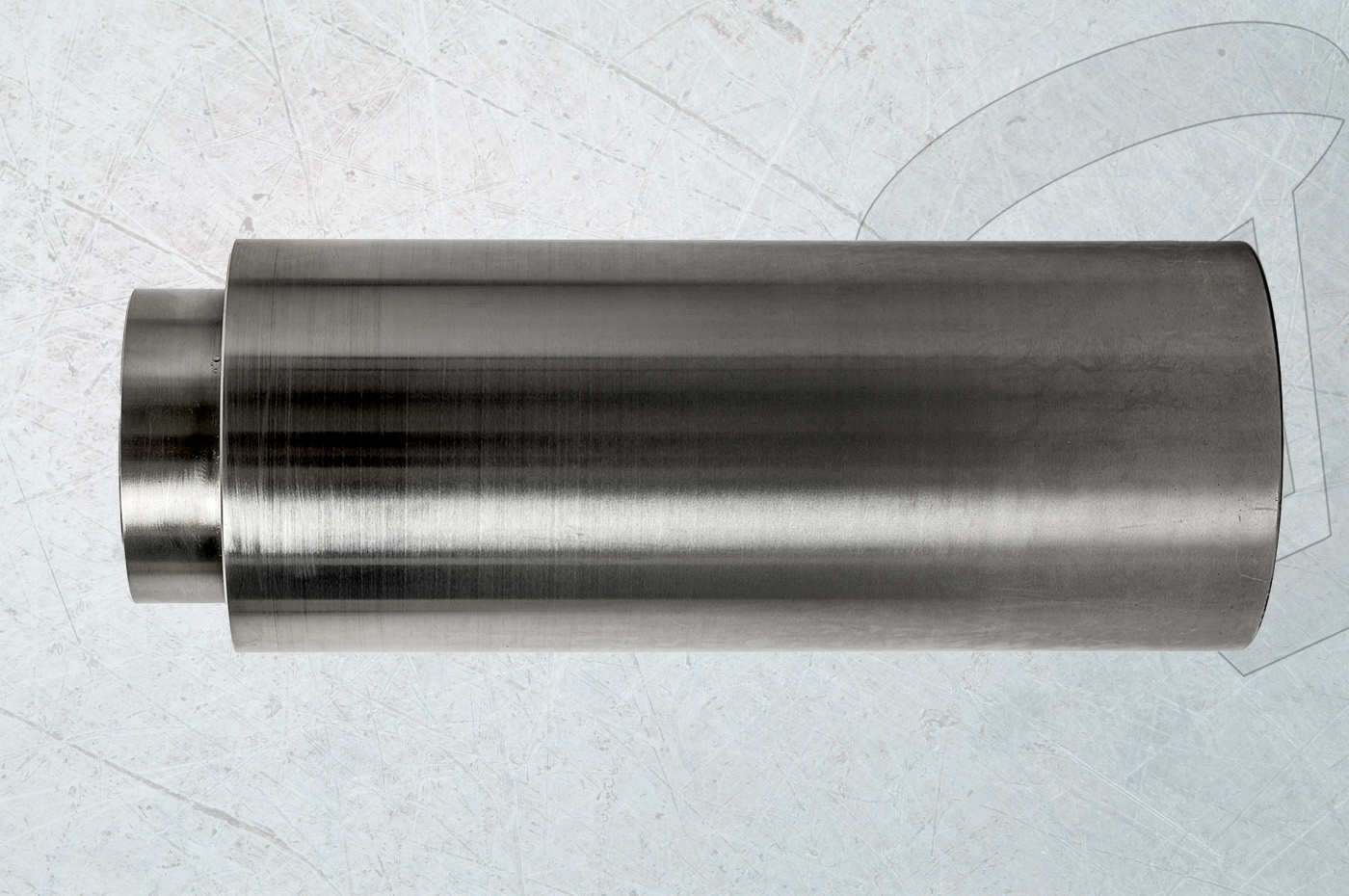

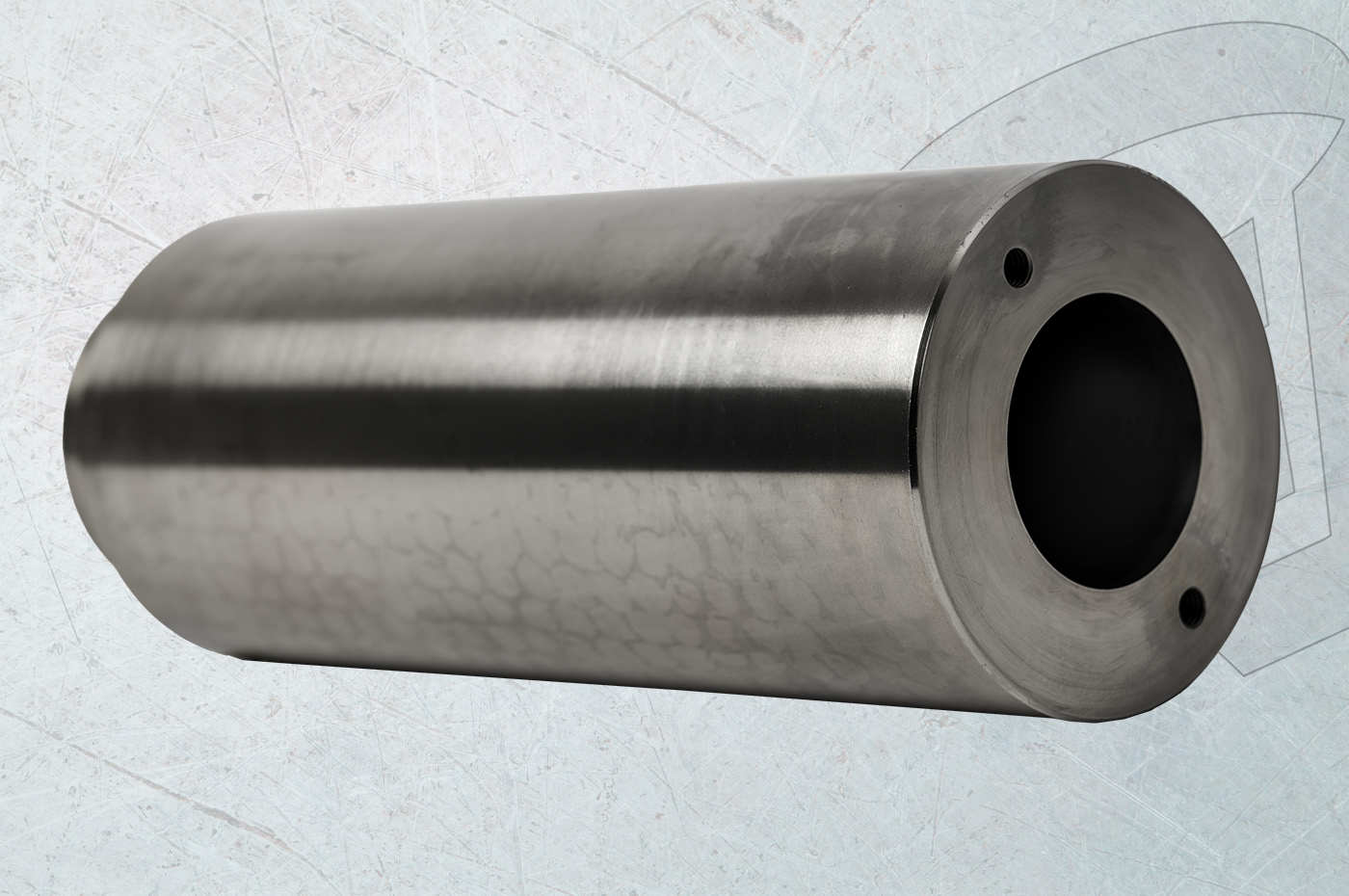

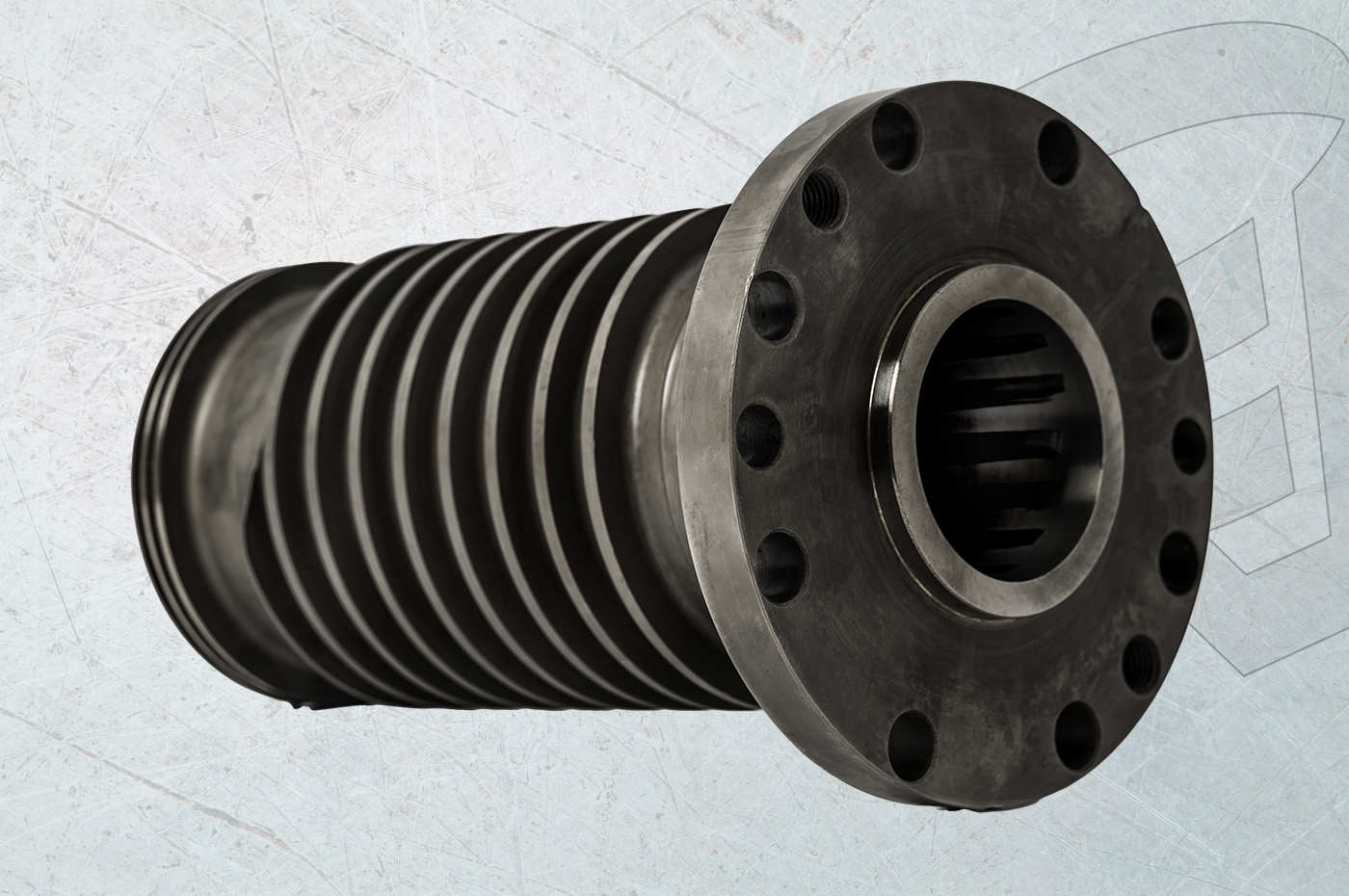

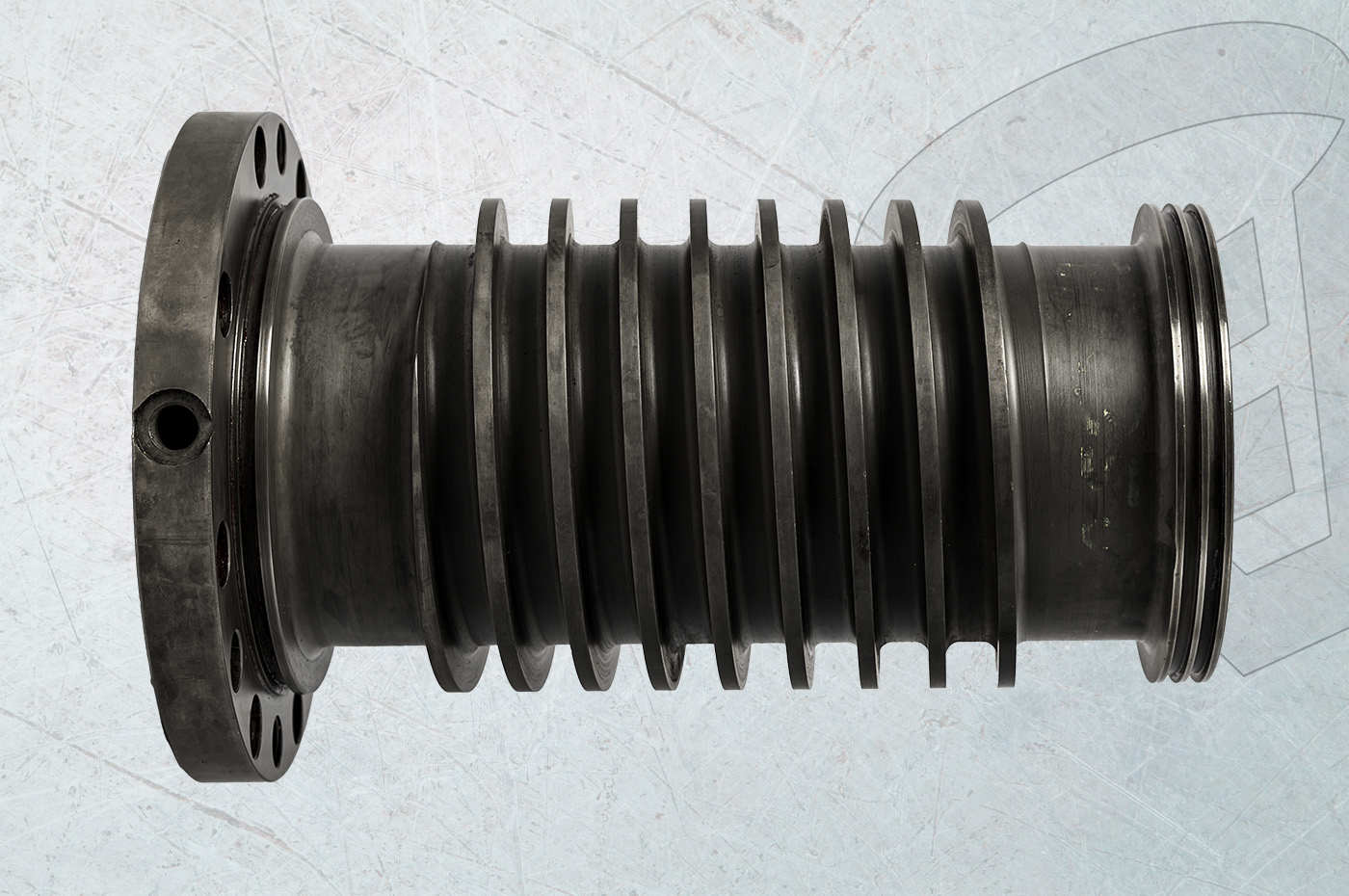

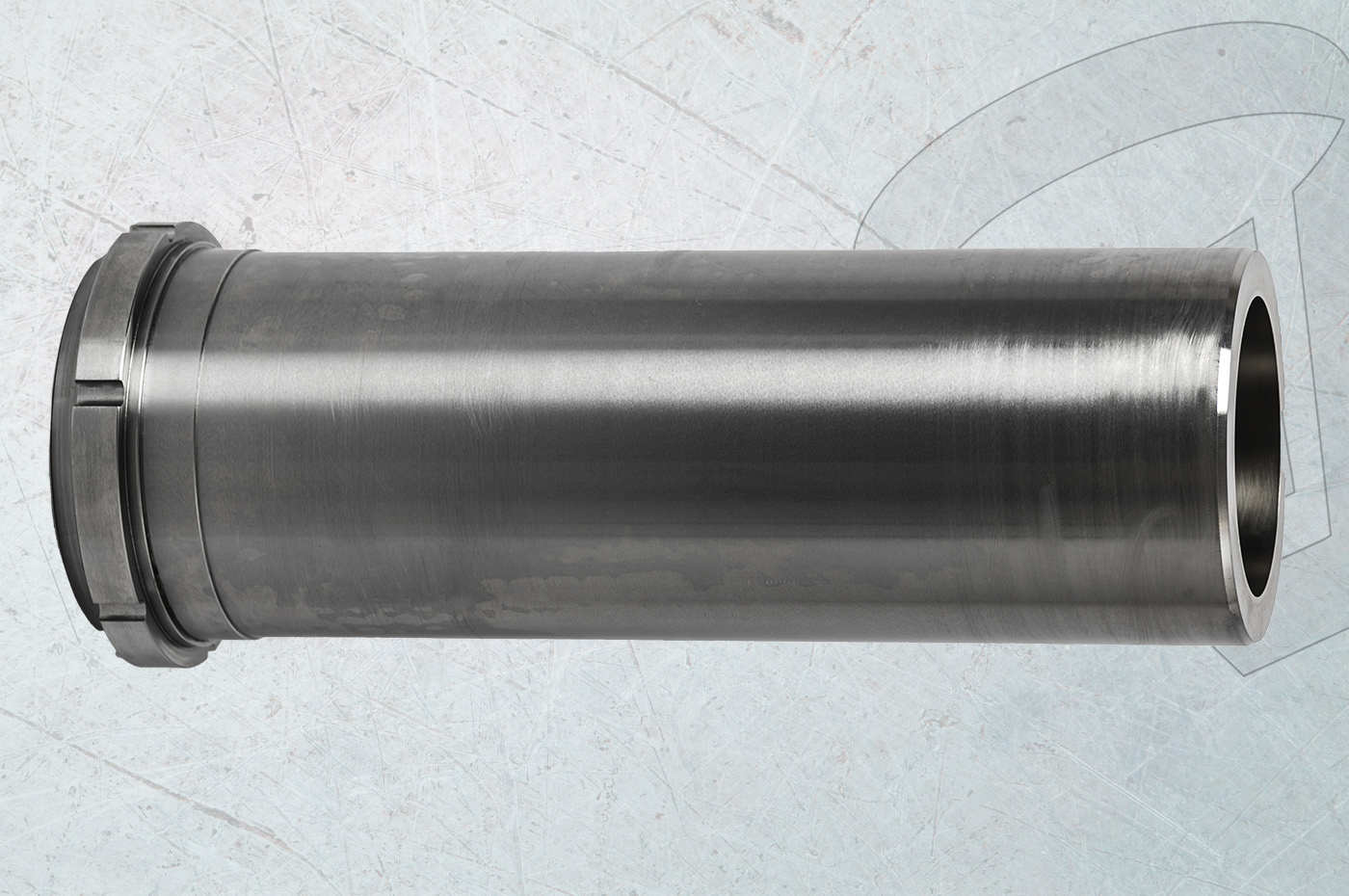

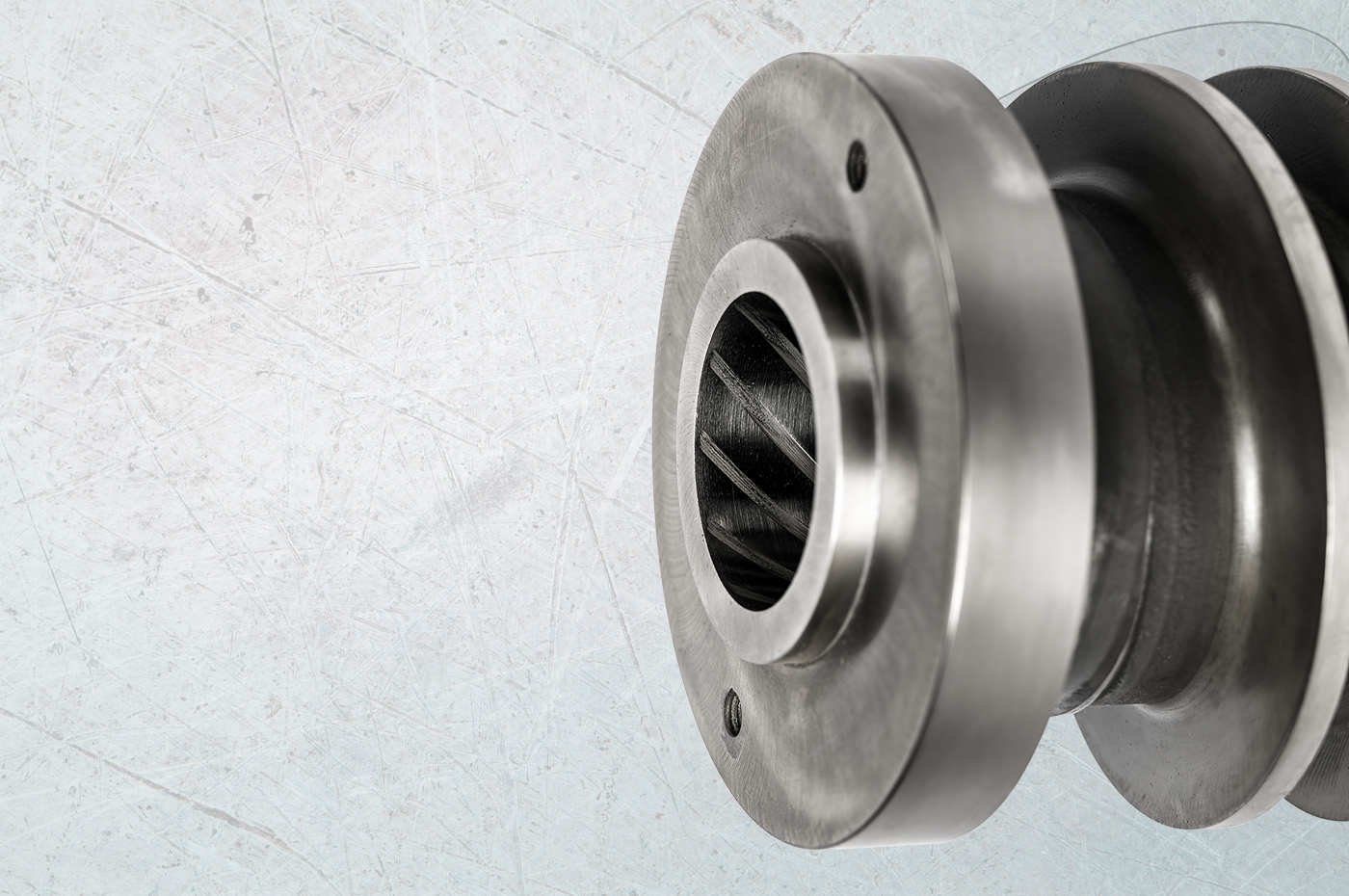

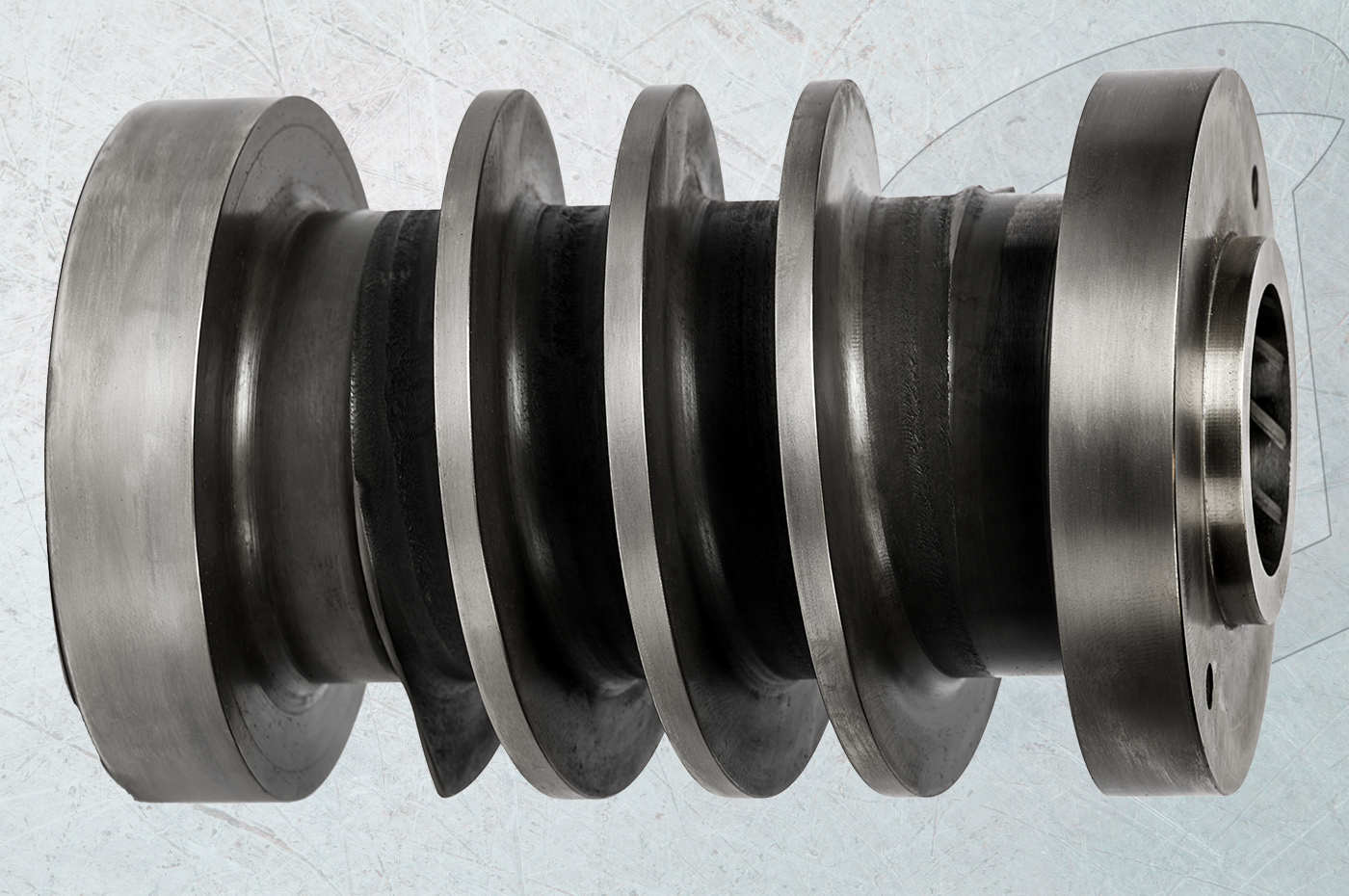

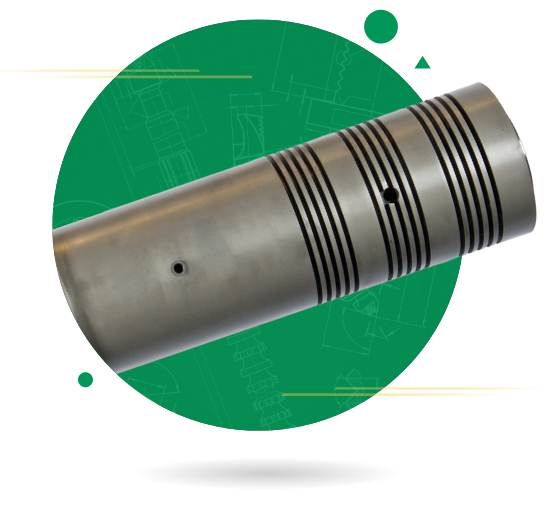

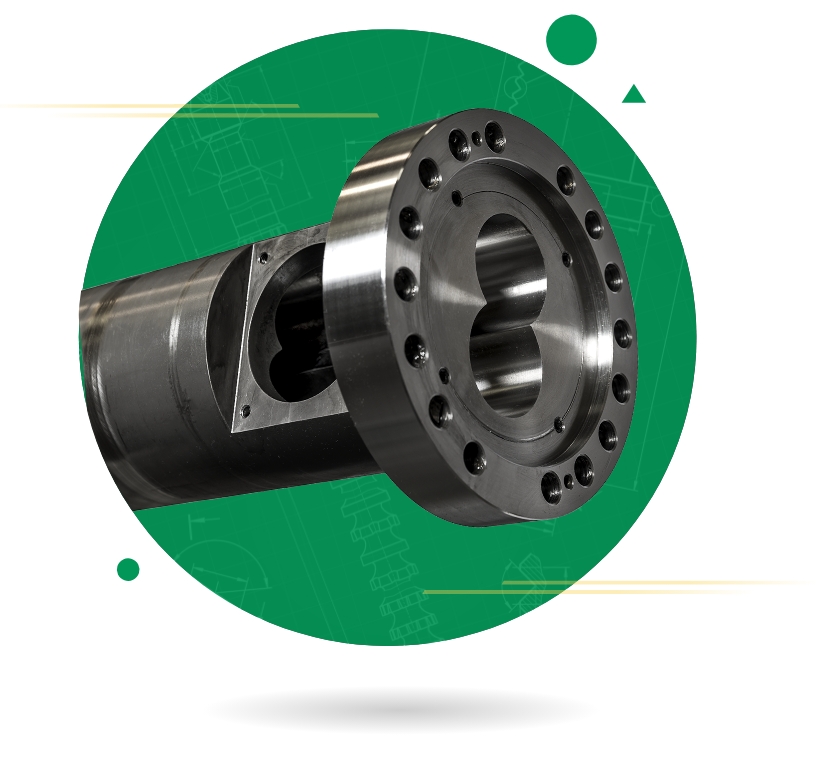

The Feed Sleeve is a crucial element in the extrusion system, especially when it is properly synchronized with the hopper underbody and matched with a correct screw geometry. This component is responsible for feeding the extruder with the plastic material.

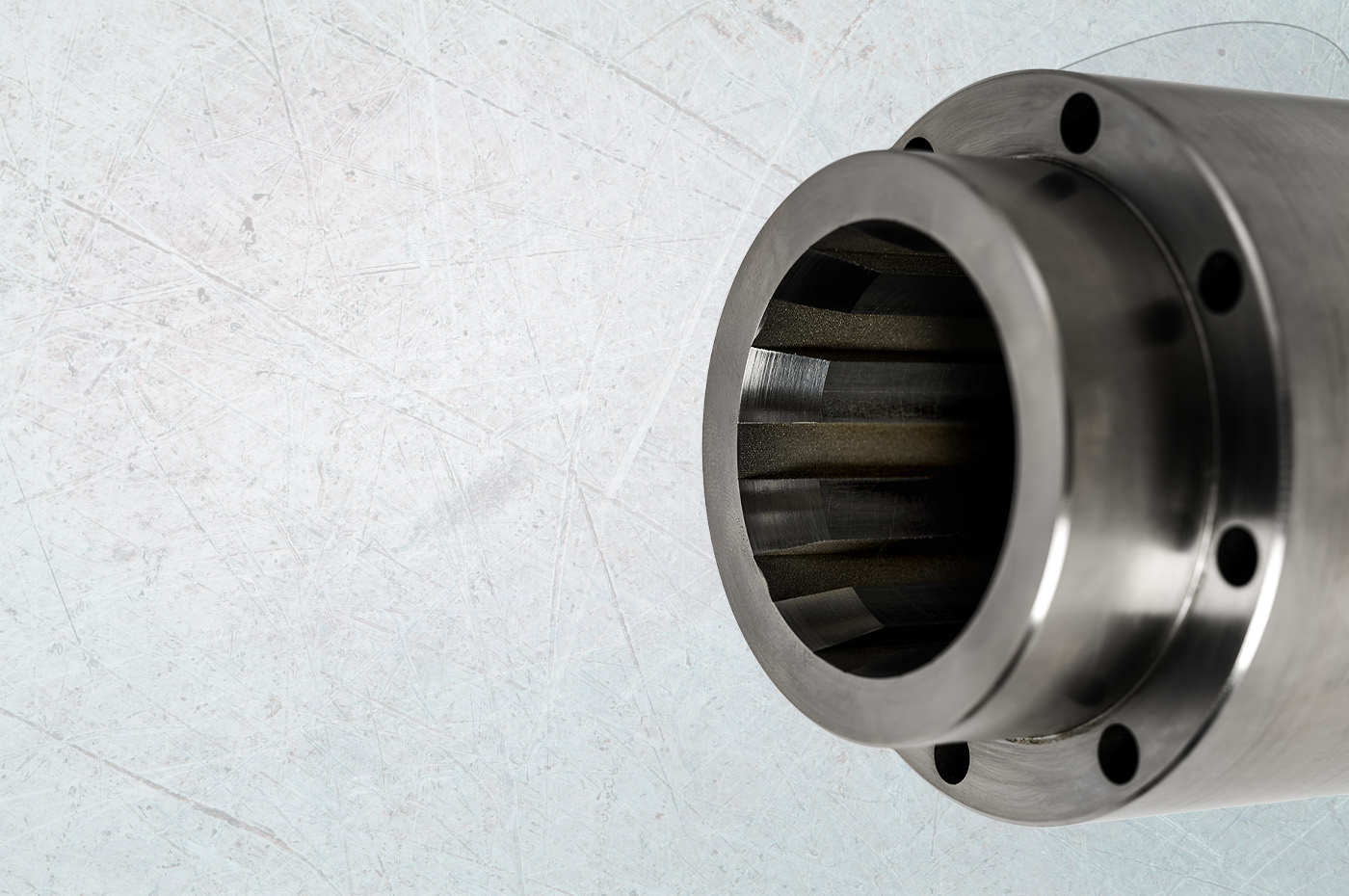

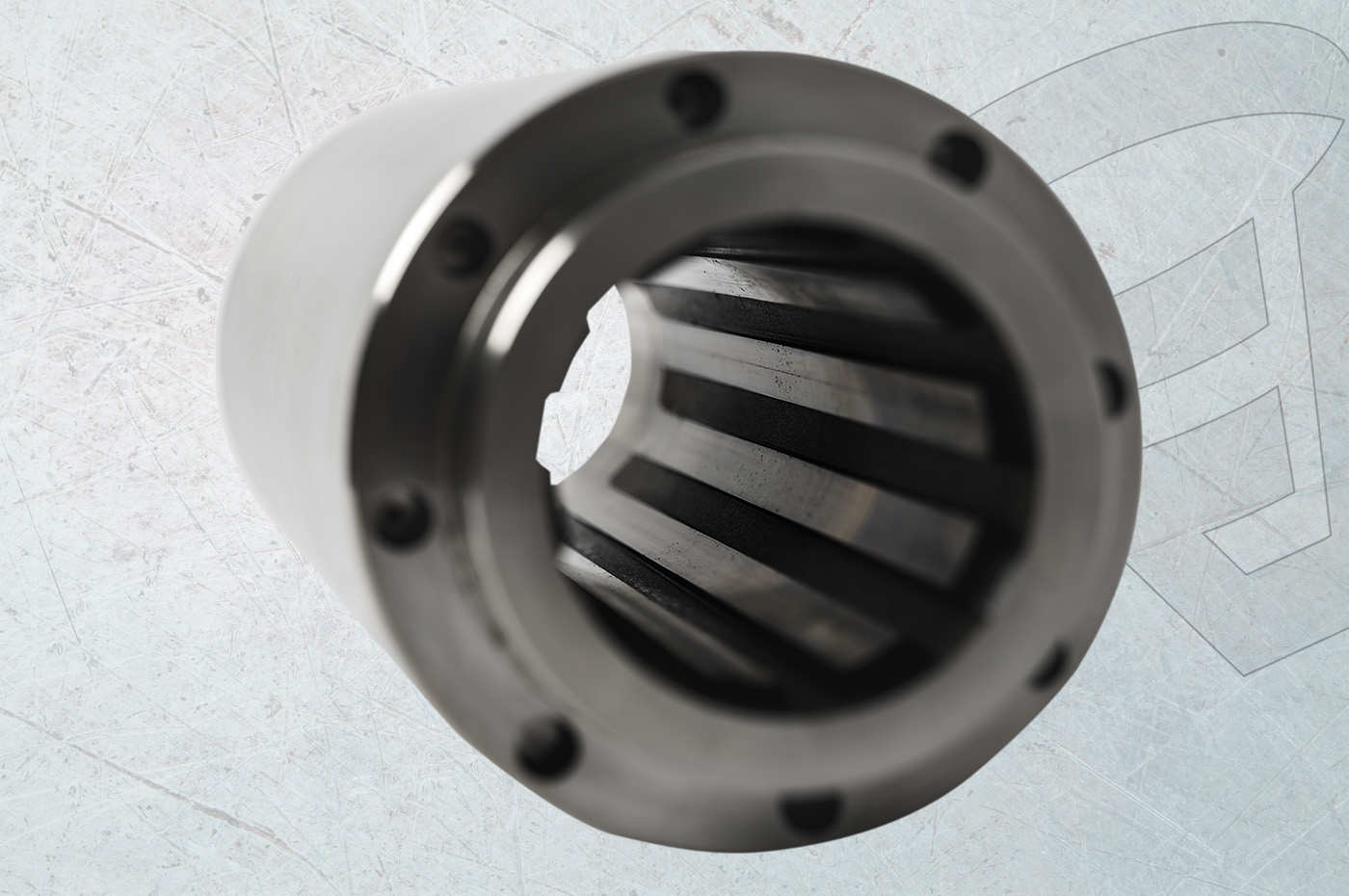

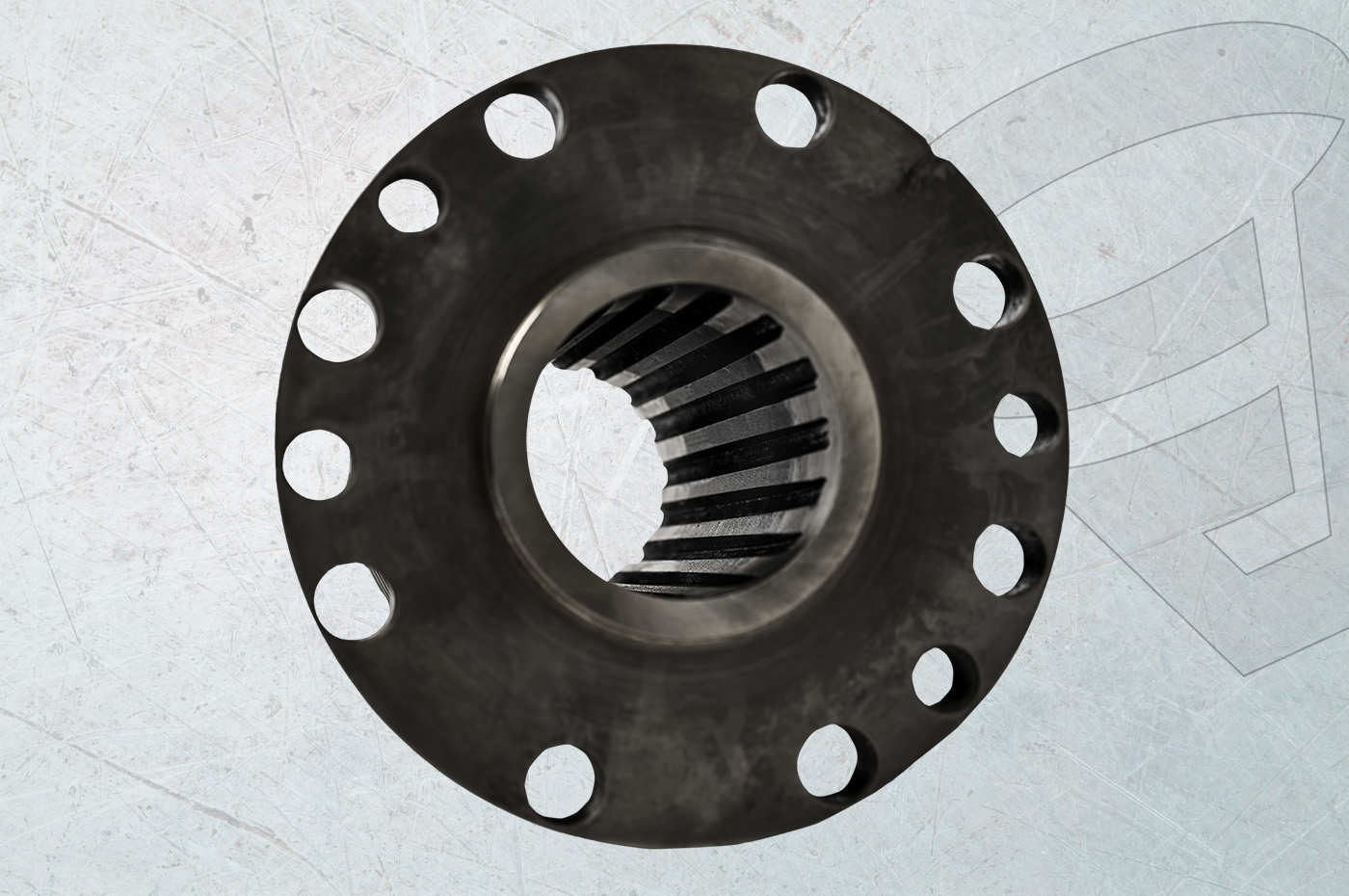

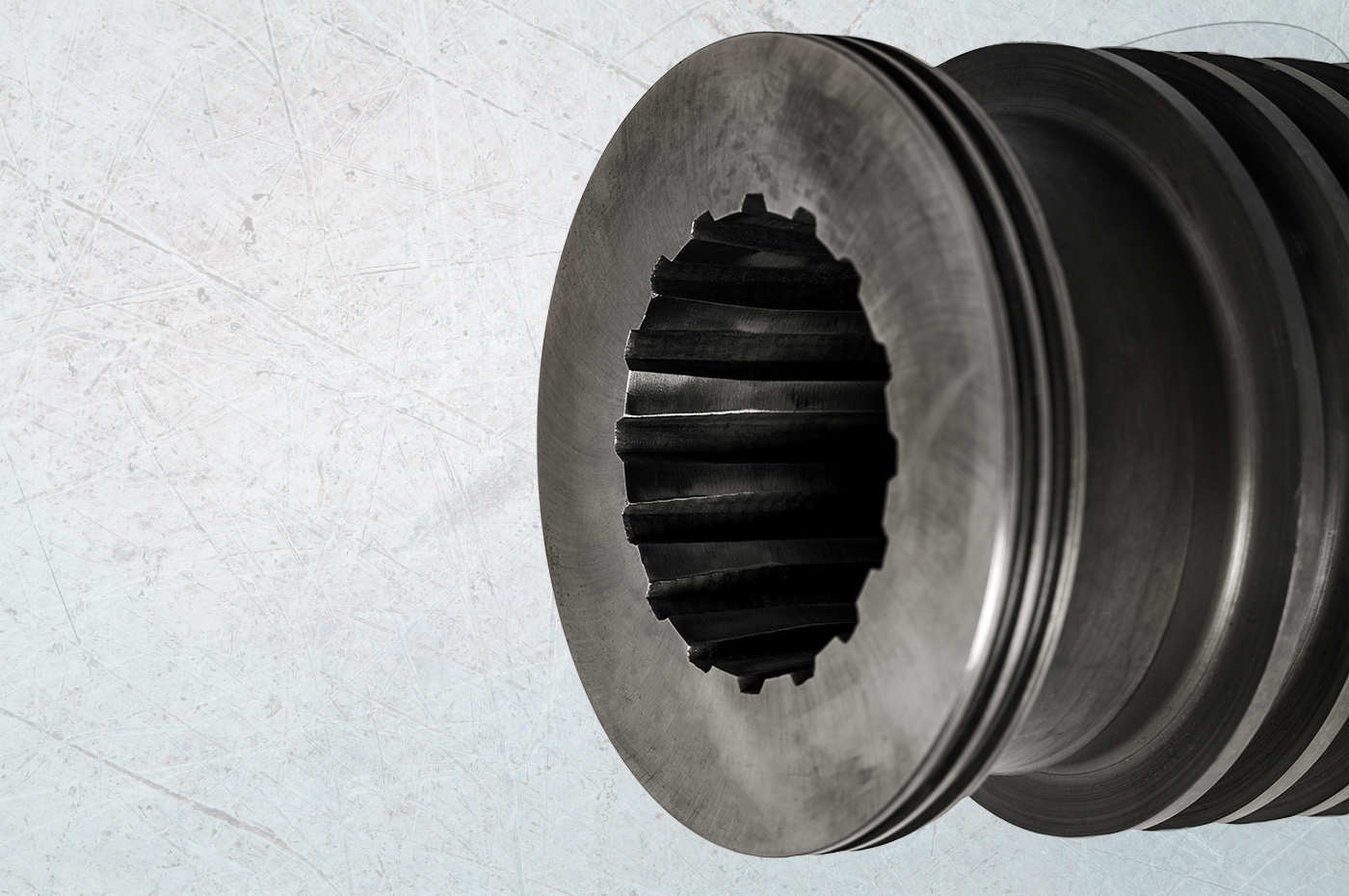

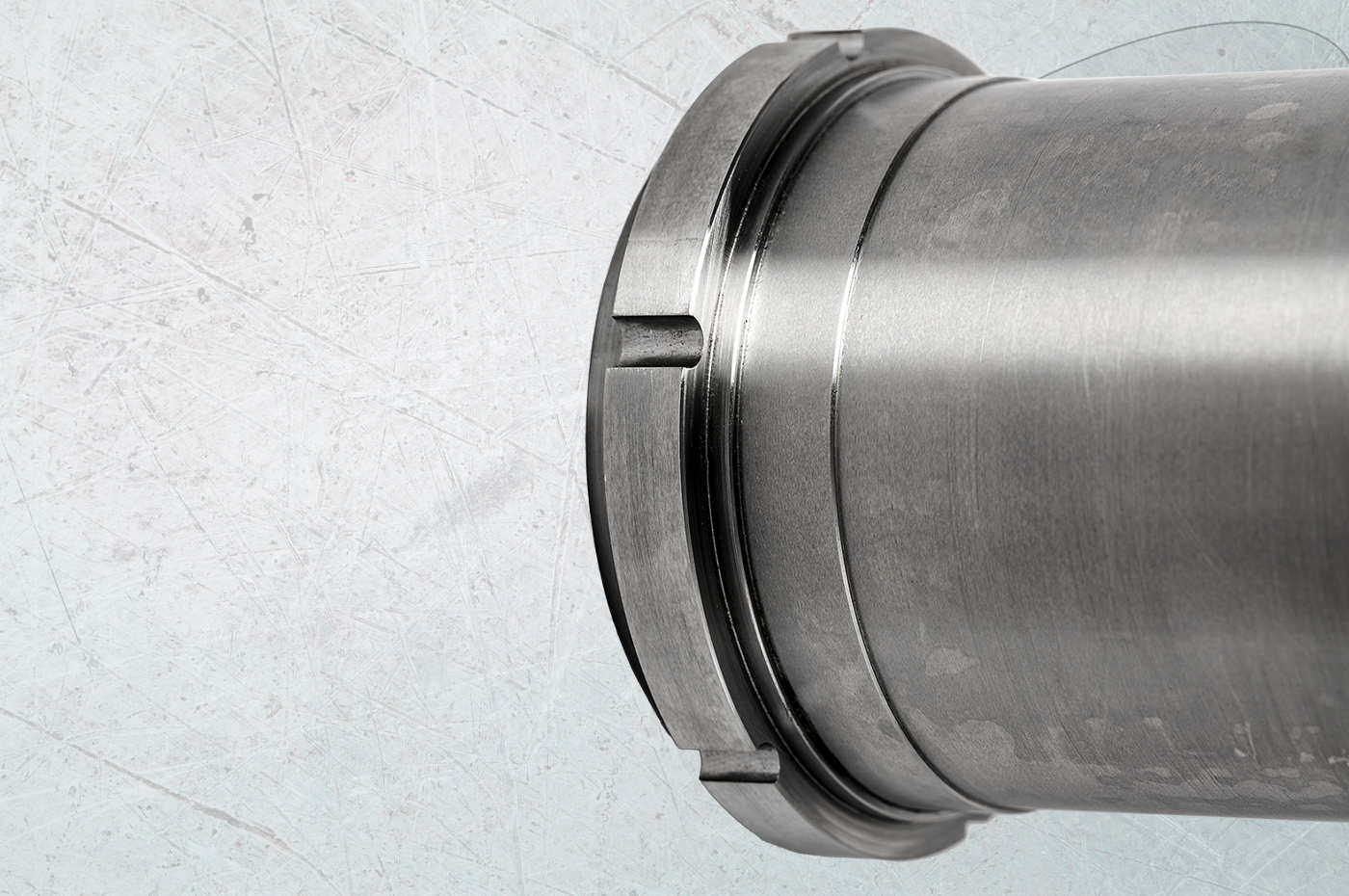

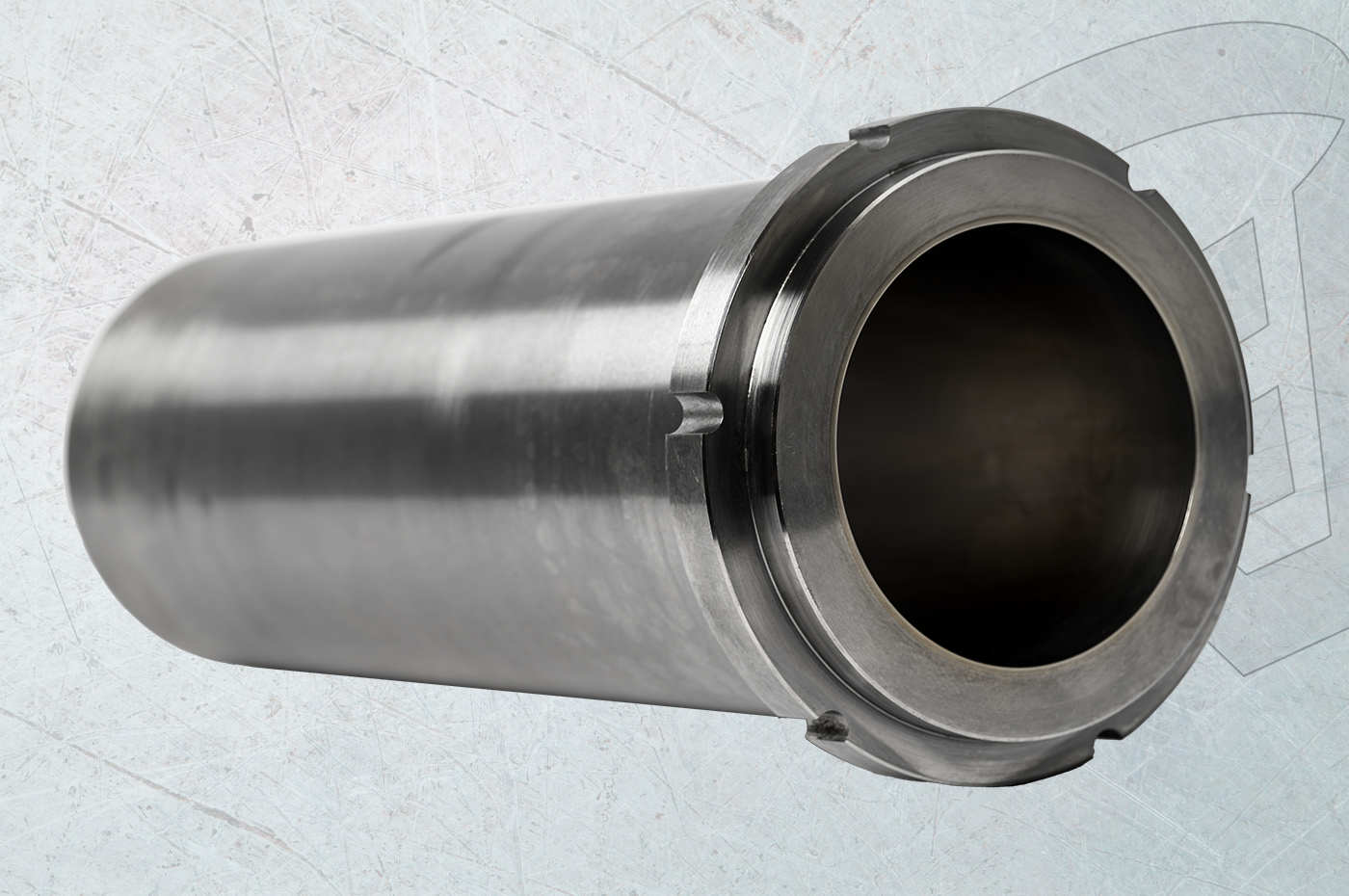

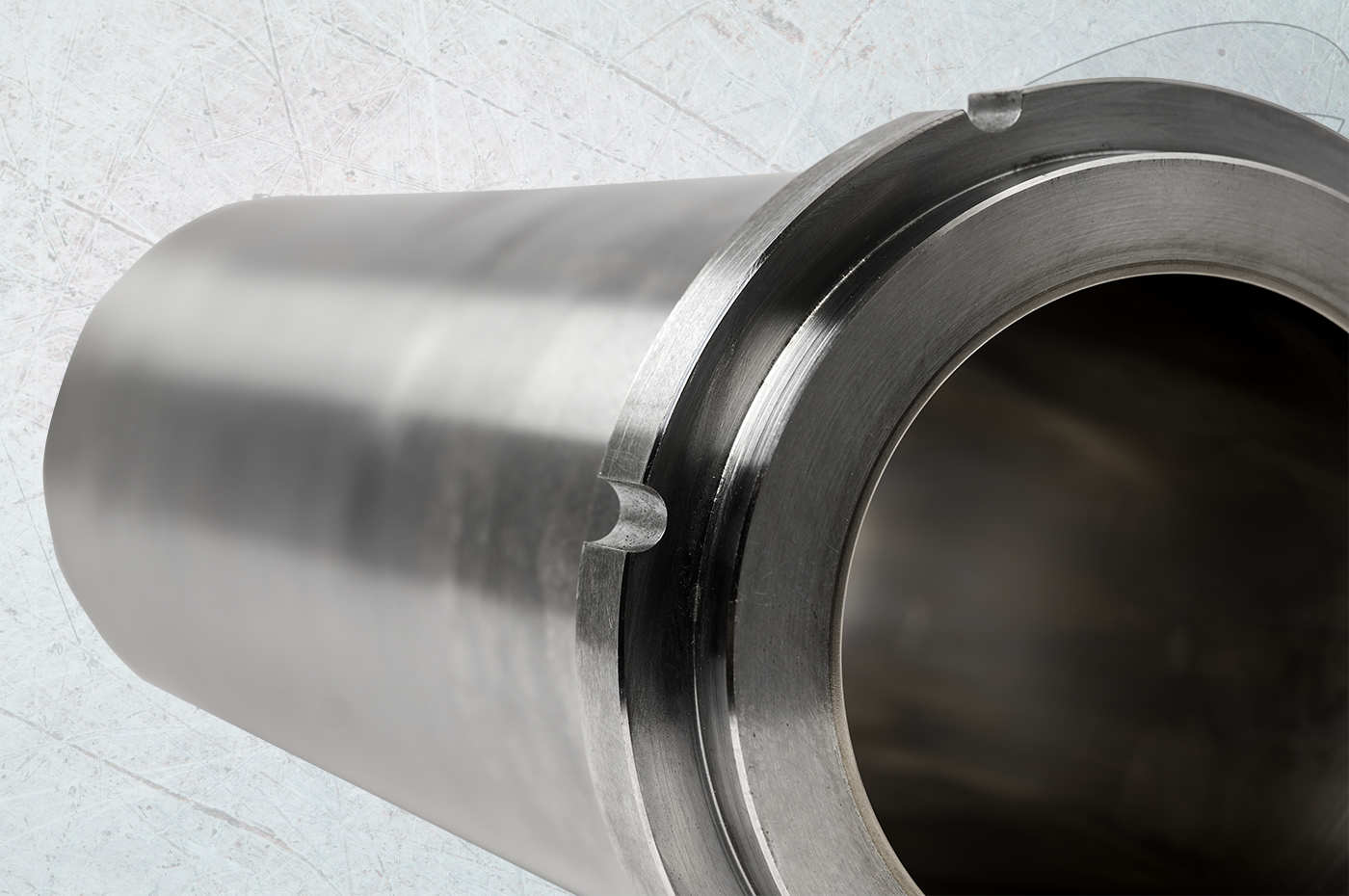

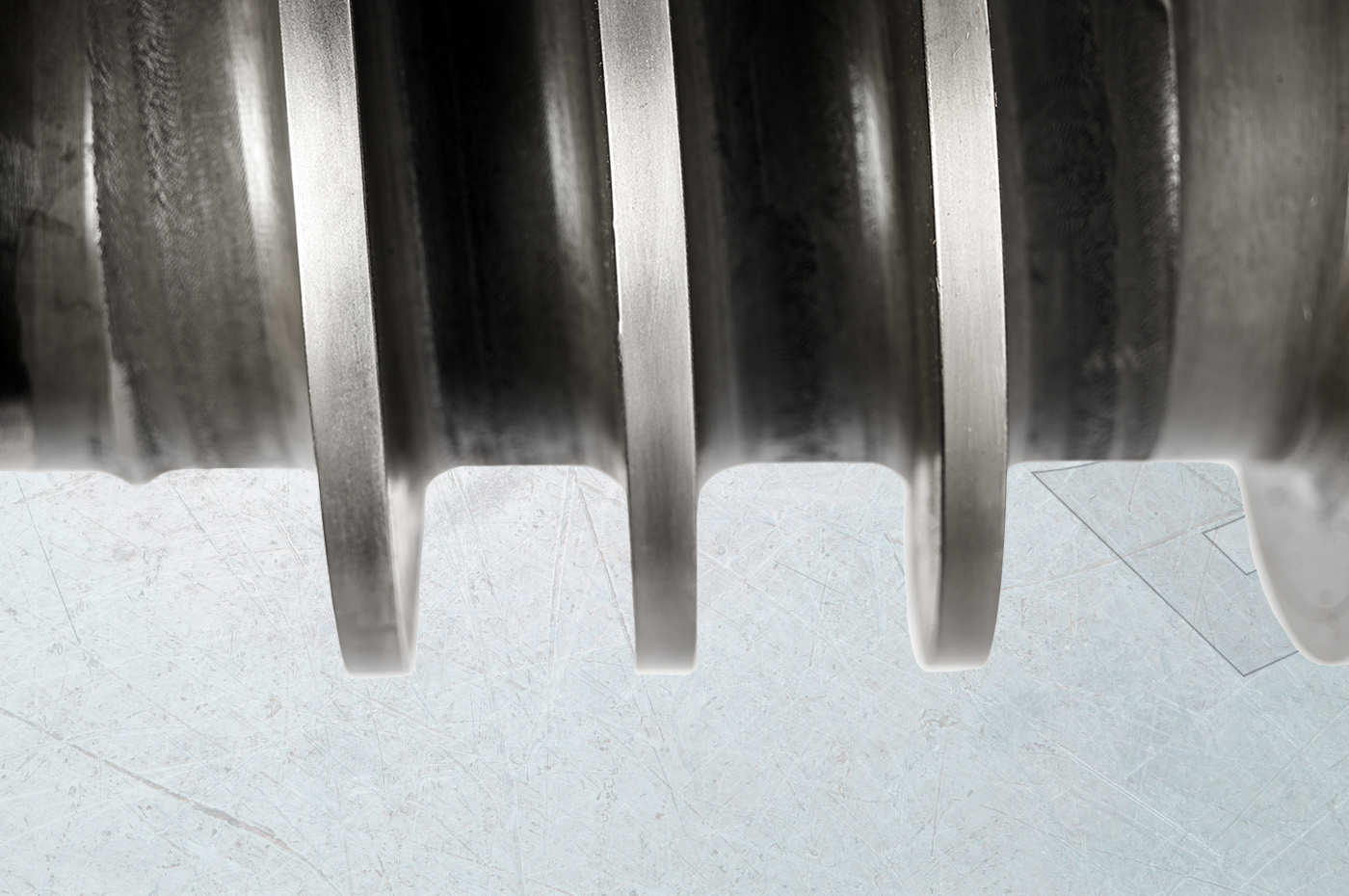

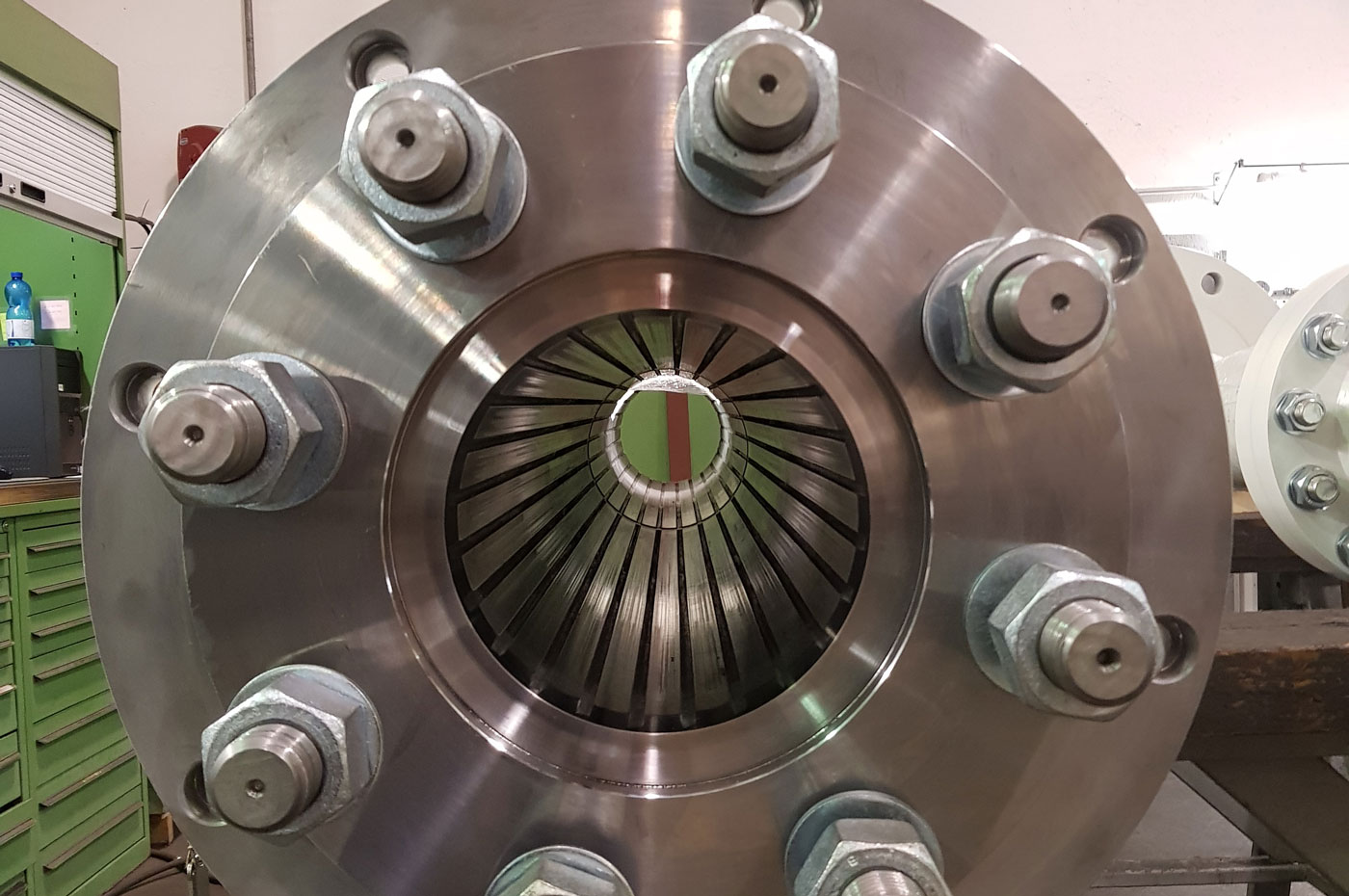

The distinctive feature of this product is its internal grooves, which can come in various configurations: linear, triangular, rectangular, or even helical. The choice of groove geometry is fundamental for the success of the extrusion process.

The arrangement and shape of the grooves inside the Feed Sleeve play an important role in regulating the flow of the plastic material. They have the power to eliminate flow fluctuations or pulsations, which can hinder the consistent flow of material. This aspect not only contributes to stabilizing the entire extrusion process but also significantly increases the amount of processed material, expressed in kg/h.

Gallery

Discover the technical information about

Feed Sleeve

| EUV CODES | STEEL TYPE | TREATMENT | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE | |

|---|---|---|---|---|---|---|

| EUV34 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV41 | Quenched and Tempered | Gas or Plasma Nitruration | Surface Hardening | 950÷1100HV | • | • |

| EUV79 | Cold work tool steel | Hardening & Tempering | Total Hardening | 58÷62HRC | ••• | •• |

| EUV400 | Bimetallic | Fe/Cr | Good against abrasion and corrosion | 62÷69HRC | •••• | ••• |

| EUV1000W | Bimetallic WC | Ni/Wc | Extreme against abrasion and corrosion | 58÷66HRC | ••••• | ••••• |

Related Products

CONTACT US

Tell us what you need

Follow us