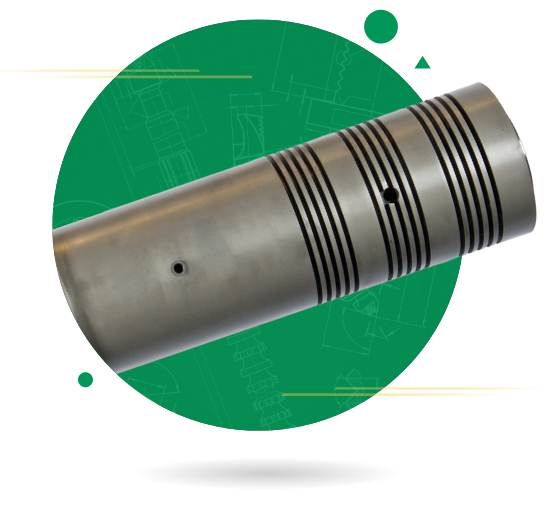

The extrusion barrel plays a simple yet fundamental role in the processing of plastic materials, whether they are virgin, regrind, recycled, or filled. There are two main types of barrels, each with specific characteristics and uses:

There are two main types of barrels, each with specific characteristics and uses:

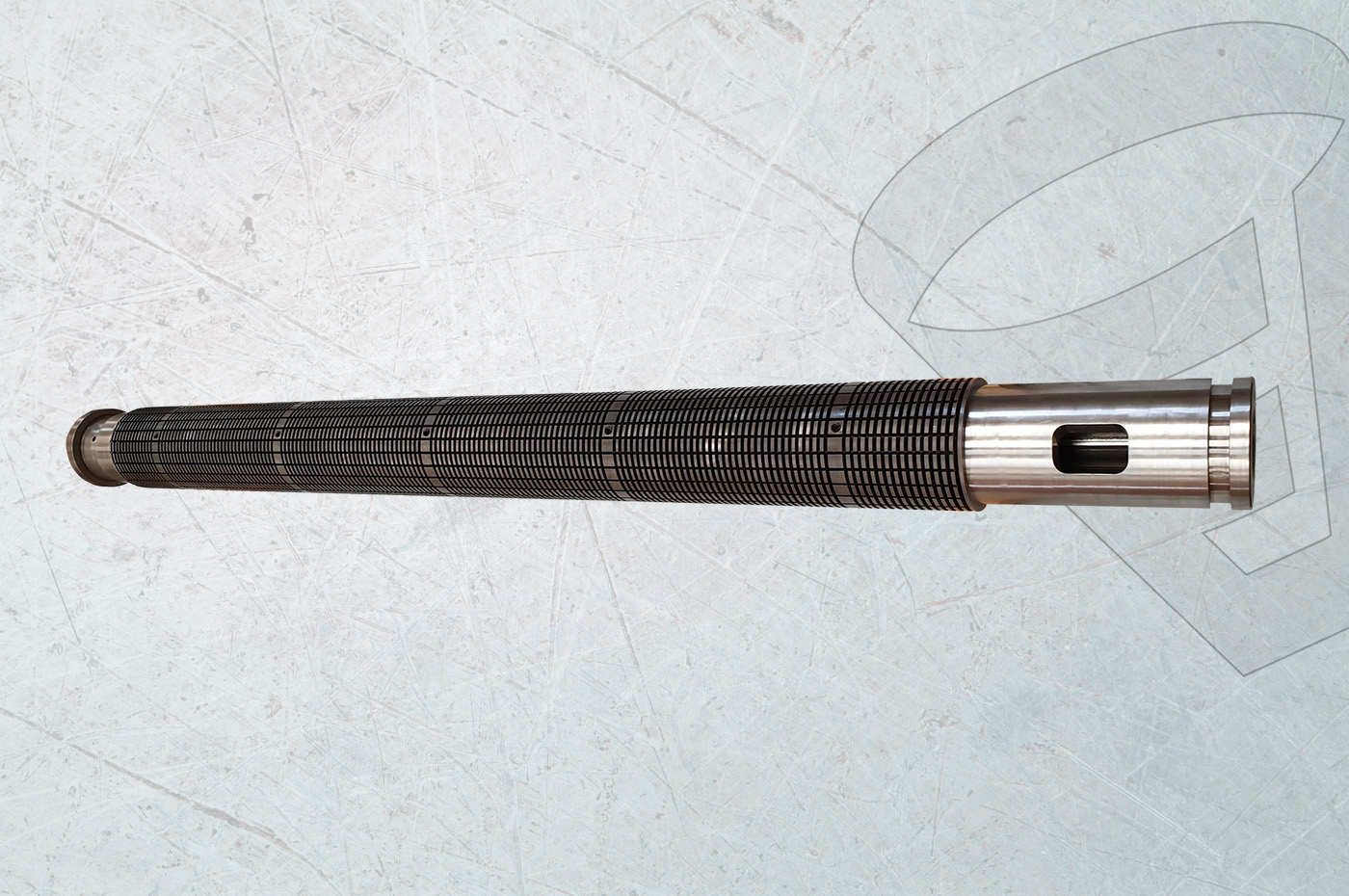

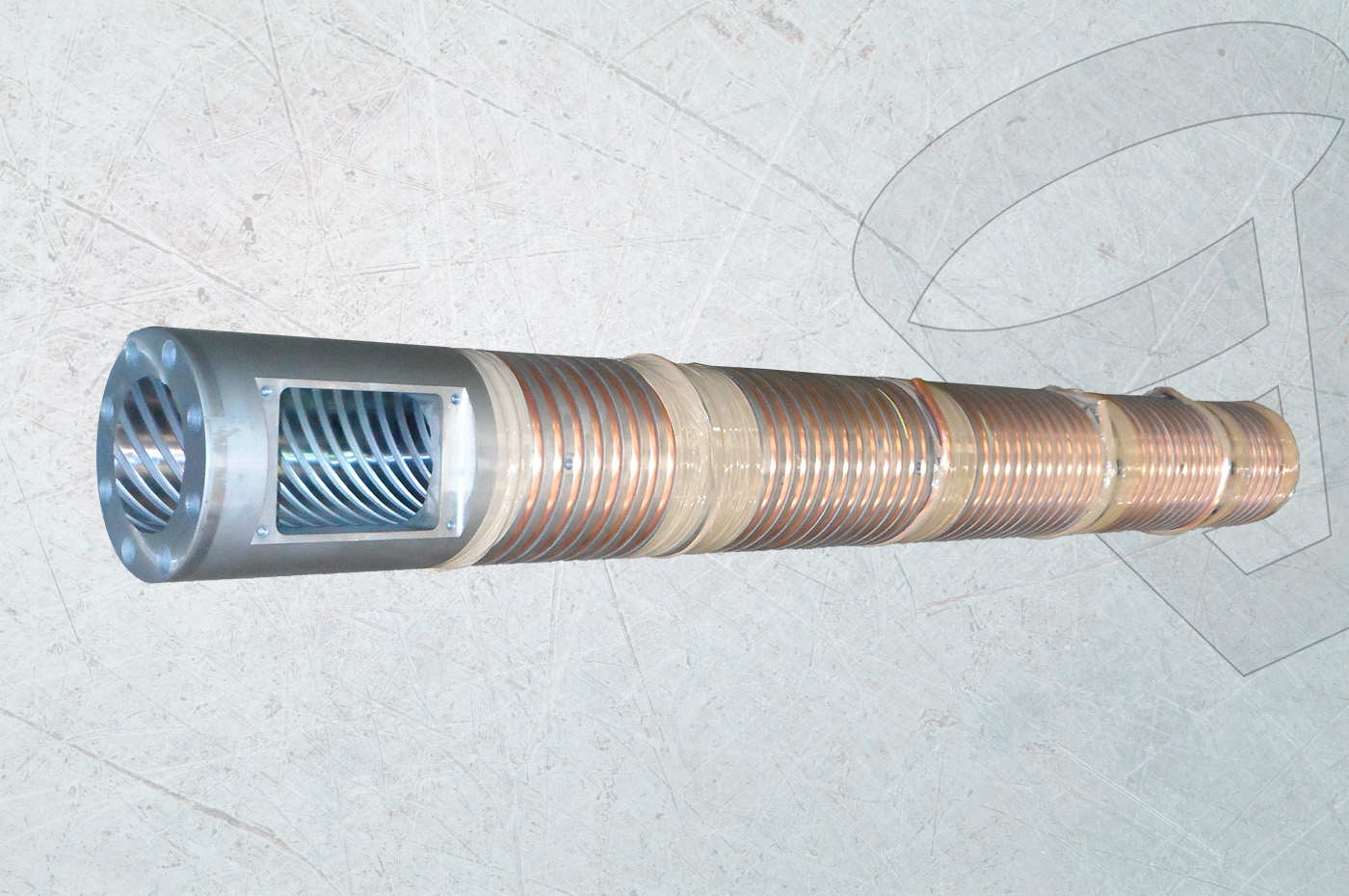

• Nitrided Barrels: These barrels undergo a specific heat treatment, nitriding, which can be carried out through gaseous or ionic processes. They are particularly suitable for operations where abrasive or corrosive wear is not present, making them ideal for applications with lesser or no wear issues at all.

• Bimetallic Barrels: Unlike nitrided barrels, bimetallic barrels offer superior resistance to wear. This characteristic makes them more suitable for situations with various types of wear, ensuring greater stability during the production process and extended durability, making them a more resilient and long-lasting choice for numerous applications.

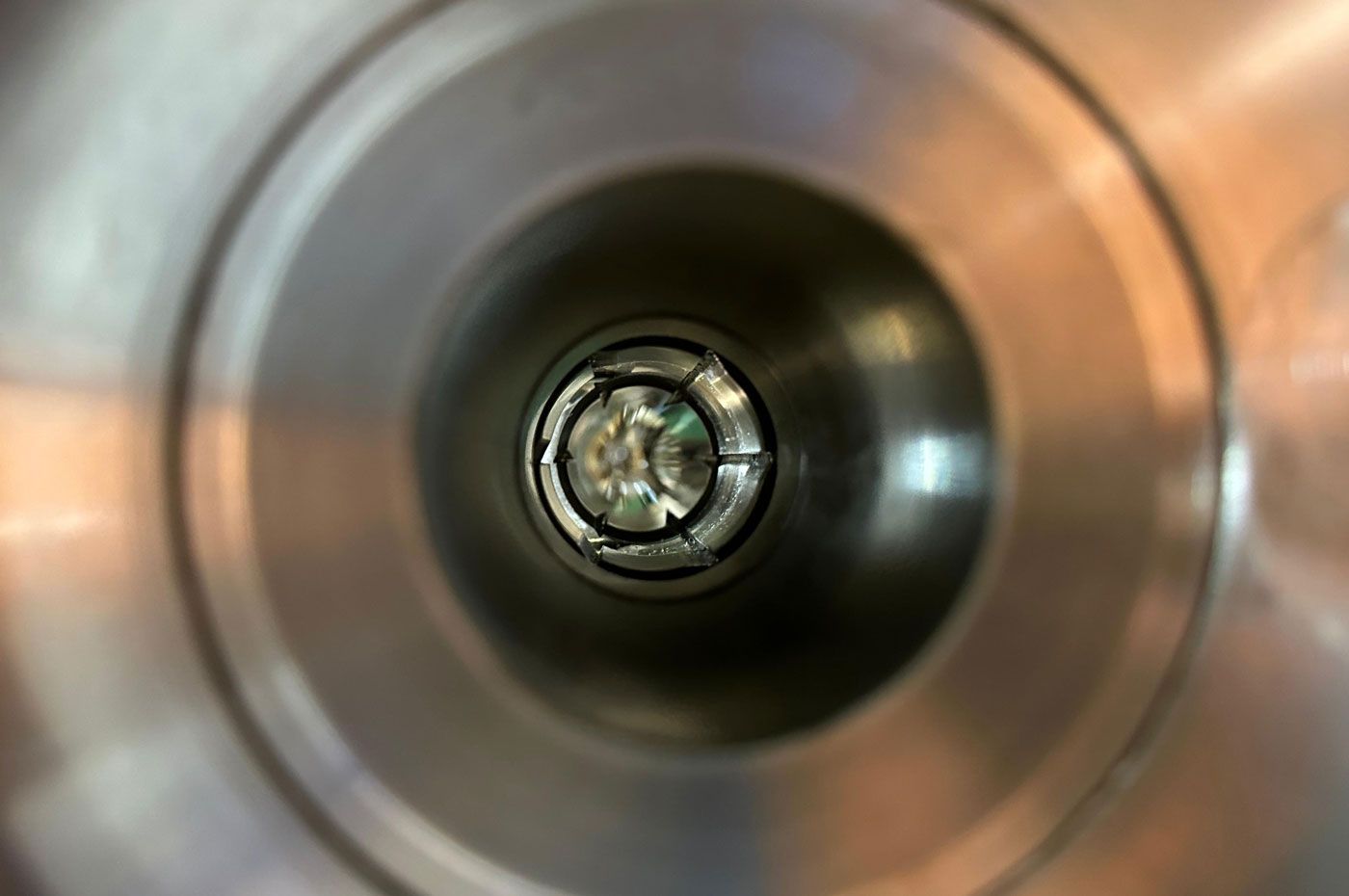

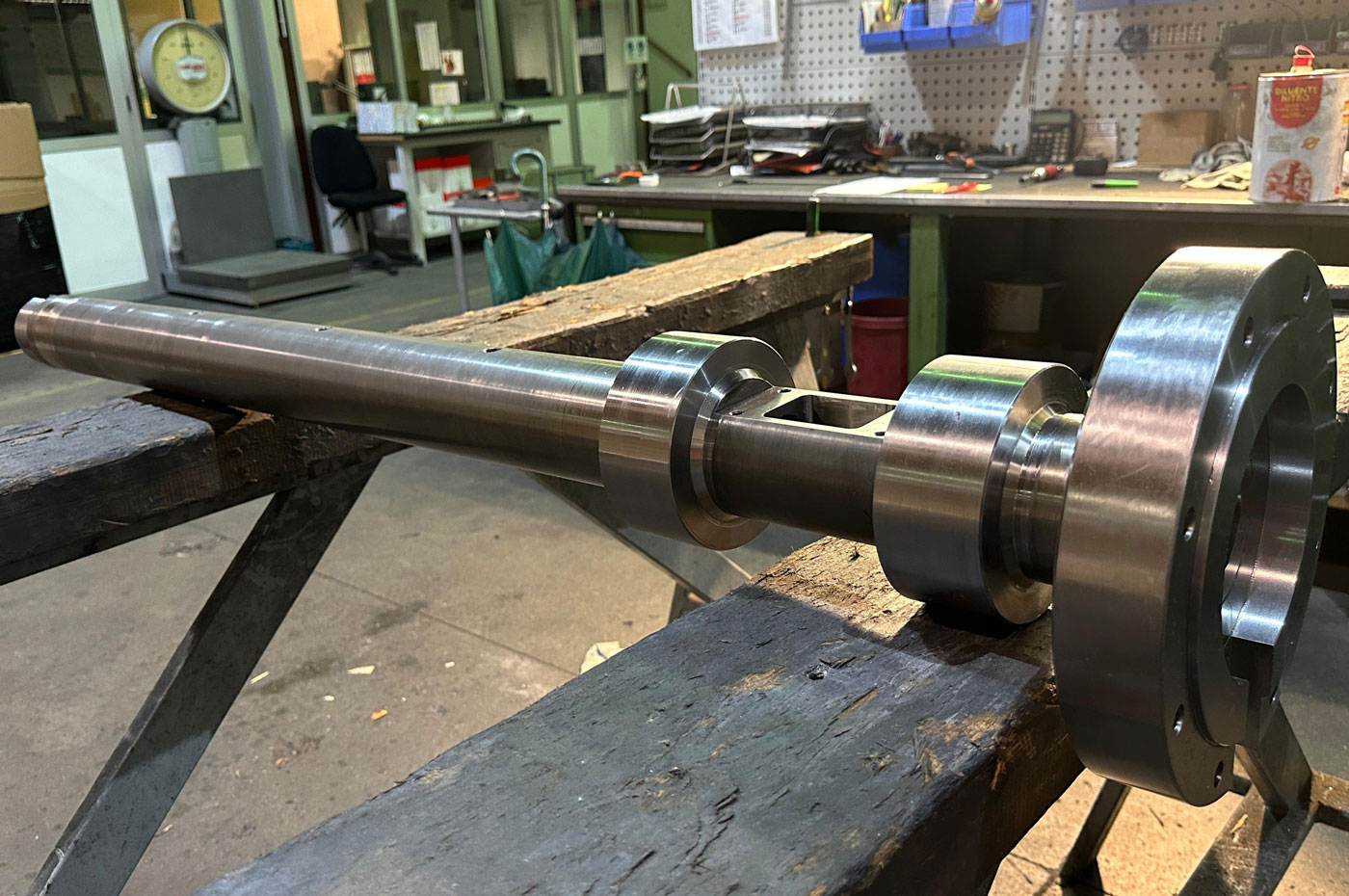

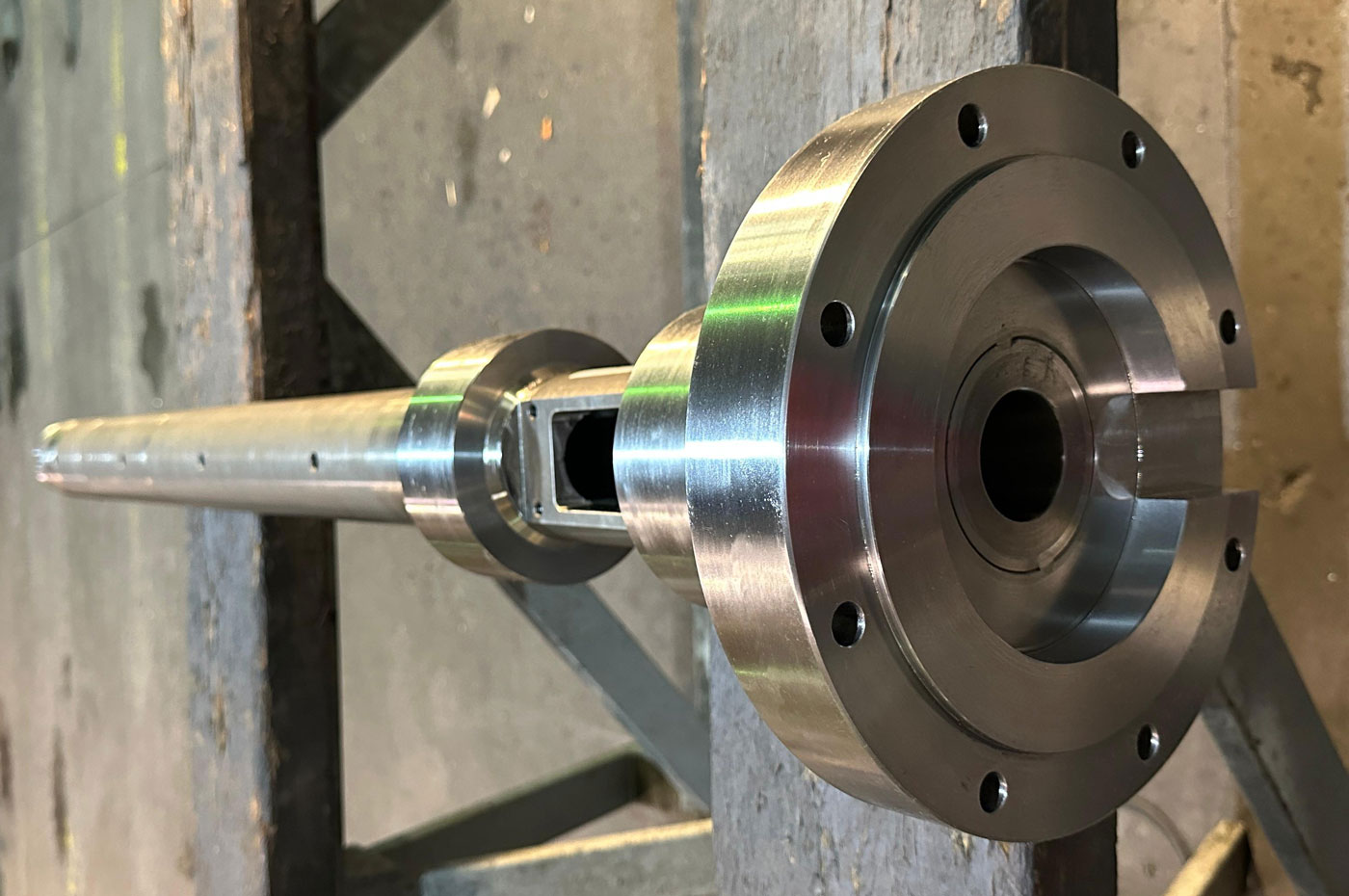

Euroviti provides spare parts for the barrels in monolithic versions, i.e., single-piece, with an integrated feeding zone. It is essential that these devices have an adequate cooling area. To optimize efficiency, internal grooves can be added to facilitate the handling of the plastic material during extrusion, improving heat distribution and promoting a more uniform material flow

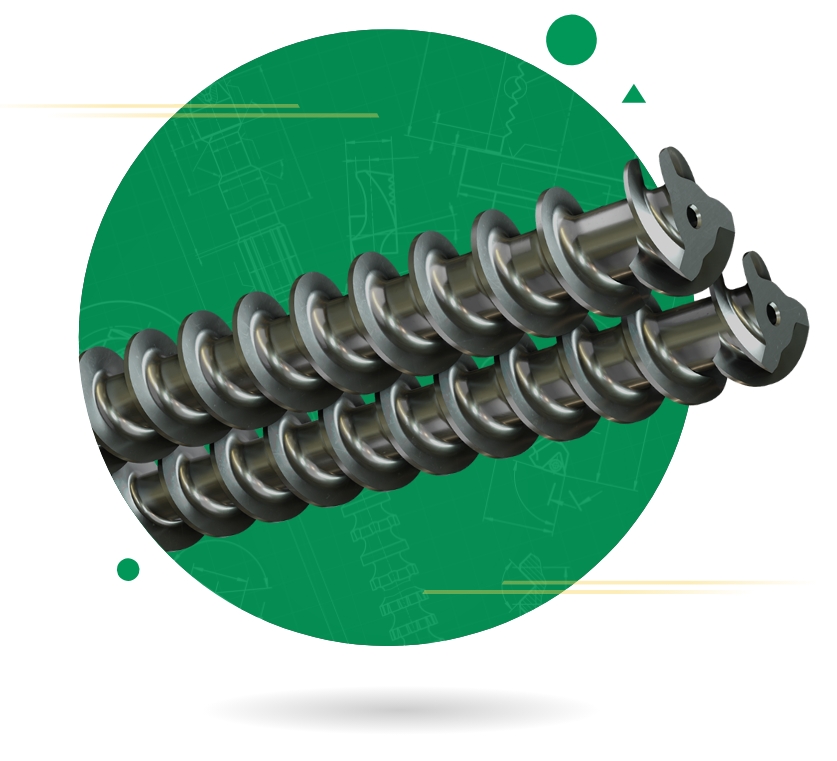

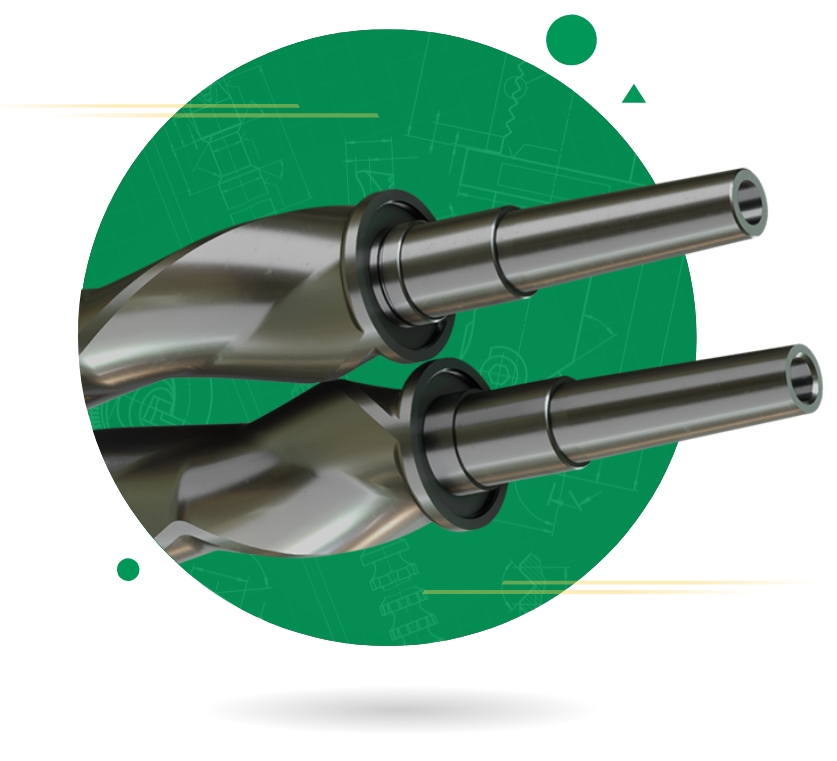

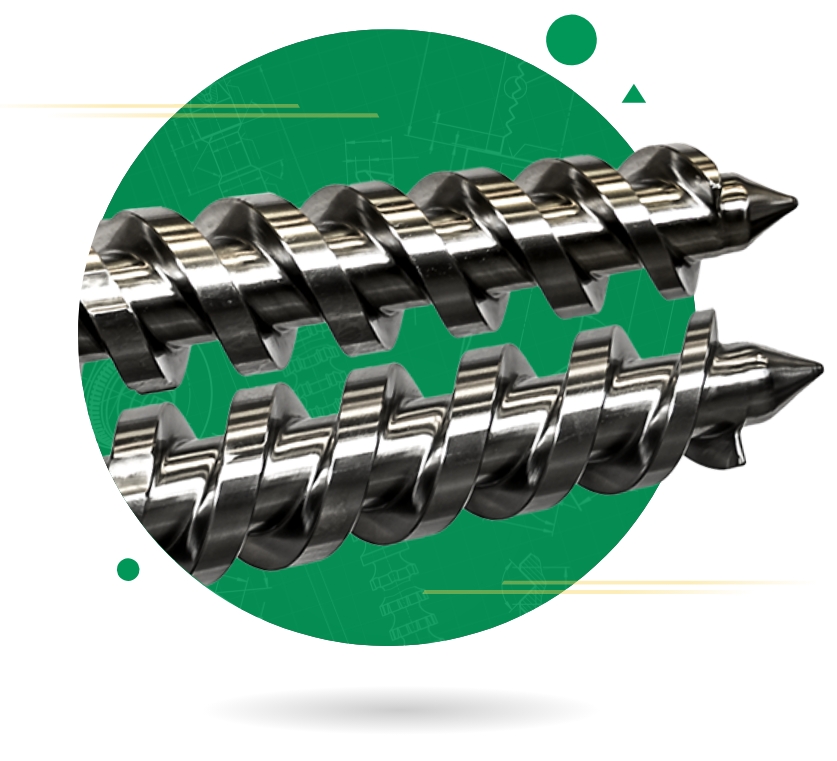

Gallery

Discover the technical information about

Barrel

| EUV CODES | TYPE | INLAY BASE ALLOY | PROTECTION LEVEL | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV100 | Bimetallic | Fe | Basic against abrasion | 58÷65HRC | •• | • |

| EUV200 | Bimetallic | Ni/Co | Total against corrosion Low agains abrasion | 48÷56HRC | • | ••••• |

| EUV400 | Bimetallic | Fe/Cr | Good against abrasion and corrosion | 62÷69HRC | •••• | ••• |

| EUV1000W | Bimetallic WC | Ni/Wc | Extreme against abrasion and corrosion | 58÷66HRC | ••••• | ••••• |

| EUV CODES | TYPE | INLAY BASE ALLOY | TREATMENT | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

| EUV31 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 700÷800HV | • | • |

| EUV34 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV | • | • |

| EUV41 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV | • | • |

Related Products

CONTACT US

Tell us what you need

Follow us