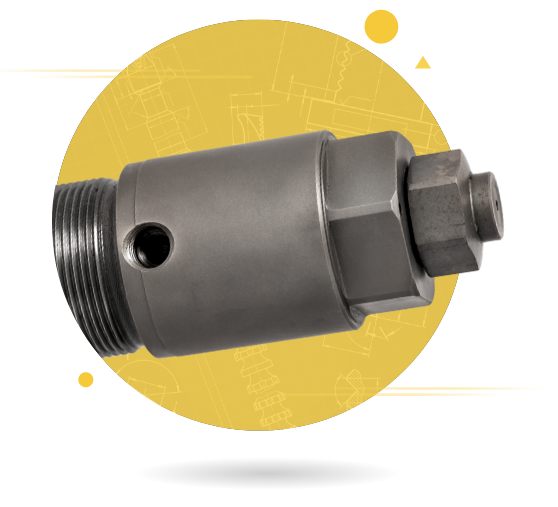

The Screw-tip is an essential component in controlling the injection process. Its shape and the materials used vary depending on the specific application within the plasticizing unit. The main task is to ensure a correct and consistent flow of the plastic material during the process and to stop the flow in the injection phase.

There are different types of screw-tip, each one with its specific applications:

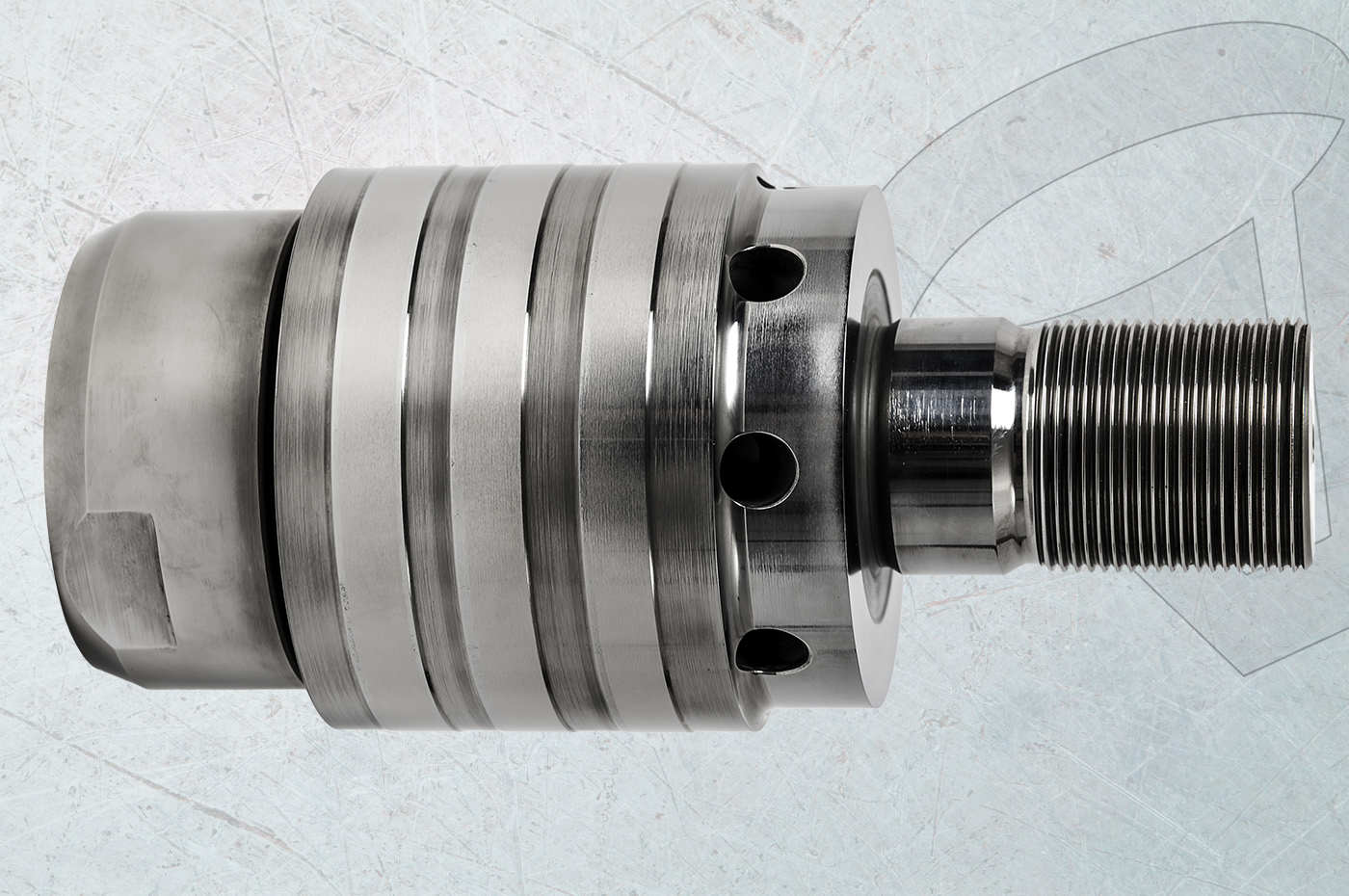

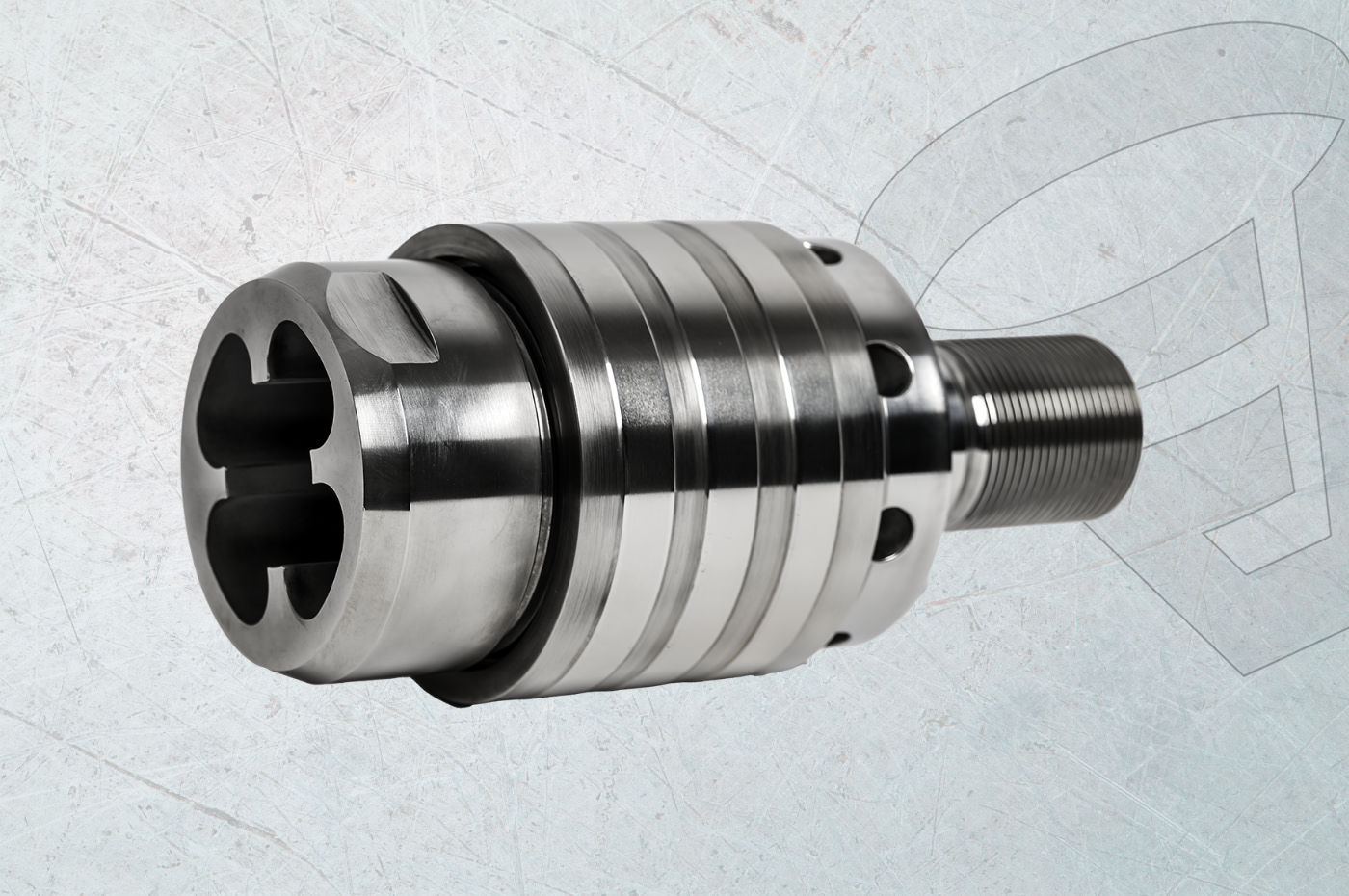

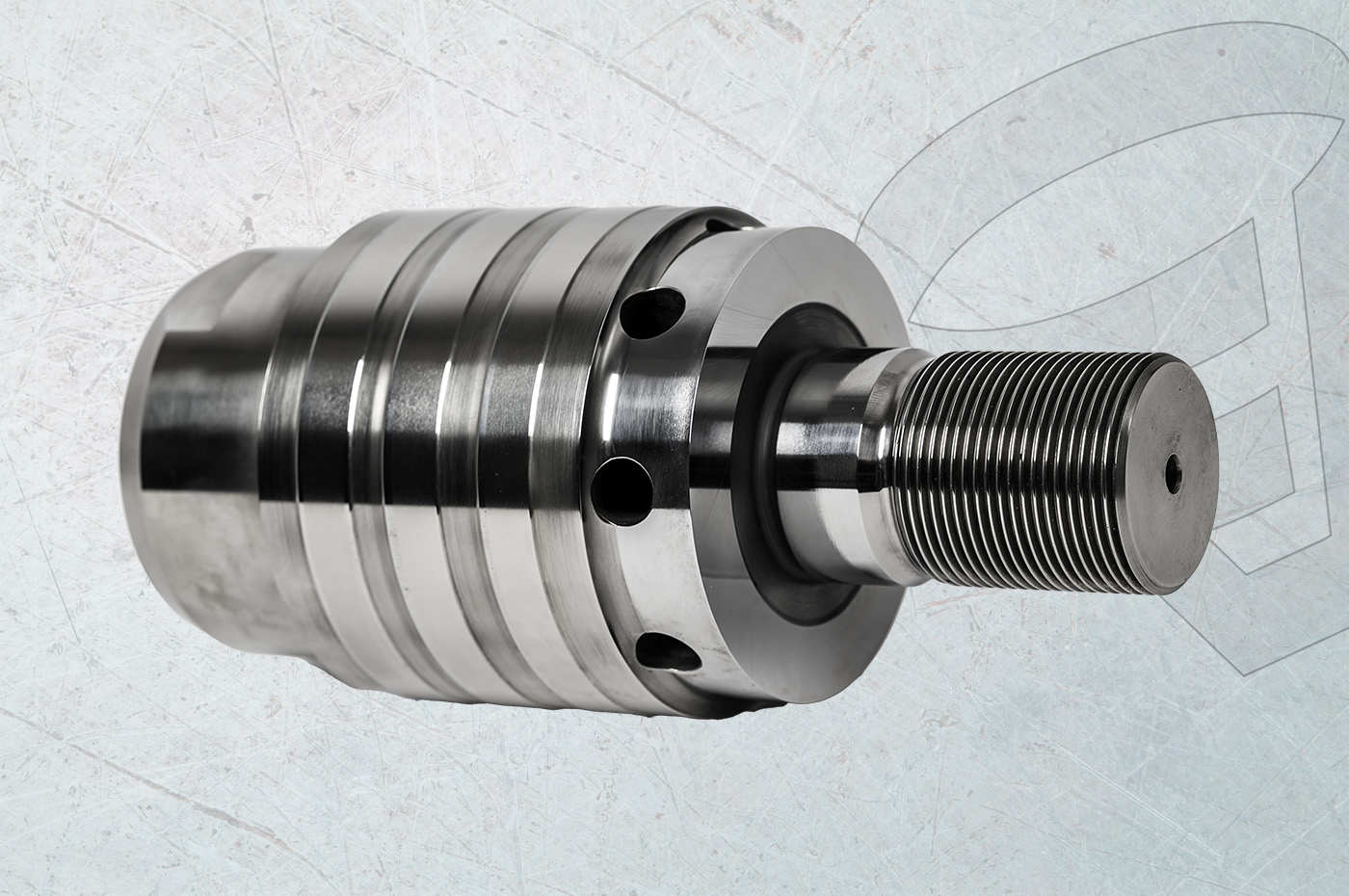

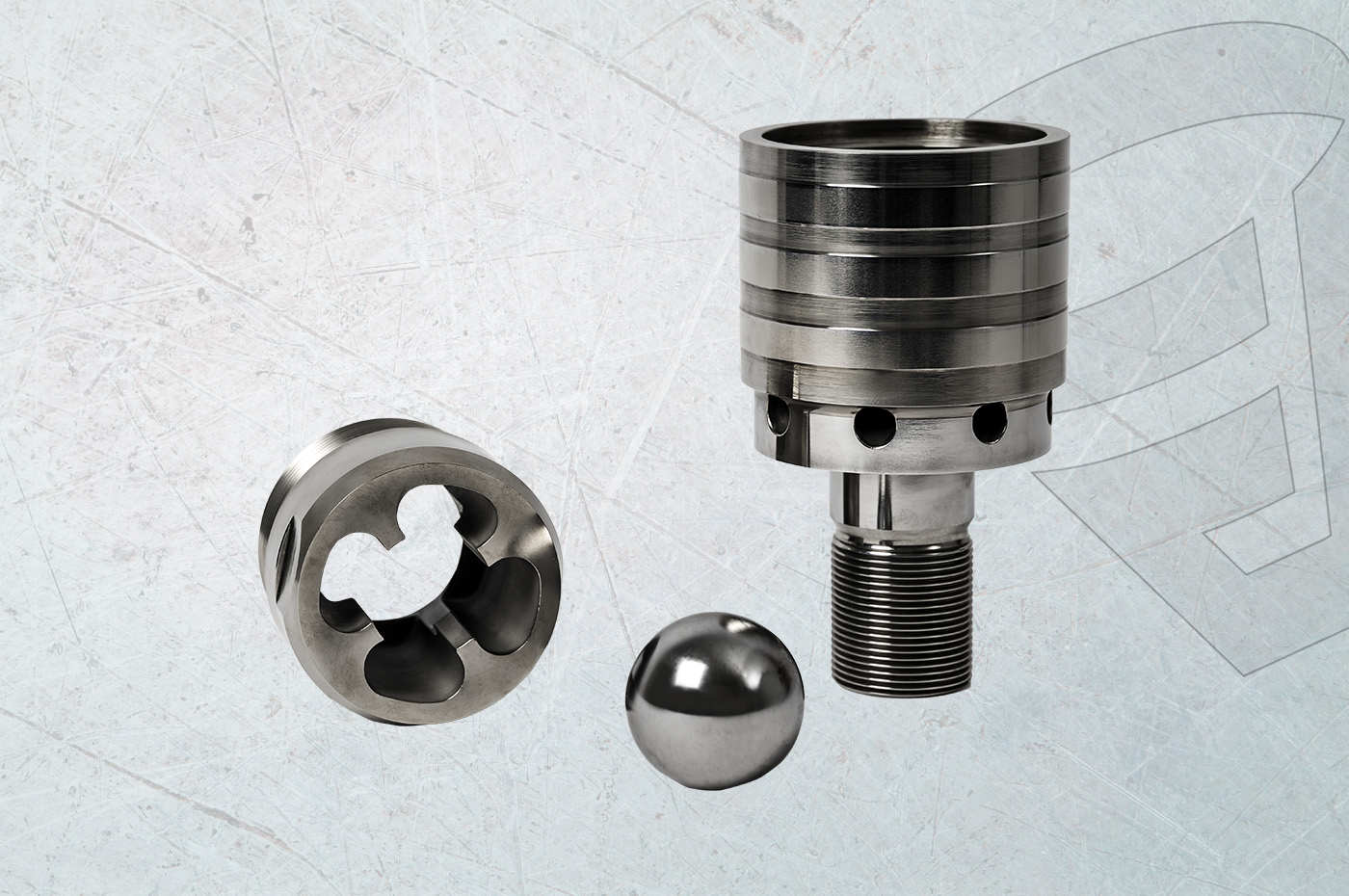

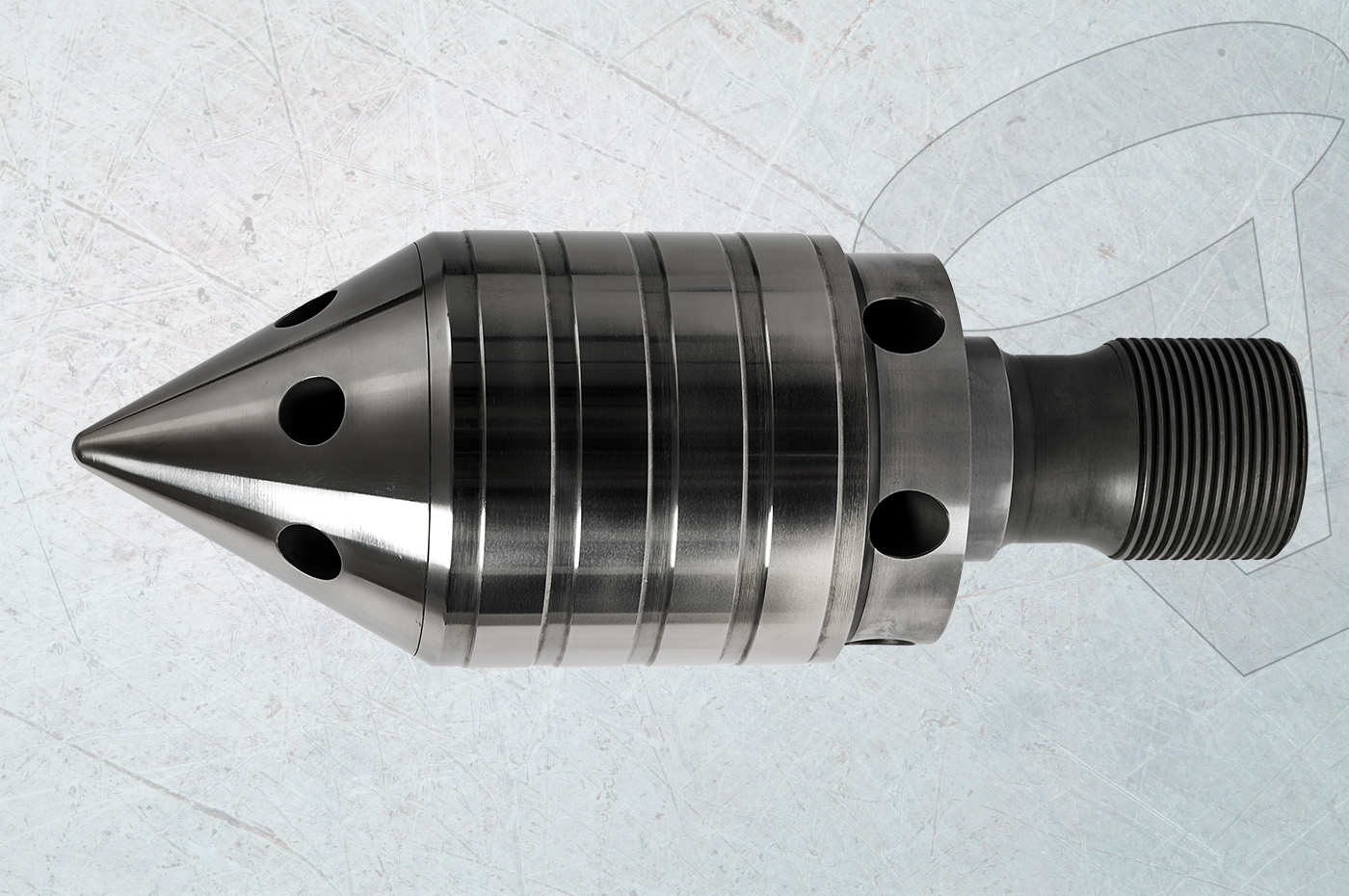

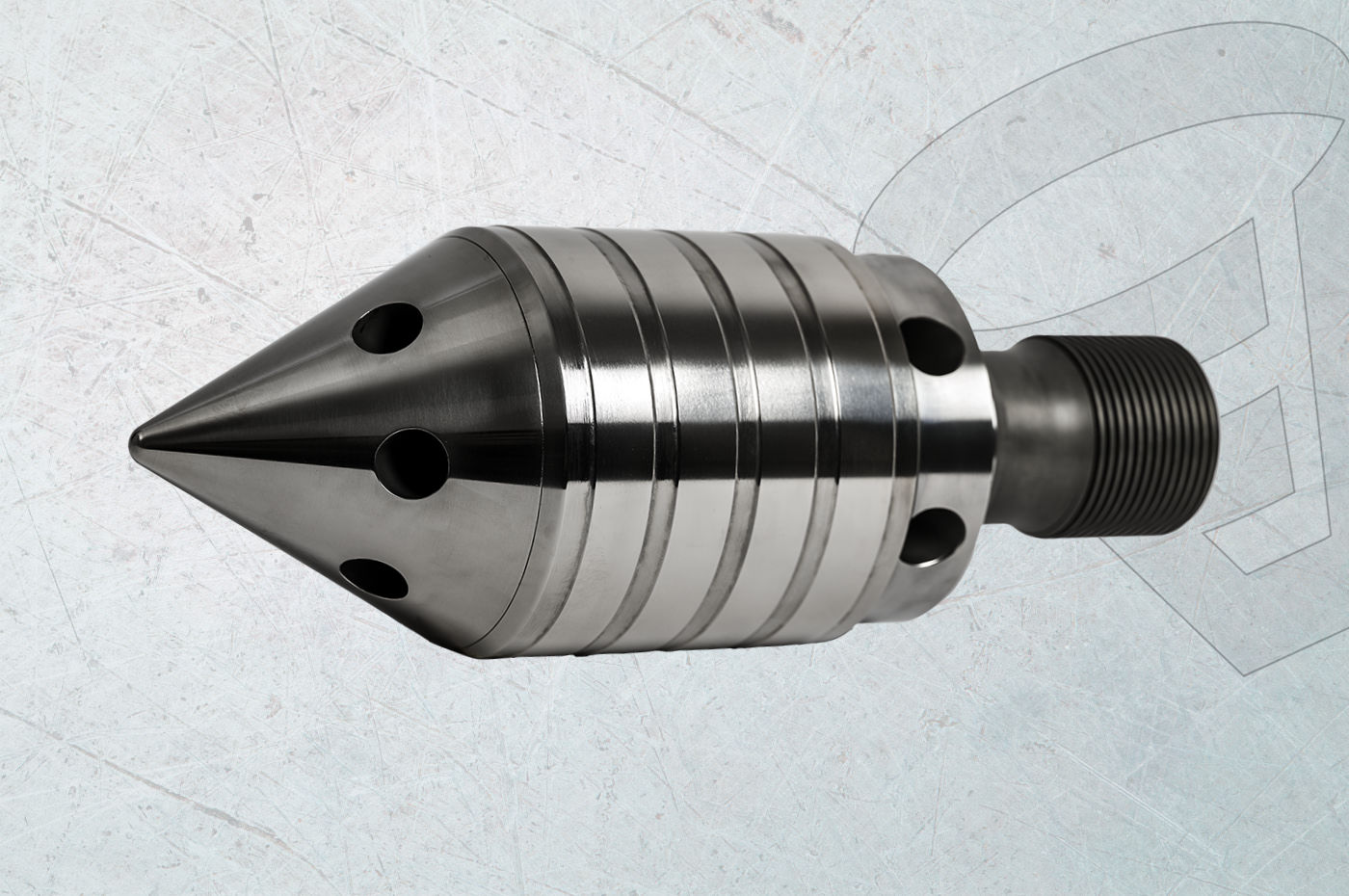

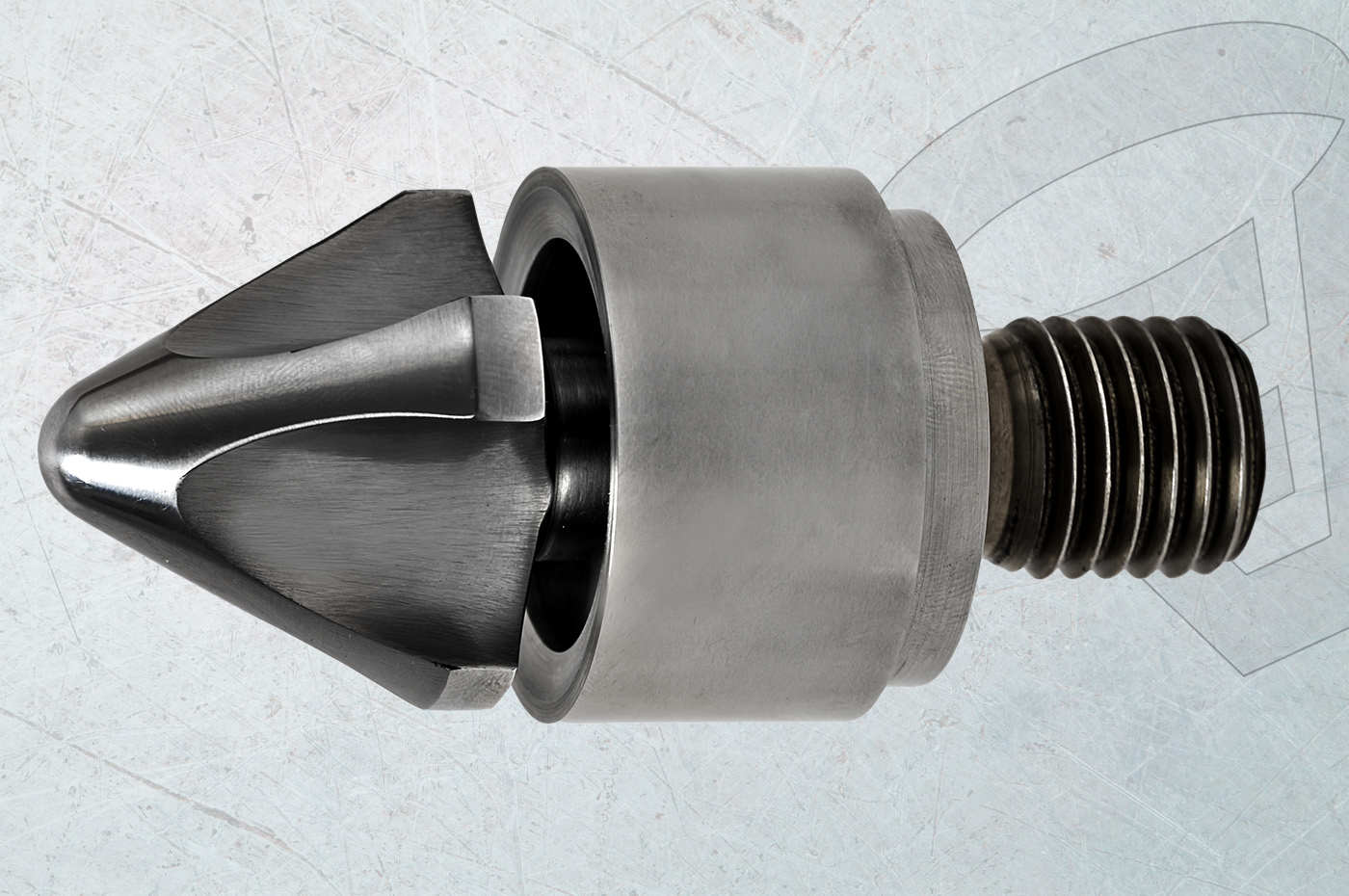

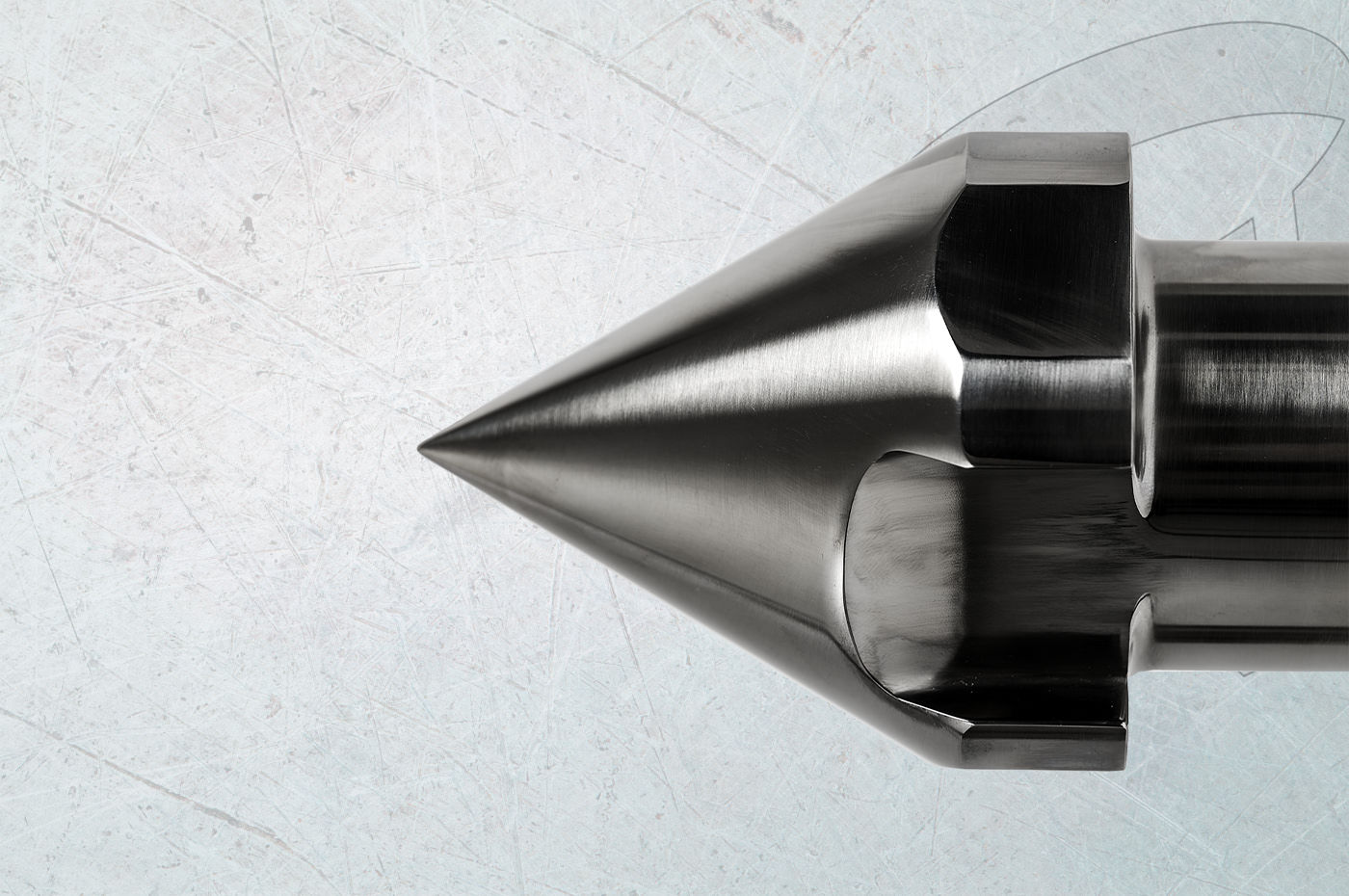

Standard: Comprising a tip, a valve, and a seat ring, they are versatile and suitable for almost all types of injection molding, making them a common choice in many applications.

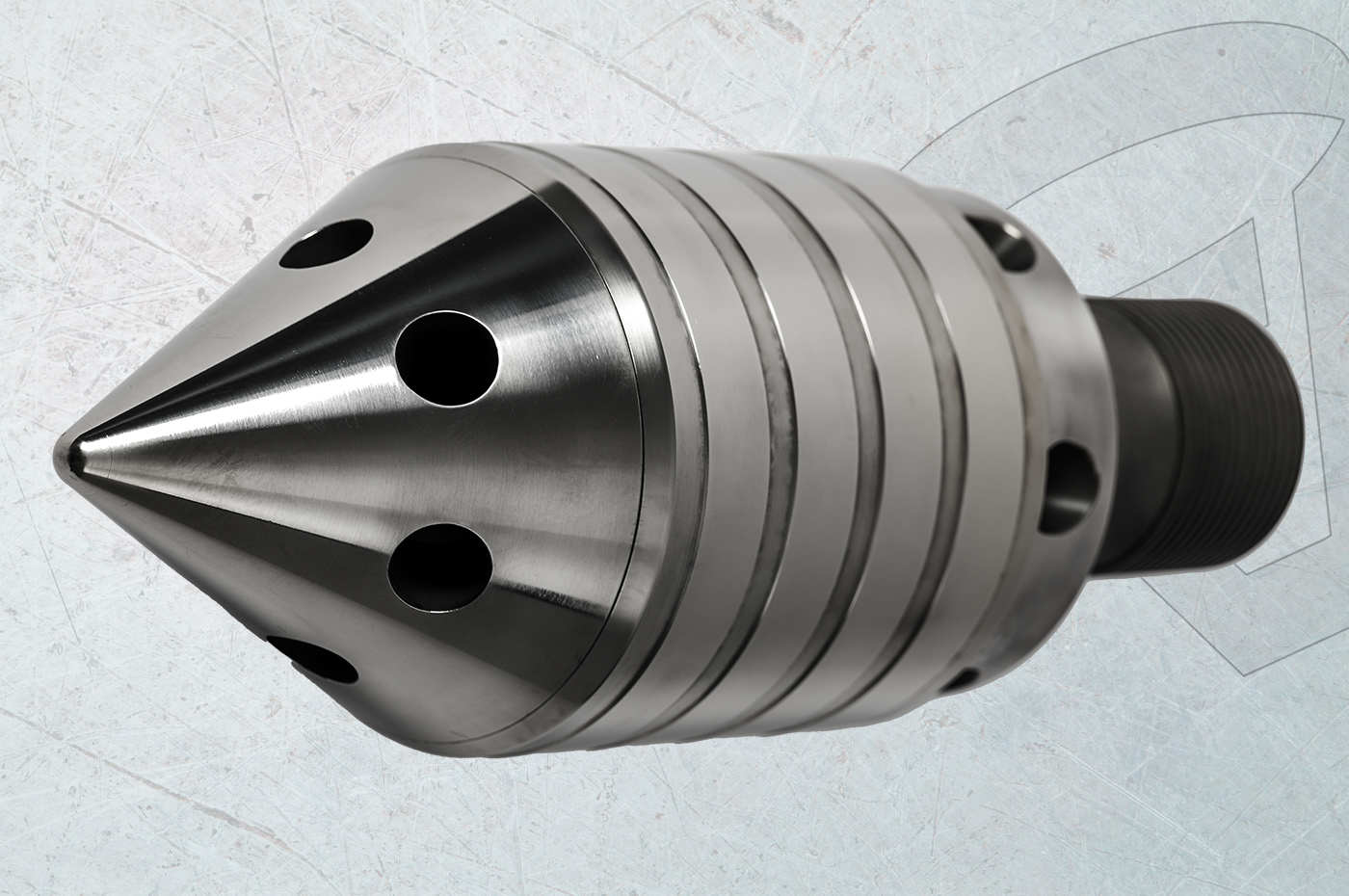

Ball: Ideal for large diameter screws, these nozzles handle large volumes of material, ensuring a steady and controlled flow.

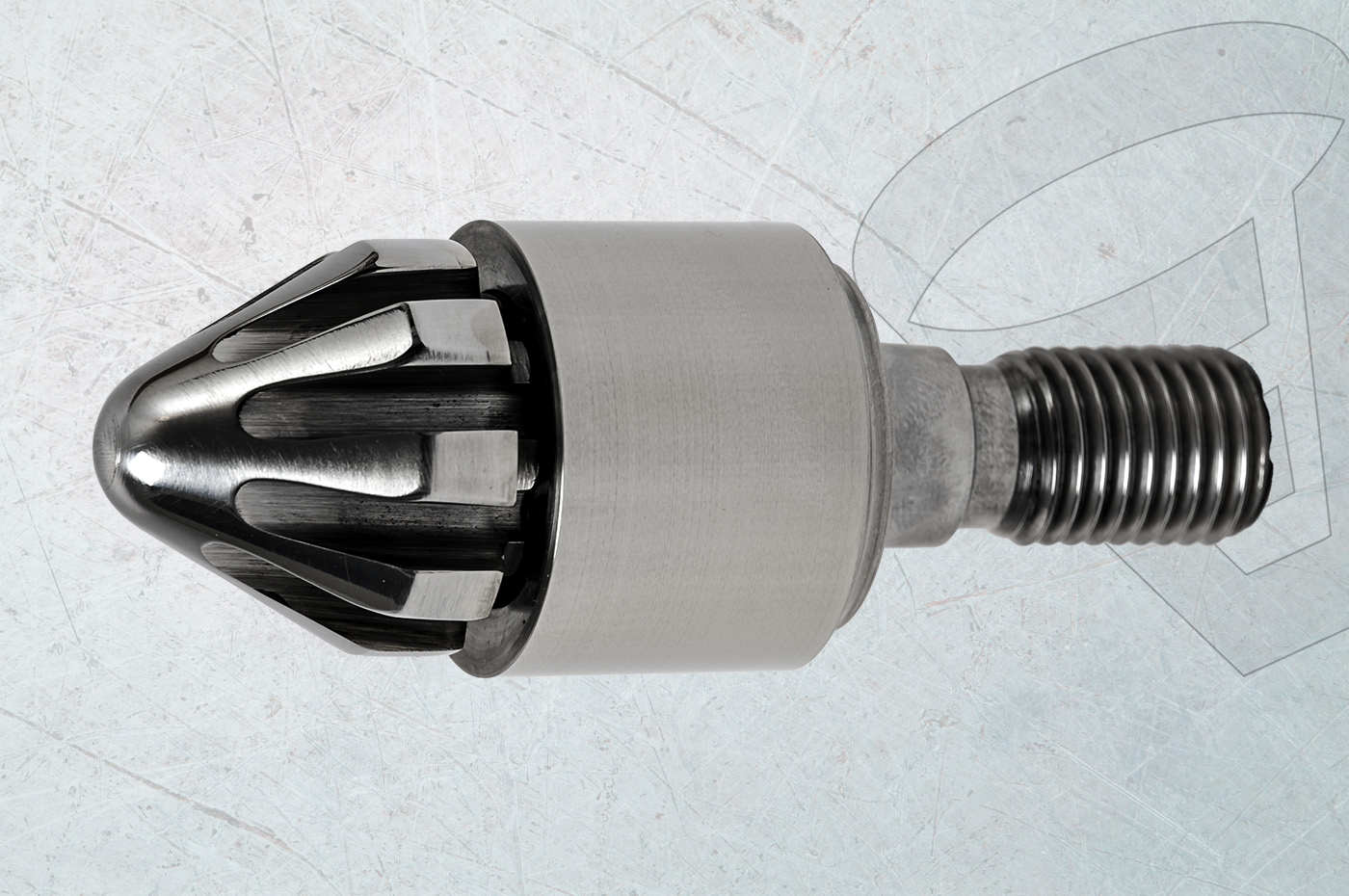

Fast Closure: A variant of the standard version, they are designed to offer greater control over the material passage, improving efficiency in the flow shut-off and in the control of the injection molding process.

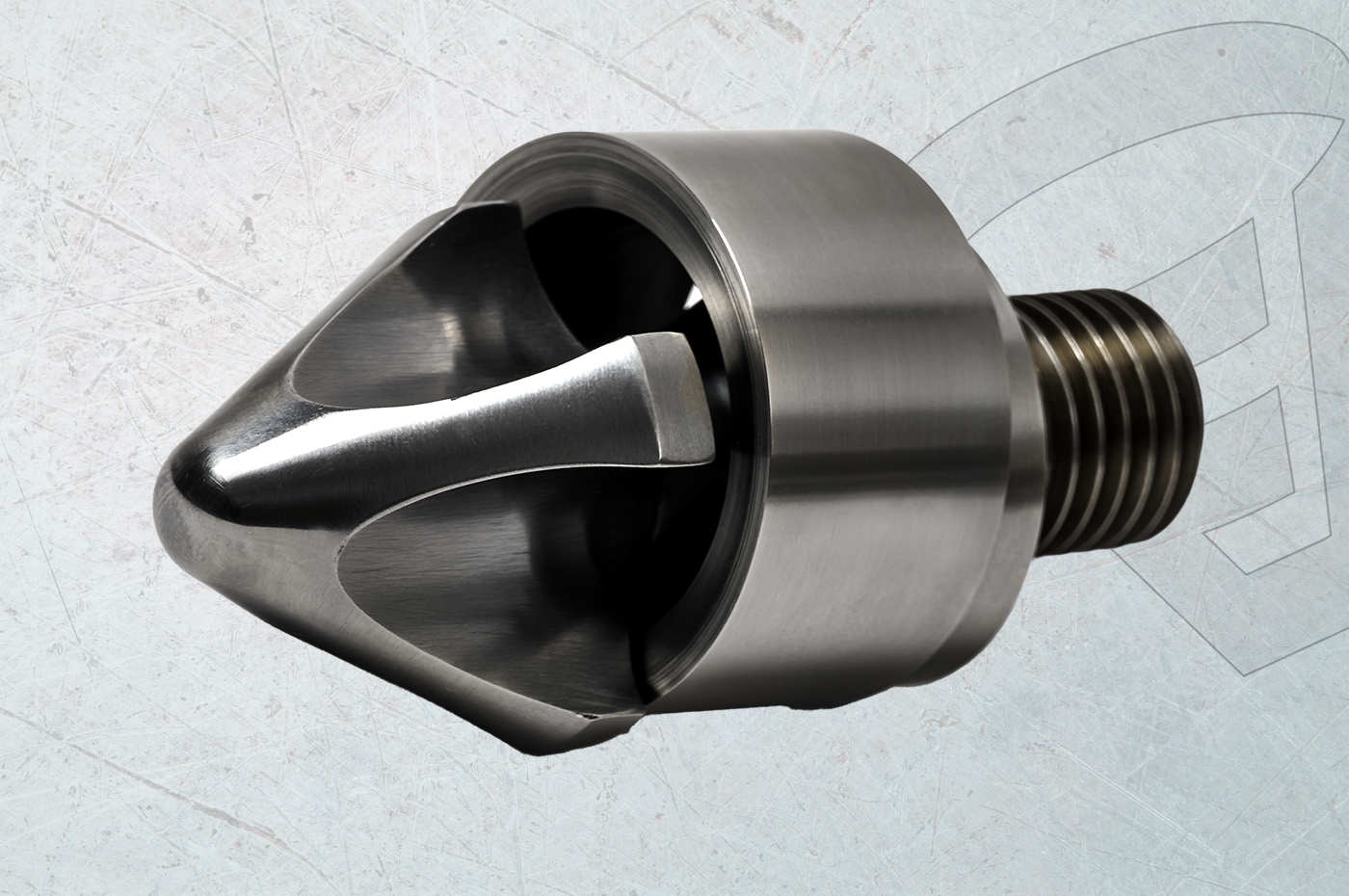

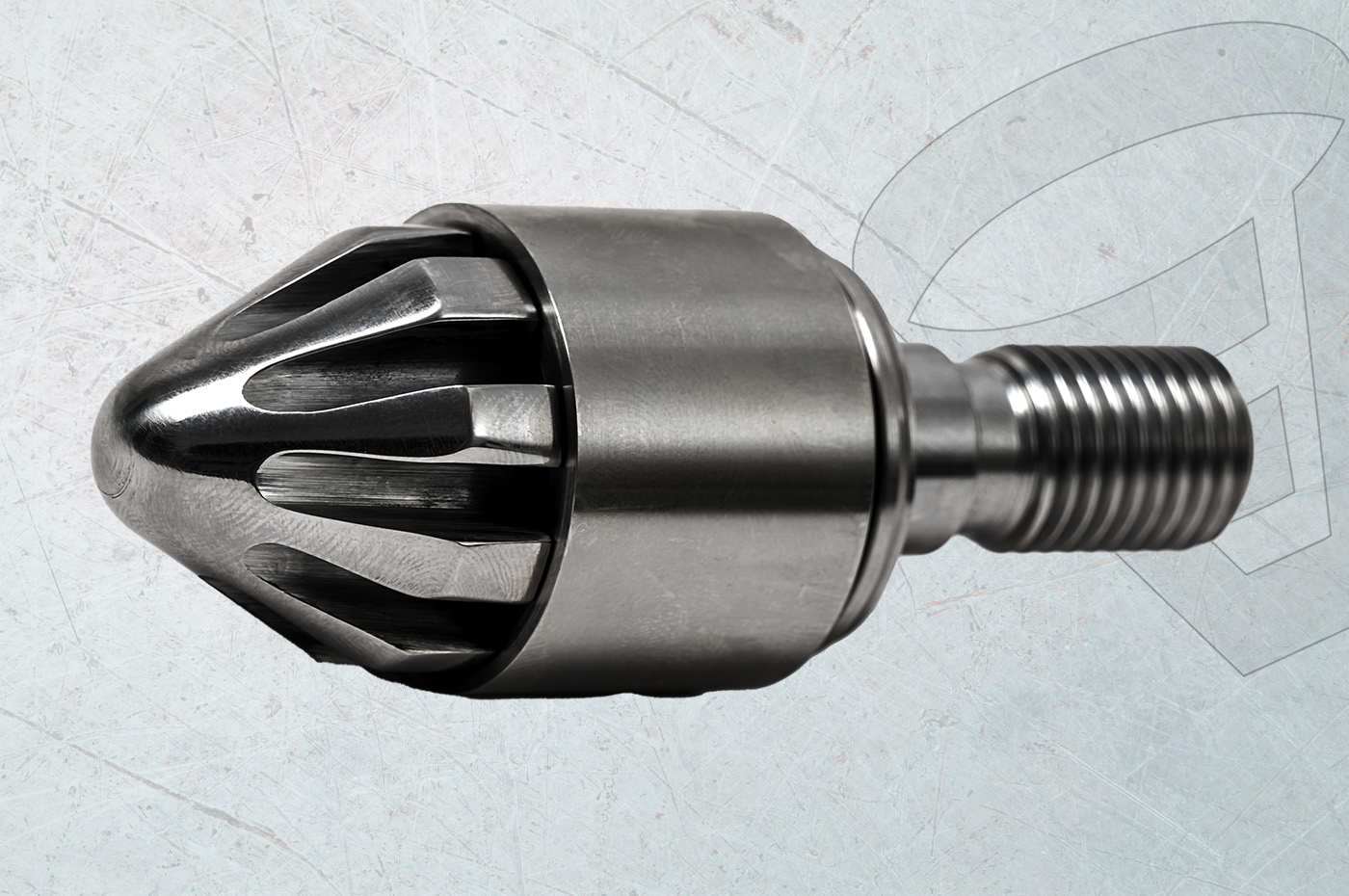

Castle-ring: The valve movement is limited by fins that allow only horizontal movement, preventing unwanted movements and maintaining a uniform material flow.

Mixing: Designed to improve the mixing and dispersion of colorants, these nozzles prevent pressure loss and increase plasticization, resulting in a superior quality final product.

The choice of the best screw-tip will be determined by the specific needs of the injection molding process and the characteristics of the material to be worked with.

Gallery

Discover the technical information about

Screw-tip

| EUV CODES | TECHNICAL SOLUTION | TREATMENT | TYPE | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV38 | Tip made in quenched and tempered steel with armoured wings area with BoroTec 10009 | |||||

| EUV79 | Rings Made in Cold work tool steel | Hardening & Tempering | Total Hardening | 58÷62HRC | ••• | •• |

| EUV CODES | TECHNICAL SOLUTION | TREATMENT | TYPE | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

| EUV300 | Entirely Made in Cold work tool steel | Hardening & Tempering | Total Hardening | 53÷55HRC | •• | •• |

| EUV90 | Entirely Made in Powder metallurgy tool steels | Special Hardening & Tempering | Total Hardening | 57÷63HRC | •••• | ••••• |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS |

|---|---|---|---|---|

| EUVCr Flash | Cr | Plating | 5÷15 μm | 65÷70HRC |

| EUVCr Thick | Cr | Plating | 50÷150 μm | 65÷70HRC |

| EUVCrNOX | CrNox | PVD Iridescent Rainbow | 2÷6 μm | 2000÷2500HV |

| EUVPro | AlCrN | PVD Dark Grey | 2÷8 μm | 2800÷3000HV |

| EUVZrN | ZrN | PVD Light Yellow | 2÷4 μm | 2600÷3100HV |

| EUVTiN | TiN | PVD Yellow Gold | 2÷4 μm | 2000÷2500HV |

| EUVCrN | CrN | PVD Silver Grey | 2÷4 μm | 1800÷2200HV |

| EUVDlC | C | PACVD Rainbow Black | 2÷4 μm | 2000÷2500HV |

Related Products

CONTACT US

Tell us what you need

Follow us