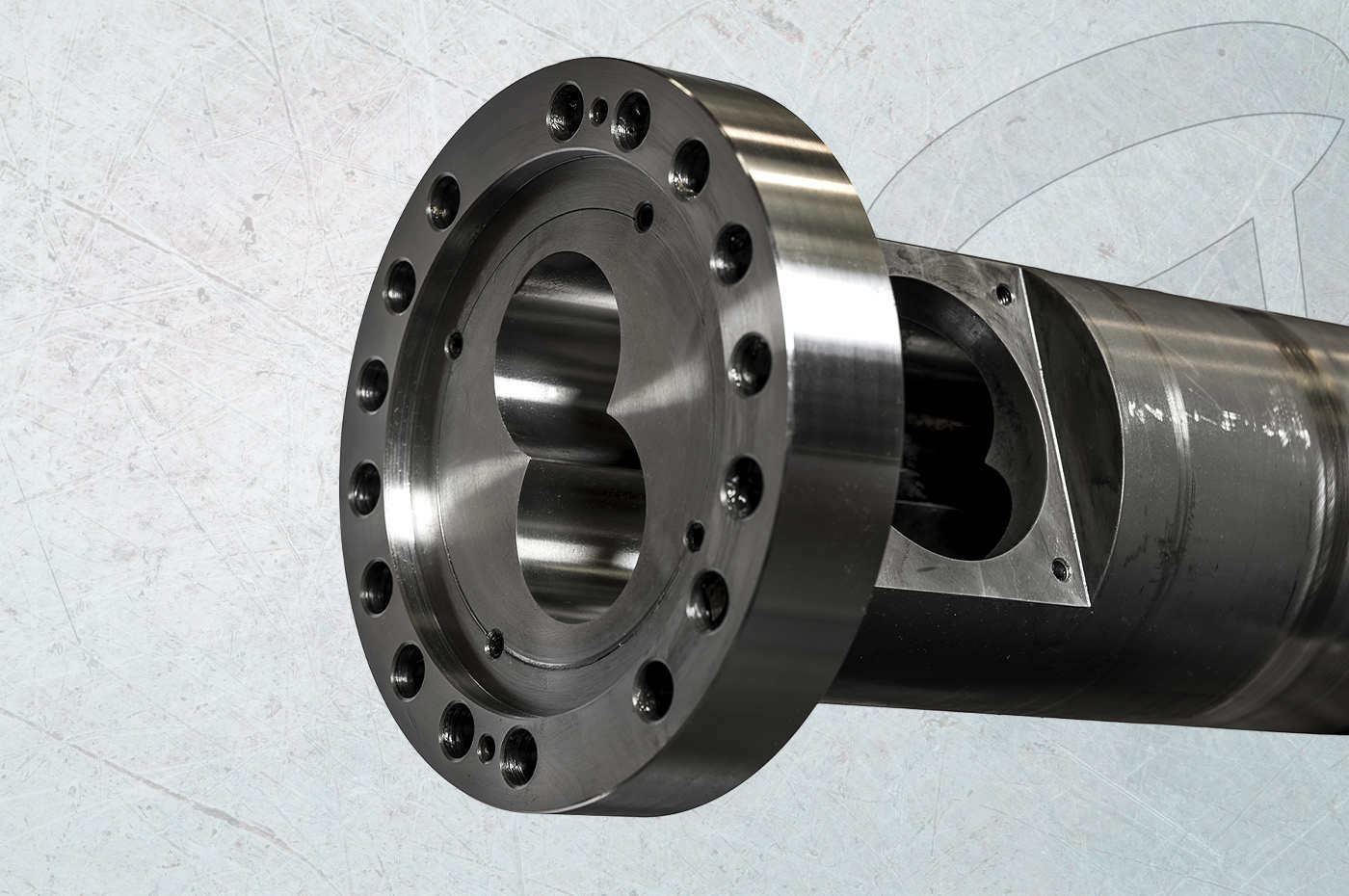

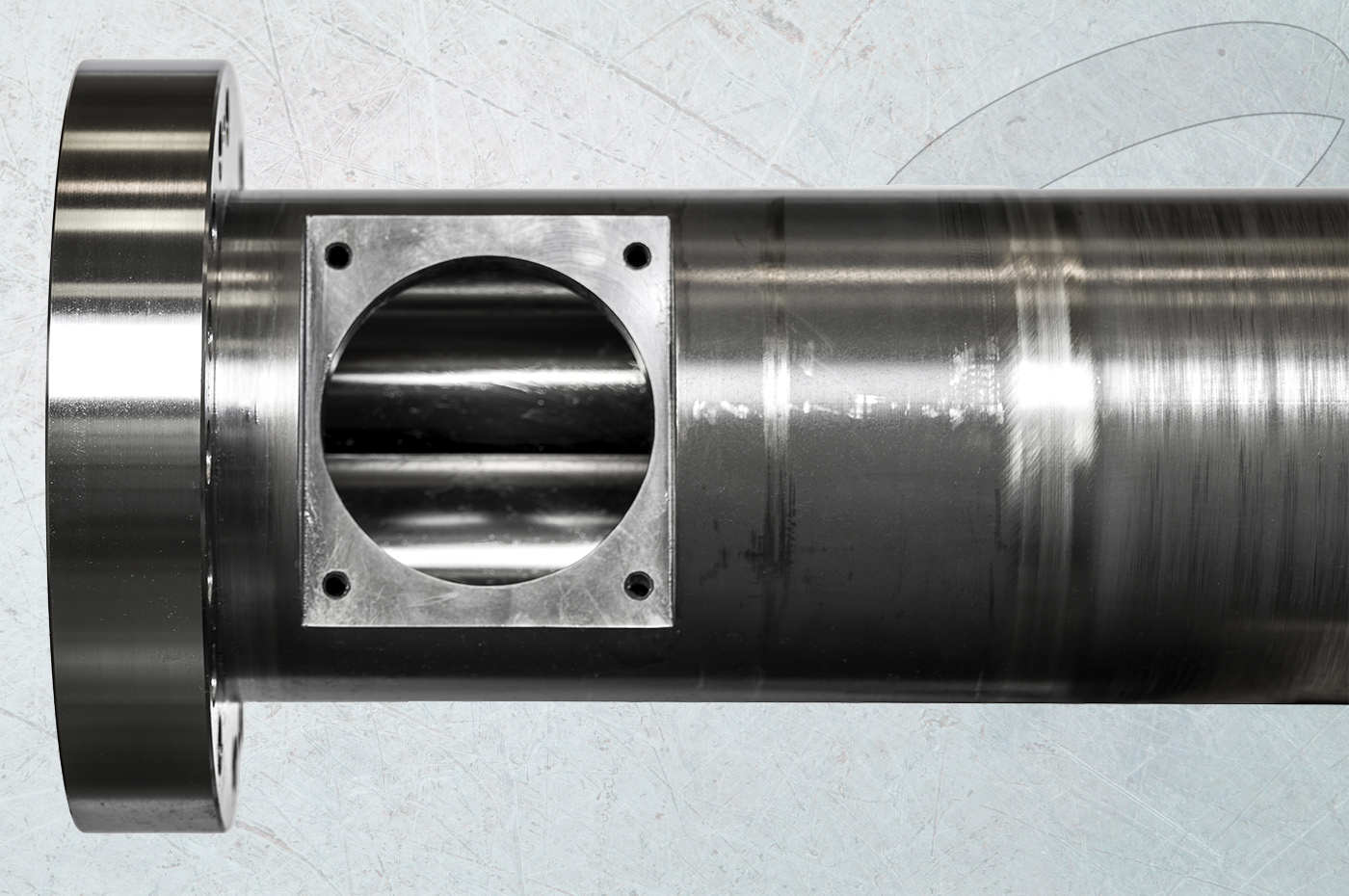

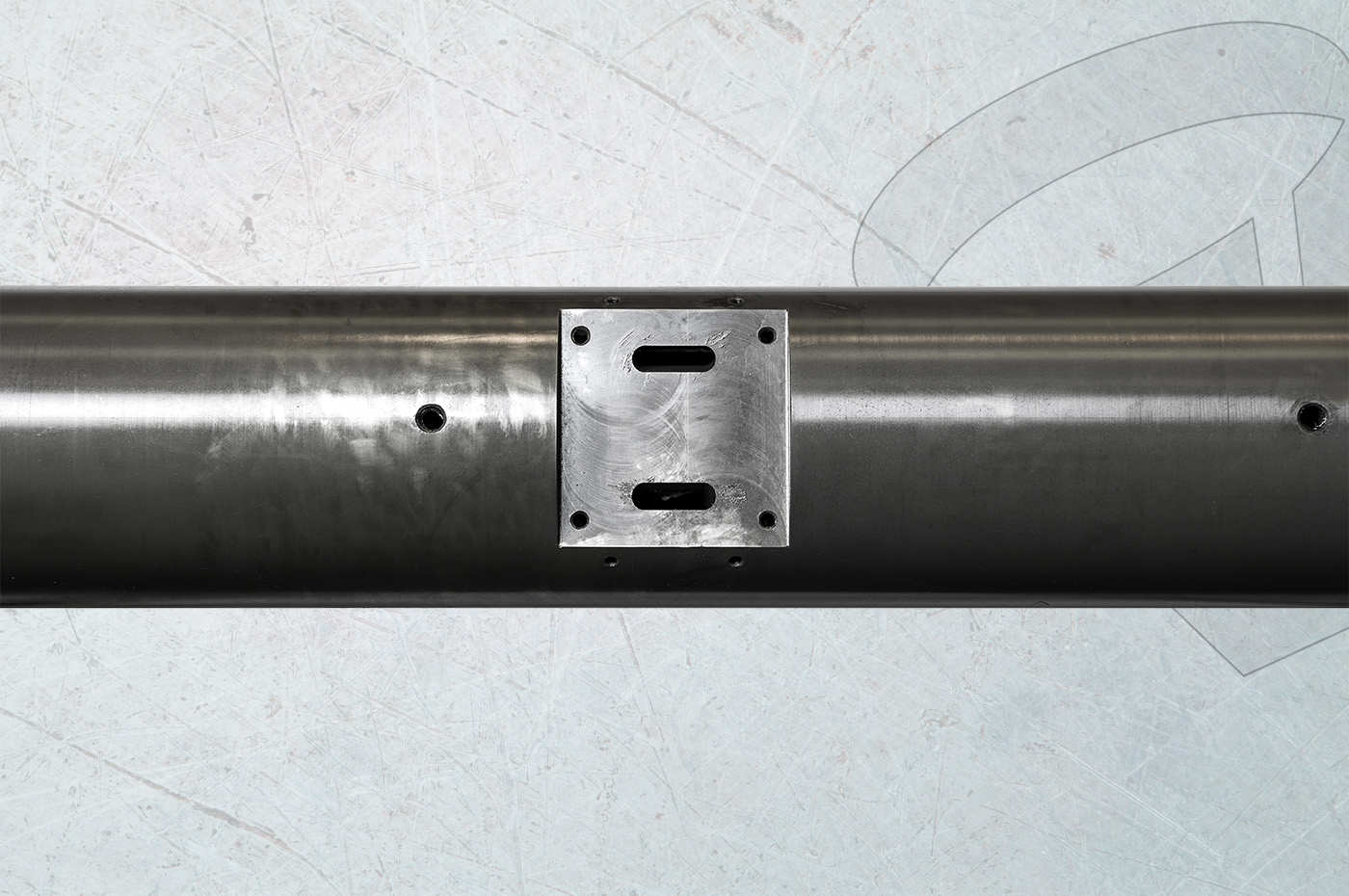

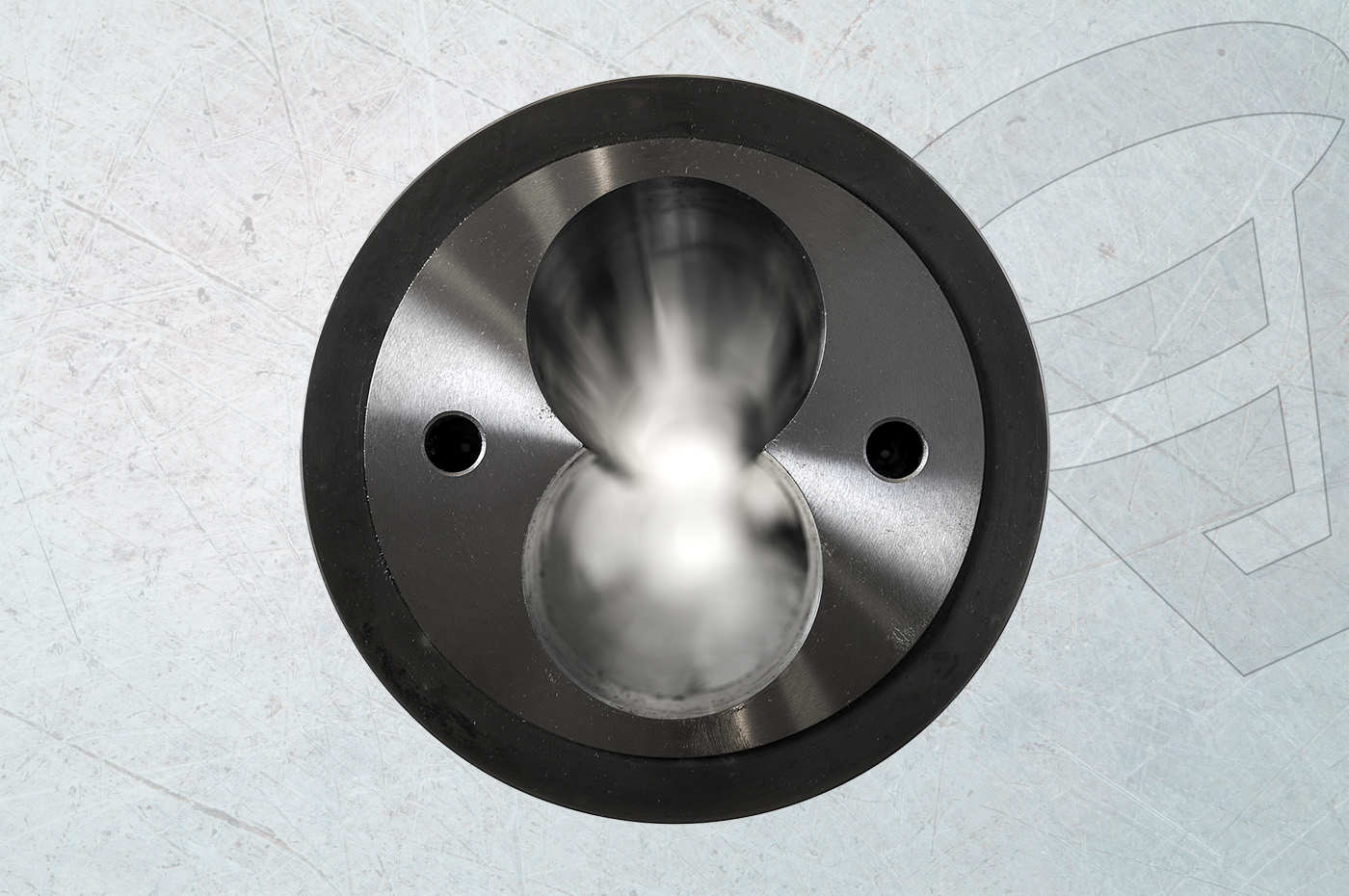

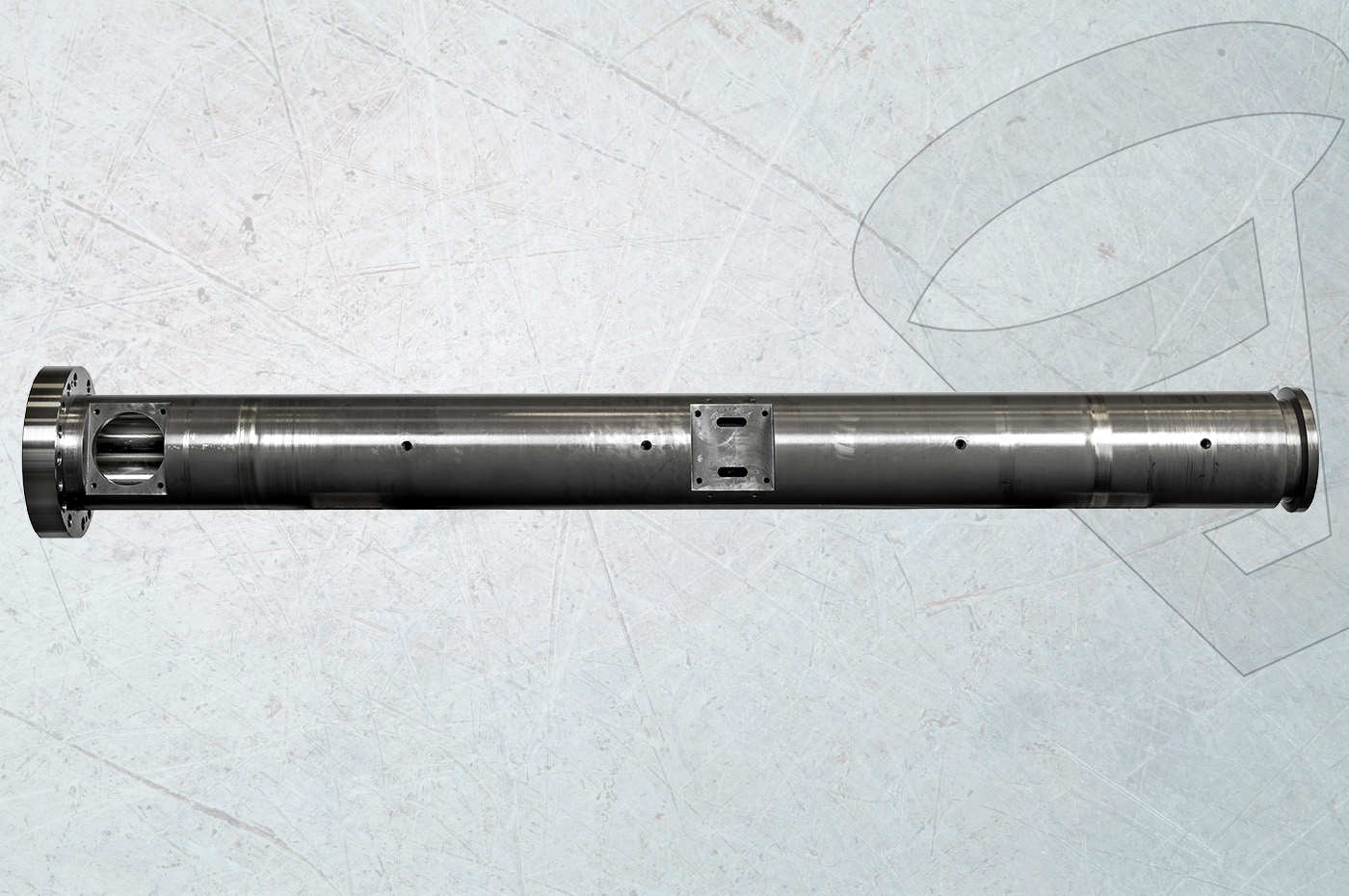

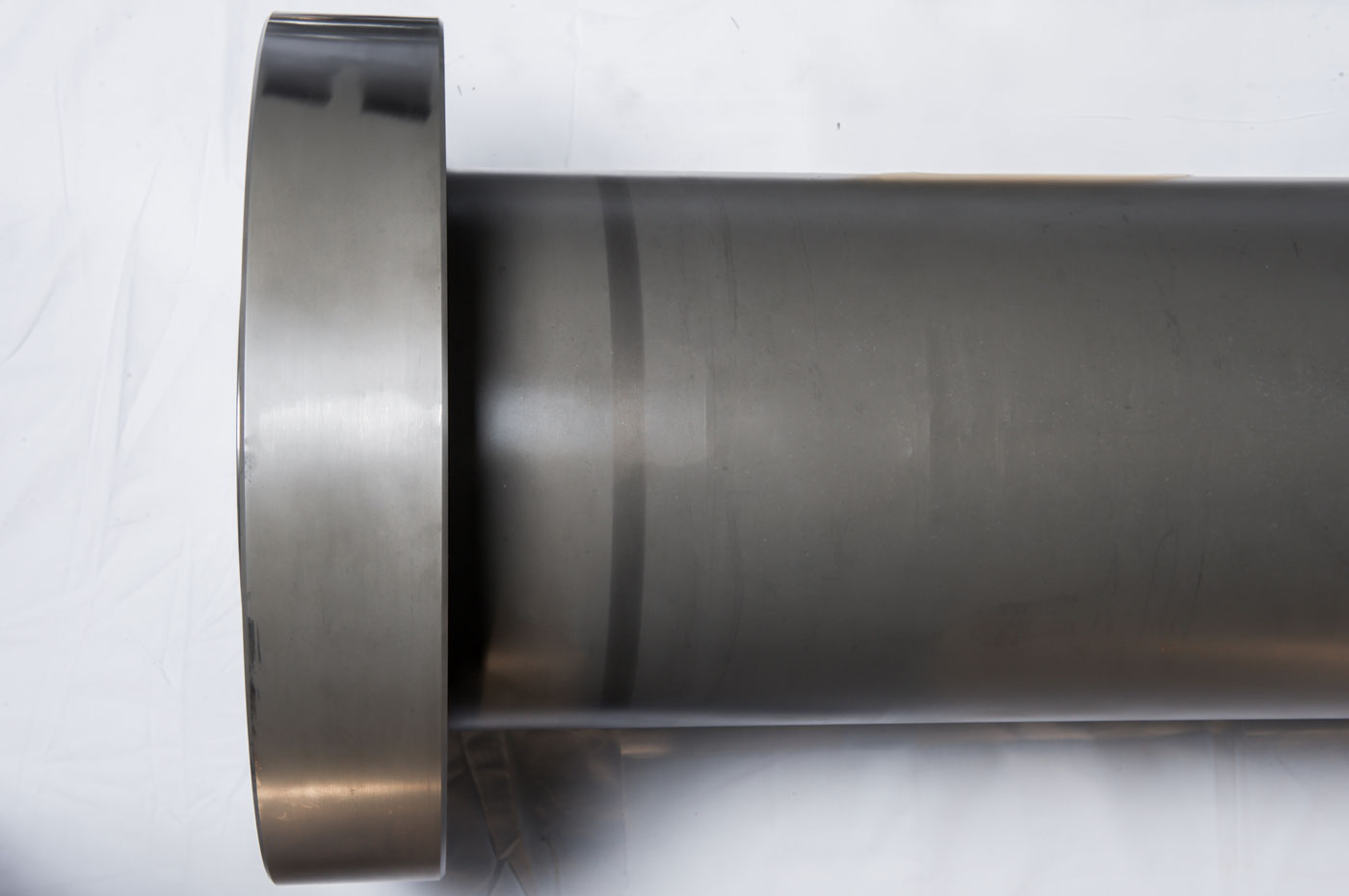

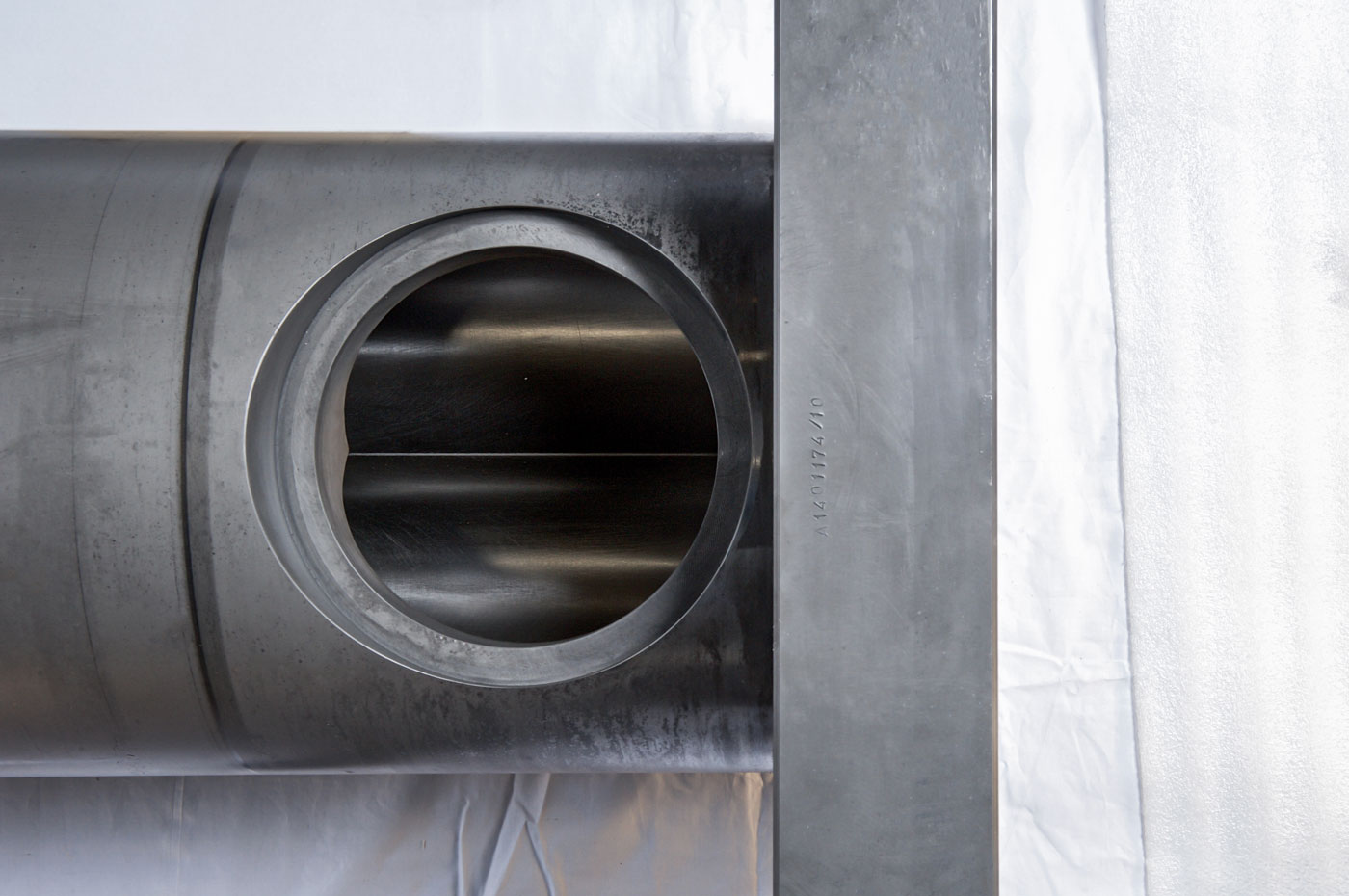

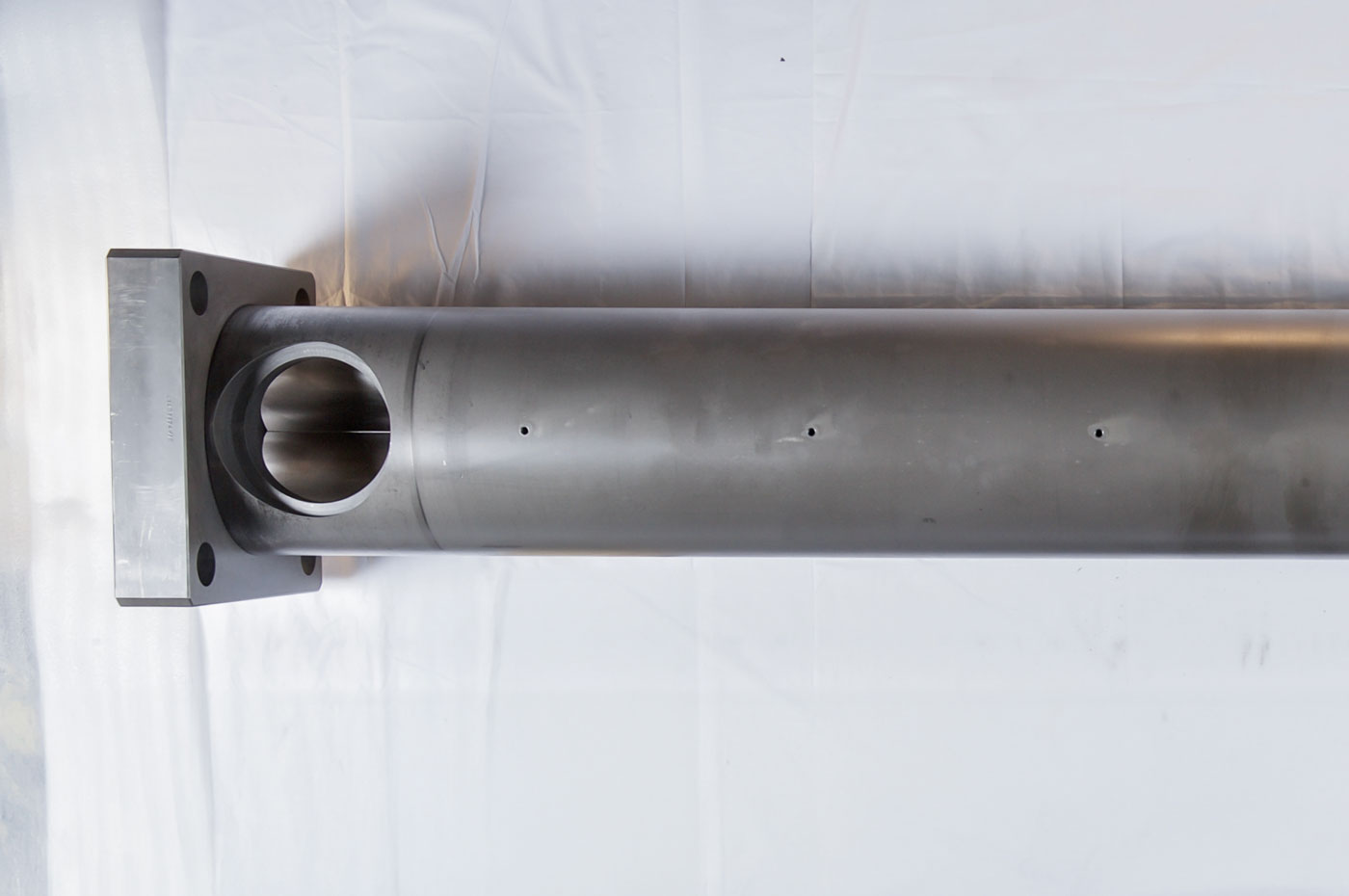

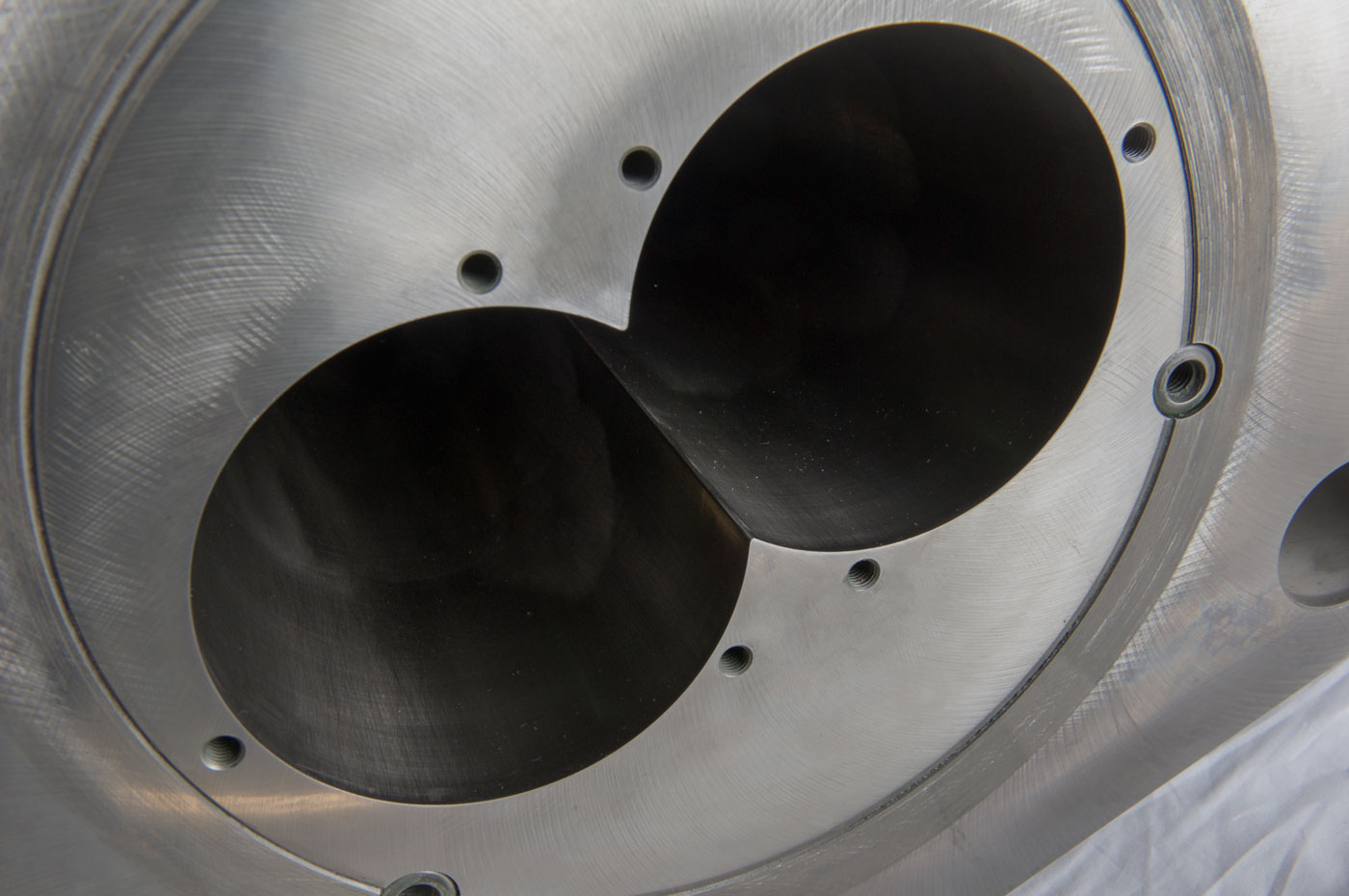

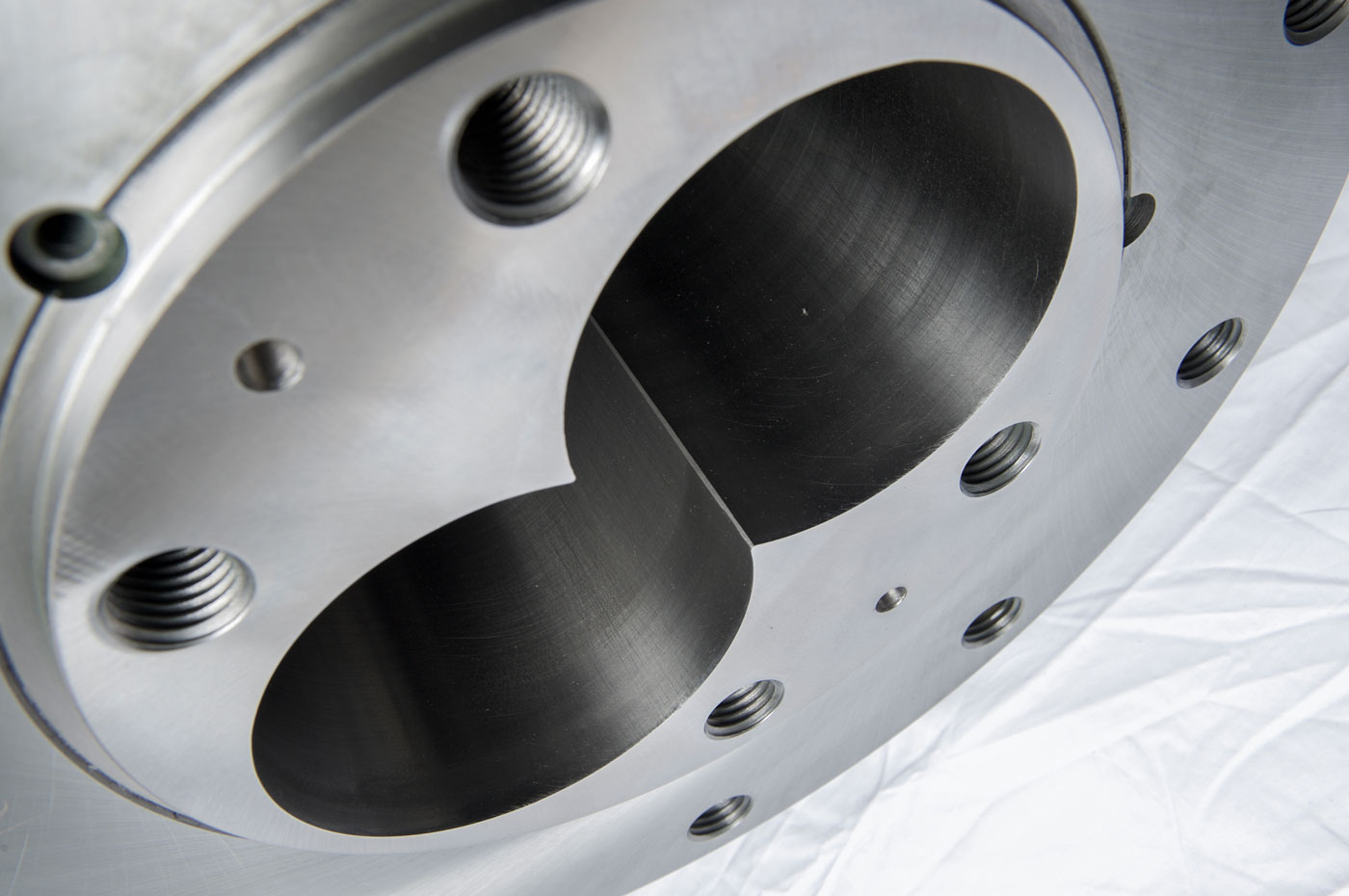

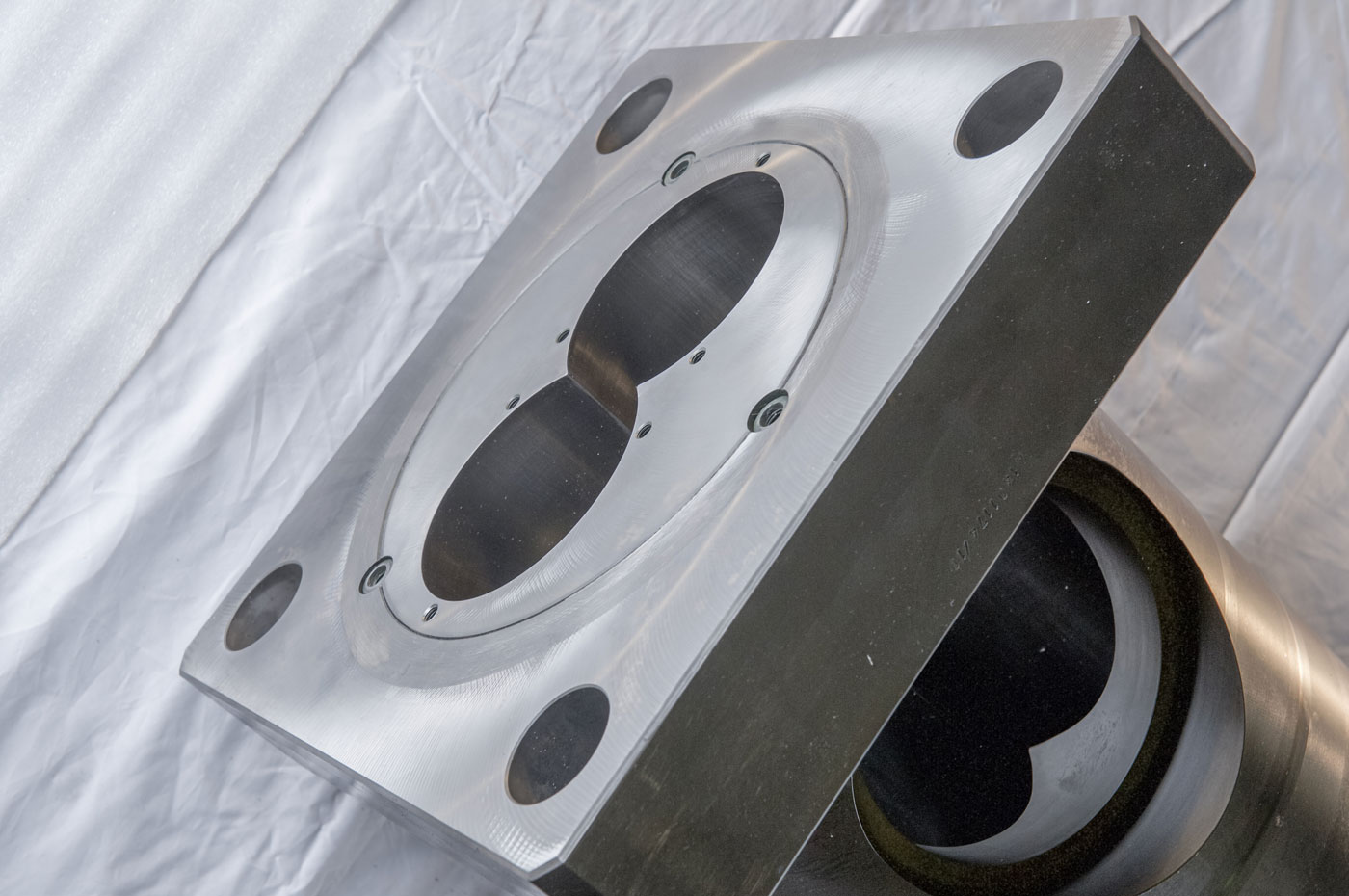

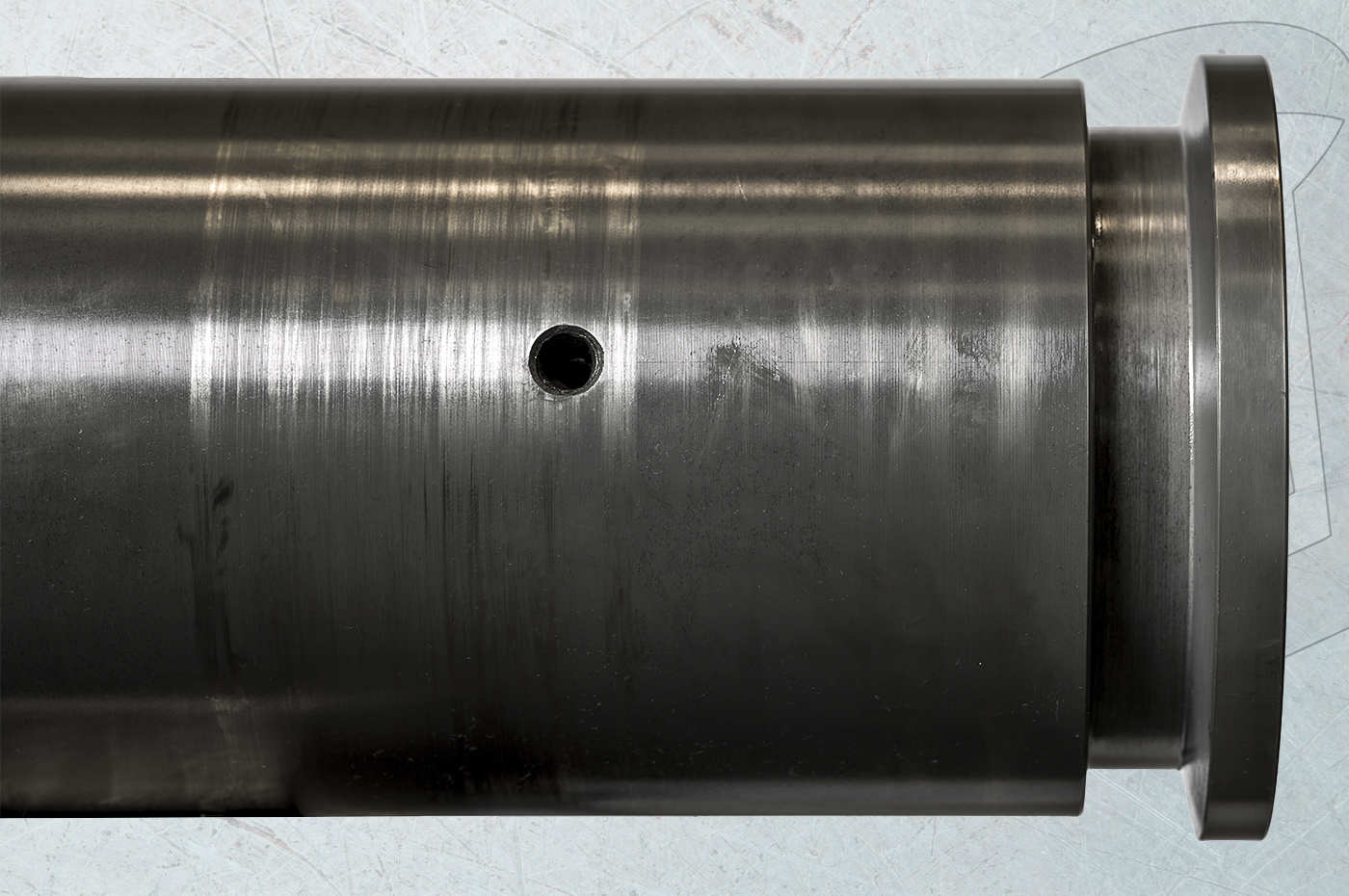

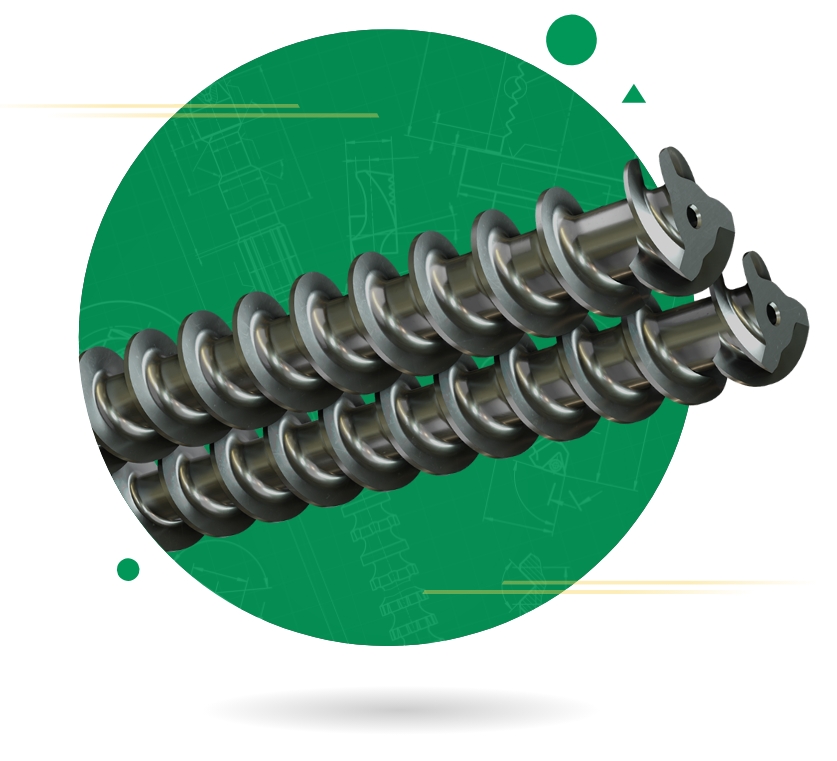

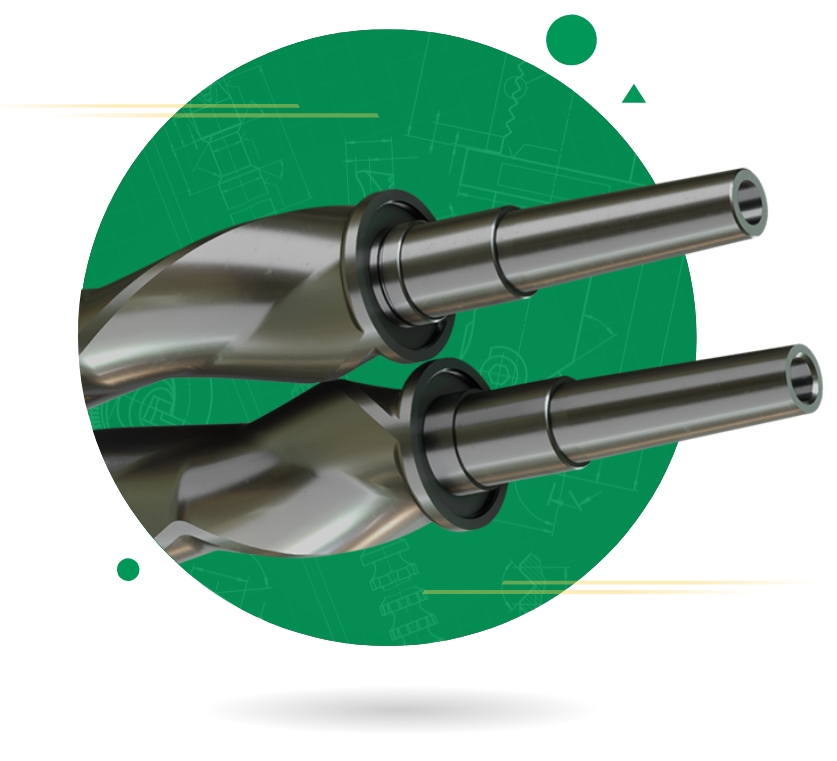

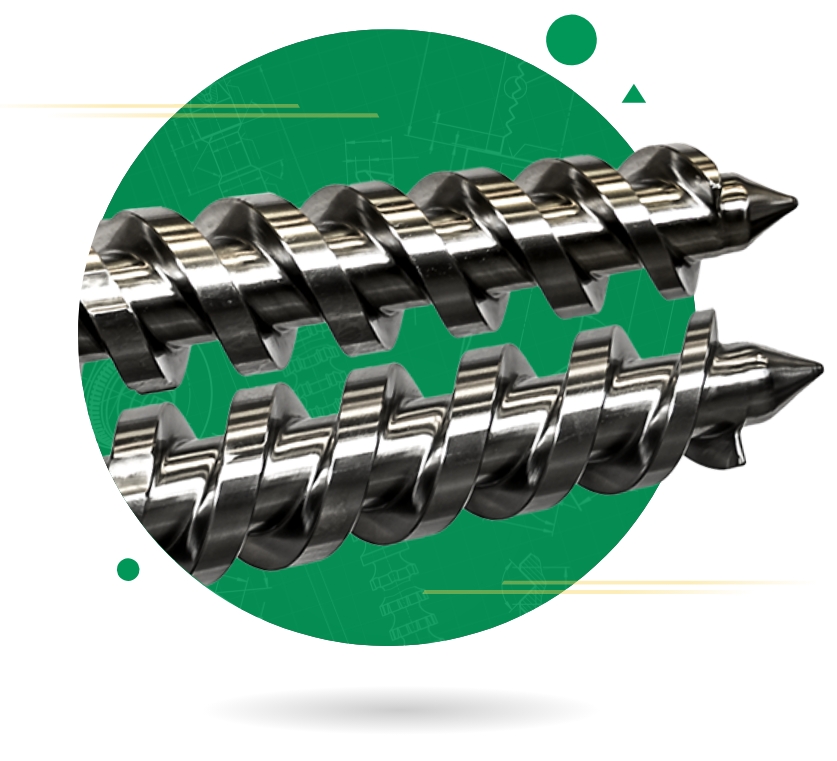

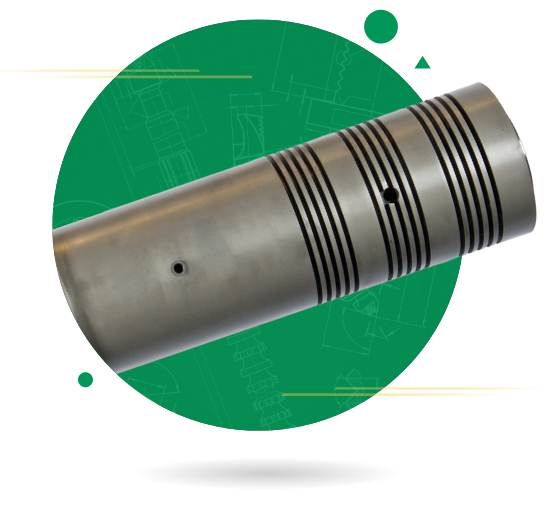

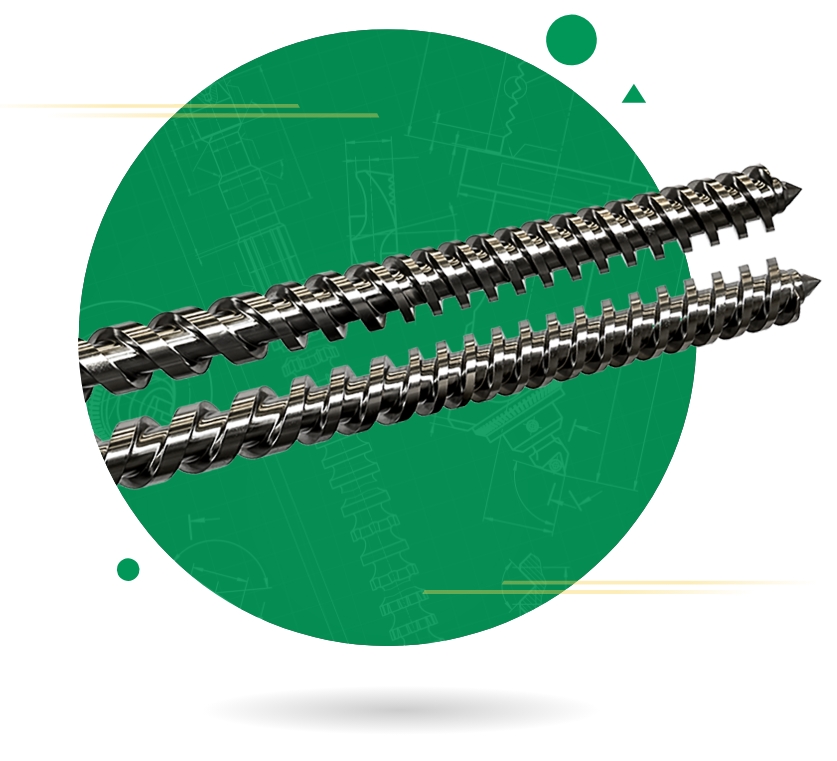

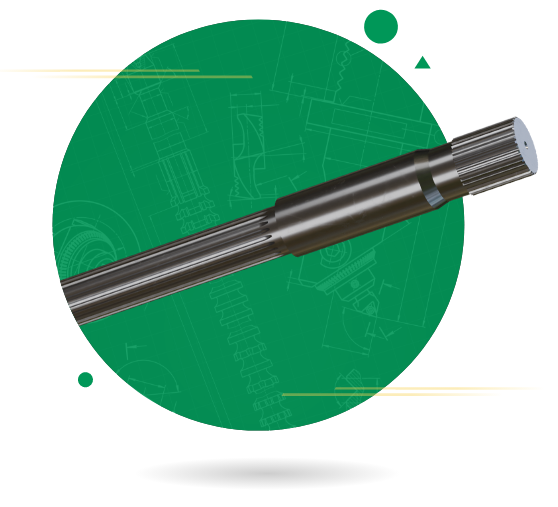

The double-hole barrel, shaped like an inverted “8”, is designed to house two screws, known as twin-screws, within its structure. This unique design allows for the efficient insertion and operation of the screws.

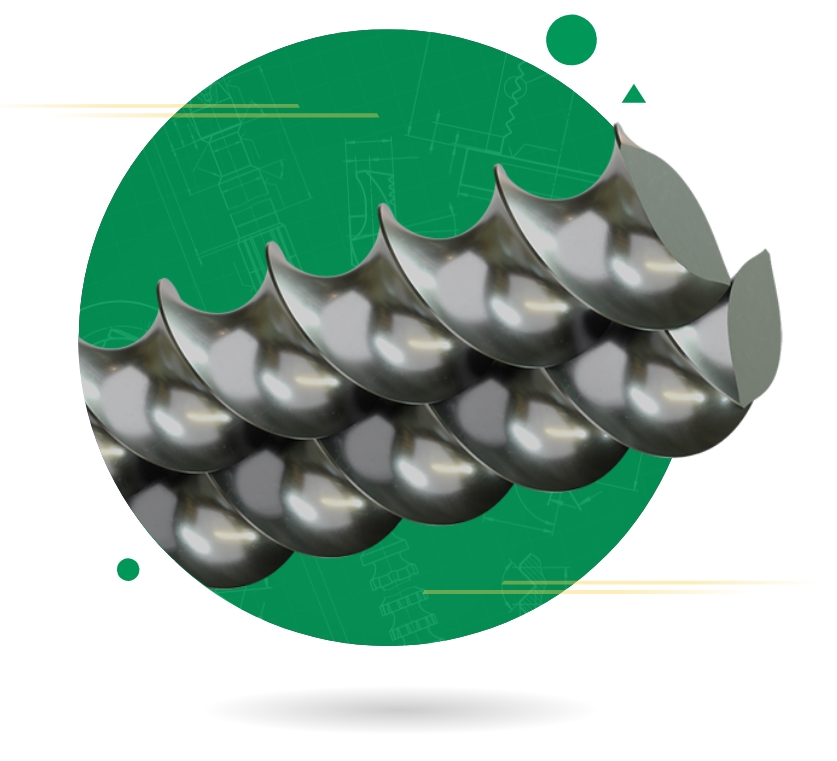

The main role of this barrel is to house the screws and the plastic material. The inner surface of the barrel is where the screws act on the plastic material during the melting process. This component is fundamental in transforming the plastic material from its original state to the desired final state.

The pairing of the double-hole barrel with the twin-screws creates an effective system for material processing. Generally, the barrels are made of nitriding steels, chosen for their strength and durability. However, based on the specific needs of the process, bimetallic barrels can also be used, which combine two different types of metal to achieve optimal characteristics.

Gallery

Discover the technical information about

Barrel

| EUV CODES | TYPE | INLAY BASE ALLOY | PROTECTION LEVEL | HARDNESS |

|---|---|---|---|---|

| EUV34 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV |

| EUV41 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV |

| EUV CODES | TYPE | INLAY BASE ALLOY | TREATMENT | HARDNESS |

| EUV400 | Bimetallic | Fe/Cr | Good against abrasion and corrosion | 62÷69HRC |

| EUV1000W | Bimetallic WC | Ni/Wc | Extreme against abrasion and corrosion | 58÷66HRC |

Related Products

CONTACT US

Tell us what you need

Follow us