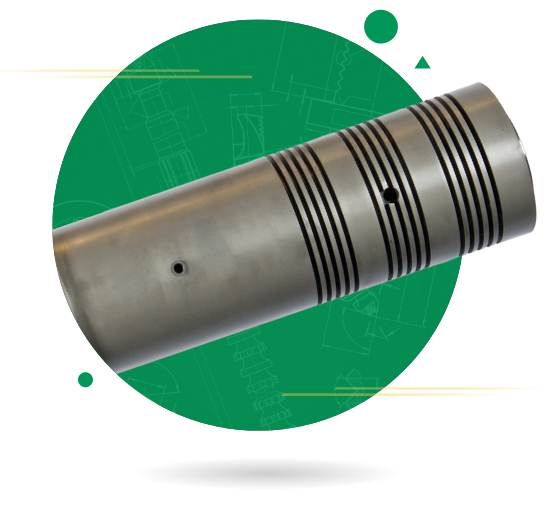

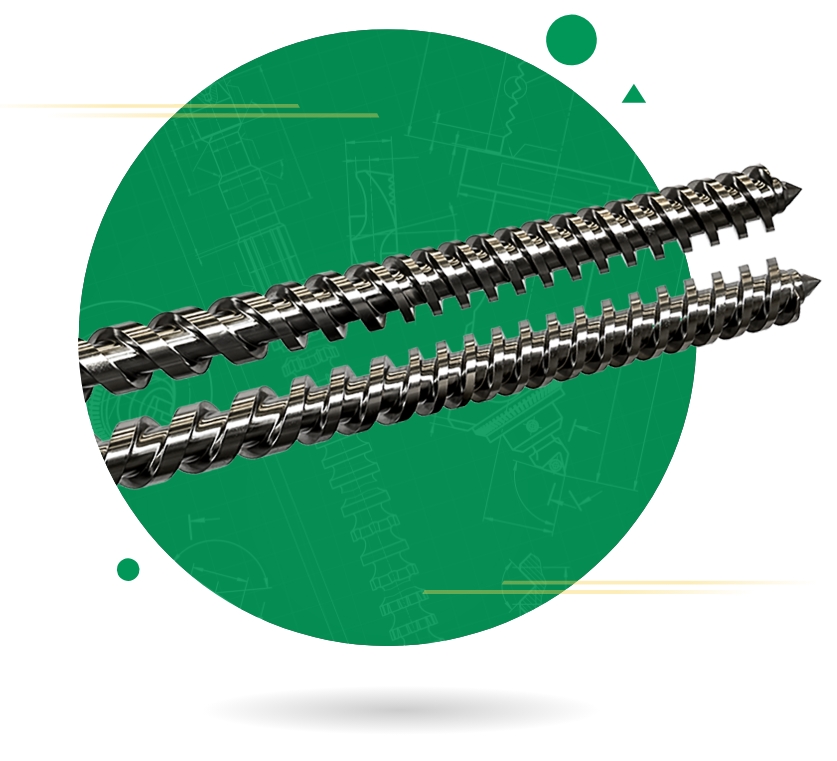

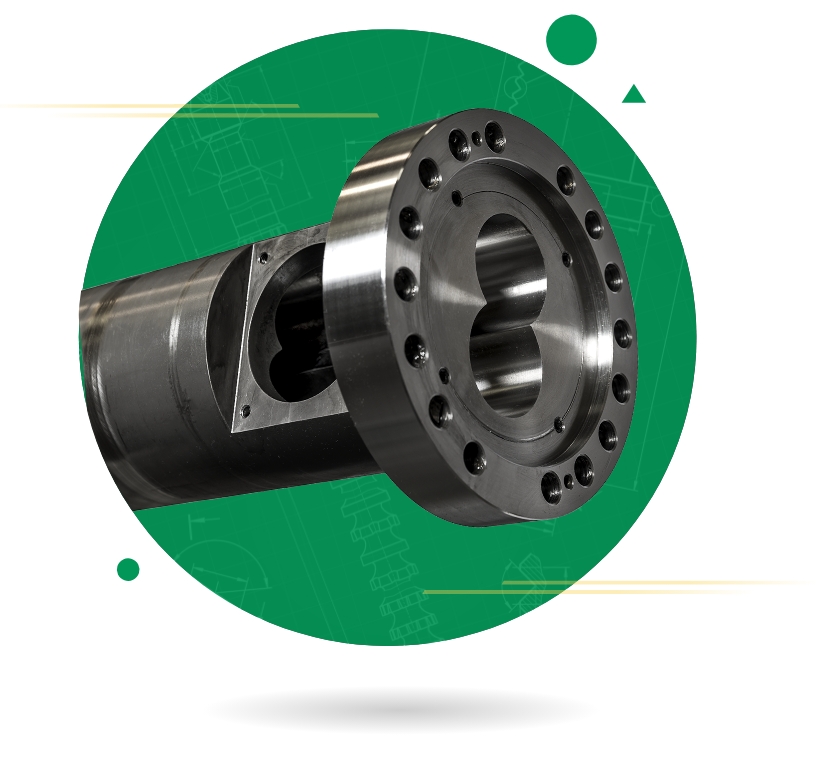

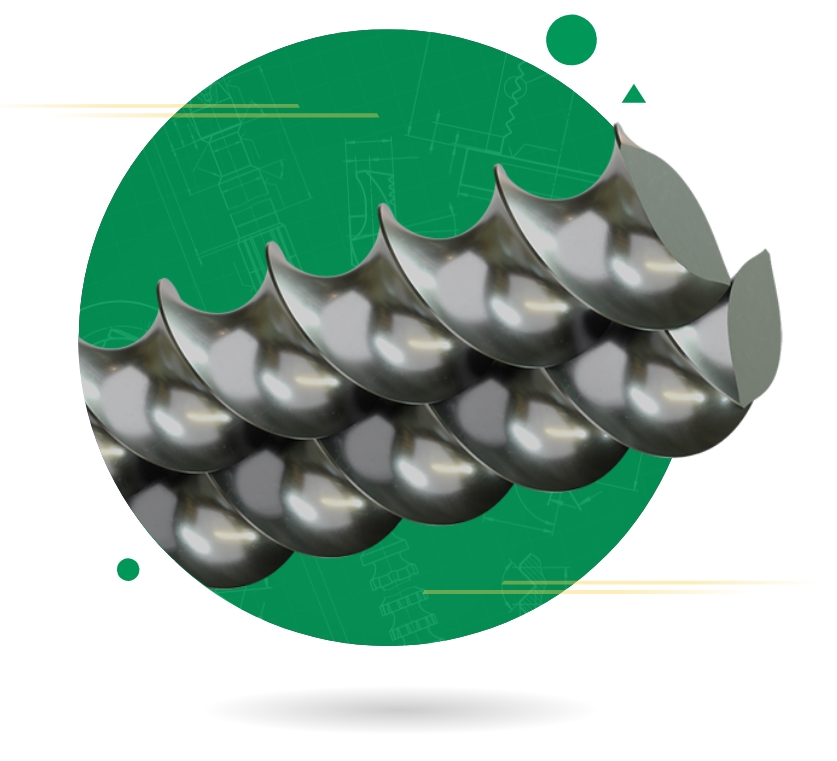

Extrusion is a continuous process where plastic material is melted by the action of a screw inside a heated by induction barrel. The screw is the heart of the extruder and plays a crucial role in the success of the production process. Choosing the most suitable screw geometry, based on the characteristics of the plastic material to be processed and the final product to be made, is essential to anticipate and manage the difficulties that might arise during the process.

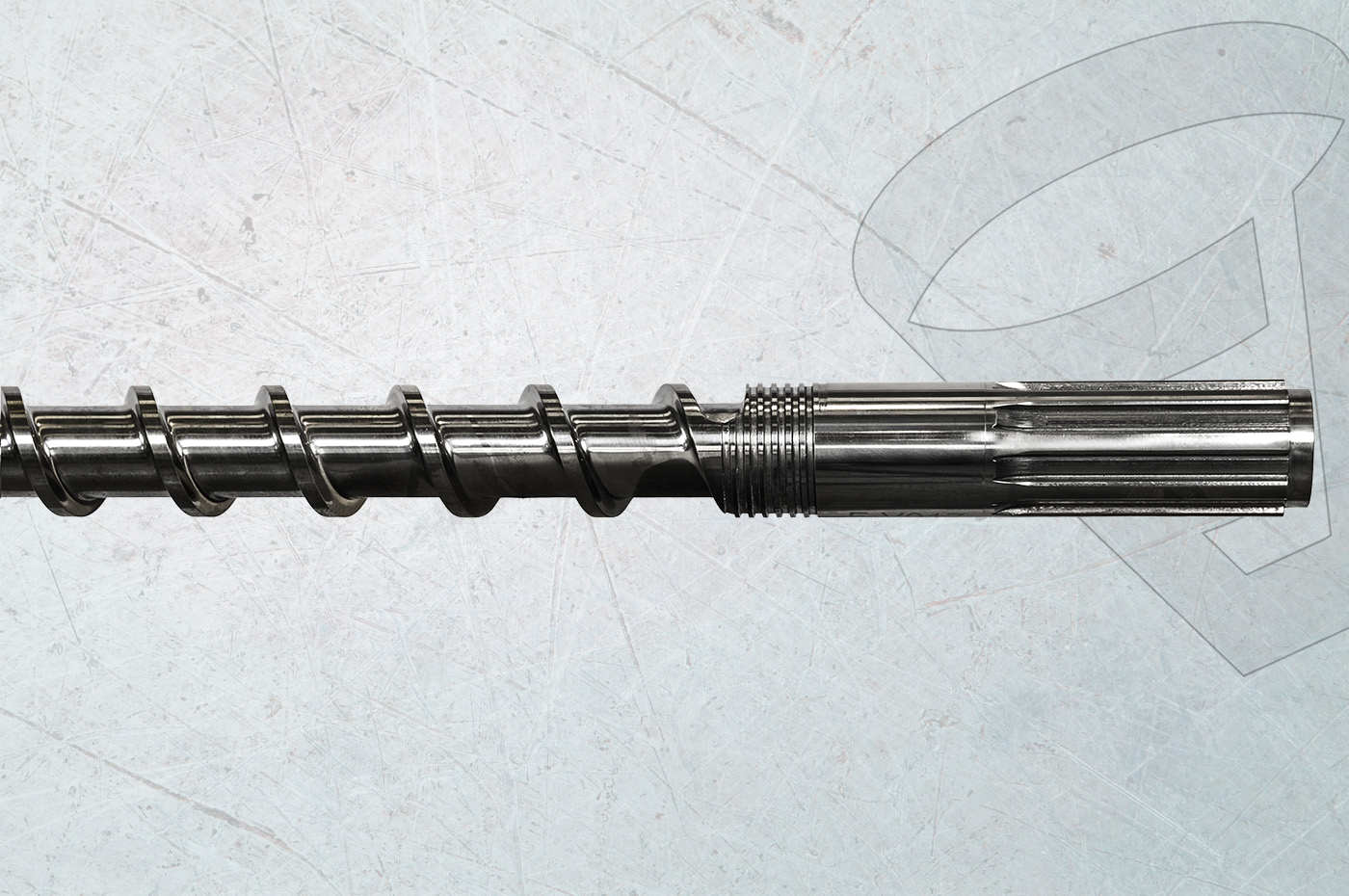

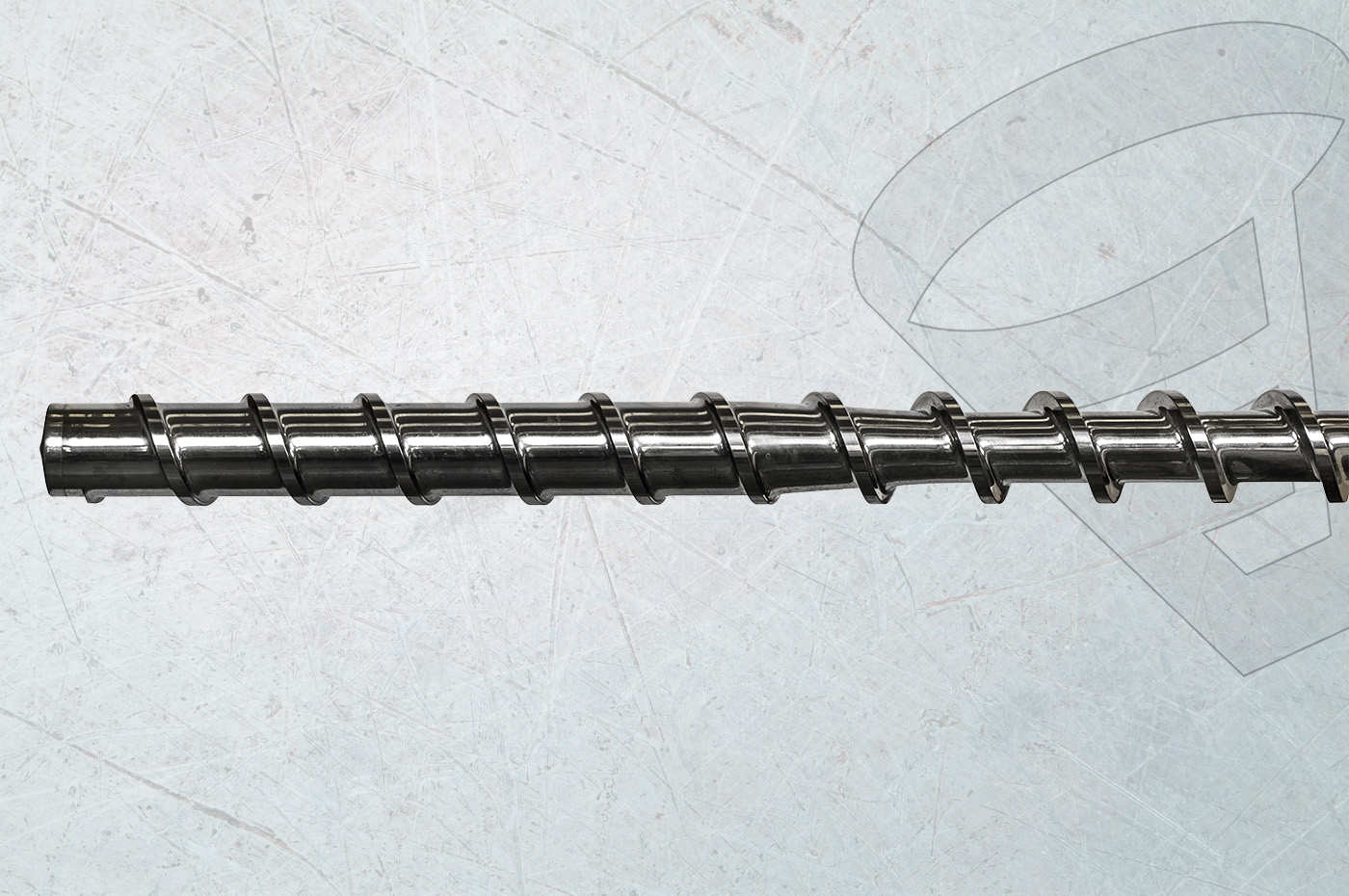

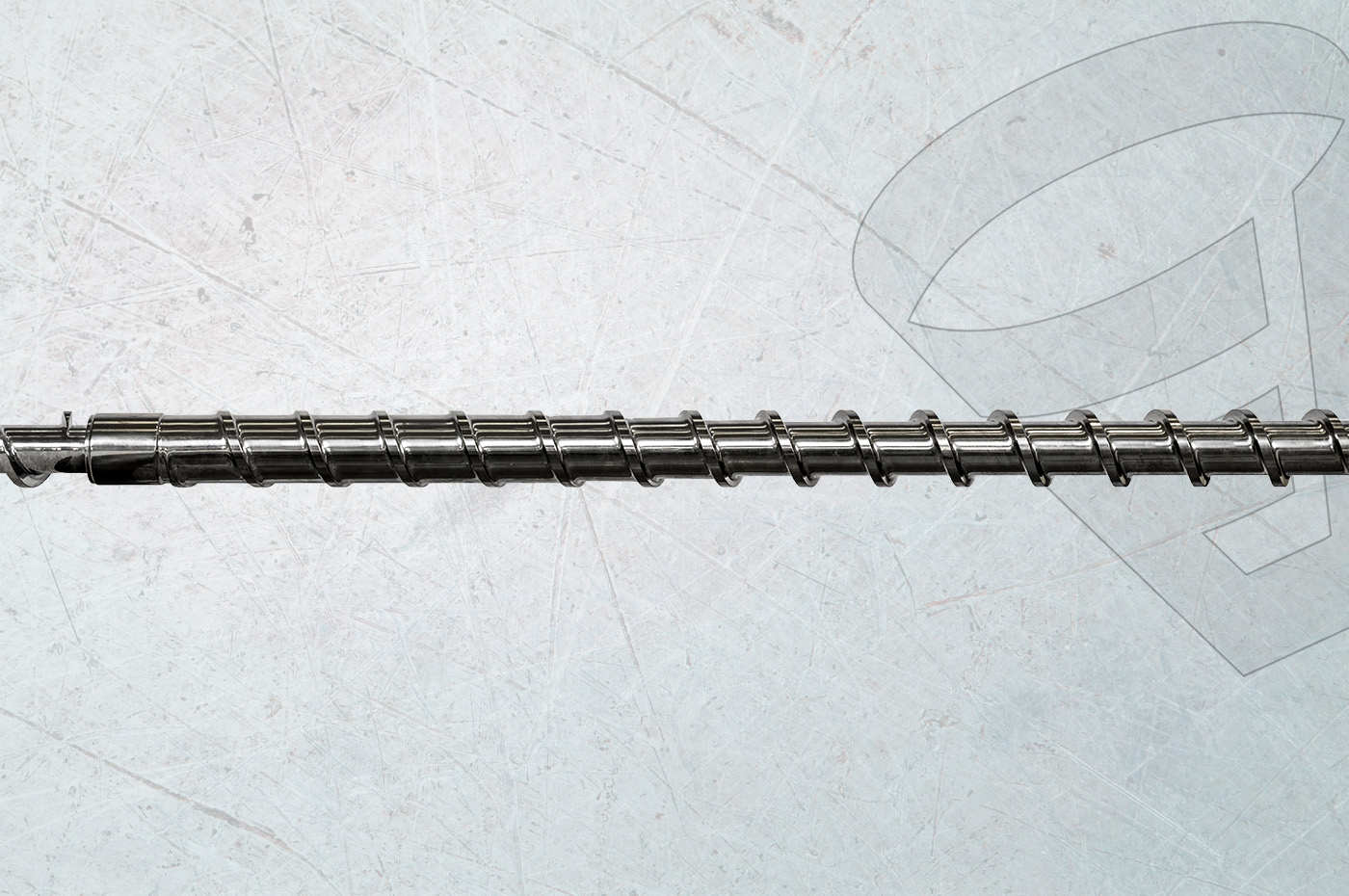

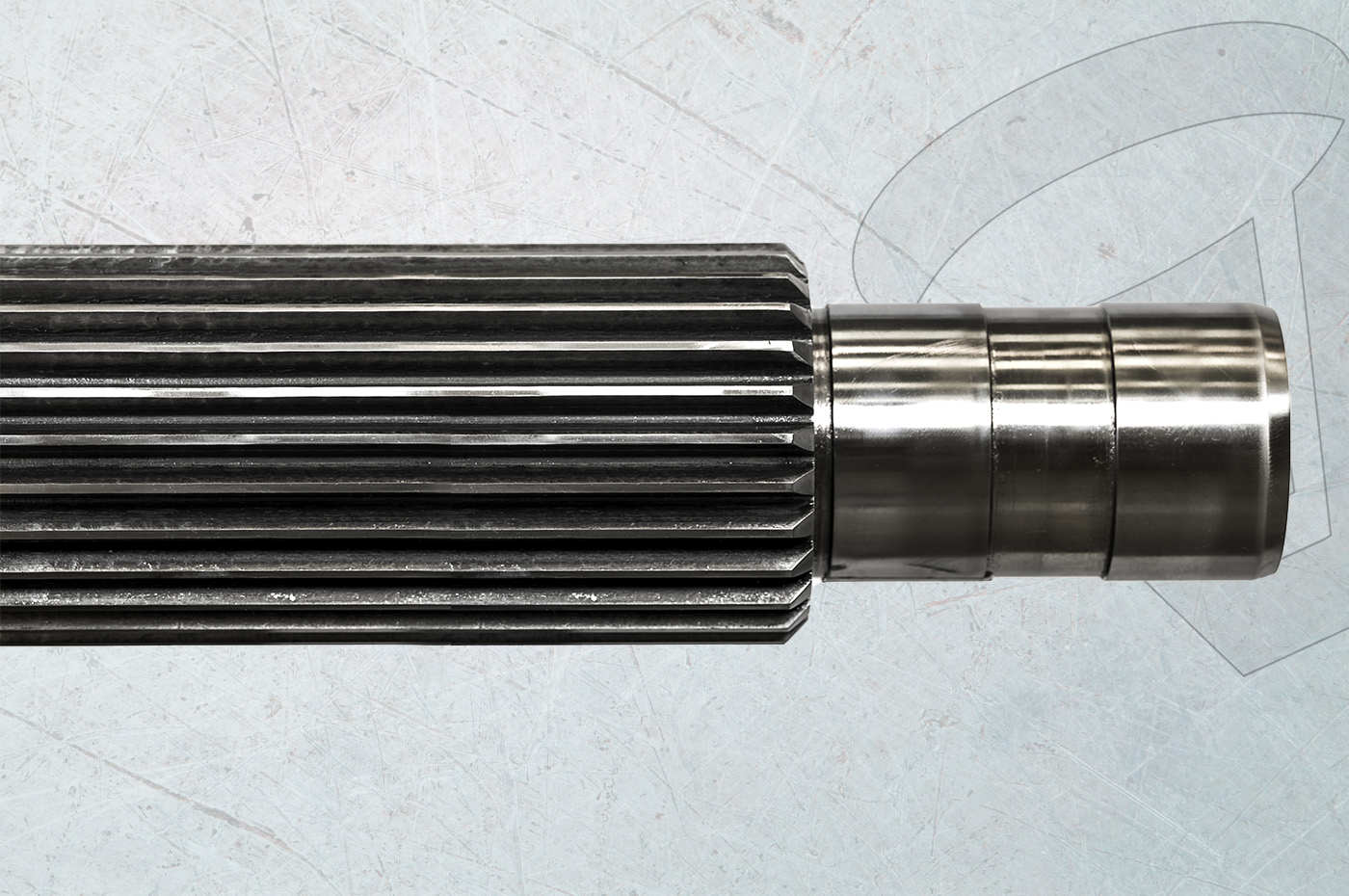

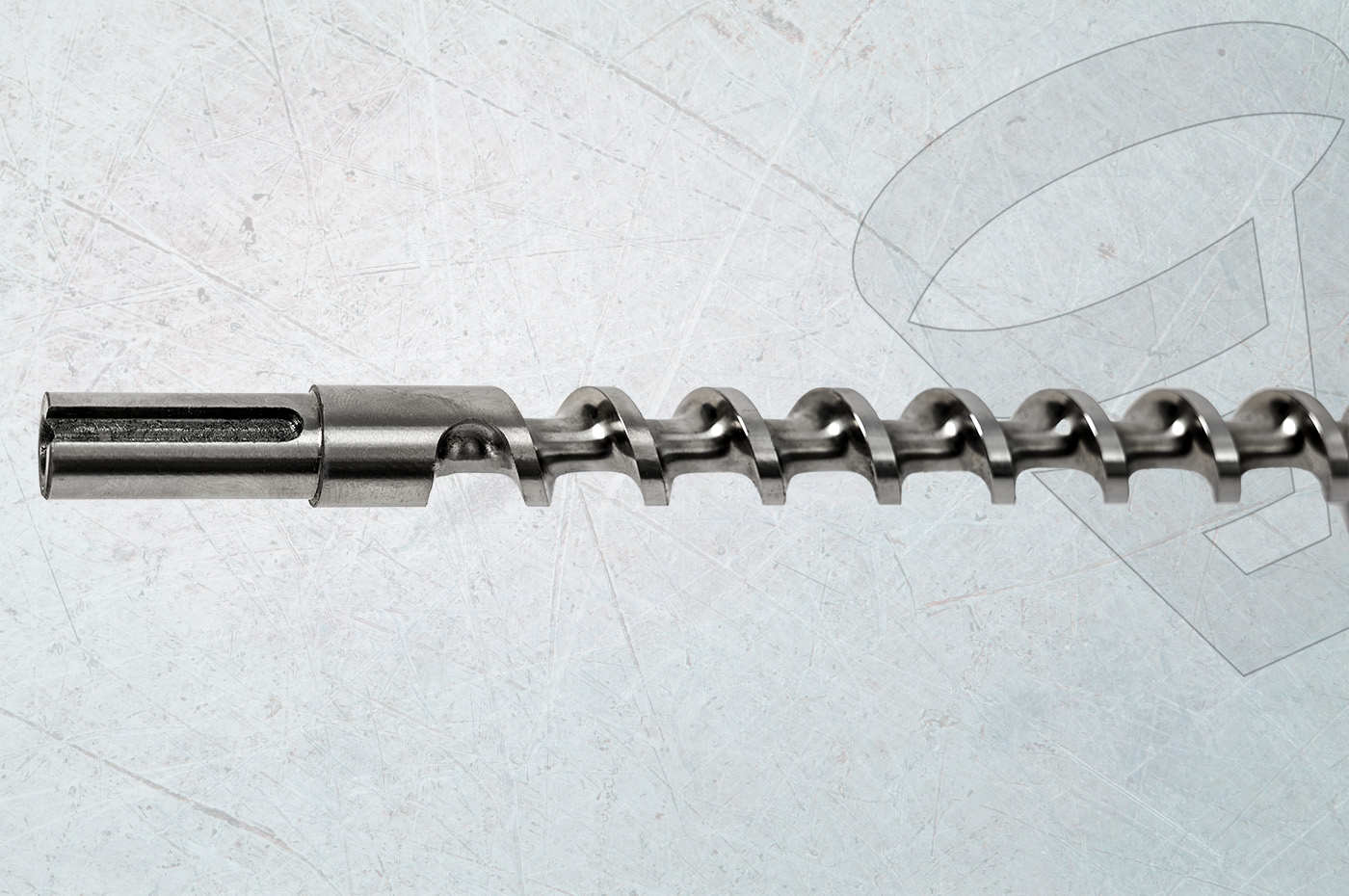

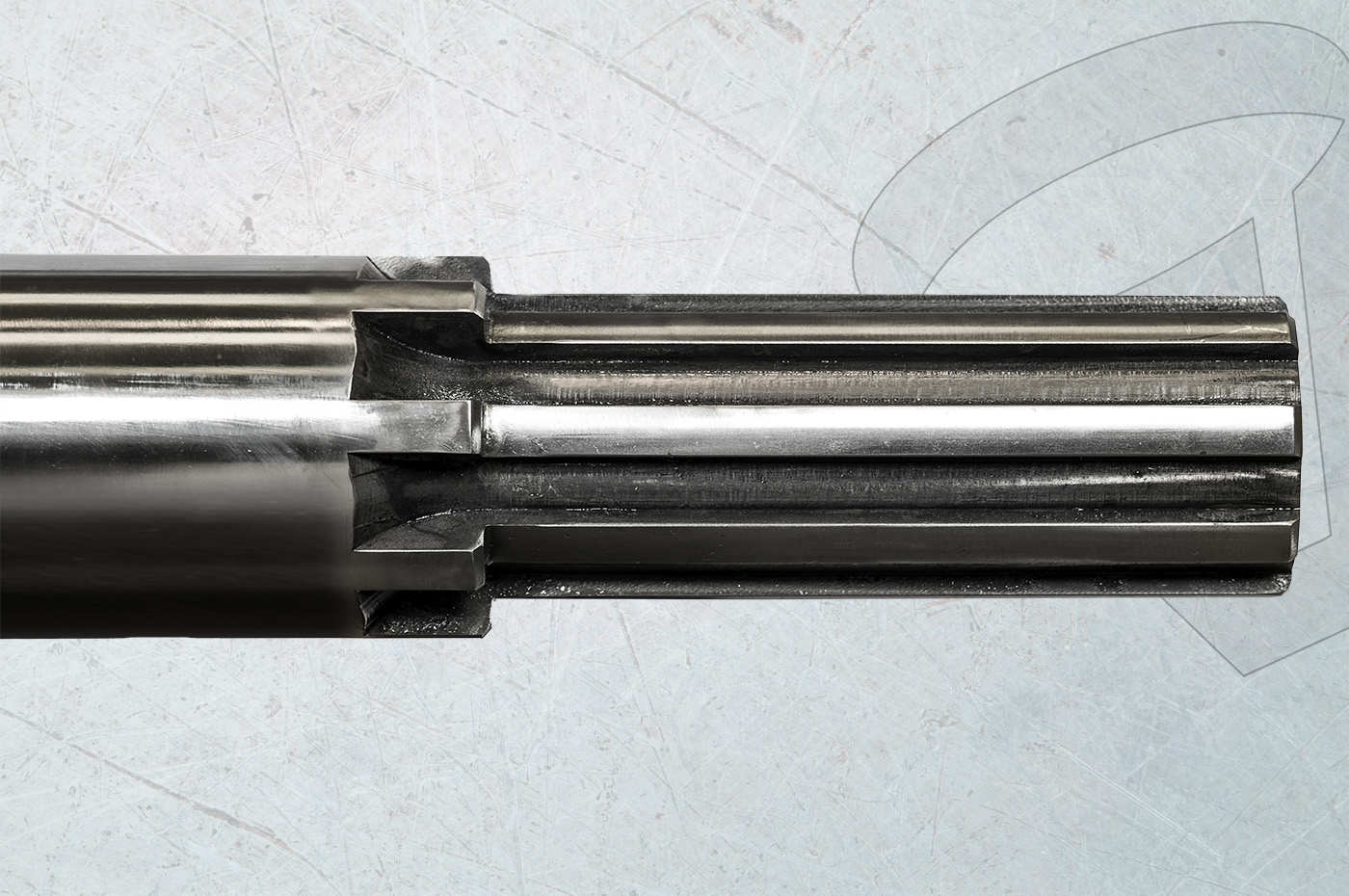

Two main aspects require particular attention to ensure the correct functioning of the system: the quality of the steel used for the screw and the profile of the screw itself. It is crucial to anticipate issues such as corrosion or abrasion caused by the extruded plastic and to choose the most suitable base steel, subjecting it to the necessary heat treatments, galvanic treatments, or coatings. Euroviti offers a wide range of options to choose from in these areas.

The profile of the screw is equally crucial in determining the quality and quantity of the finished product (expressed in kg/h). After a detailed analysis of the extruder system, Euroviti is able to propose a new high-performance screw profile, designed to address and solve existing issues and criticalities in the extrusion system.

In conclusion, Euroviti provides a thorough analysis of the extrusion system and proposes customized solutions to address problems of abrasion and/or corrosion, thus ensuring the highest possible performance. The choice of high-quality screws, with the right profile and made from the most suitable base steel, is essential to improve the qualitative and quantitative performance of the plant. Euroviti guarantees the selection of the most suitable option among the many alternatives available.

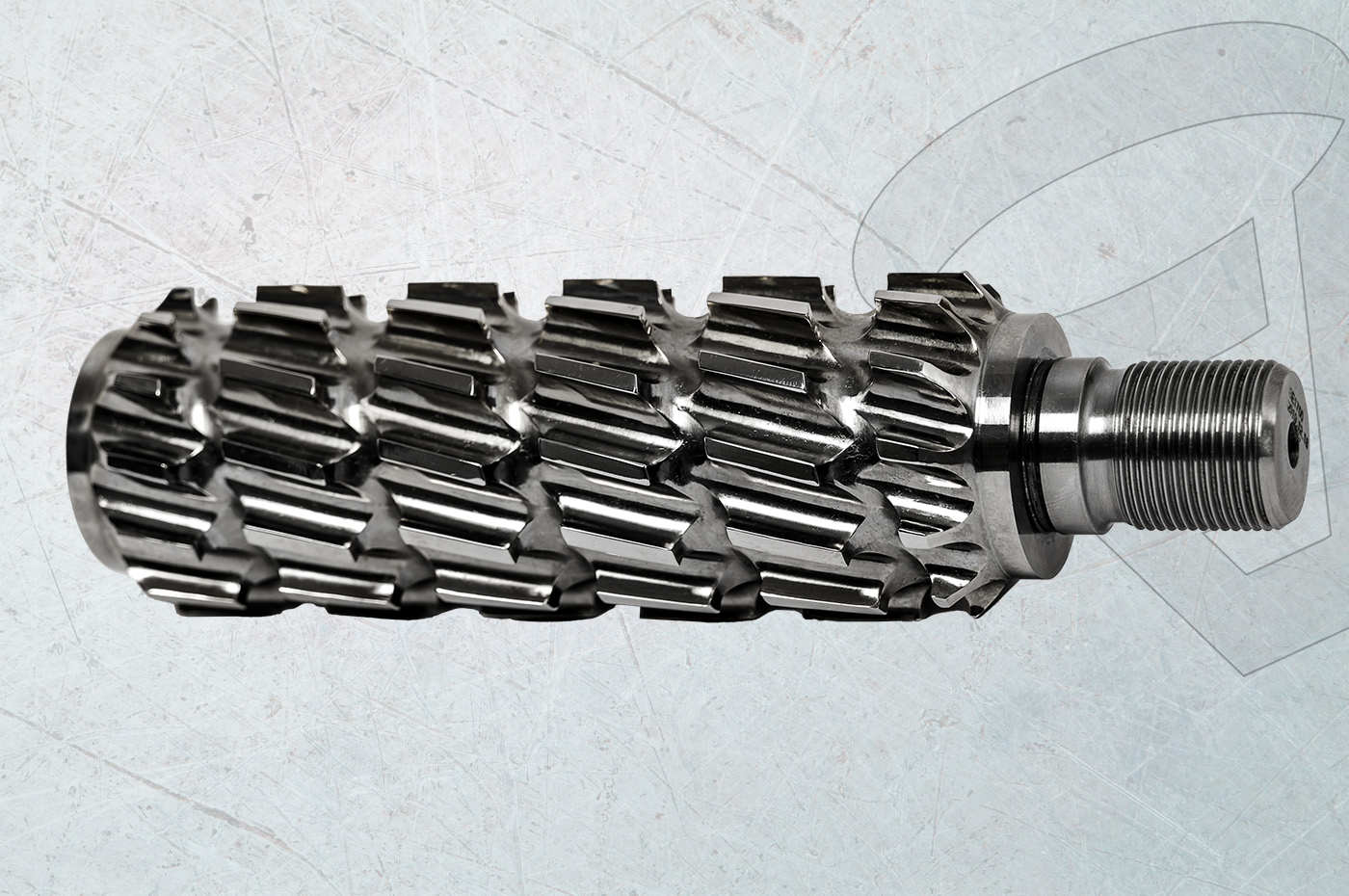

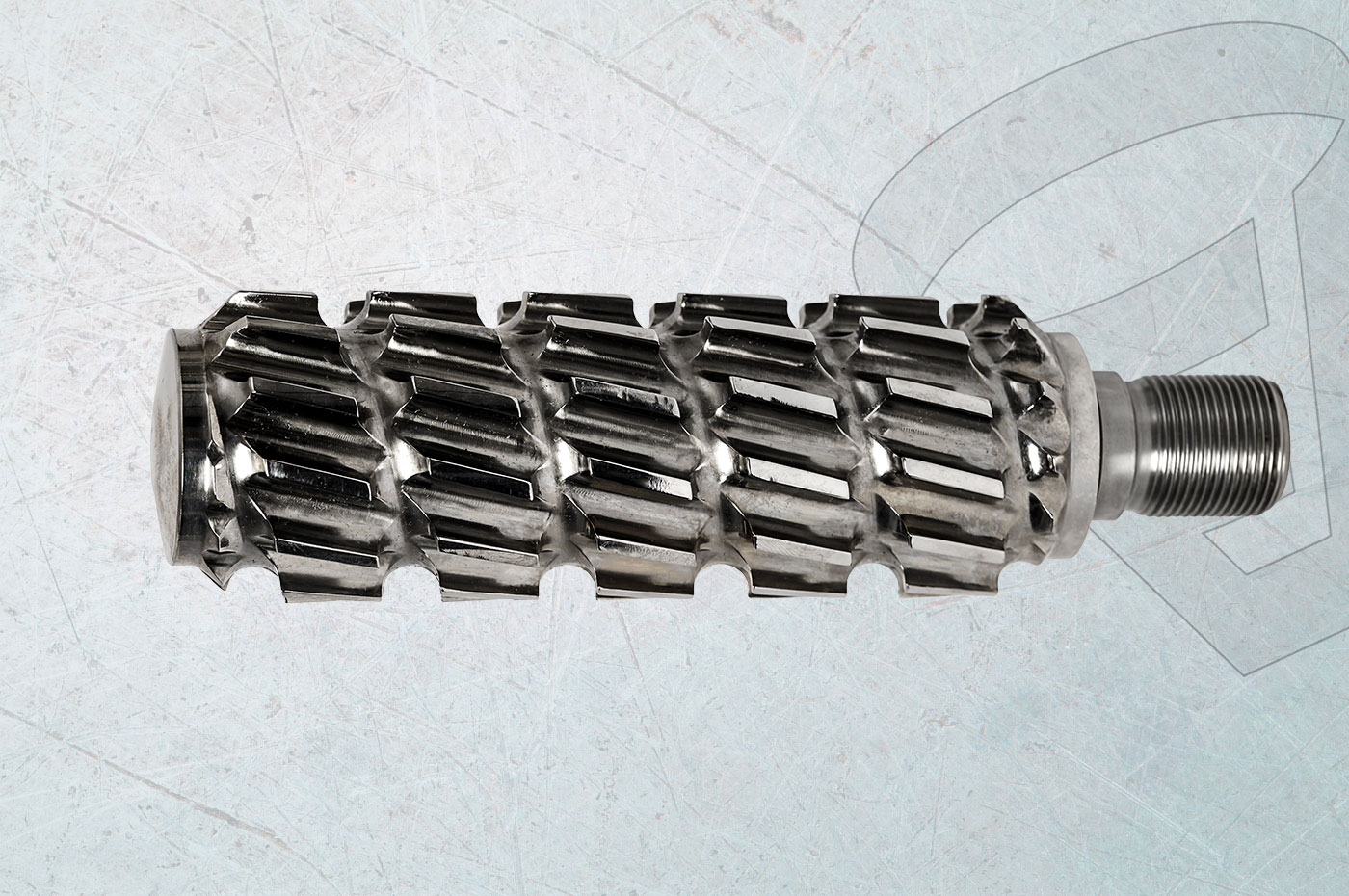

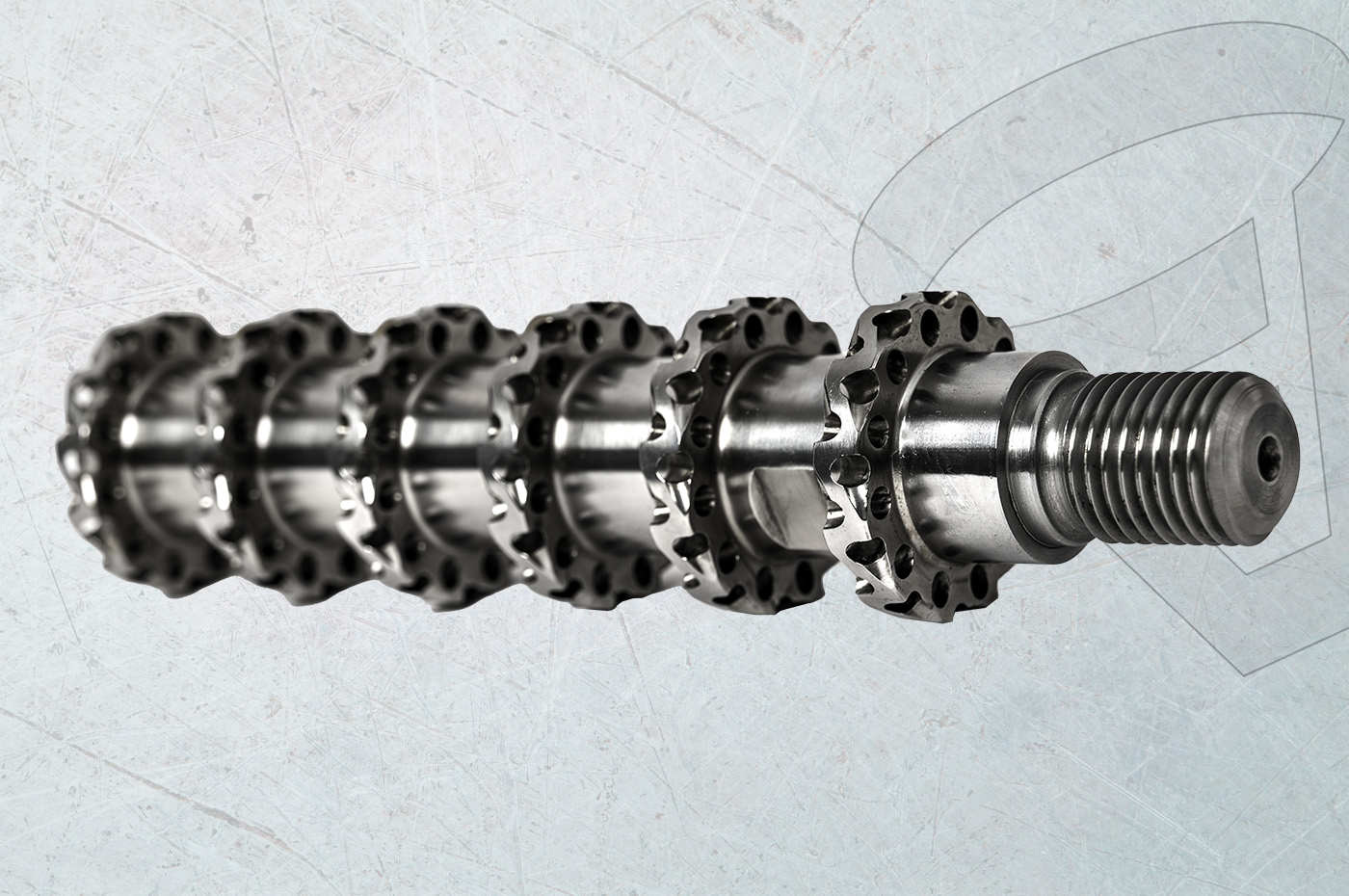

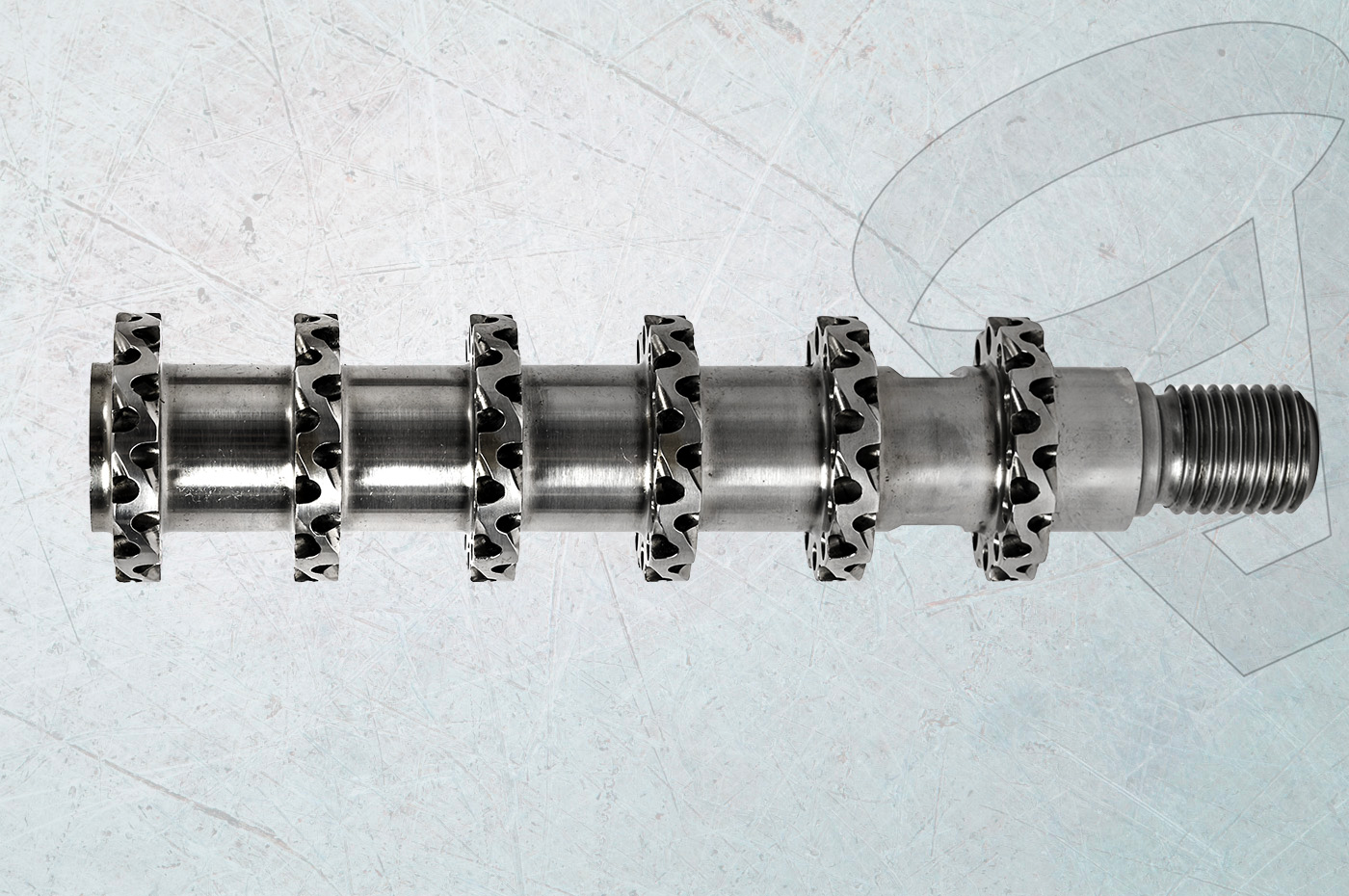

Gallery

Discover the technical information about

Screw

| EUV CODES | STEEL TYPE | TREATMENT | TYPE | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV31 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 700÷800HV | • | • |

| EUV34 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV38 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 500÷600HV | • | • |

| EUV41 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV79 | Cold Work Tool Steel | Hardening & Tempering | Total Hardening | 58÷62HRC | ••• | •• |

| EUV10 | Powder Metallurgy Steel - Protection from Abrasion | Hardening & Tempering | Total Hardening | 58÷64HRC | •••• | • |

| EUV90 | Powder Metallurgy Tool Steels | Special Hardening & Tempering | Total Hardening | 57÷63HRC | •••• | ••••• |

| EUV276 | Superalloy | Blank | Blank | 32÷37HRC | ••• | ••••• |

| EUV50 | Stainless steels | Special Hardening & Tempering / Induction Hardening / Blank | Total or Partial Hardening or Blank | 44÷52HRC | ••• | •••• |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV12 | Co | PTA | 1÷3mm | 46÷50HRC | ••• | ••• |

| EUV5 | Fe | TIG | 1÷3mm | 58÷62HRC | •••• | •• |

| EUV56 | Ni | PTA | 1÷3mm | 46÷58HRC | ••• | ••• |

| EUV60 | Ni | PTA | 1÷3mm | 57÷62HRC | •••• | •••• |

| EUV83 | Ni-Wc | PTA | 1÷3mm | 49÷56HRC | ••••• | •••• |

| EUV700 | Mo | THERMAL SPRAY | 200÷400 μm | 56÷60HRC | ••••• | •••• |

| EUV950 | Wc-Co-Cr | HVOF | 100÷300 μm | 1100÷1300HV | •••••+ | •••••+ |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS |

|---|---|---|---|---|

| EUVCr Flash | Cr | Plating | 5÷15 μm | 65÷70HRC |

| EUVCr Thick | Cr | Plating | 50÷150 μm | 65÷70HRC |

| EUVCrNOX | CrNox | PVD Iridescent Rainbow | 2÷6 μm | 2000÷2500HV |

| EUVPro | AlCrN | PVD Dark Grey | 2÷8 μm | 2800÷3000HV |

| EUVZrN | ZrN | PVD Light Yellow | 2÷4 μm | 2600÷3100HV |

| EUVTiN | TiN | PVD Yellow Gold | 2÷4 μm | 2000÷2500HV |

| EUVCrN | CrN | PVD Silver Grey | 2÷4 μm | 1800÷2200HV |

| EUVDlC | C | PACVD Rainbow Black | 2÷4 μm | 2000÷2500HV |

| EUV950 INCAPSULATED | Wc-Co-Cr | HVOF | 100÷300 μm | 1100÷1300HV |

| EUVFeO | FeO | Thermochemical treatment Black | 4÷5 μm | 850÷900HV |

Related Products

CONTACT US

Tell us what you need

Follow us