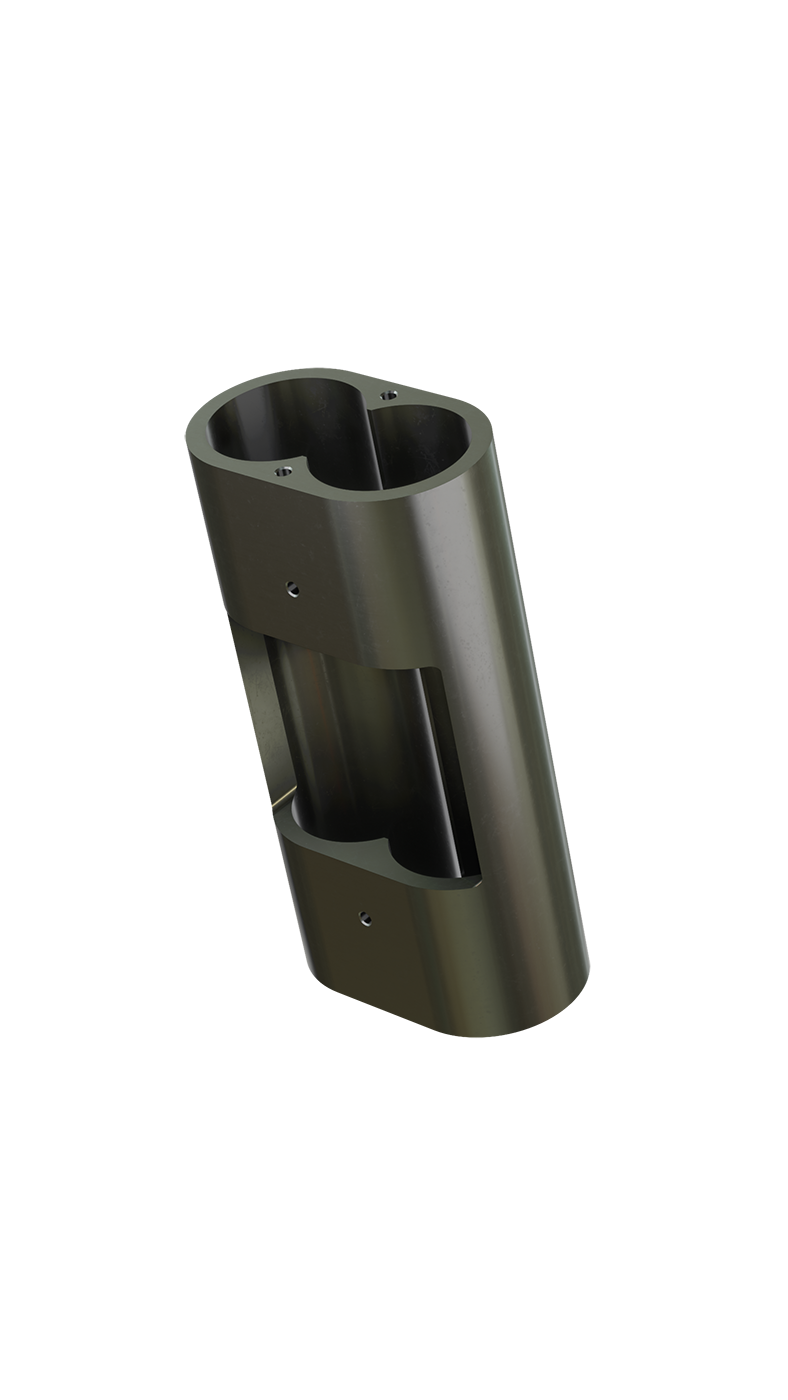

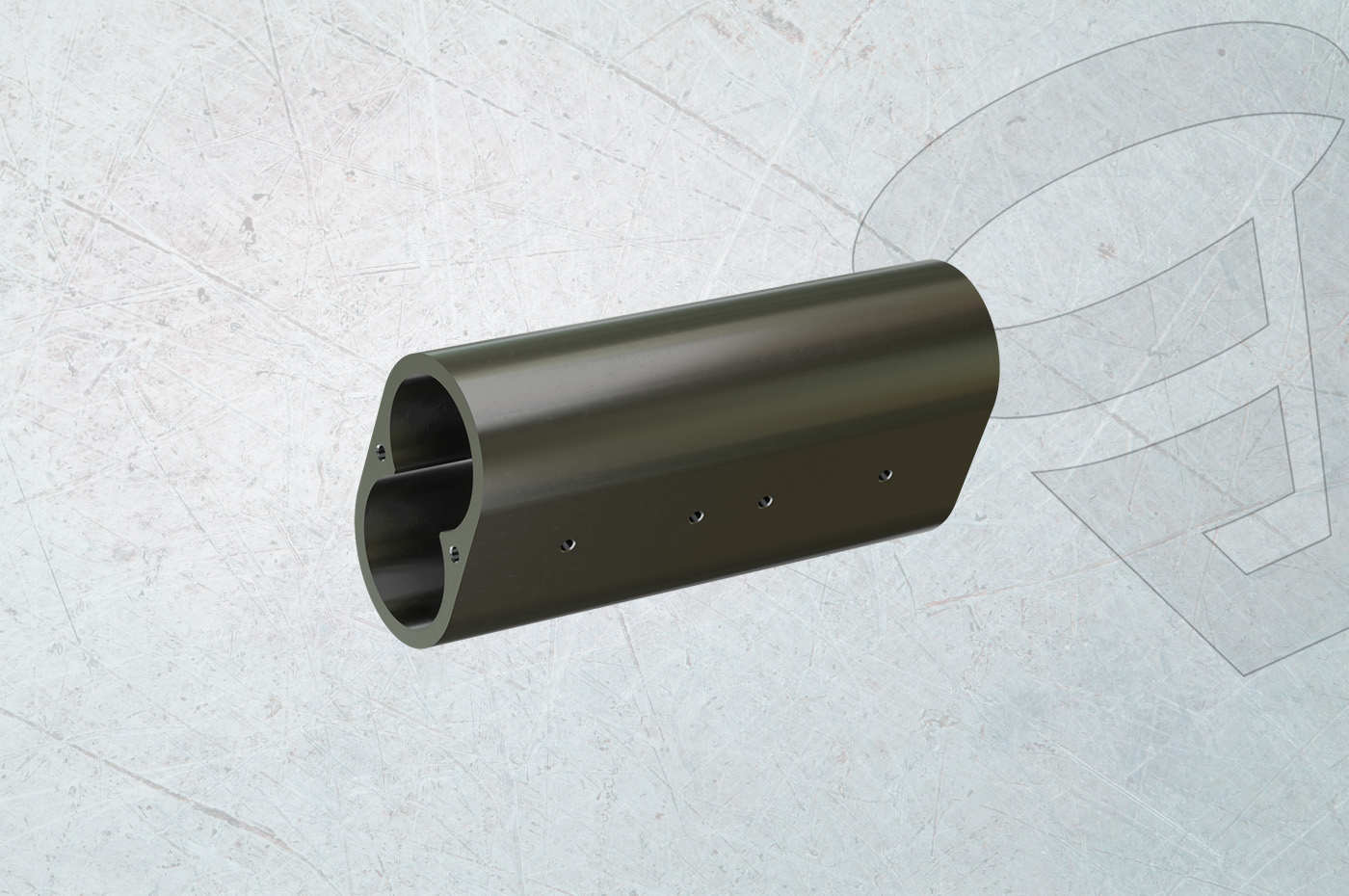

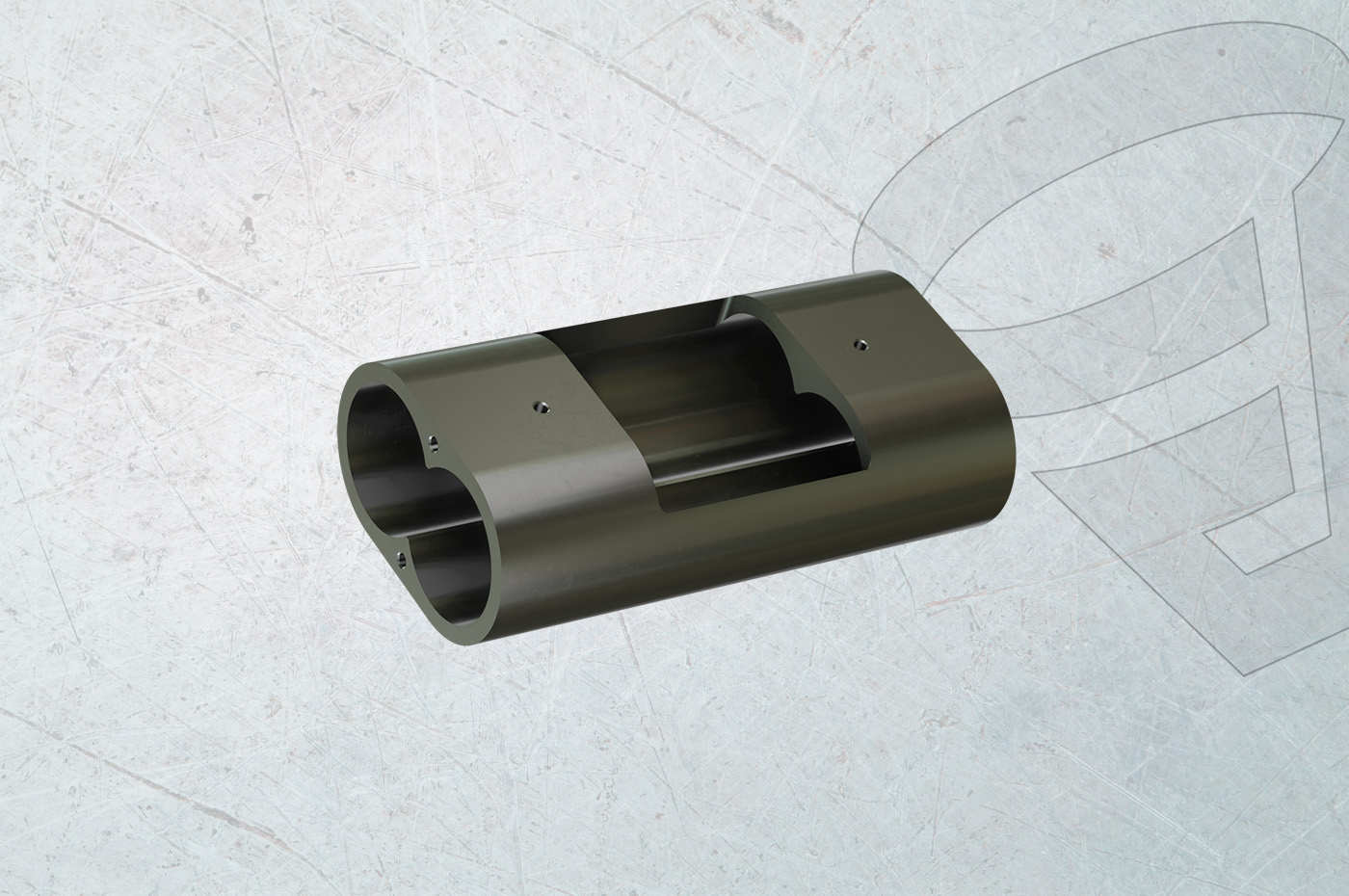

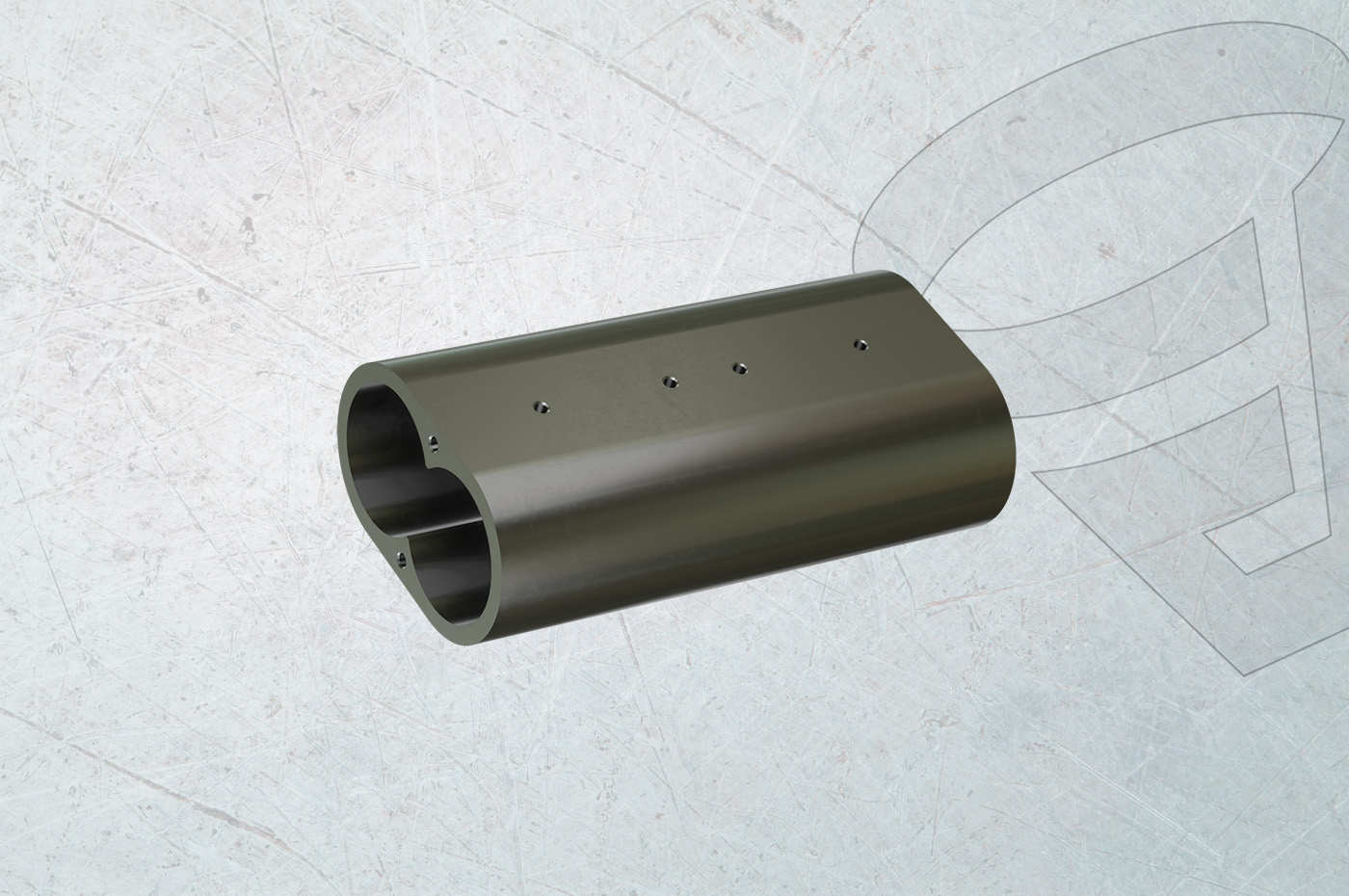

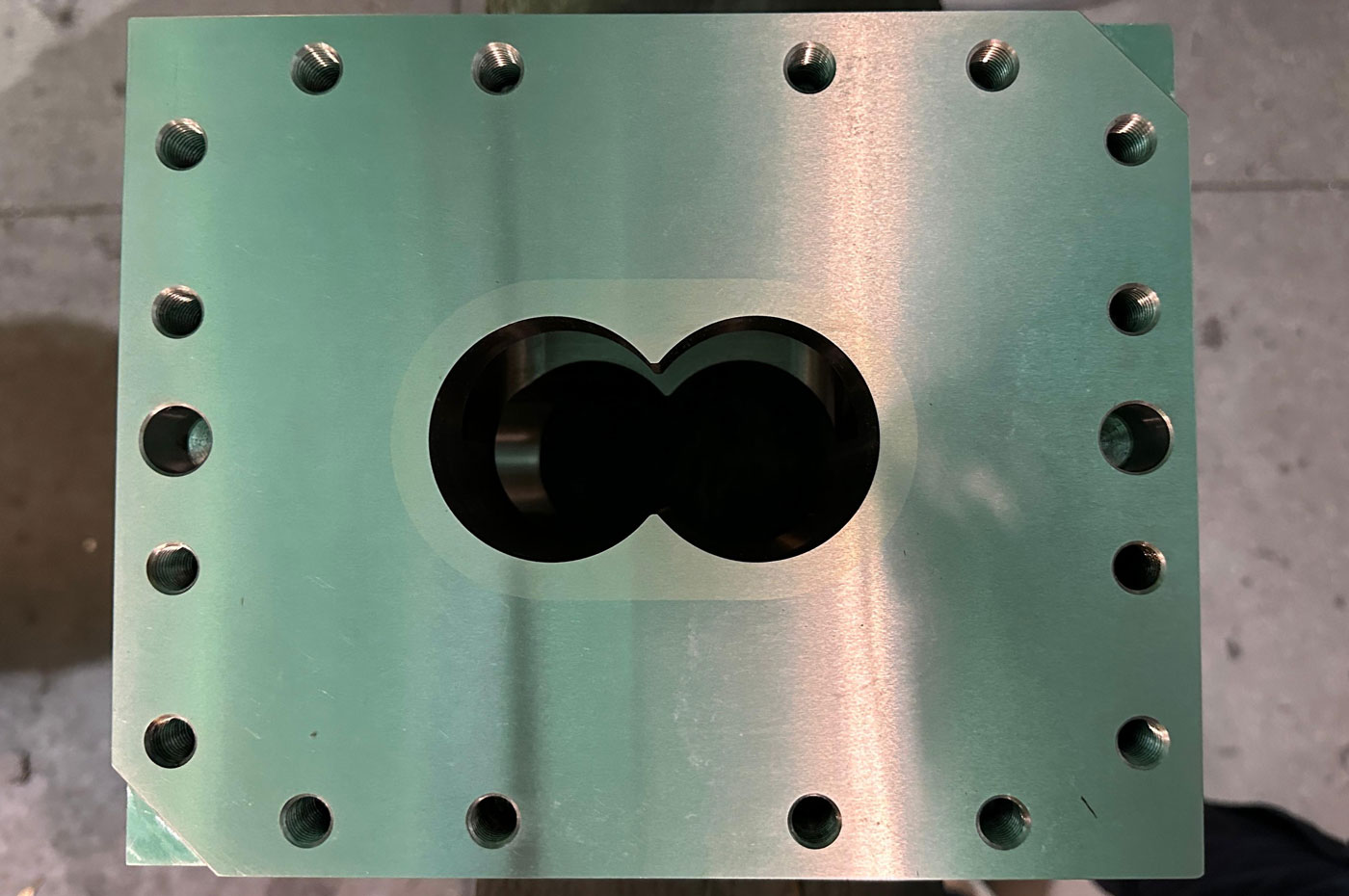

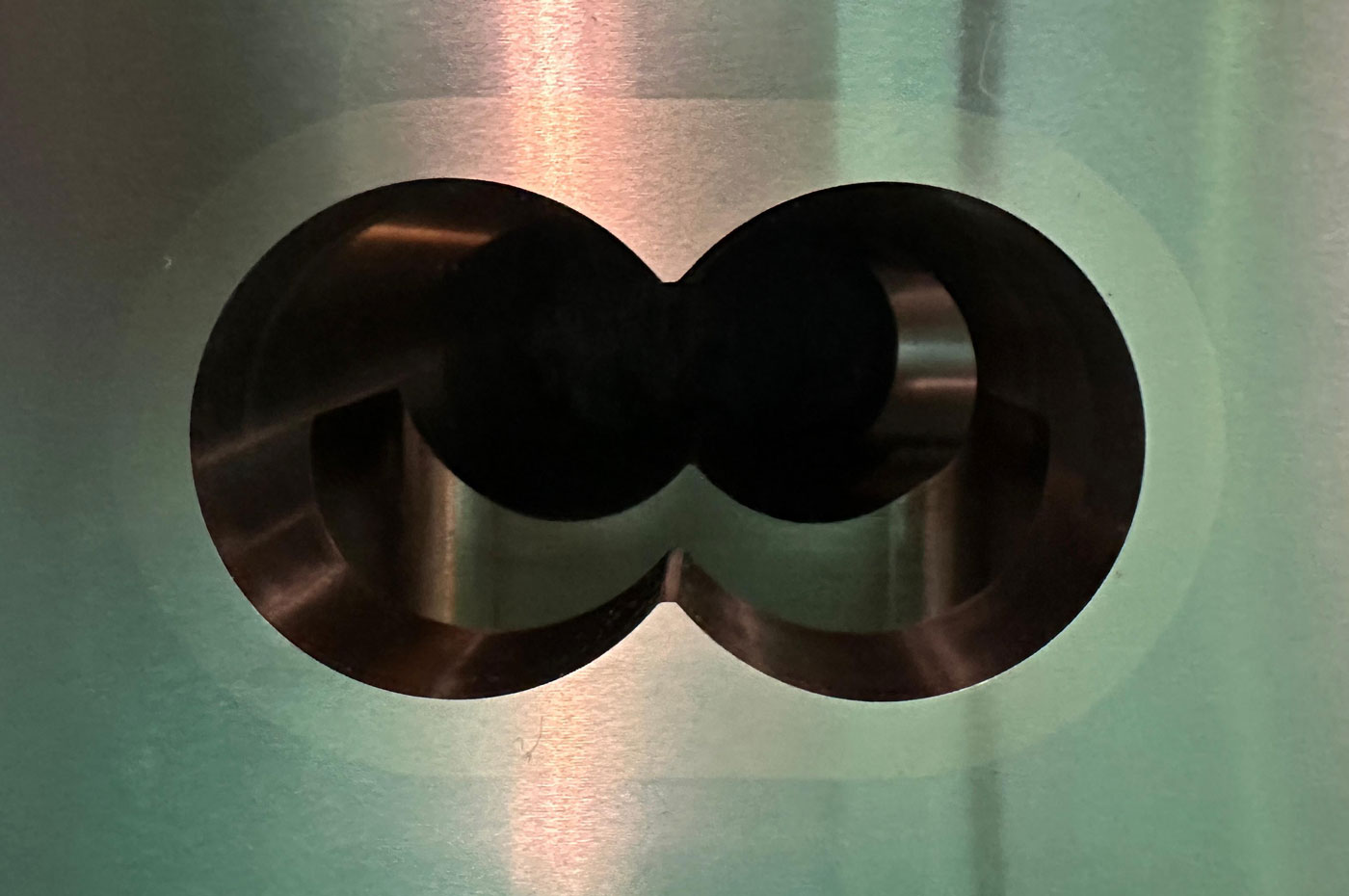

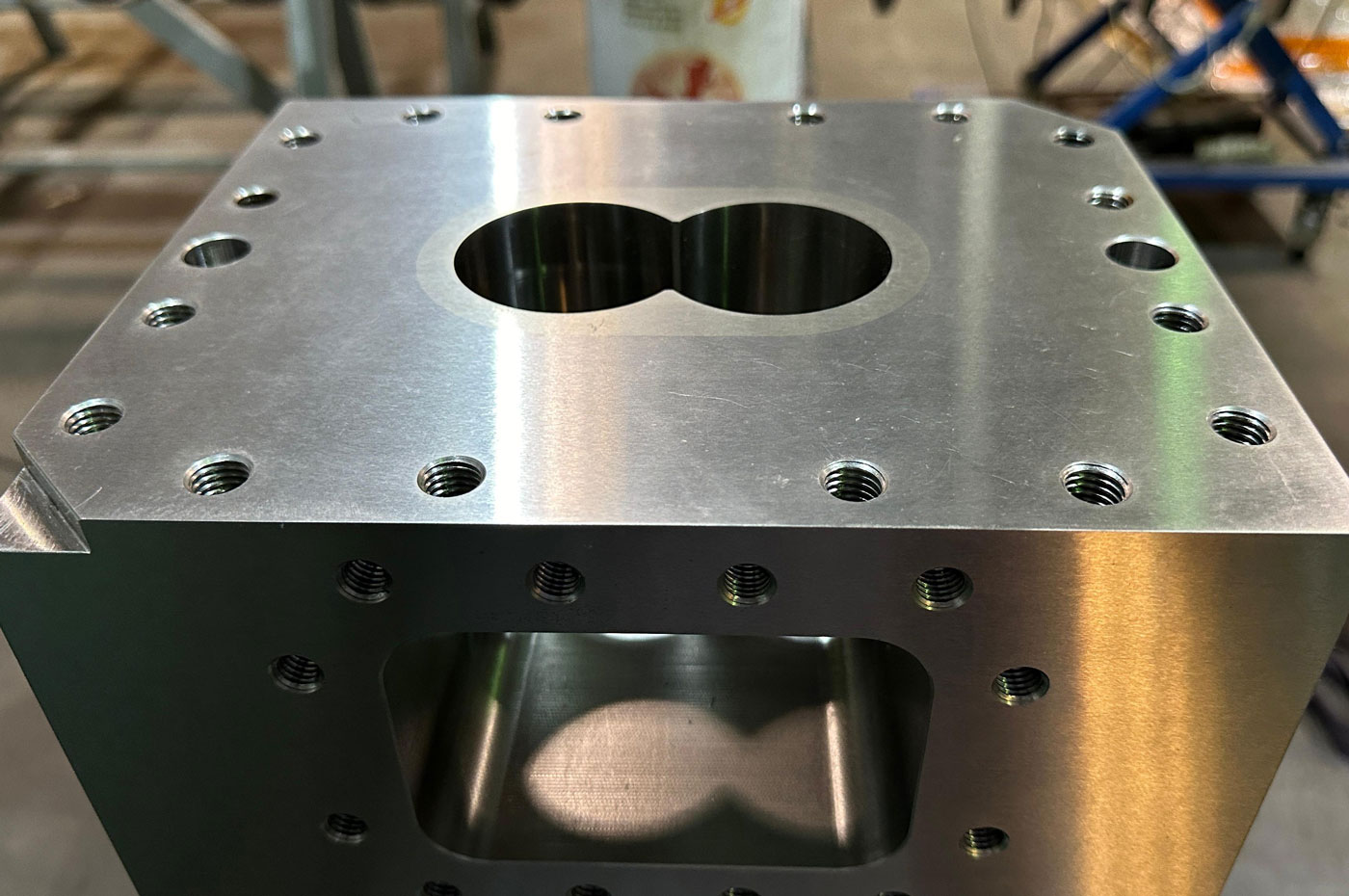

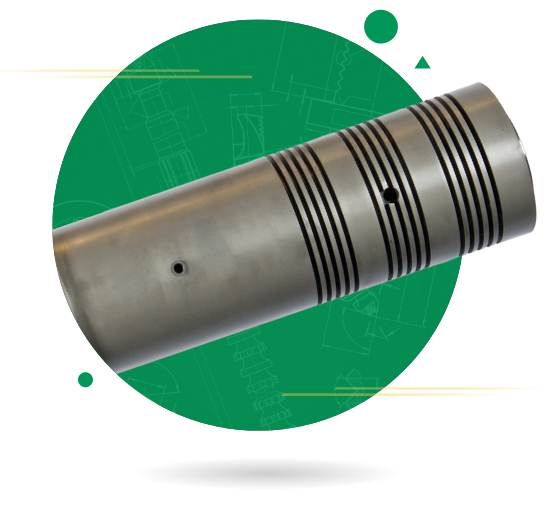

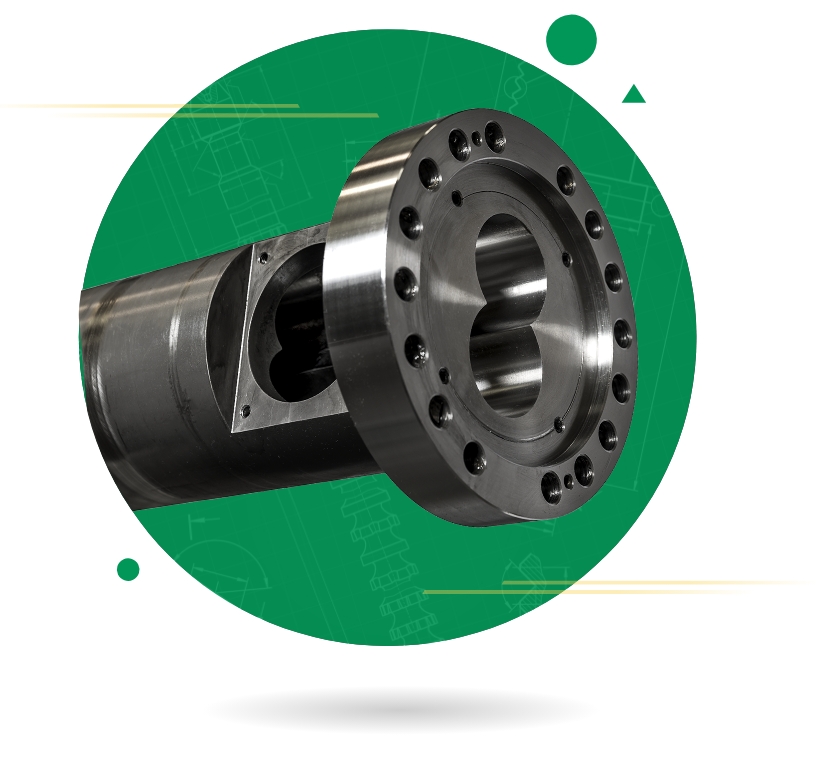

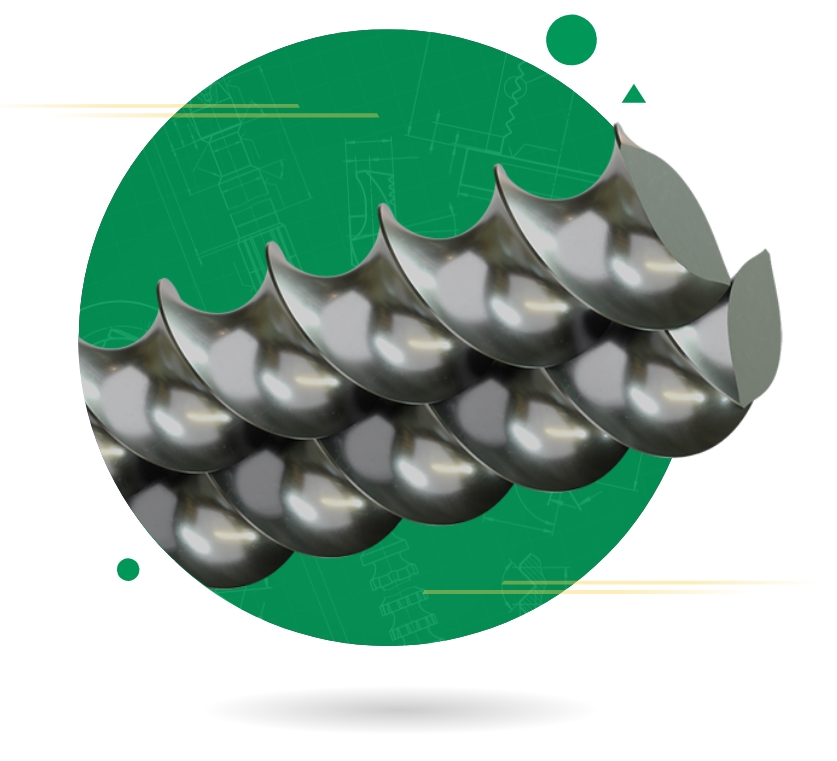

A particularly advantageous aspect of the bi-hole barrel for co-rotating extruders is the ability to incorporate an internal sleeve made of hardened steel. This feature not only increases the barrel’s resistance to corrosion but also helps to combat abrasive wear, significantly prolonging the life of the barrel itself.

Besides durability, another important advantage of this design is practicality in terms of maintenance. In case of wear, the internal sleeve can be easily replaced without the need to change the entire outer body of the barrel. This targeted replacement option represents a considerable saving on maintenance costs and makes the use of the bi-hole barrel for co-rotating extruders an efficient and economical option in the long term.

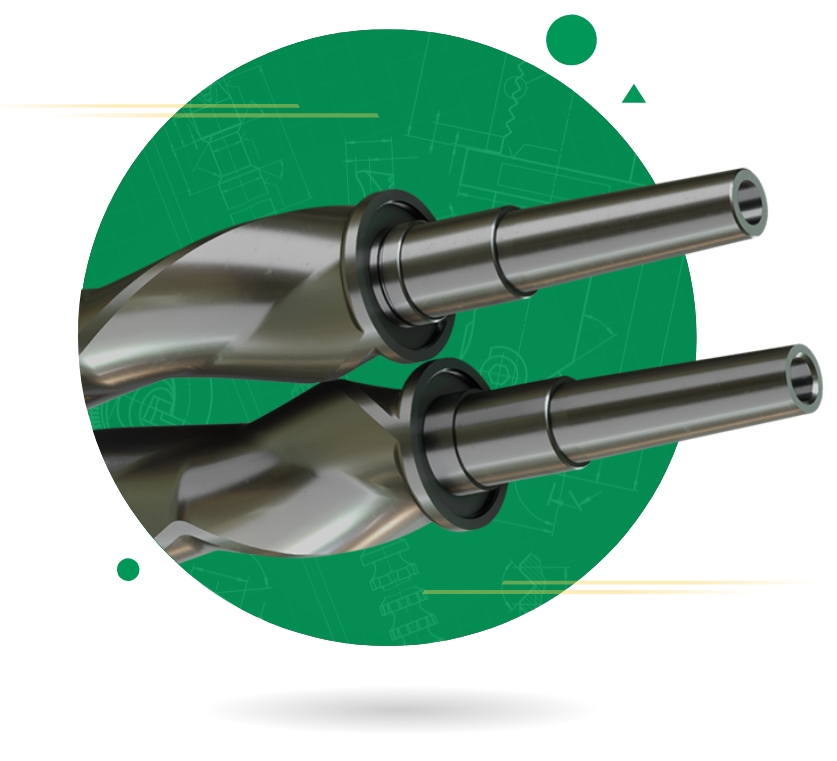

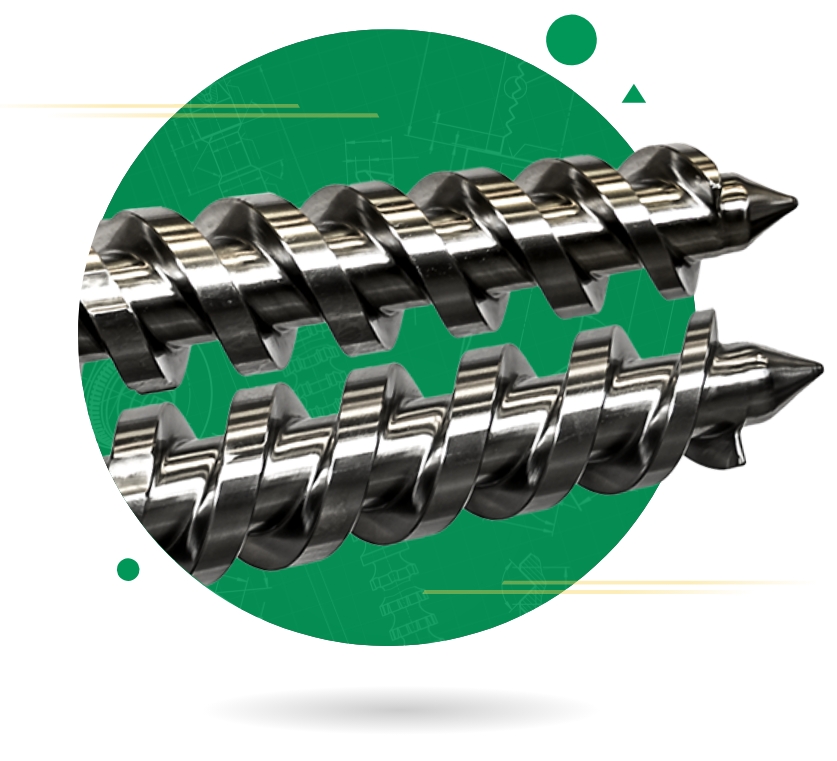

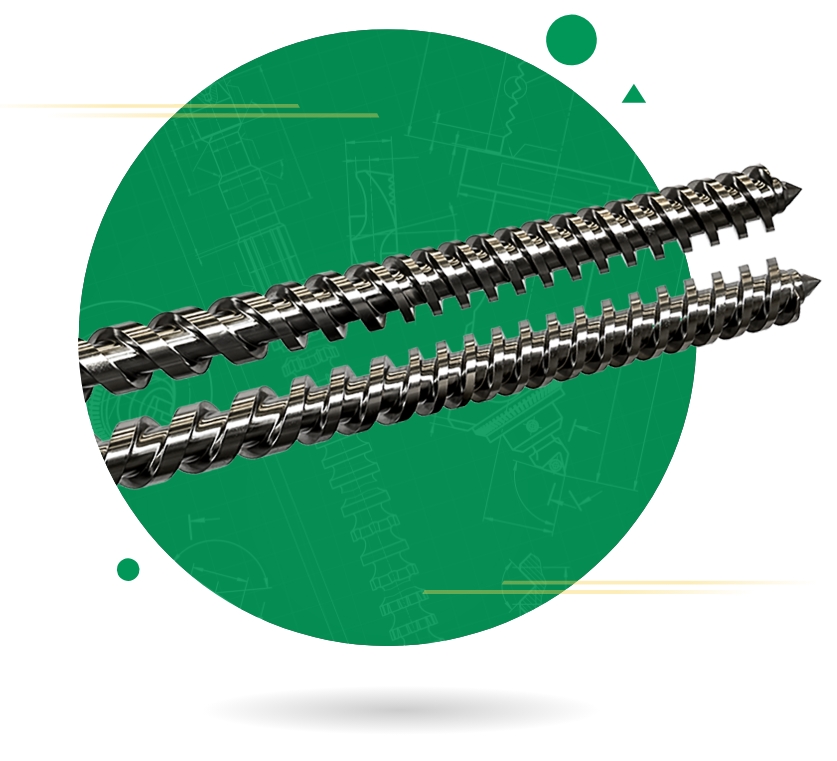

Gallery

Discover the technical information about

Internal Sleeve

| EUV CODES | STEEL TYPE | TREATMENT | TYPE | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV41 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV79 | Cold Work Tool Steel | Hardening & Tempering | Total Hardening | 58÷62HRC | ••• | •• |

| EUV10 | Powder metallurgy steel - Protection from abrasion | Hardening & Tempering | Total Hardening | 58÷64HRC | •••• | • |

| EUV90 | Powder metallurgy tool steels | Special Hardening & Tempering | Total Hardening | 57÷63HRC | •••• | ••••• |

| EUV400 | Bimetallic | Fe/Cr | Good against abrasion and corrosion | 62÷69HRC | •••• | ••• |

| EUV1000W | Bimetallic WC | Ni/Wc | Extreme against abrasion and corrosion | 58÷66HRC | •••••+ | •••••+ |

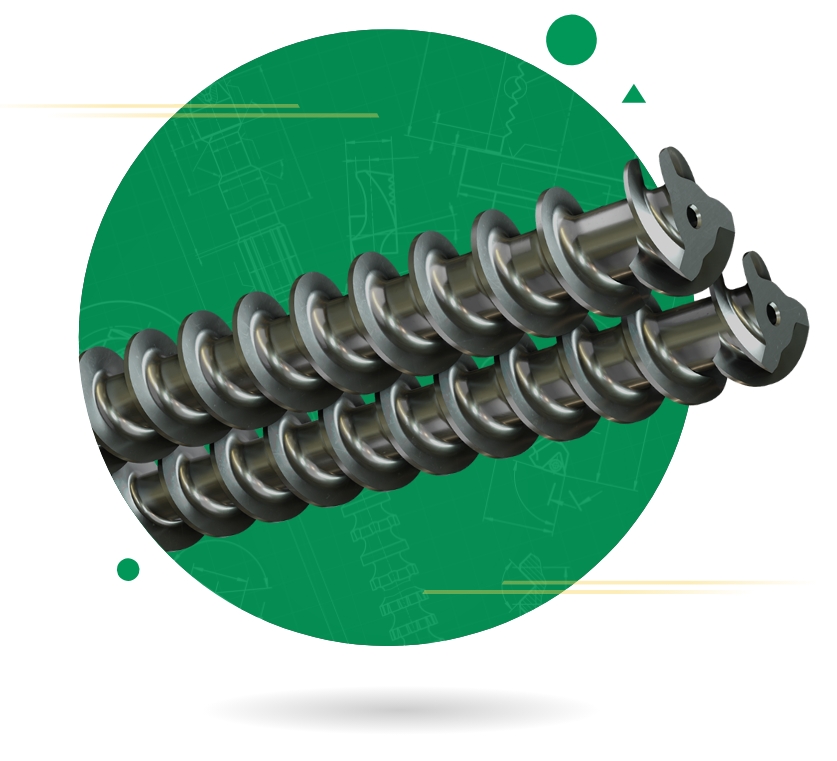

Related Products

CONTACT US

Tell us what you need

Follow us