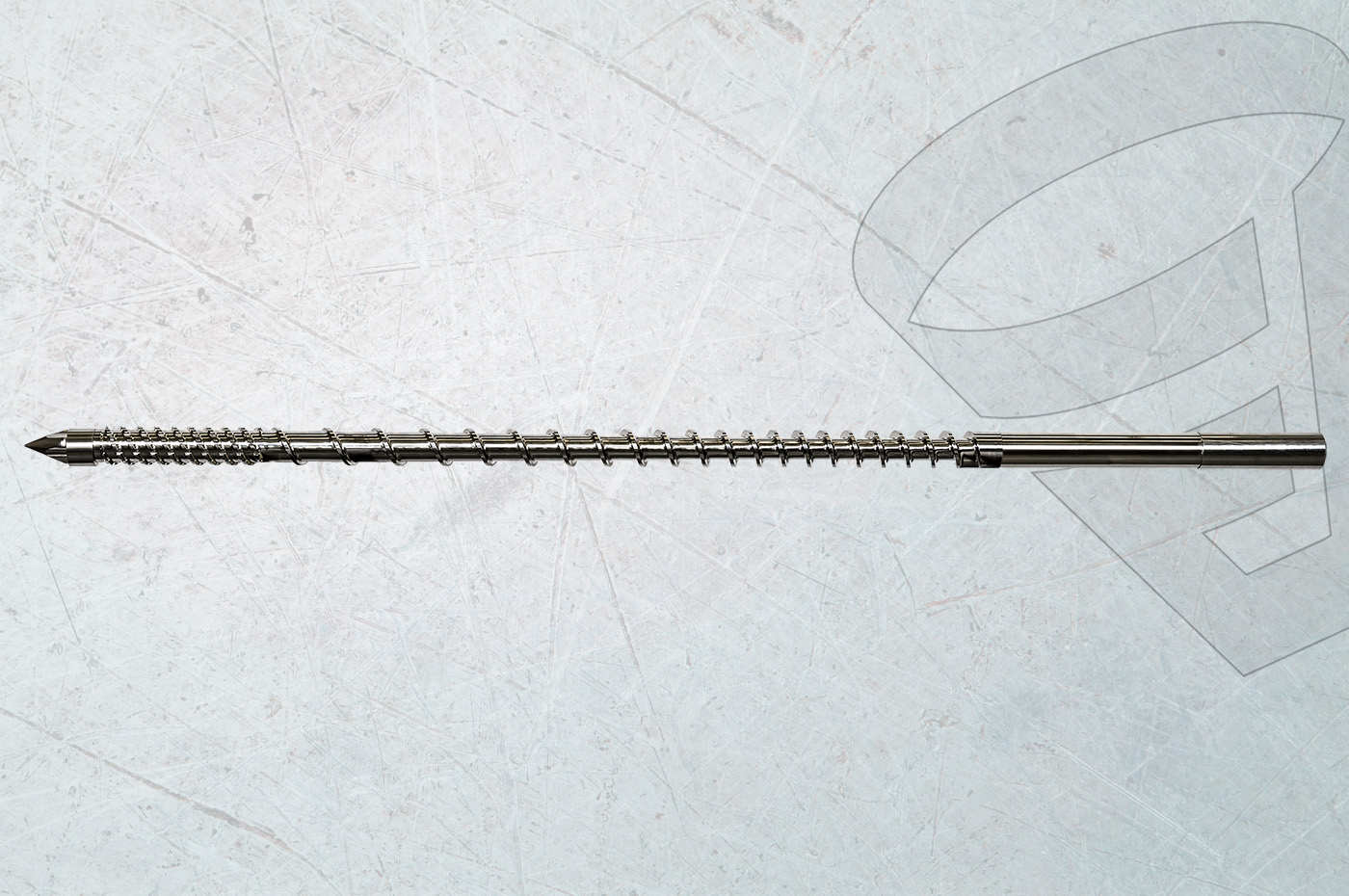

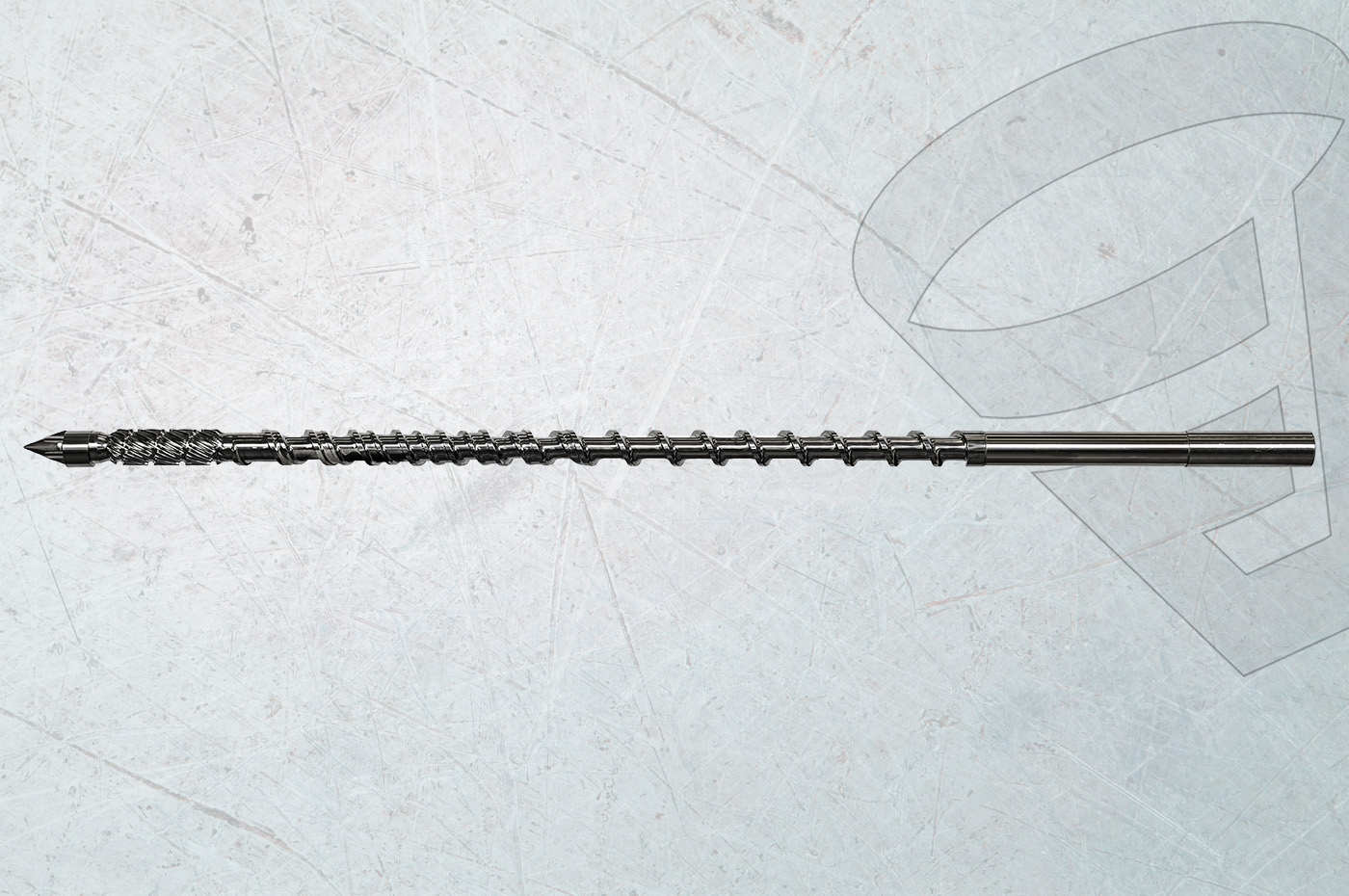

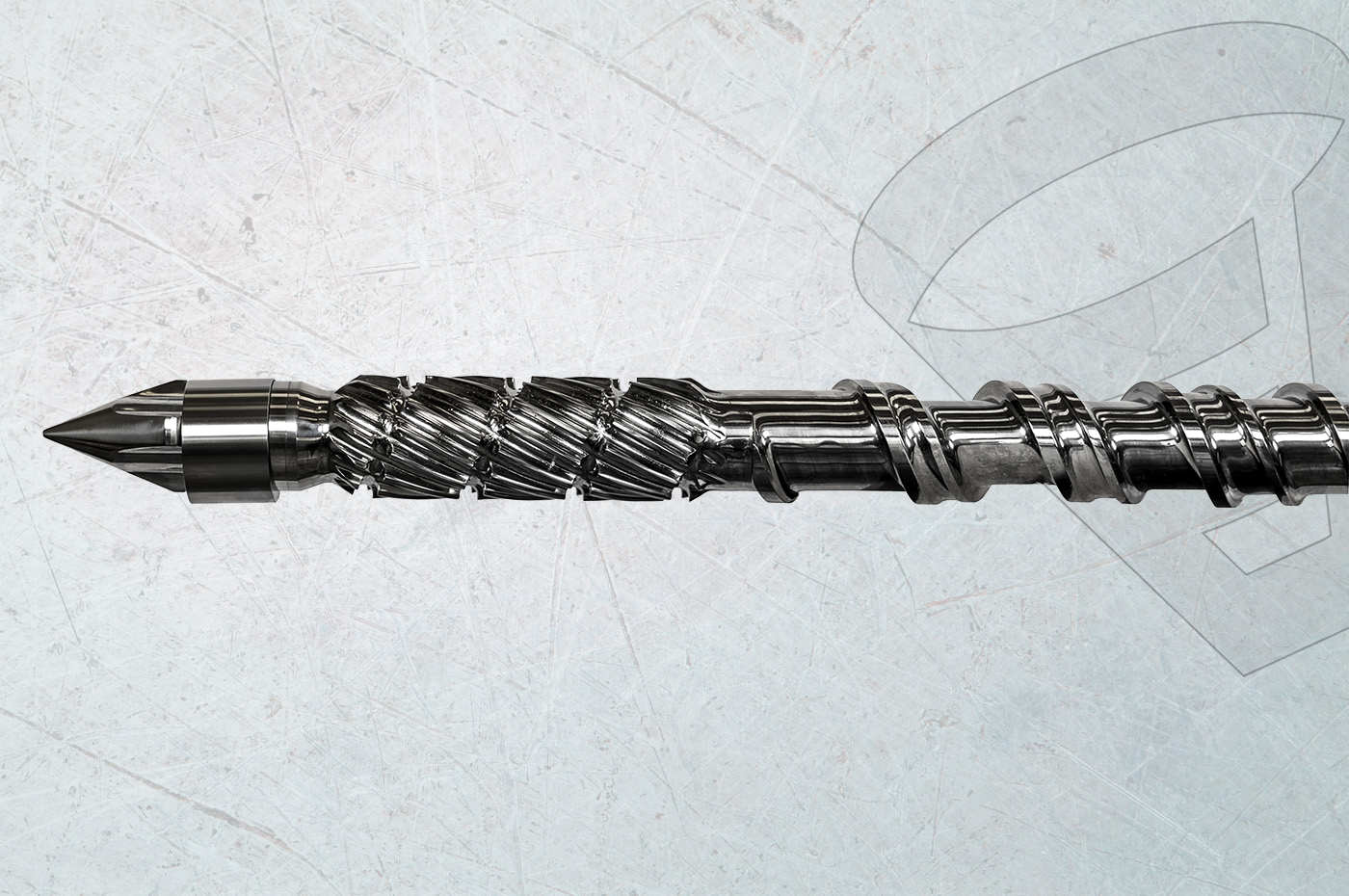

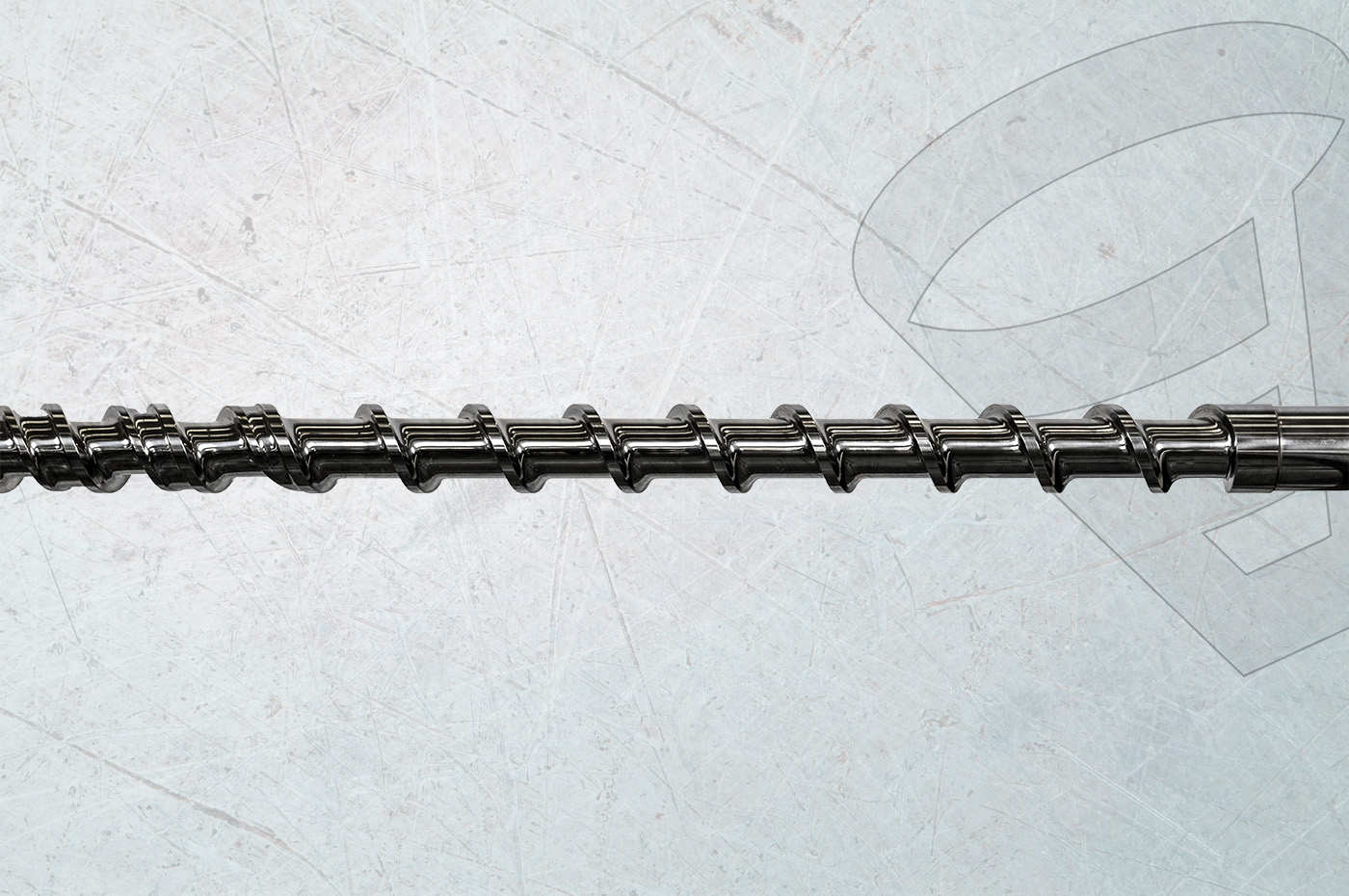

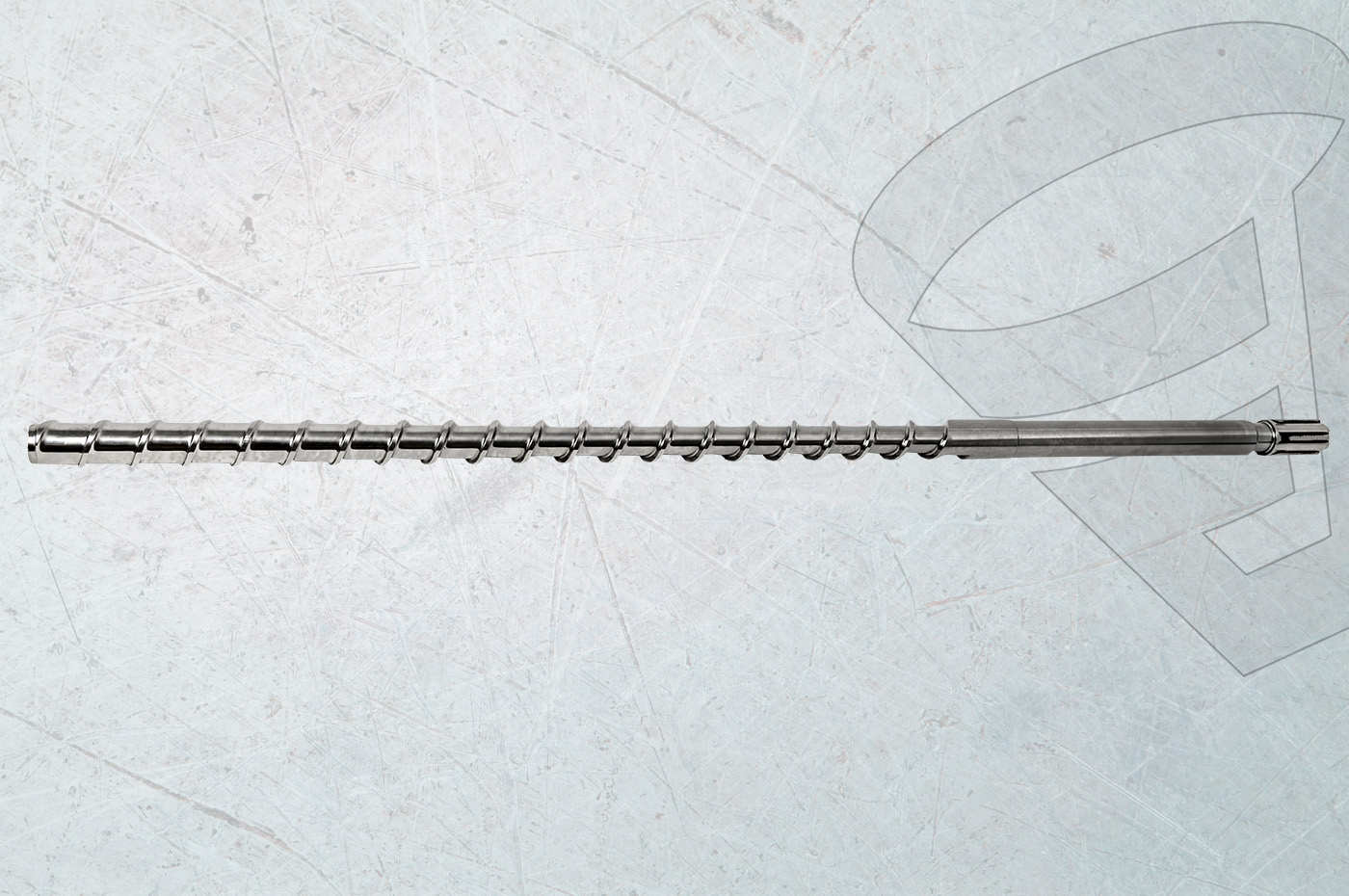

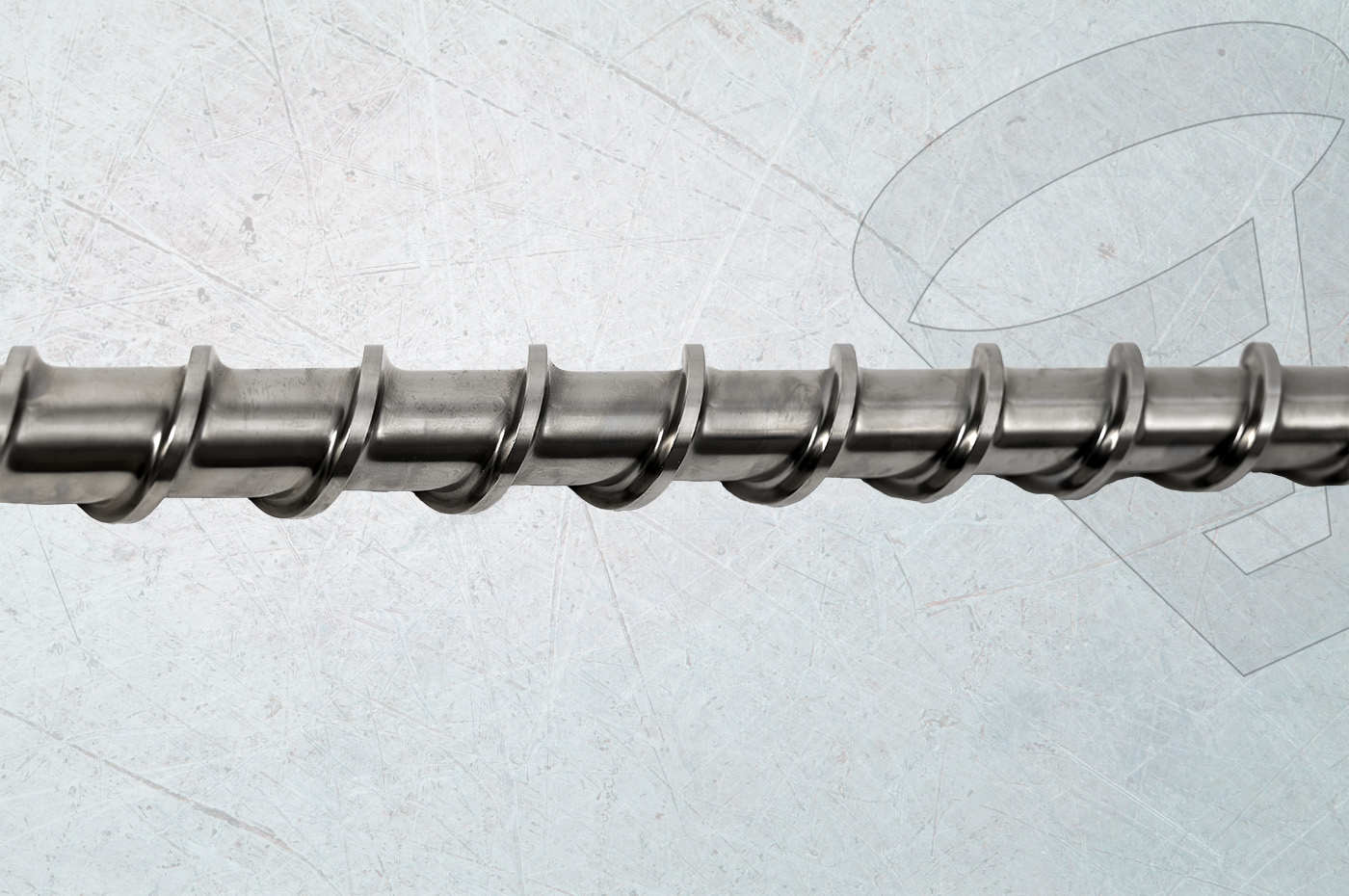

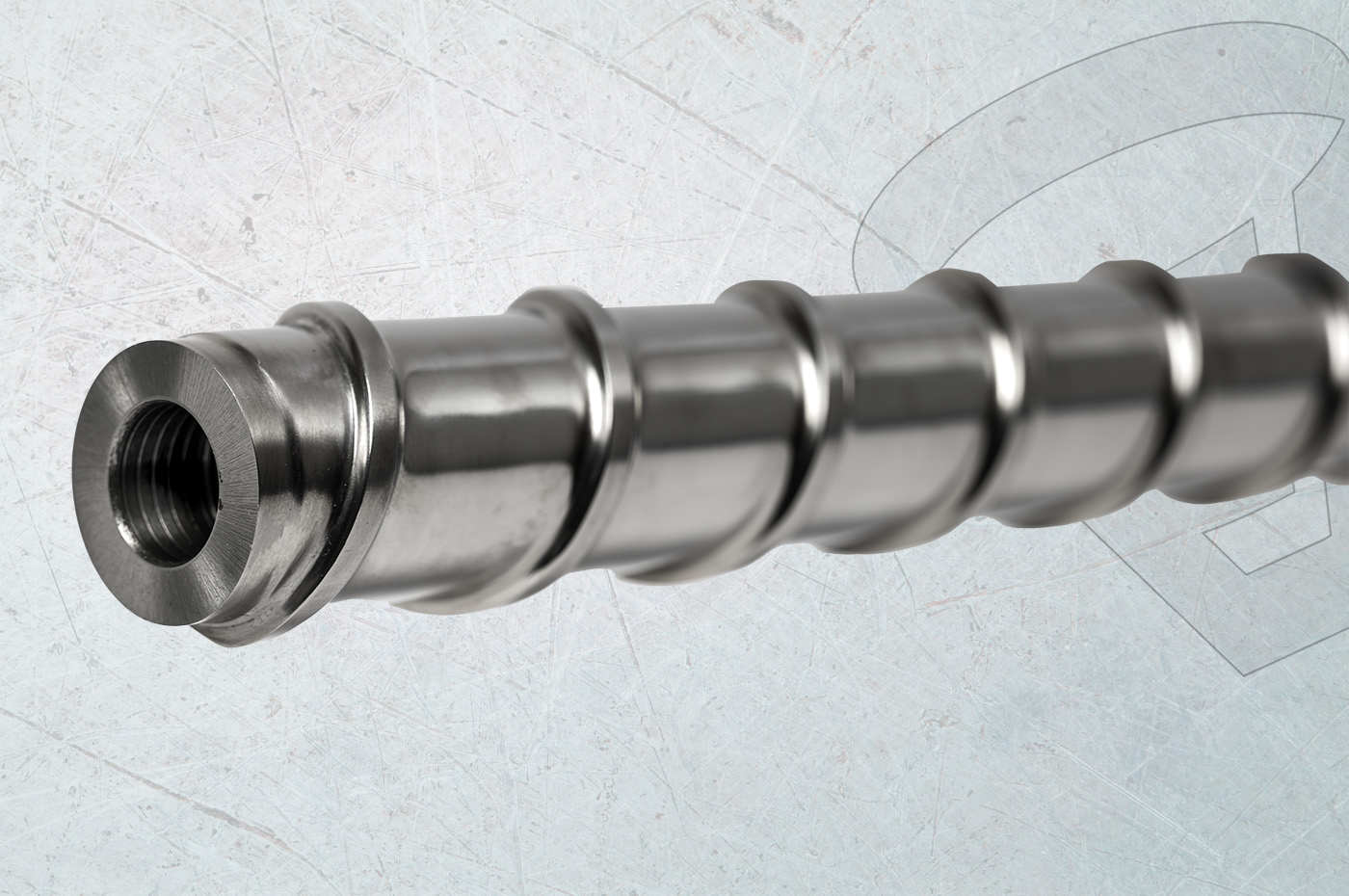

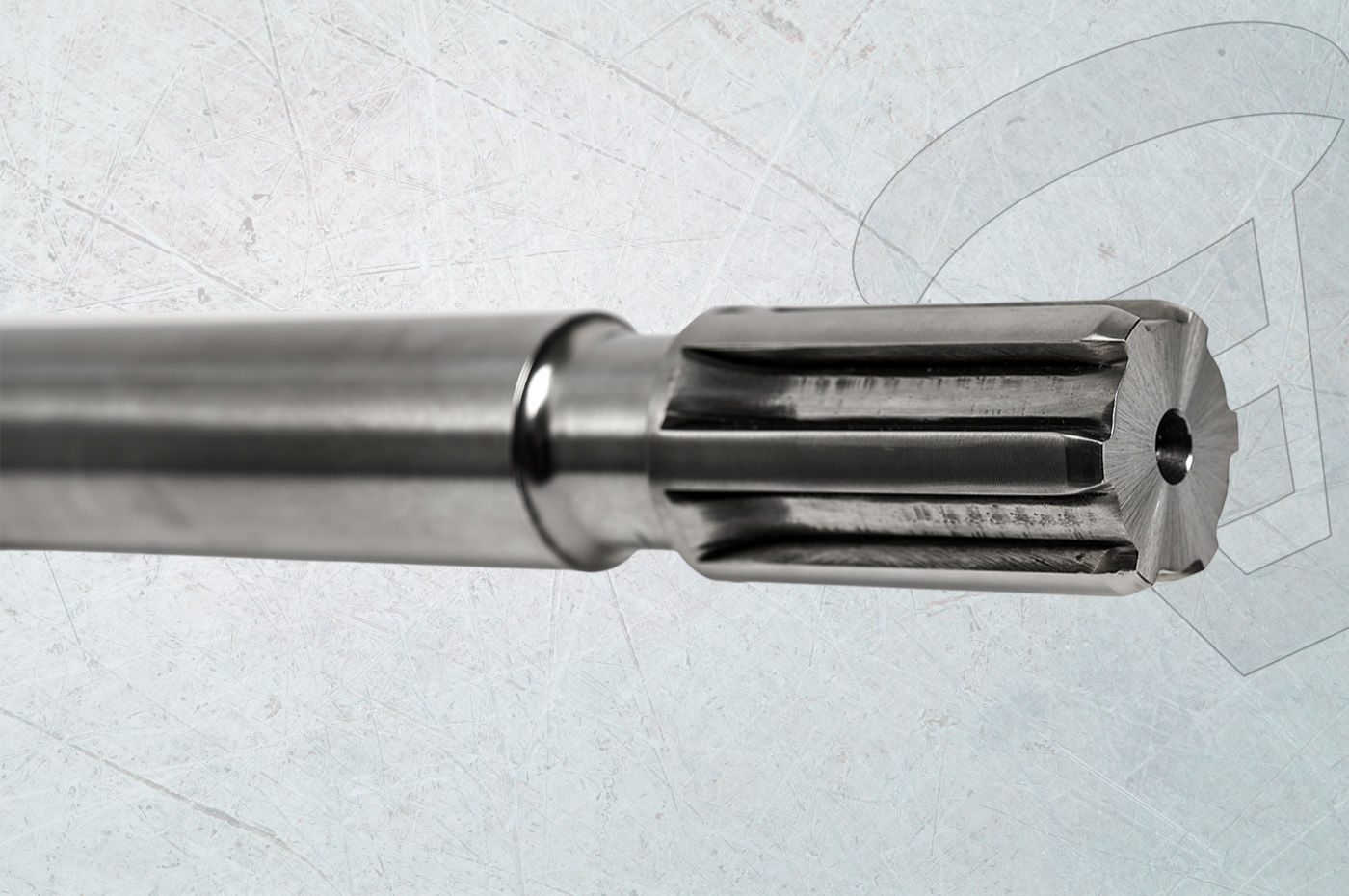

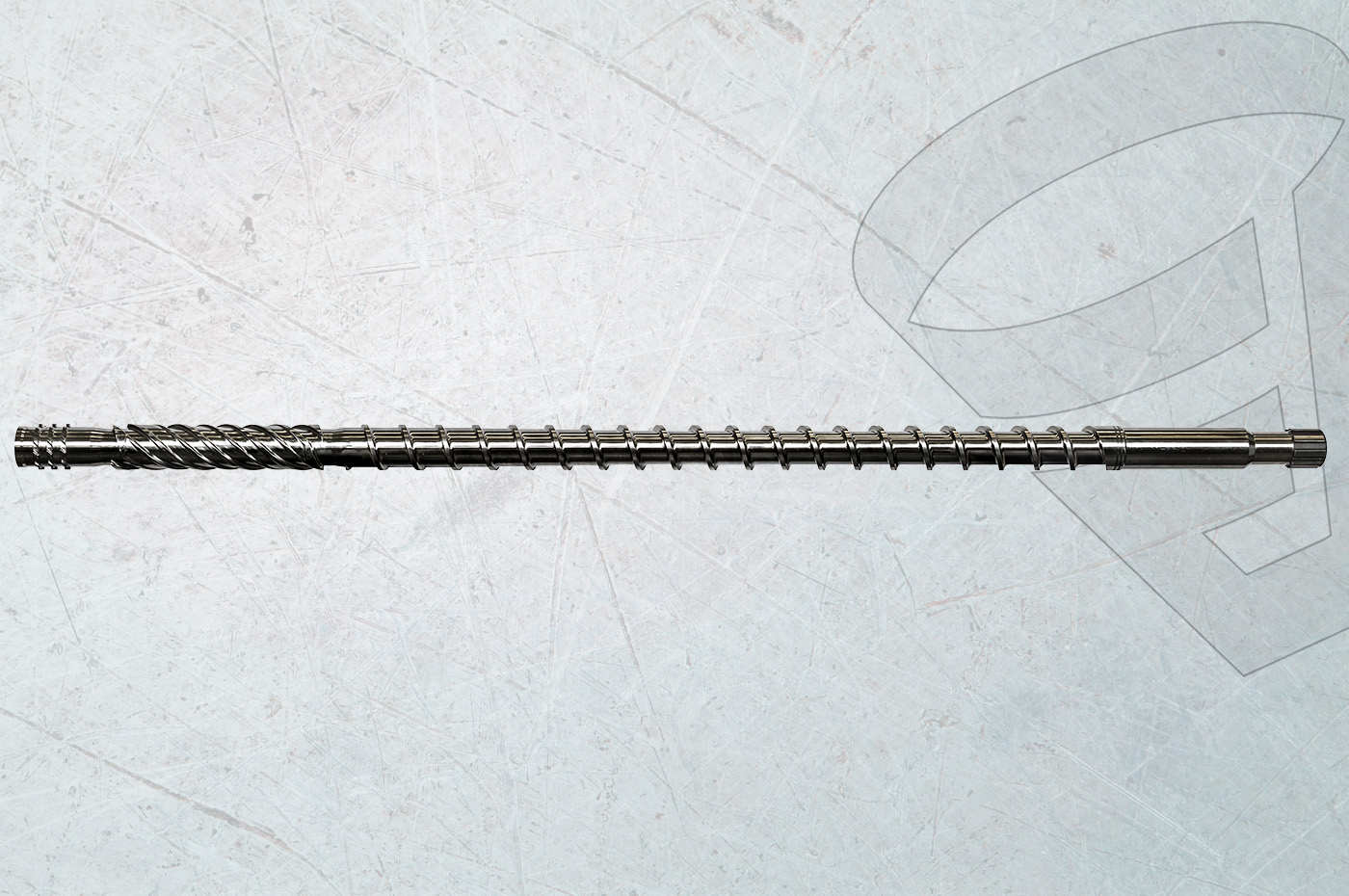

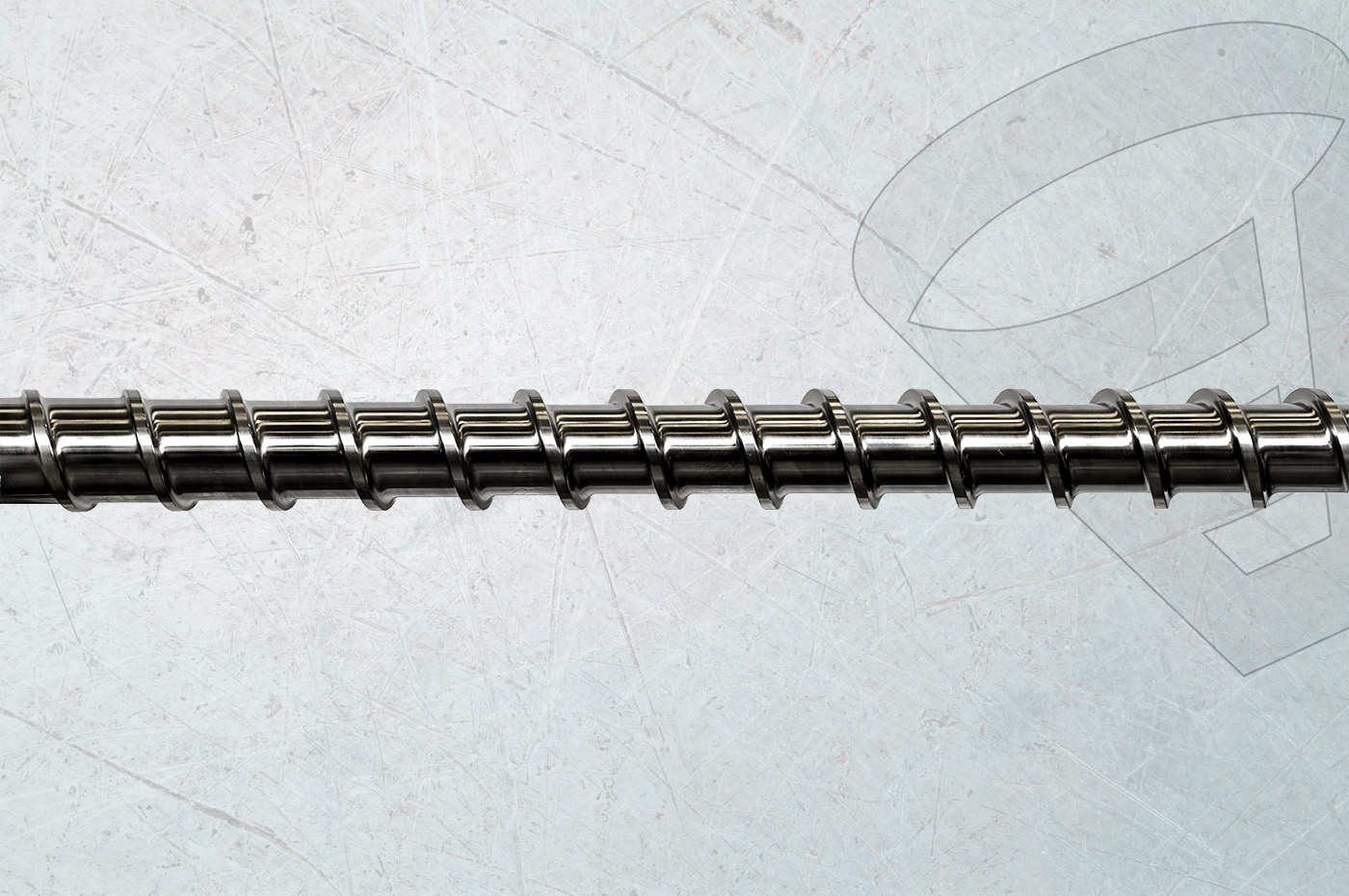

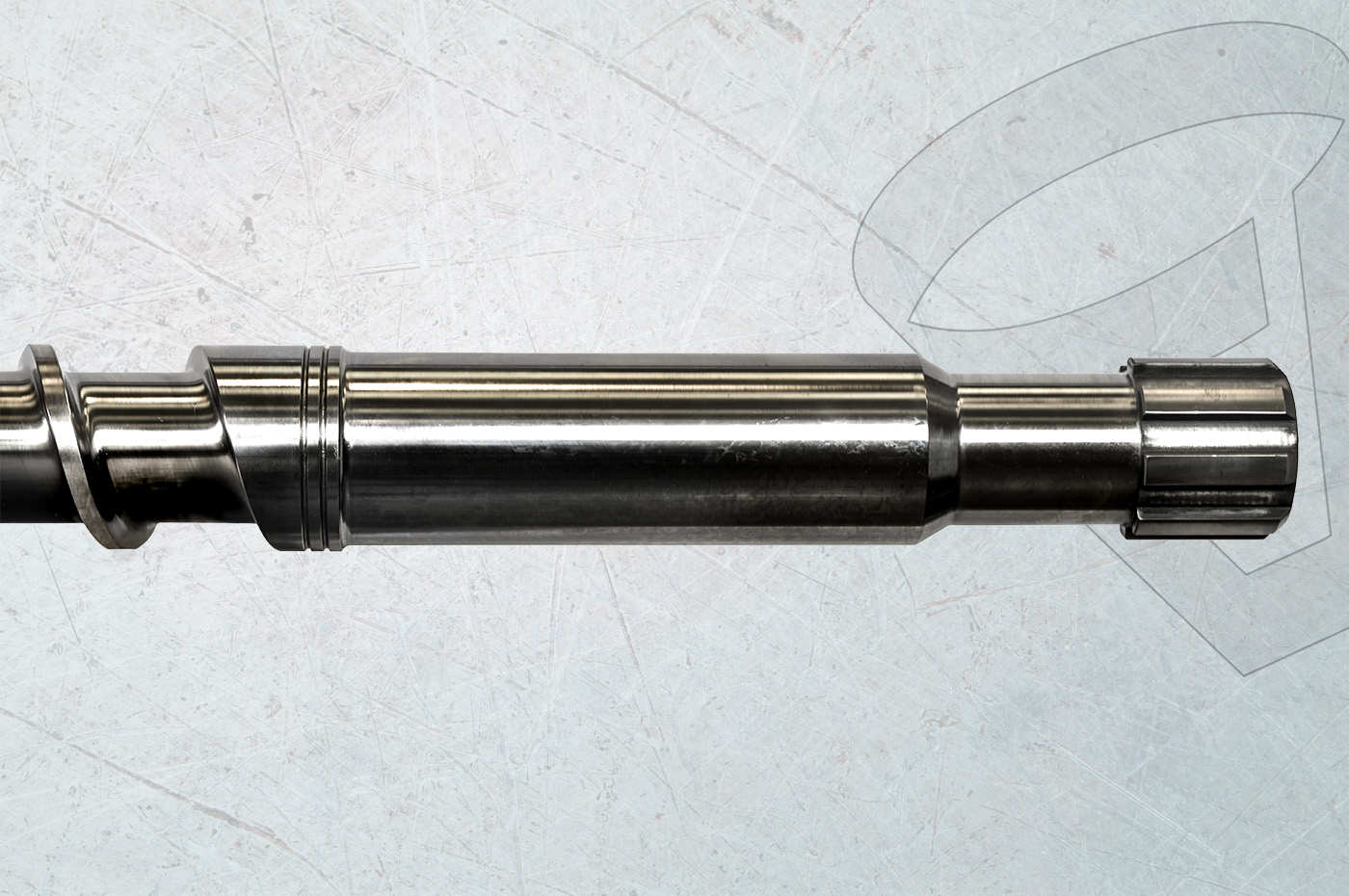

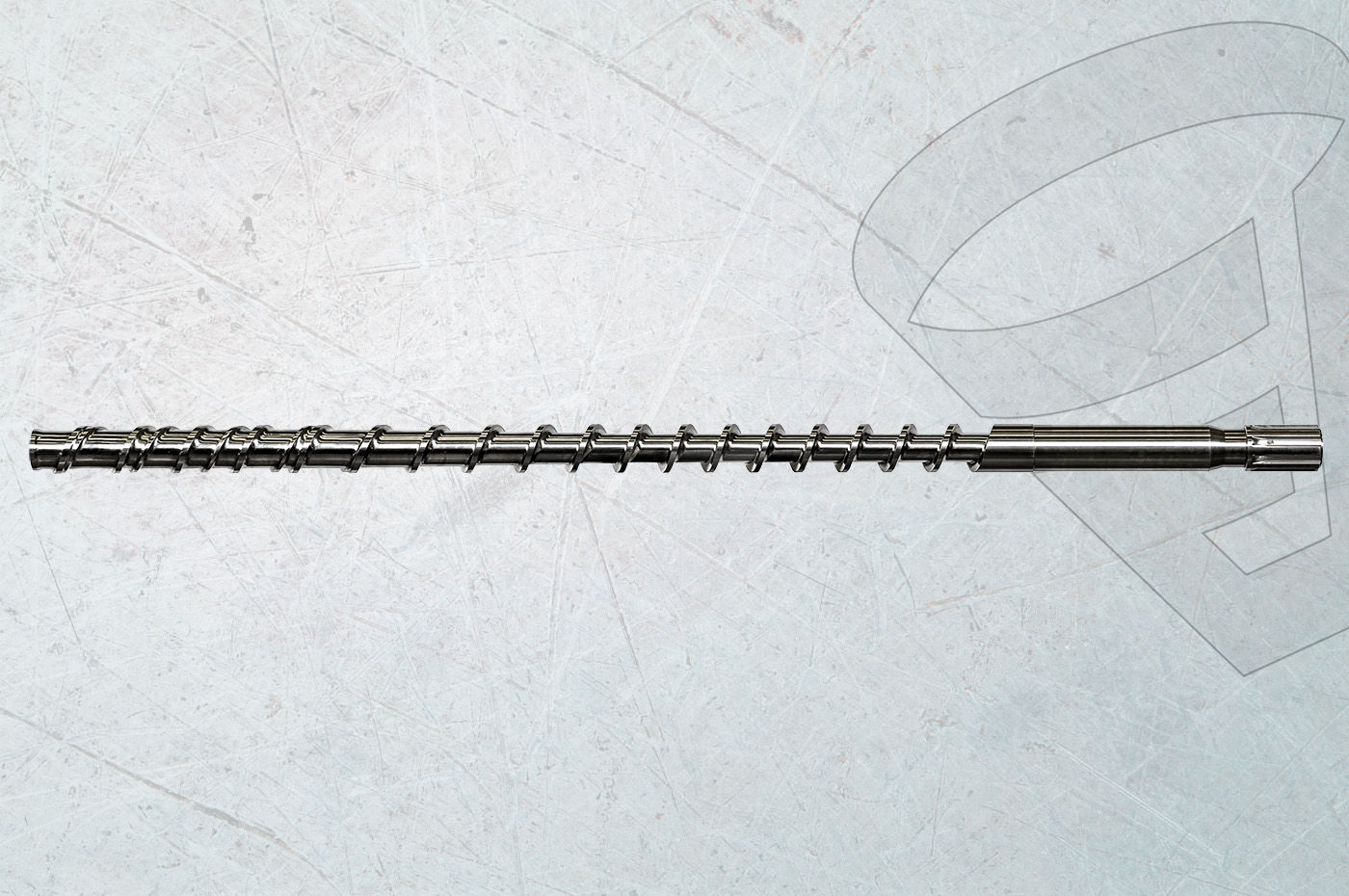

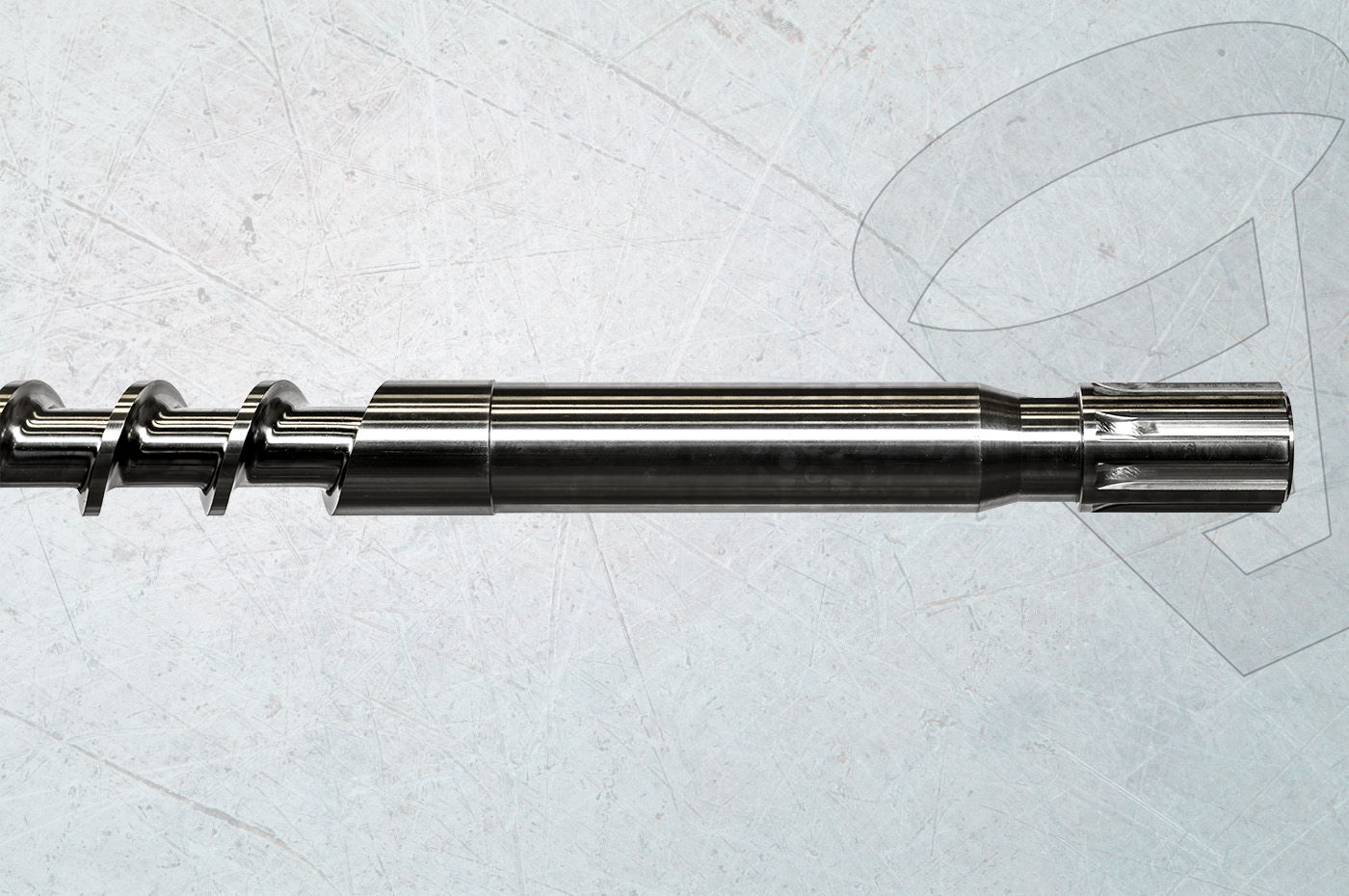

The screw is a crucial component in the injection molding process. A correctly chosen screw geometry can significantly increase the efficiency of the process, allowing for greater production capacity in less time. Therefore, optimal design of the screw geometry is essential to improve production efficiency.

The construction material of the screw is equally important. Similar to barrels, there are three types of screws: nitrided, hardened, and “bimetallic“.

• Nitrided Screws: These screws undergo a specific heat treatment, either gaseous or ionic, which increases their hardness and wear resistance.

• Hardened Screws: They are produced with various types of steel, chosen based on the plastics or compounds to be processed, and subjected to hardening and tempering treatments.

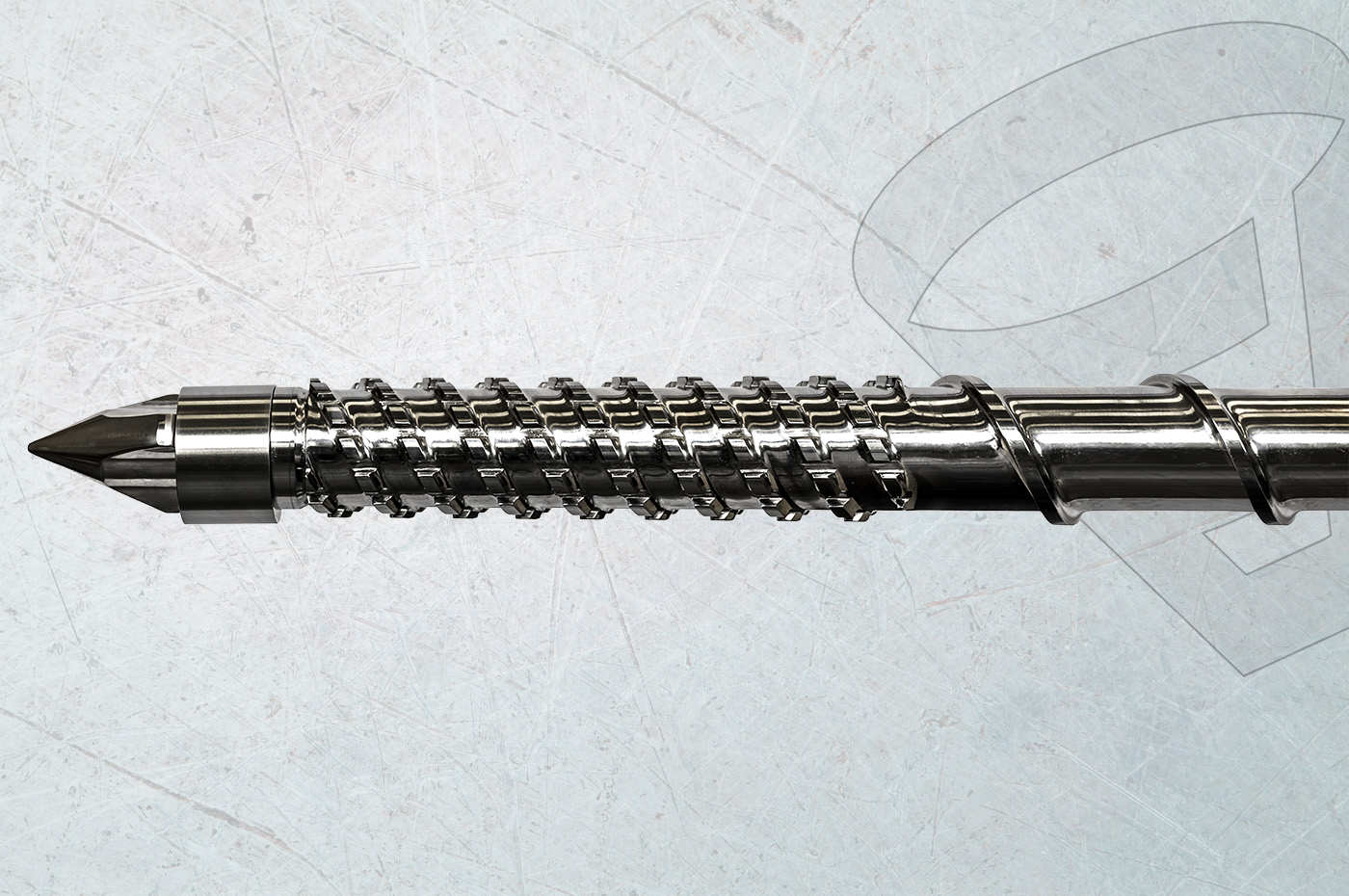

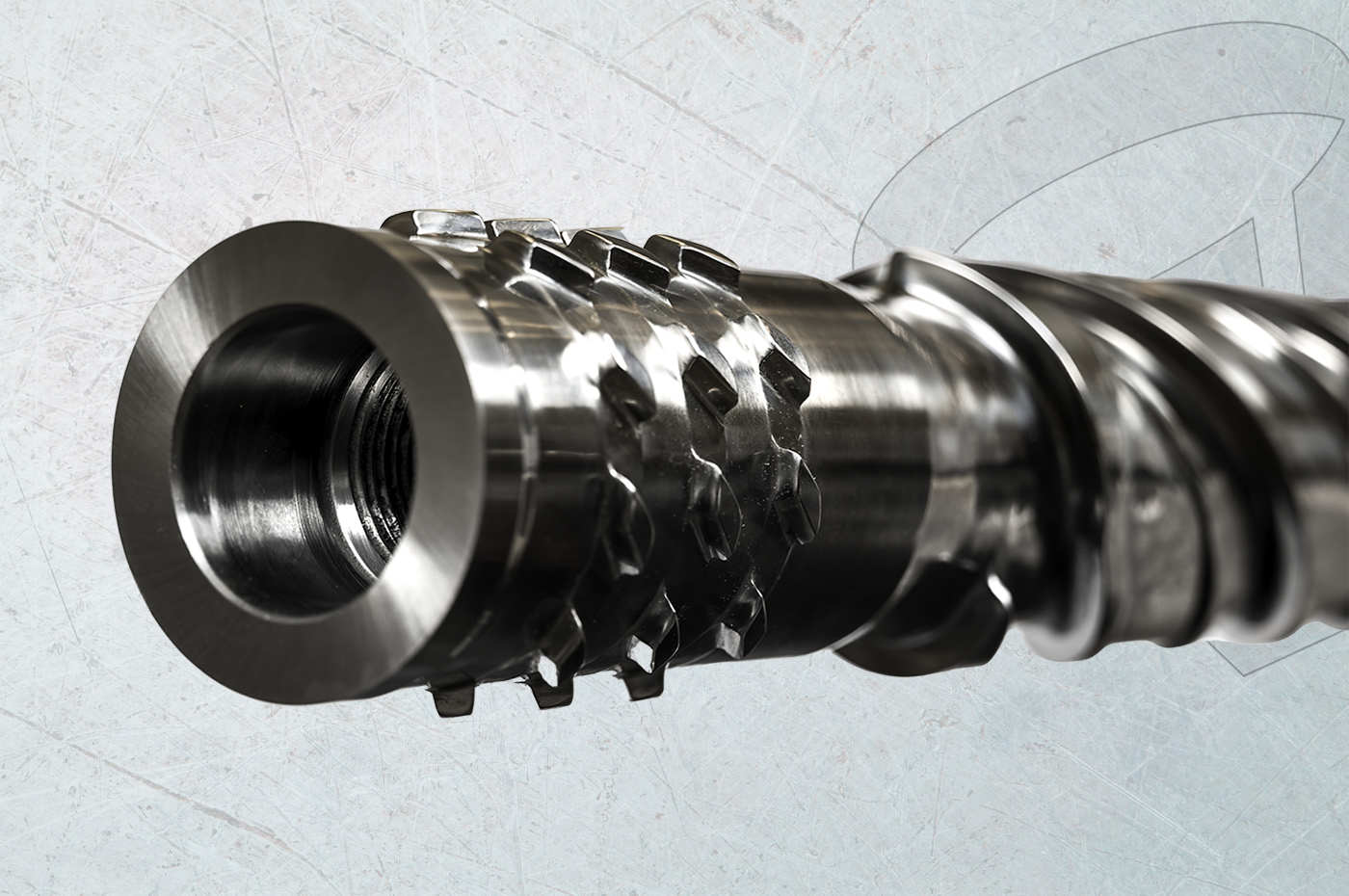

• “Bimetallic” Screws: These are based on the structure of nitrided screws, but with an added feature: the welding of different types of alloys on the top of the flight, which increases their wear resistance. These screws can be regenerated and reused until wear becomes excessive, offering a more sustainable and long-lasting solution for the injection molding process.

The choice of the type of screw will depend on the specific needs of the molding process, the characteristics of the material to be processed, and the dimensions of the screw.

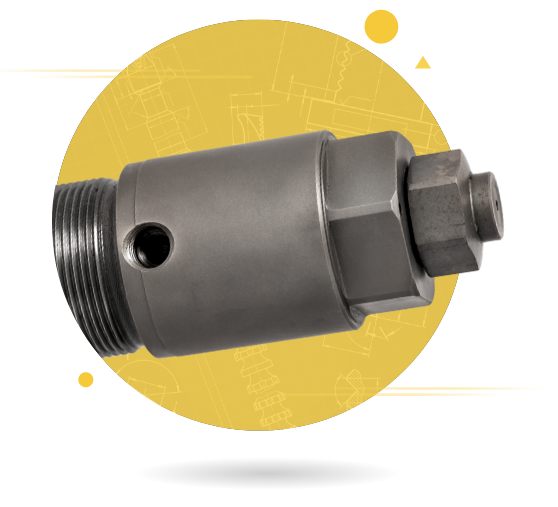

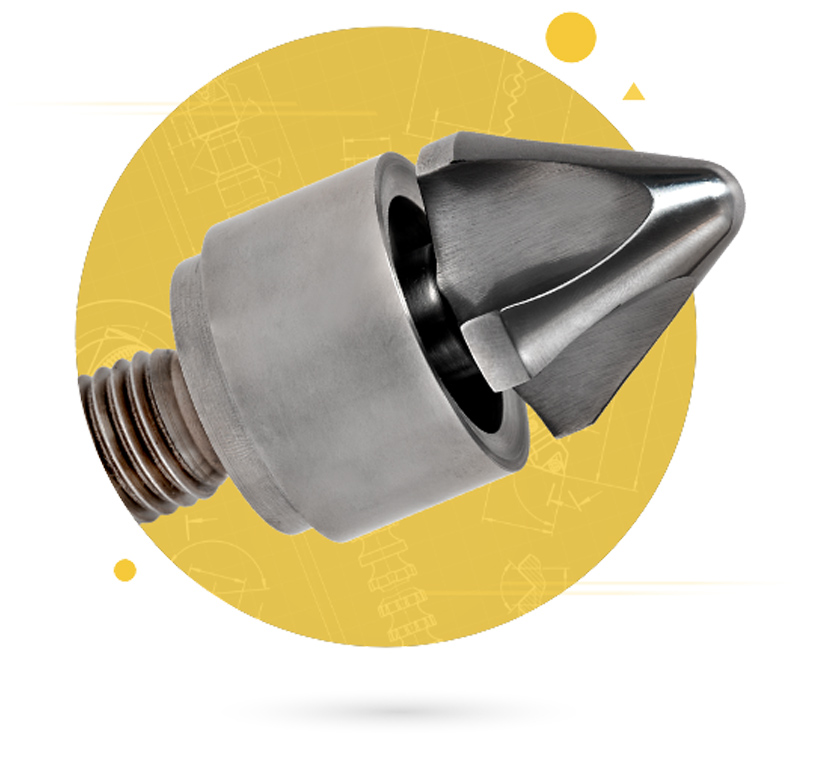

Gallery

Discover the technical information about

Screw

| EUV CODES | STEEL TYPE | TREATMENT | TYPE | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV31 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 700÷800HV | • | • |

| EUV34 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV38 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 500÷600HV | • | • |

| EUV41 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV79 | Cold Work Tool Steel | Hardening & Tempering | Total Hardening | 58÷62HRC | ••• | •• |

| EUV10 | Powder Metallurgy Steel - Protection from Abrasion | Hardening & Tempering | Total Hardening | 58÷64HRC | •••• | • |

| EUV90 | Powder Metallurgy Tool Steels | Special Hardening & Tempering | Total Hardening | 57÷63HRC | •••• | ••••• |

| EUV276 | Superalloy | Blank | Blank | 32÷37HRC | ••• | ••••• |

| EUV50 | Stainless steels | Special Hardening & Tempering / Induction Hardening / Blank | Total or Partial Hardening or Blank | 44÷52HRC | ••• | •••• |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| EUV12 | Co | PTA | 1÷3mm | 46÷50HRC | ••• | ••• |

| EUV5 | Fe | TIG | 1÷3mm | 58÷62HRC | •••• | •• |

| EUV56 | Ni | PTA | 1÷3mm | 46÷58HRC | ••• | ••• |

| EUV60 | Ni | PTA | 1÷3mm | 57÷62HRC | •••• | •••• |

| EUV83 | Ni-Wc | PTA | 1÷3mm | 49÷56HRC | ••••• | •••• |

| EUV700 | Mo | THERMAL SPRAY | 200÷400 μm | 56÷60HRC | ••••• | •••• |

| EUV950 | Wc-Co-Cr | HVOF | 100÷300 μm | 1100÷1300HV | •••••+ | •••••+ |

| EUV CODES | MAIN ALLOY(s) | TECHNOLOGY | THICKNESS | HARDNESS |

|---|---|---|---|---|

| EUVCr Flash | Cr | Plating | 5÷15 μm | 65÷70HRC |

| EUVCr Thick | Cr | Plating | 50÷150 μm | 65÷70HRC |

| EUVCrNOX | CrNox | PVD Iridescent Rainbow | 2÷6 μm | 2000÷2500HV |

| EUVPro | AlCrN | PVD Dark Grey | 2÷8 μm | 2800÷3000HV |

| EUVZrN | ZrN | PVD Light Yellow | 2÷4 μm | 2600÷3100HV |

| EUVTiN | TiN | PVD Yellow Gold | 2÷4 μm | 2000÷2500HV |

| EUVCrN | CrN | PVD Silver Grey | 2÷4 μm | 1800÷2200HV |

| EUVDlC | C | PACVD Rainbow Black | 2÷4 μm | 2000÷2500HV |

| EUV950 INCAPSULATED | Wc-Co-Cr | HVOF | 100÷300 μm | 1100÷1300HV |

| EUVFeO | FeO | Thermochemical treatment Black | 4÷5 μm | 850÷900HV |

Related Products

CONTACT US

Tell us what you need

Follow us