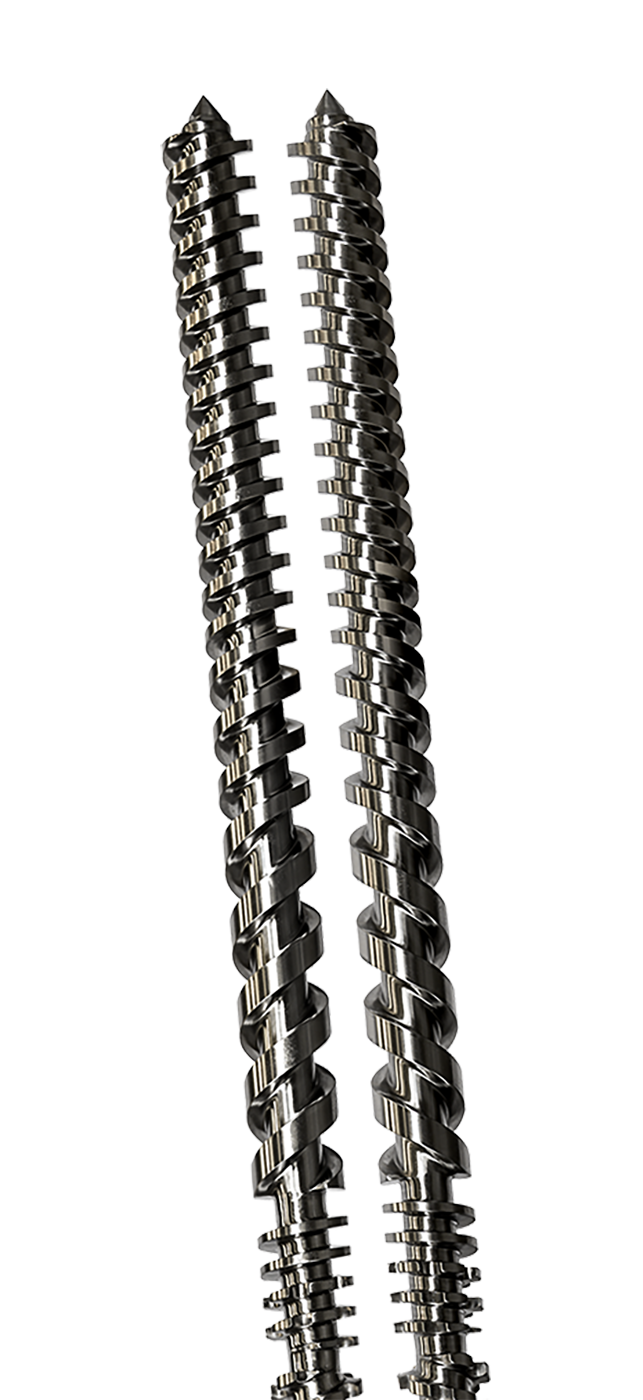

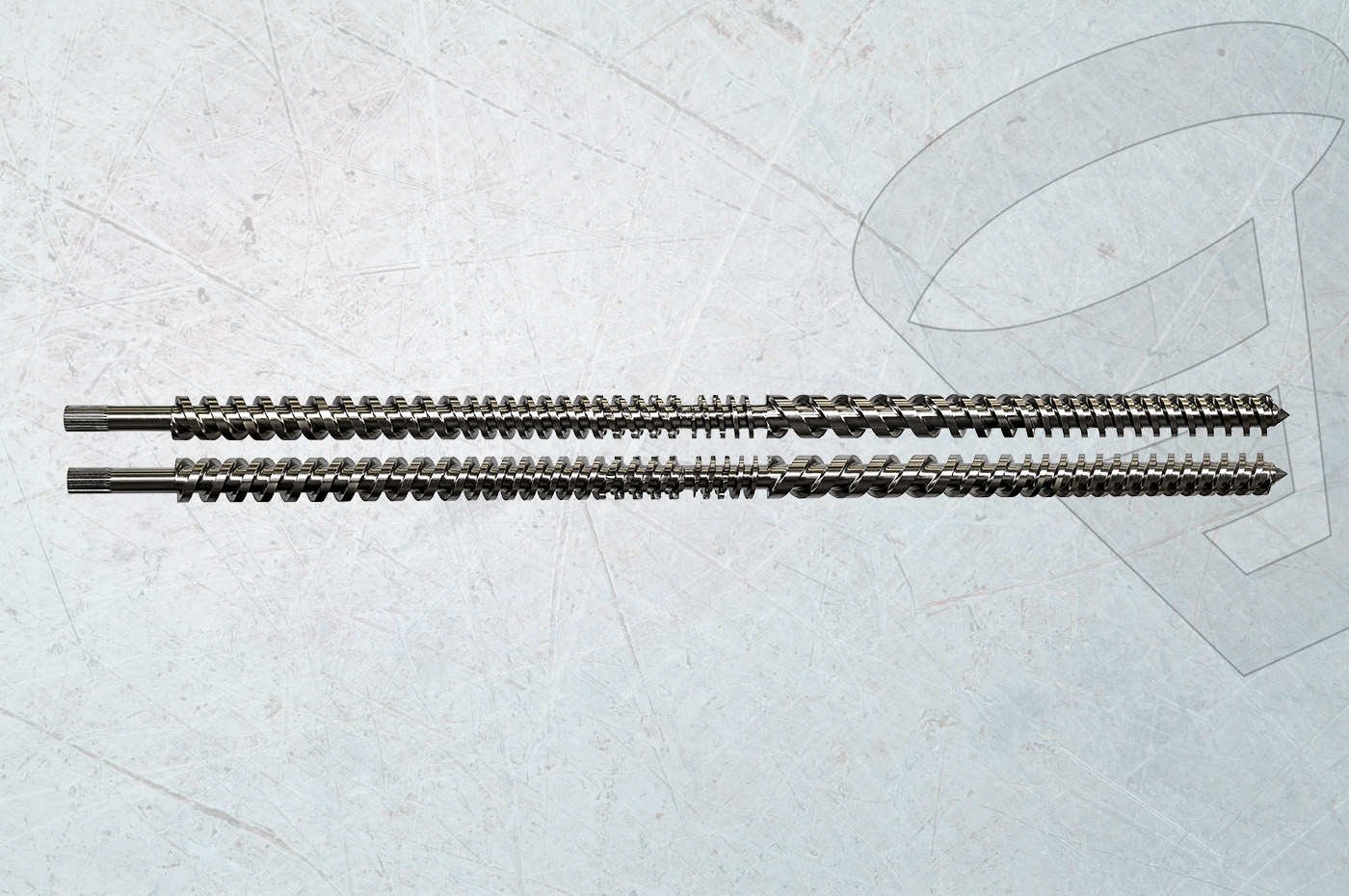

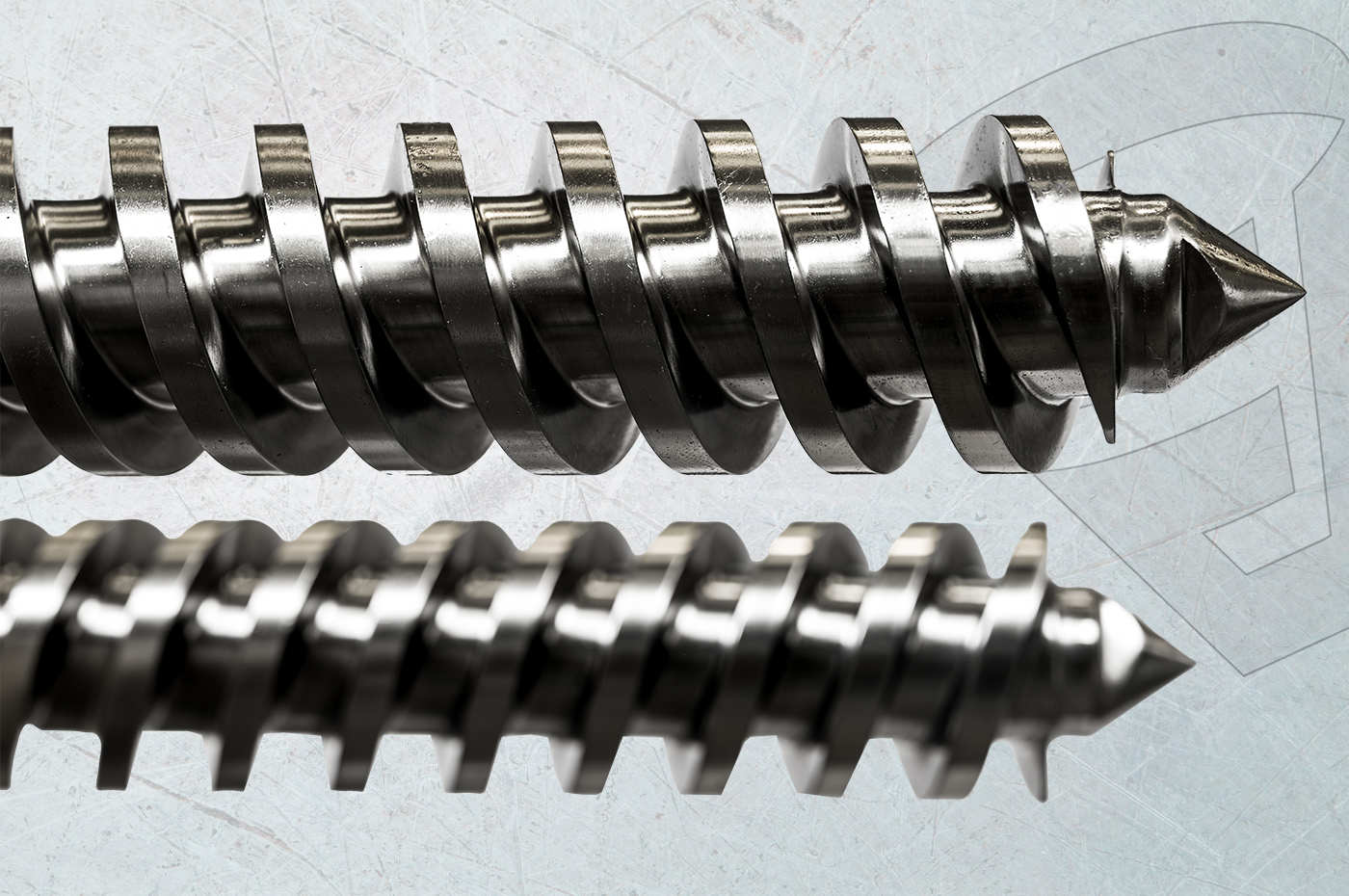

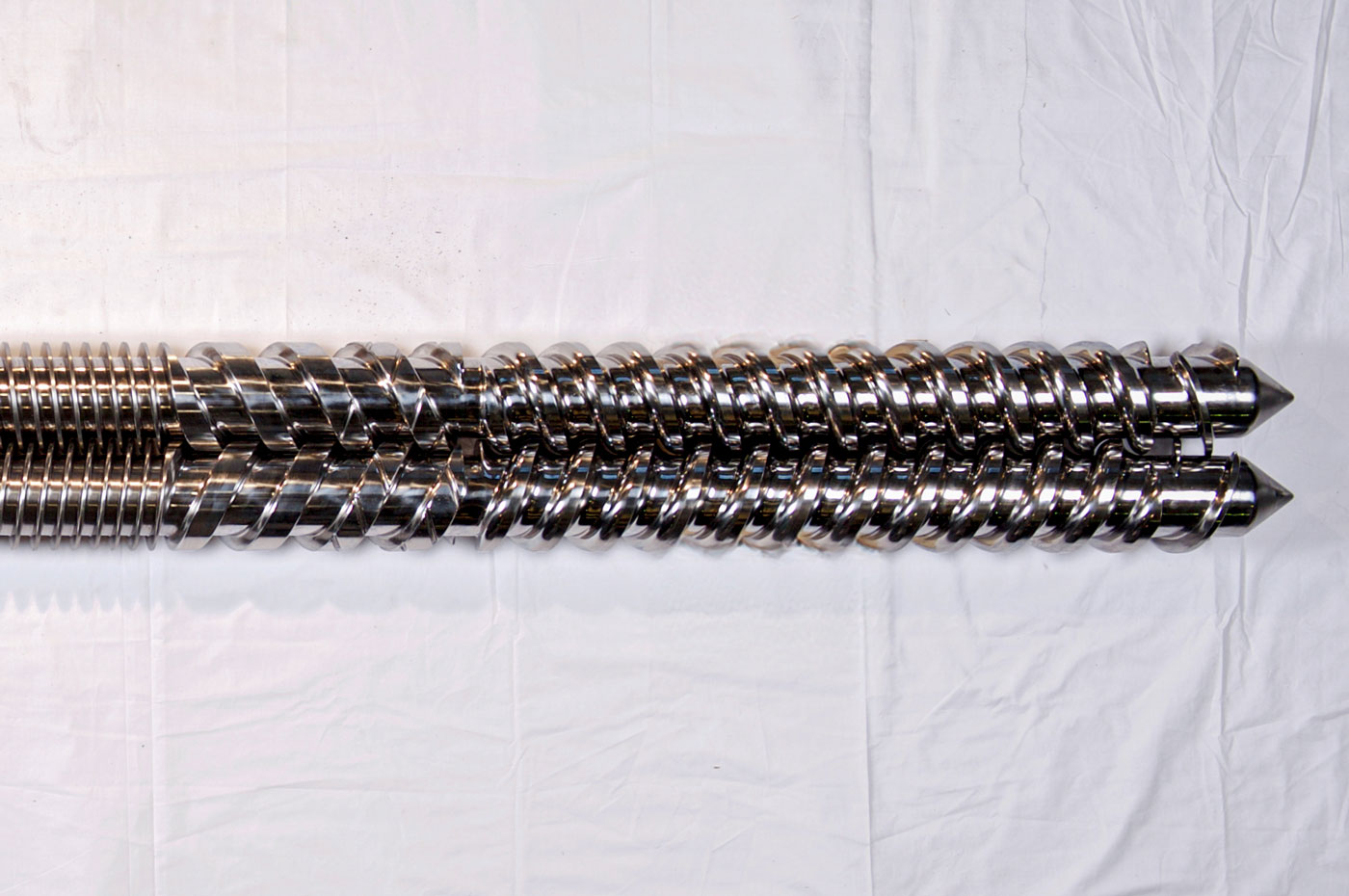

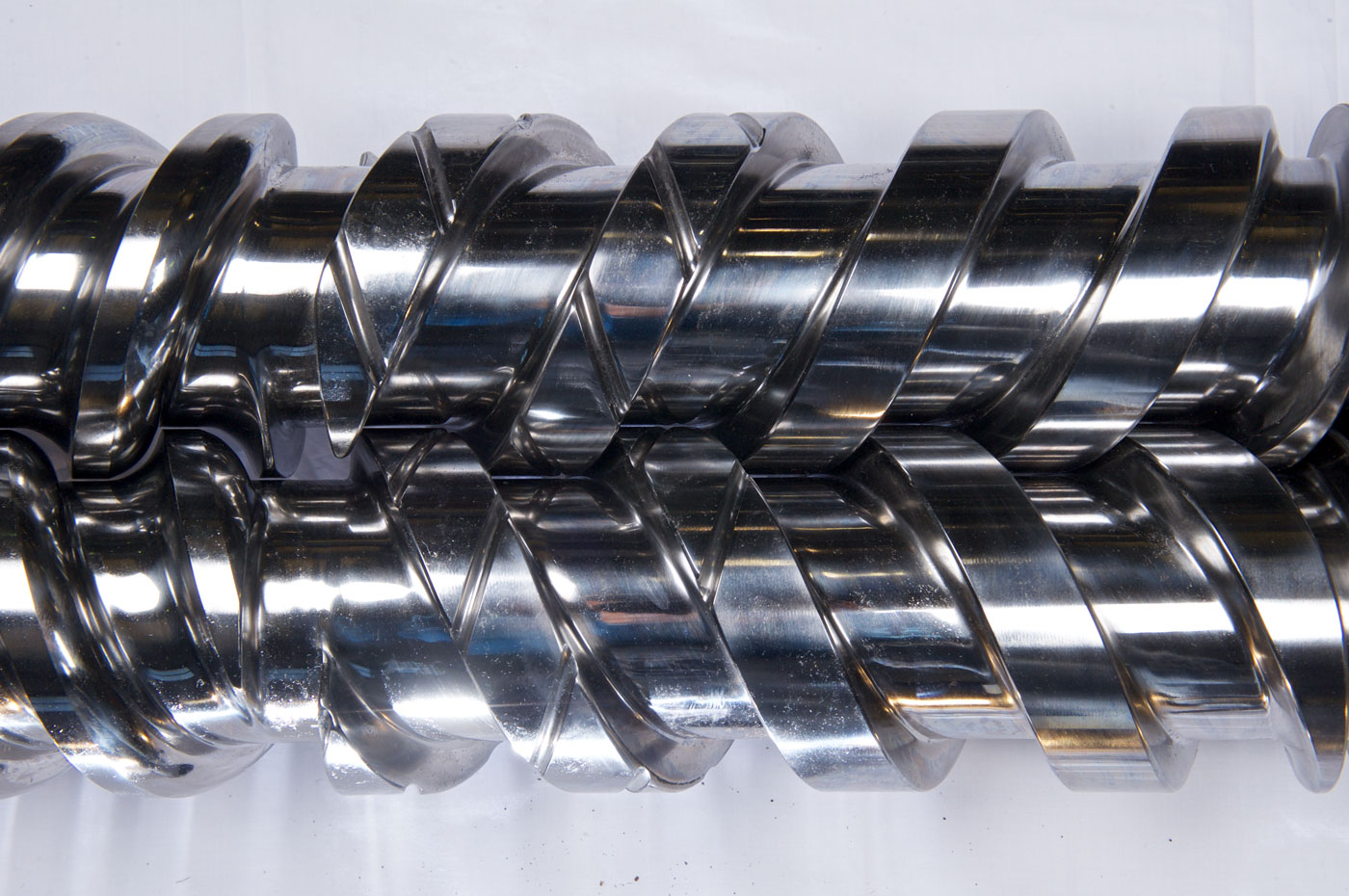

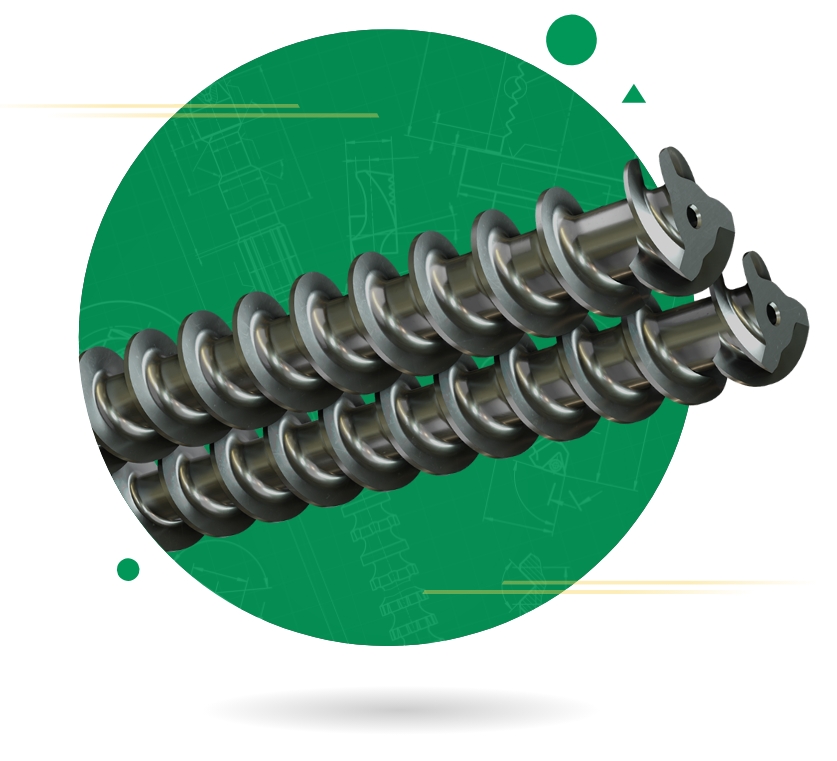

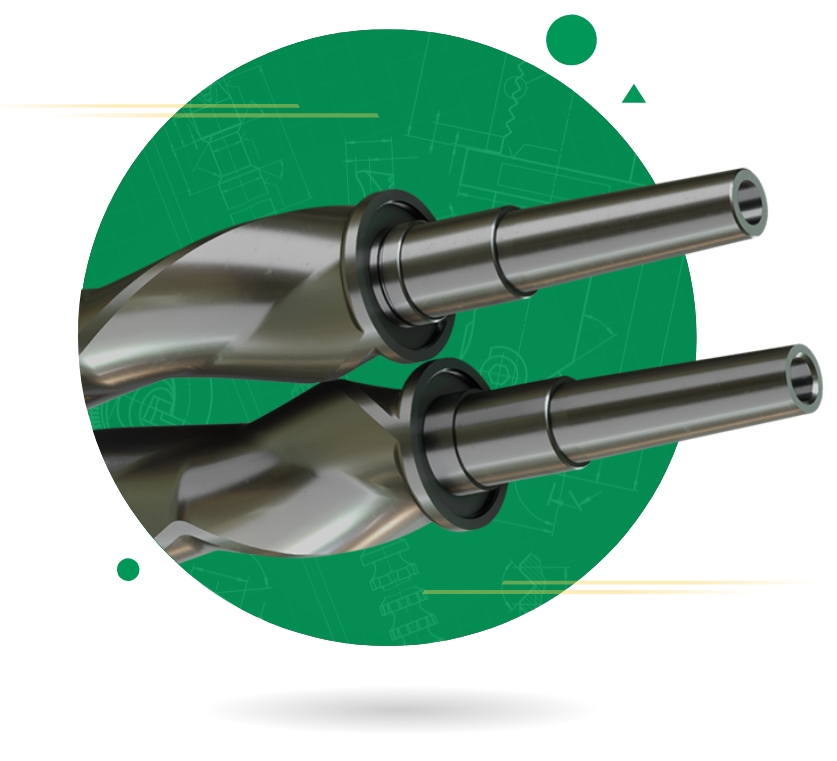

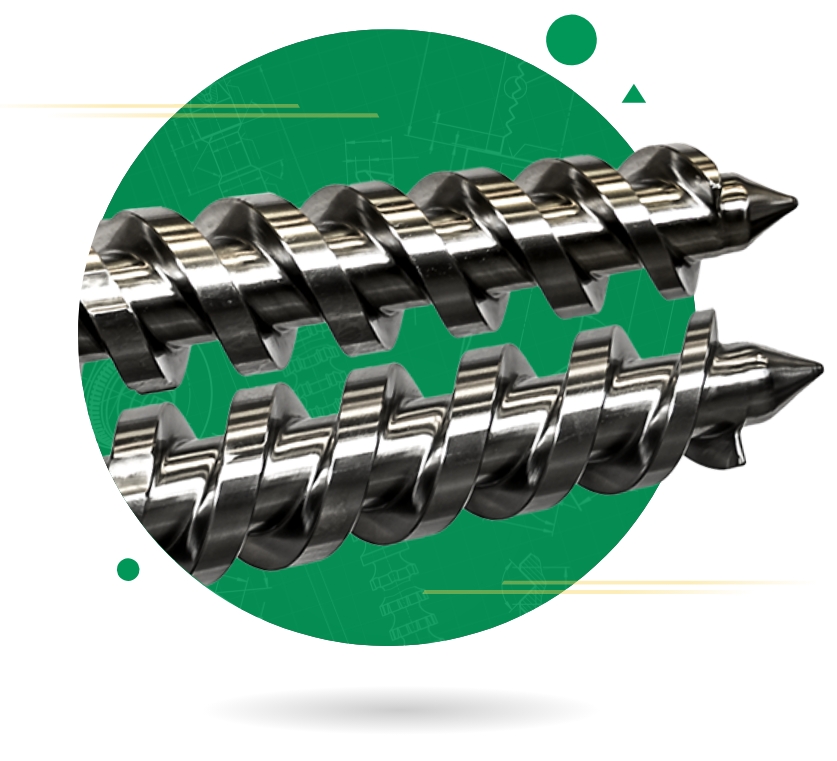

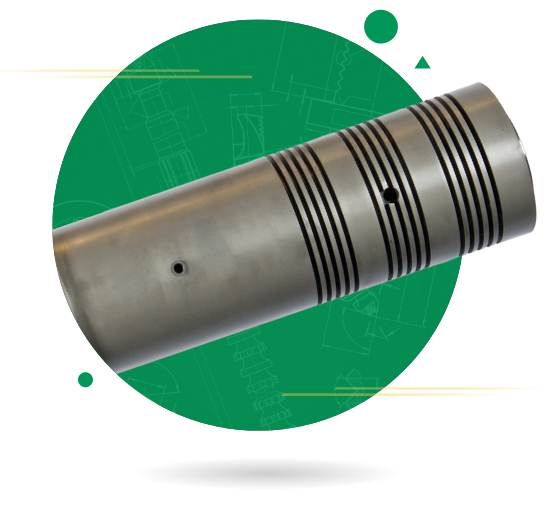

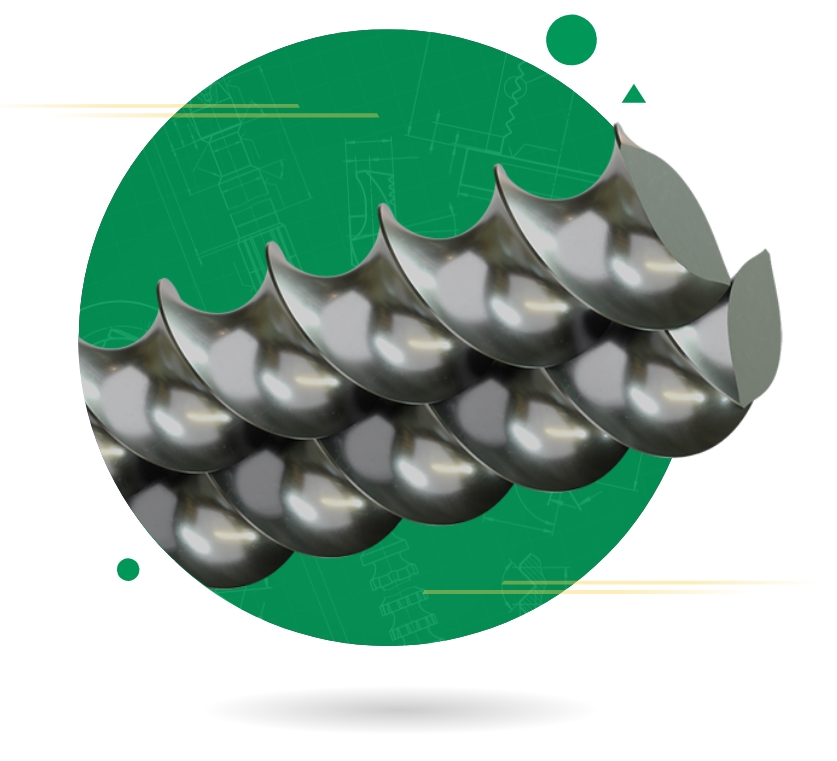

The counter-rotating twin-screw is distinguished by the presence of two parallel screws rotating in opposite directions synchronously, giving rise to its characteristic name.

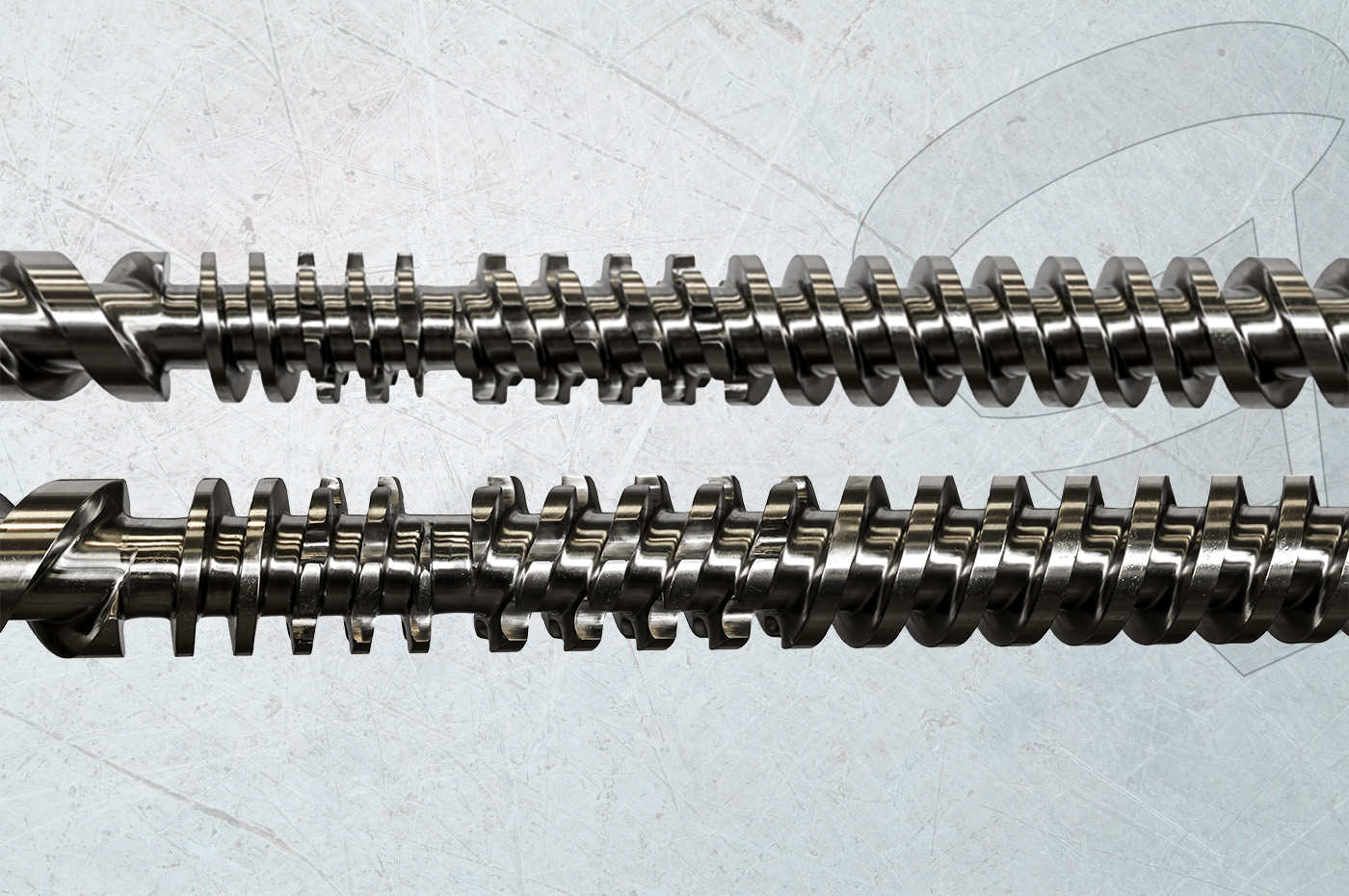

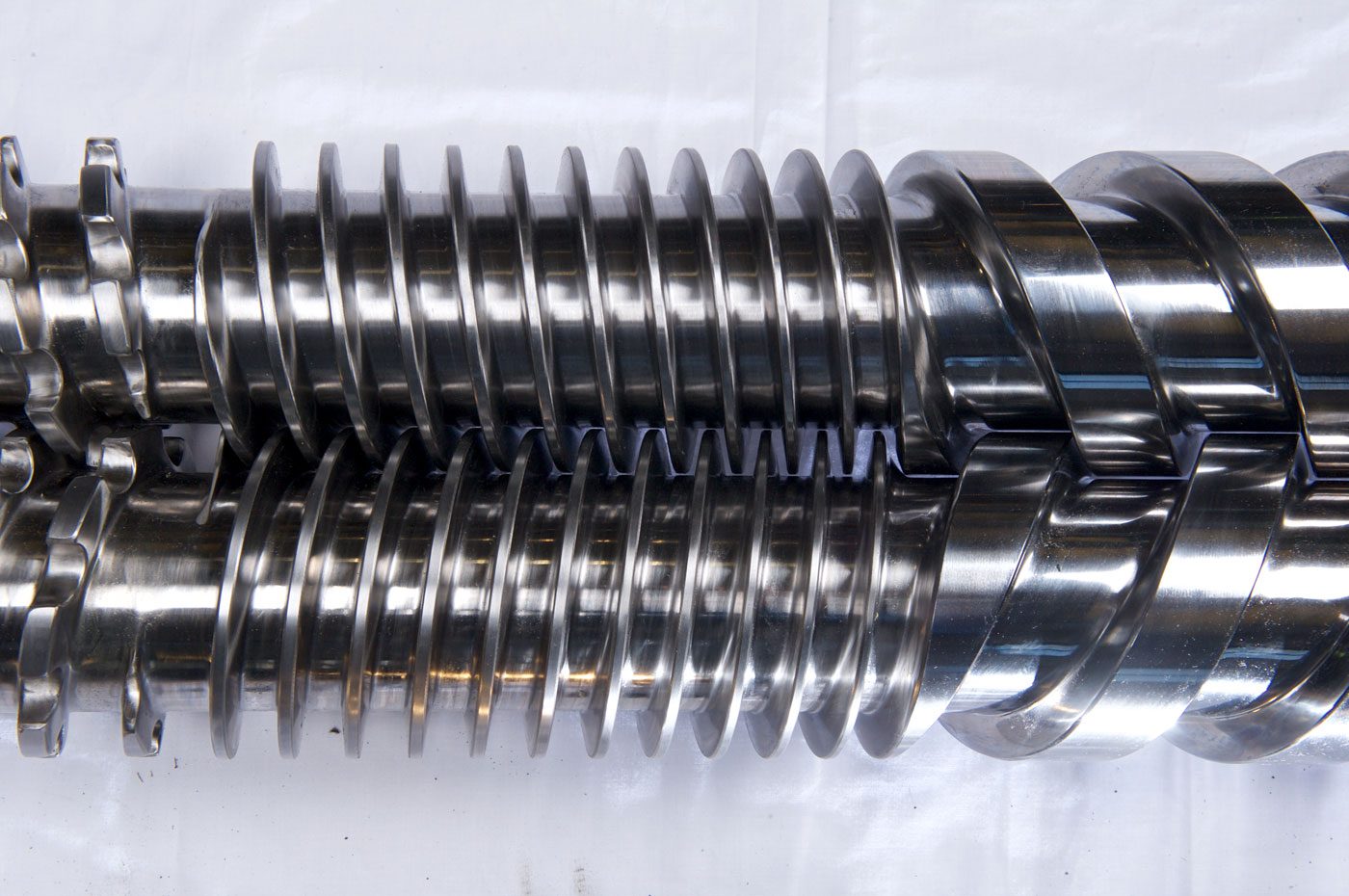

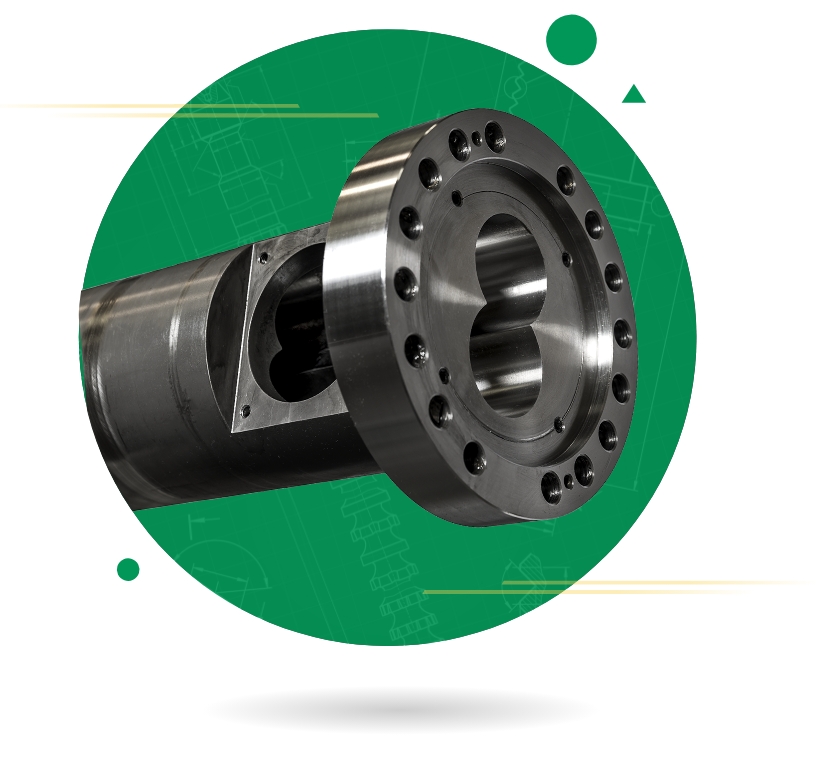

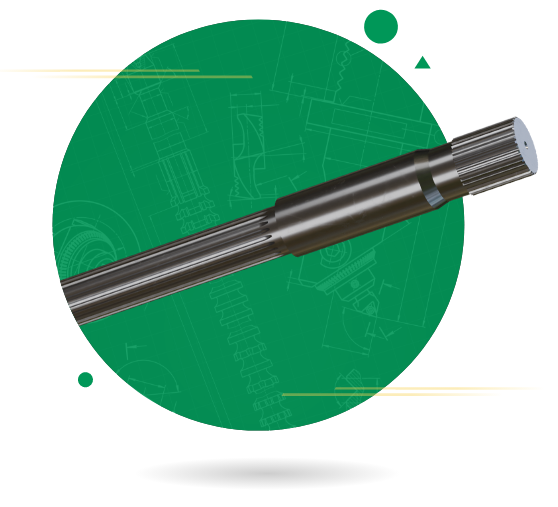

Structurally, the profile of the counter-rotating twin-screw is divided into several segments, each with a specific function in the plasticizing process. These include feeding, where the material enters the unit; compression, which reduces the volume of the material; plasticizing, which transforms the material into a malleable form; degassing, which eliminates trapped gases; and homogenization, which ensures a uniform consistency of the product.

The counter-rotating twin-screw offers significant advantages over the single-screw system. For example, it melts the material more effectively, thereby reducing energy consumption. Additionally, it is particularly suitable for processing complex materials, such as PVC, which require greater processing strength.

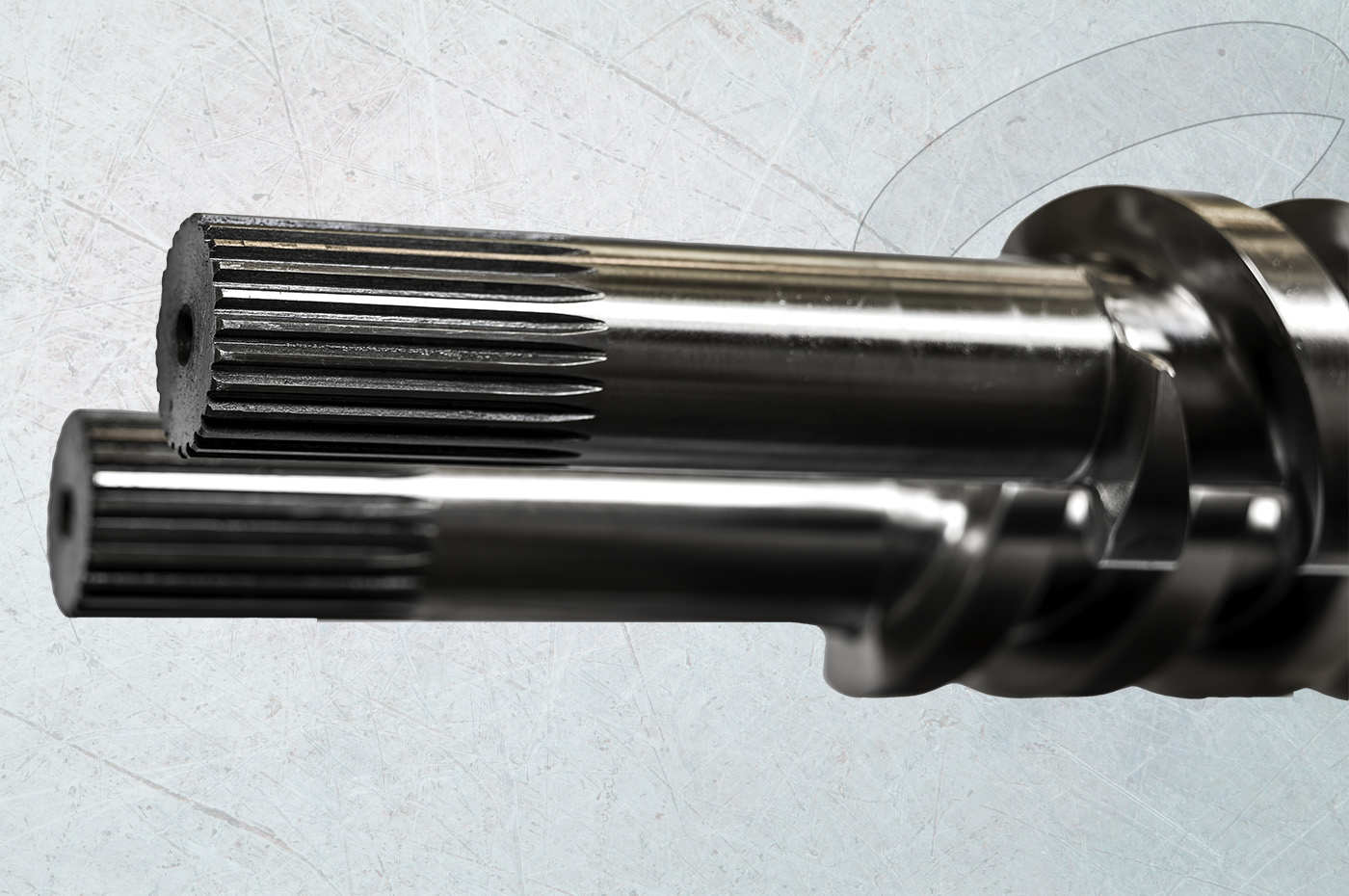

Regarding construction, the production of counter-rotating twin-screws requires a careful selection of materials, based on the quality of the material mix to be processed. Traditionally, nitriding steels are used, but depending on the specific needs, various types of welding overlays or H.V.O.F technologies can also be employed.

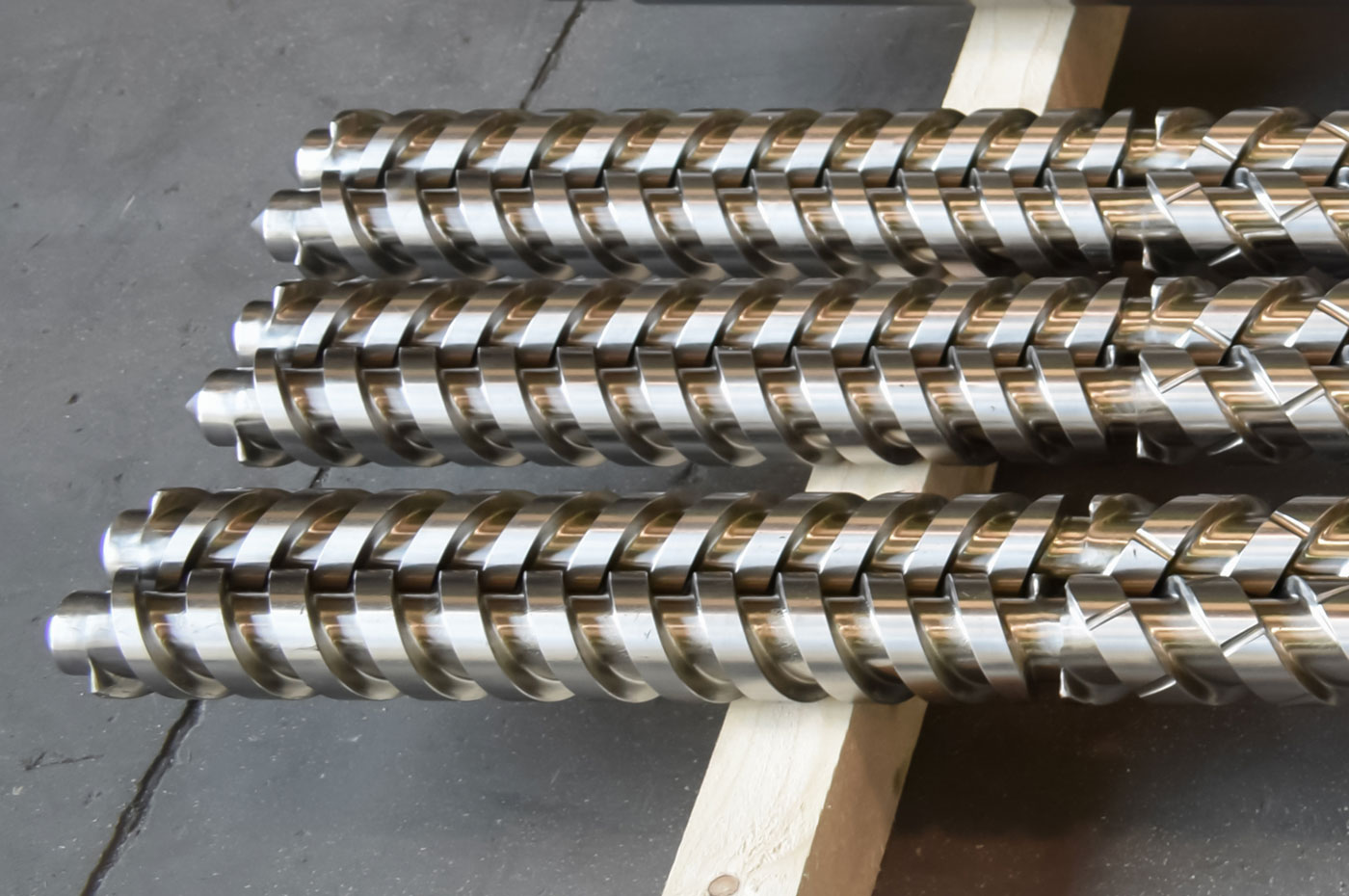

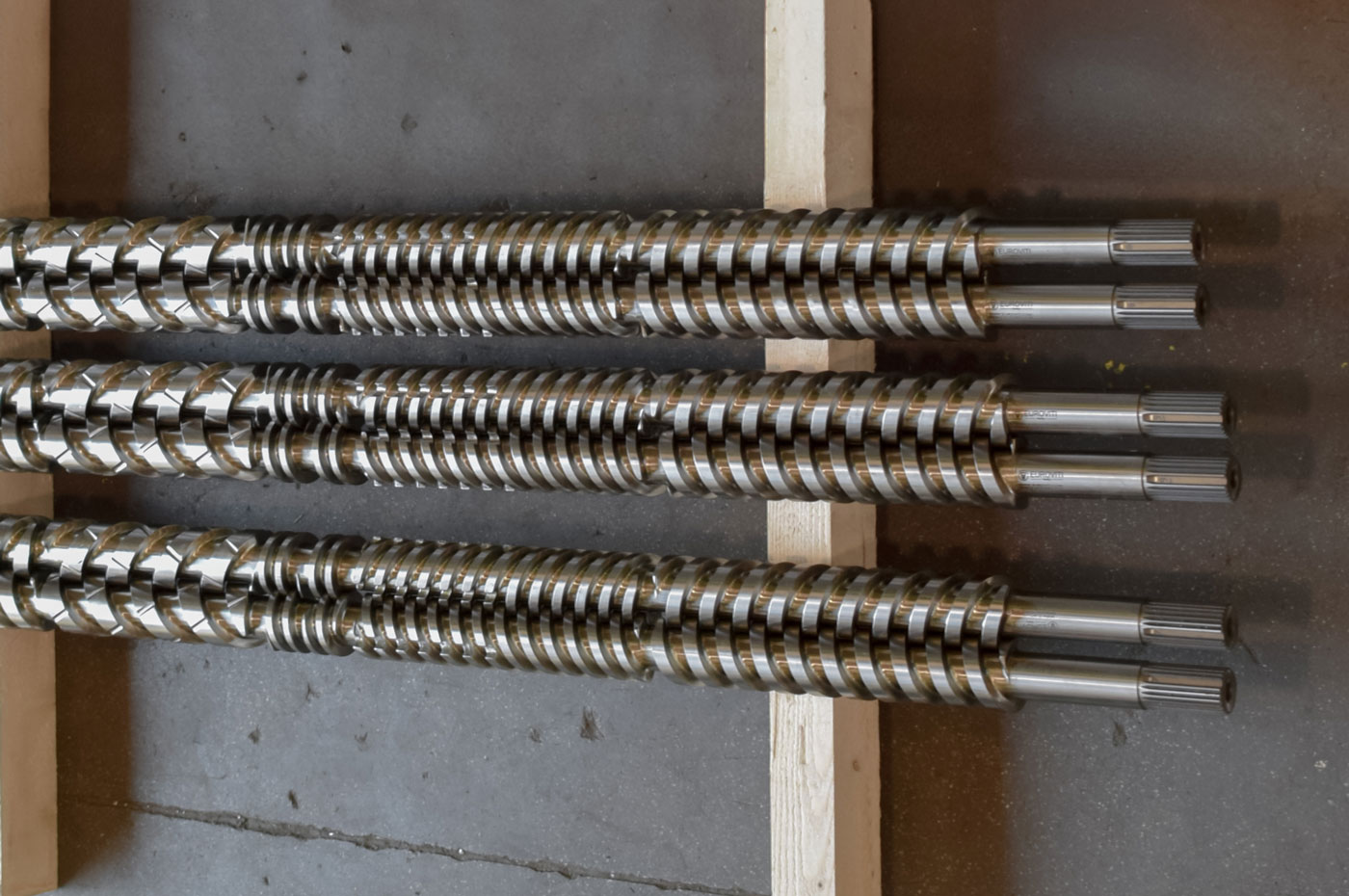

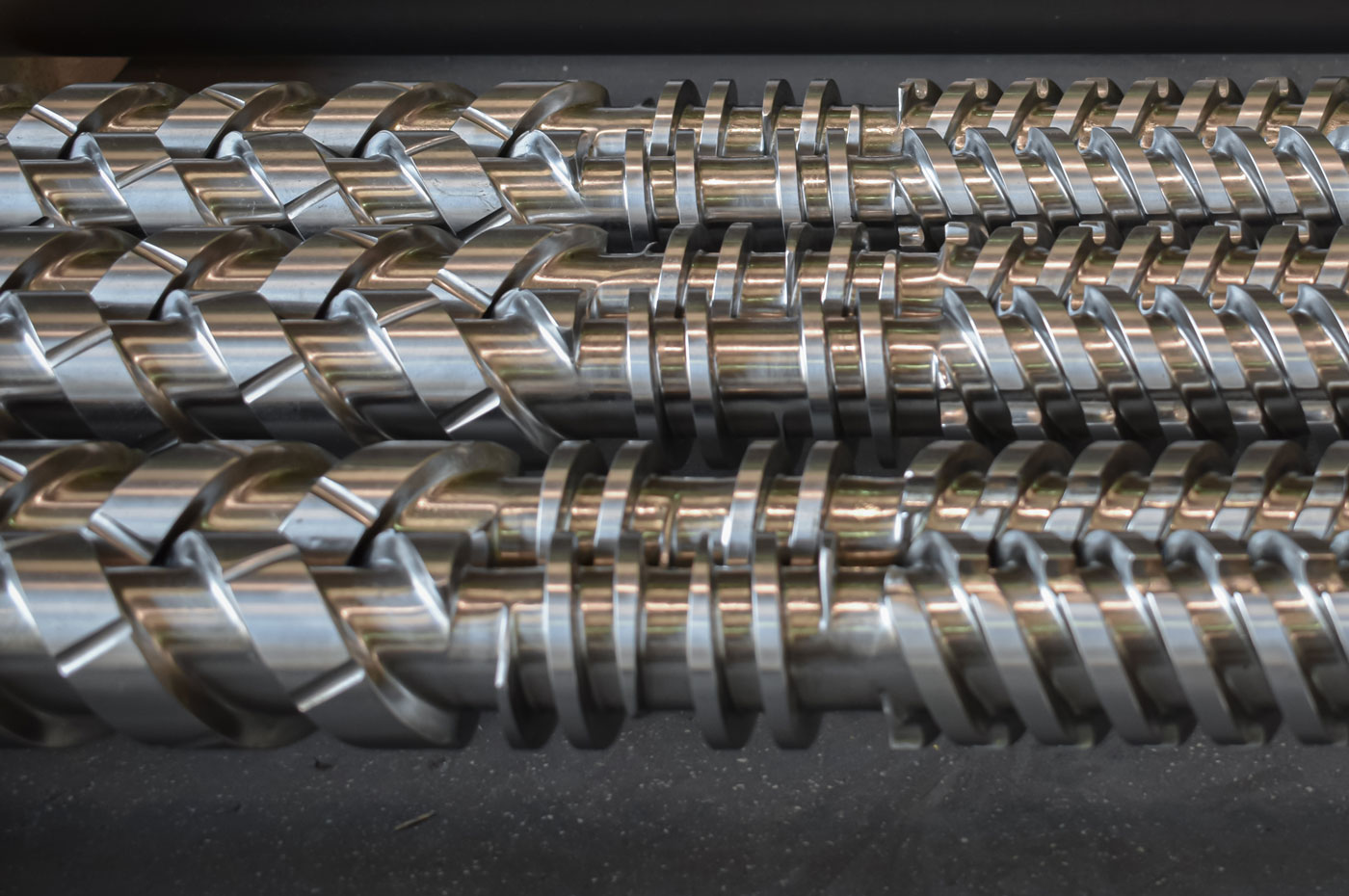

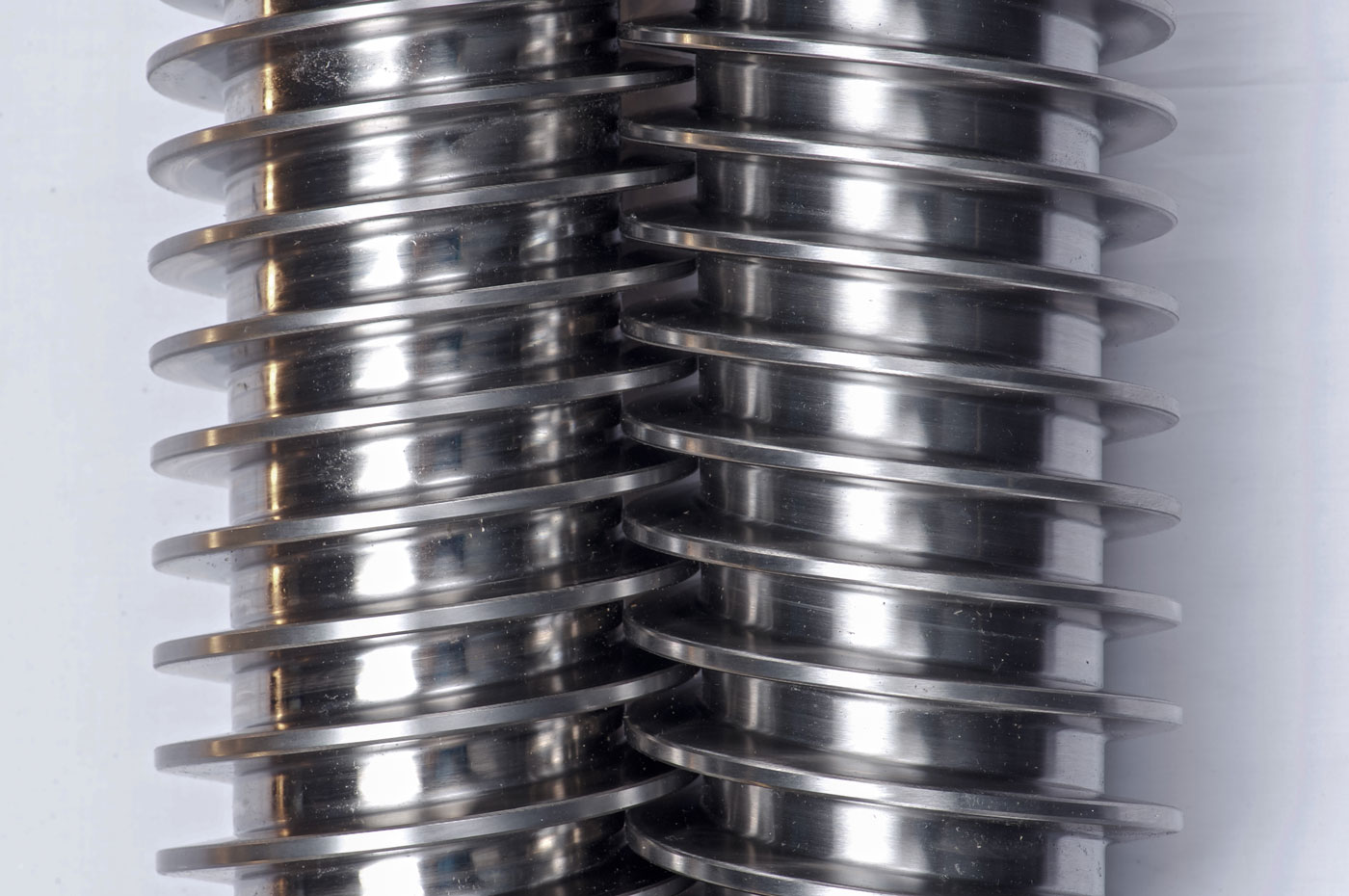

Gallery

Discover the technical information about

Screw

| EUV CODES | STEEL TYPE | TREATMENT | HARDNESS | |

|---|---|---|---|---|

| EUV31 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 700÷800HV |

| EUV41 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV |

| EUV50 | Stainless steels | Special Hardening & Tempering / Induction Hardening / Blank | Total or Partial Hardening or blank | 44÷52HRC |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV12 | Co | PTA | 1÷3mm | 46÷50HRC | ••• | ••• |

| EUV5 | Fe | TIG | 1÷3mm | 58÷62HRC | •••• | •• |

| EUV56 | Ni | PTA | 1÷3mm | 46÷58HRC | ••• | ••• |

| EUV60 | Ni | PTA | 1÷3mm | 57÷62HRC | •••• | •••• |

| EUV83 | Ni-Wc | PTA | 1÷3mm | 49÷56HRC | ••••• | •••• |

| EUV700 | Mo | THERMAL SPRAY | 200÷400 μm | 56÷60HRC | ••••• | •••• |

| EUV950 | Wc-Co-Cr | HVOF | 100÷300 μm | 1100÷1300HV | •••••+ | •••••+ |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS |

|---|---|---|---|---|

| EUVCr Flash | Cr | Plating | 5÷15 μm | 65÷70HRC |

| EUVCr Thick | Cr | Plating | 50÷150 μm | 65÷70HRC |

| EUVCrNOX | CrNox | PVD Iridescent Rainbow | 2÷6 μm | 2000÷2500HV |

| EUVPro | AlCrN | PVD Dark Grey | 2÷8 μm | 2800÷3000HV |

| EUVZrN | ZrN | PVD Light Yellow | 2÷4 μm | 2600÷3100HV |

| EUVTiN | TiN | PVD Yellow Gold | 2÷4 μm | 2000÷2500HV |

| EUVCrN | CrN | PVD Silver Grey | 2÷4 μm | 1800÷2200HV |

| EUVDlC | C | PACVD Rainbow Black | 2÷4 μm | 2000÷2500HV |

| EUV950 INCAPSULATED | Wc-Co-Cr | HVOF | 100÷300 μm | 1100÷1300HV |

| EUVFeO | FeO | Thermochemical treatment Black | 4÷5 μm | 850÷900HV |

Related Products

CONTACT US

Tell us what you need

Follow us