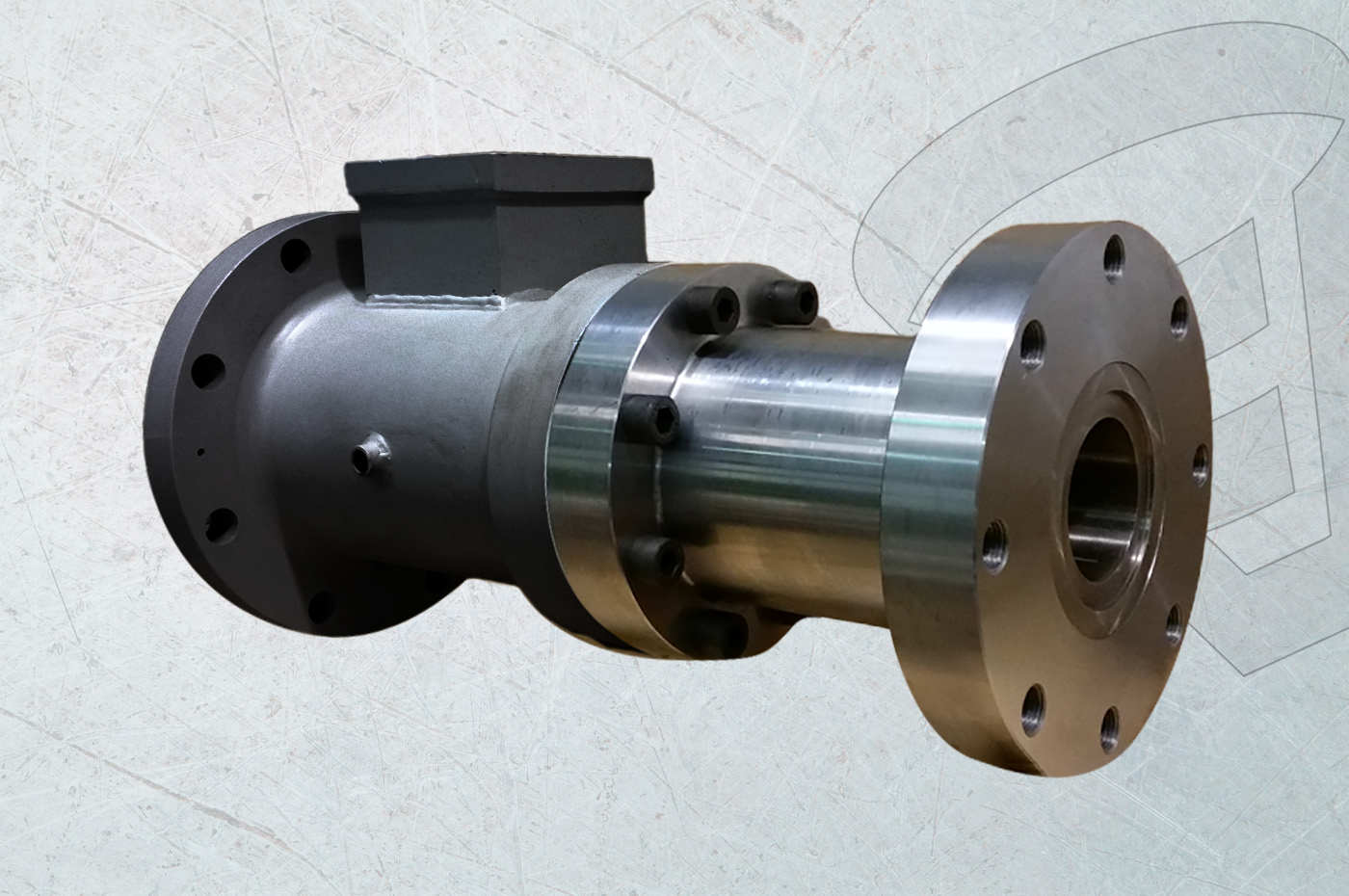

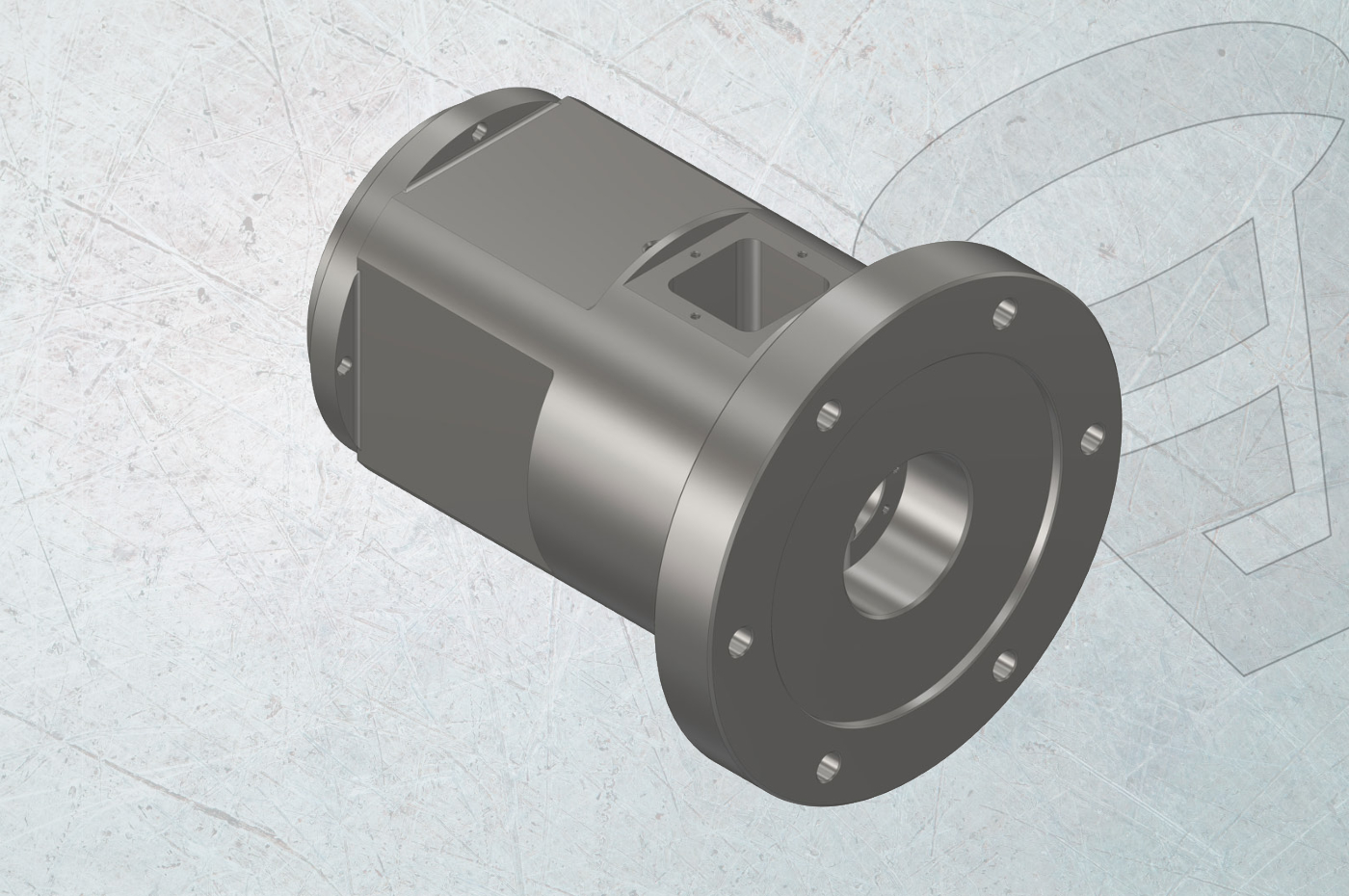

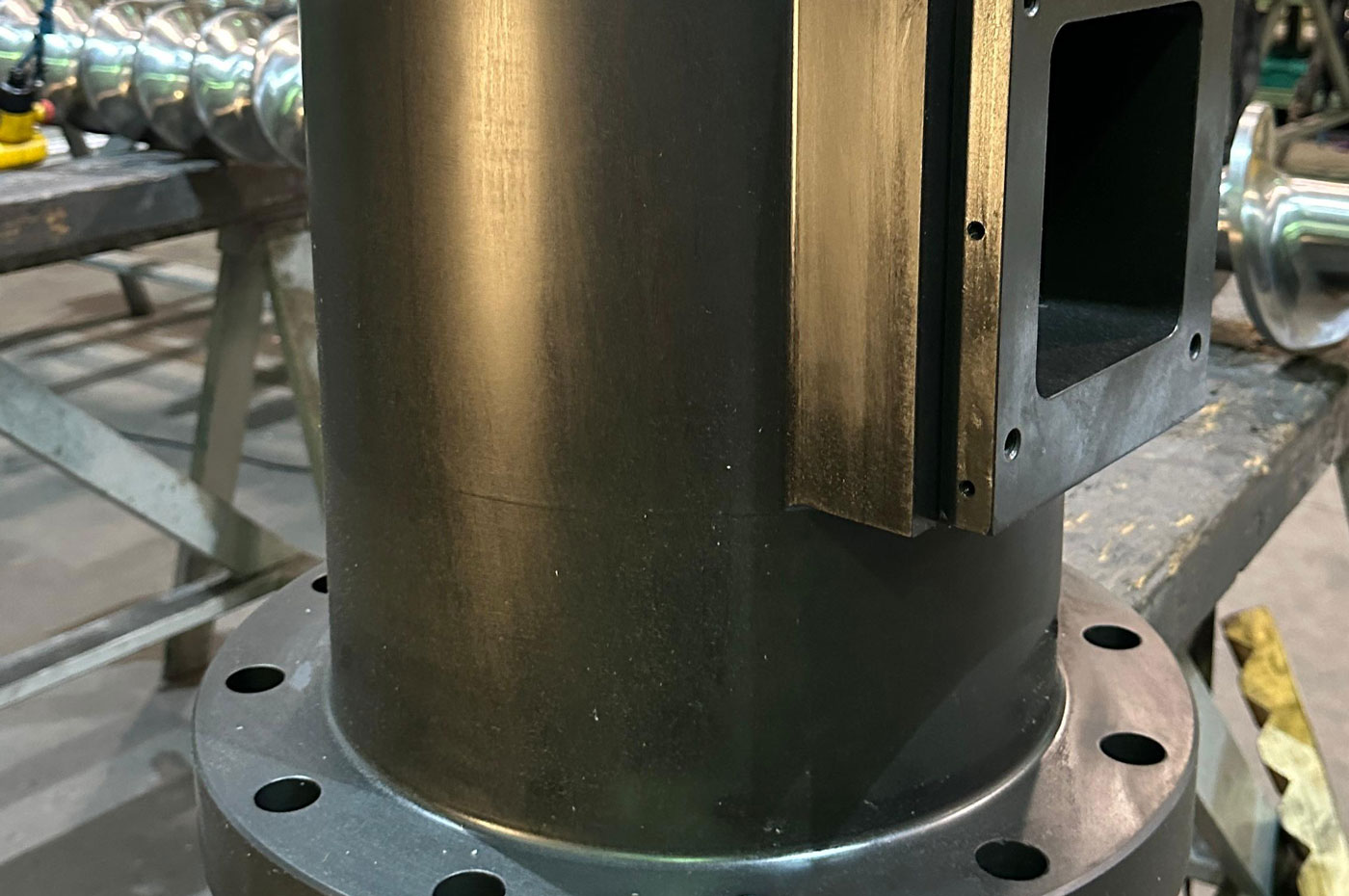

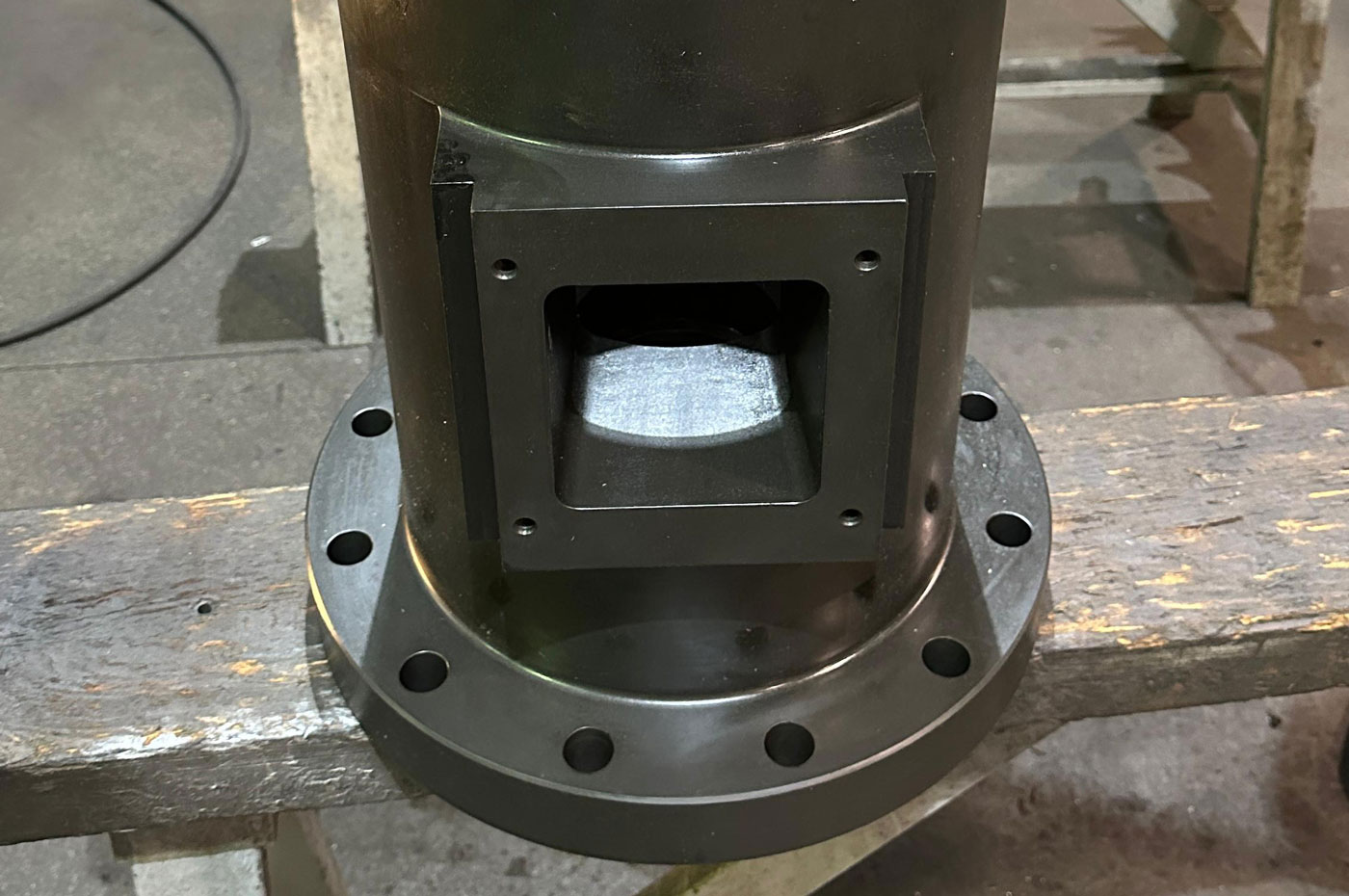

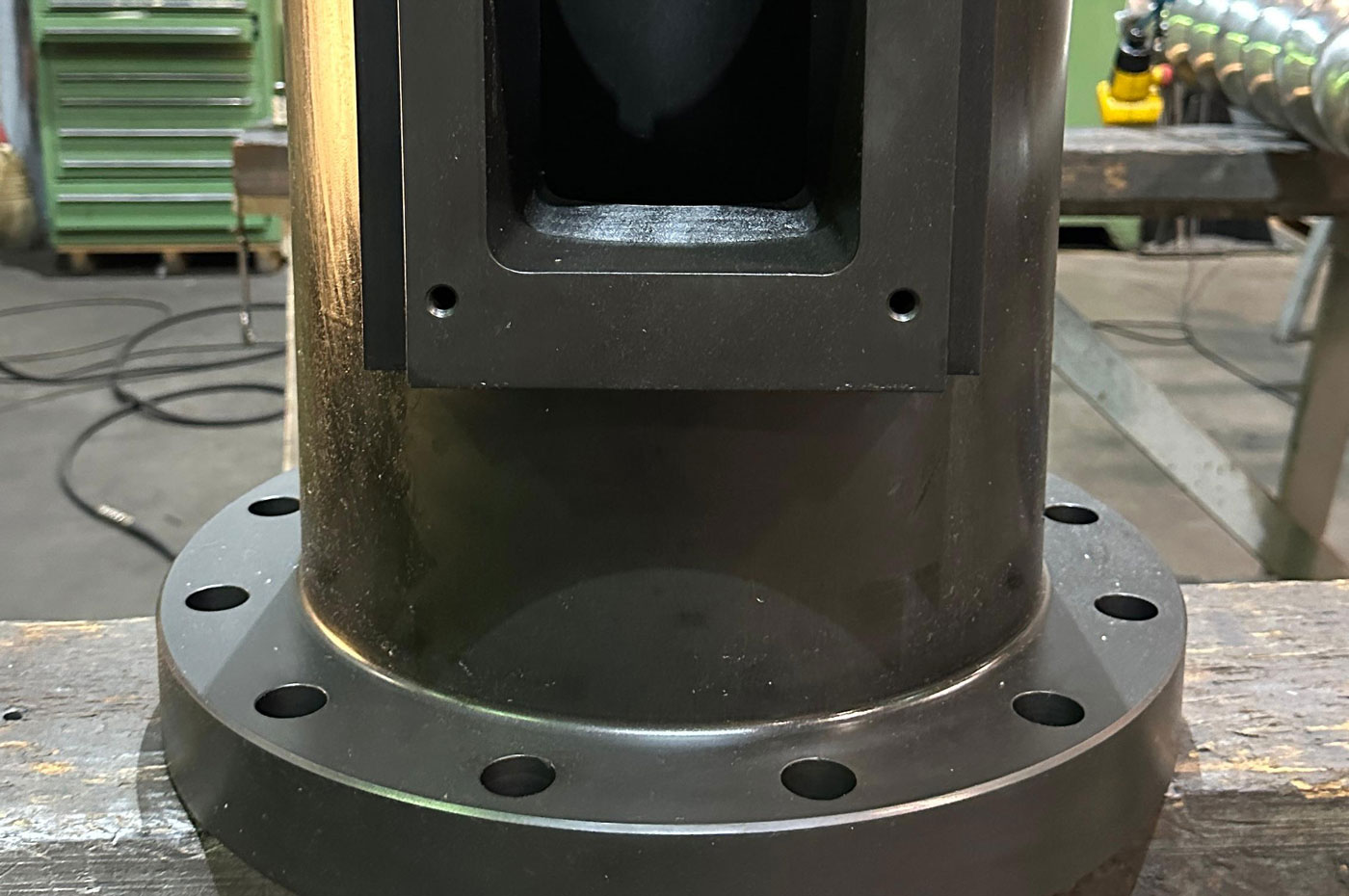

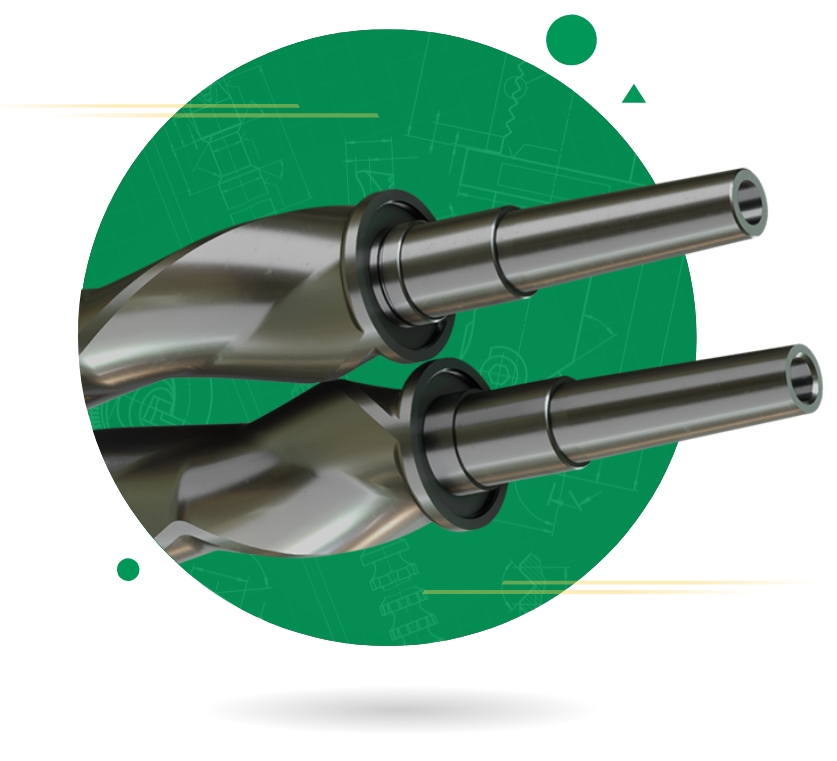

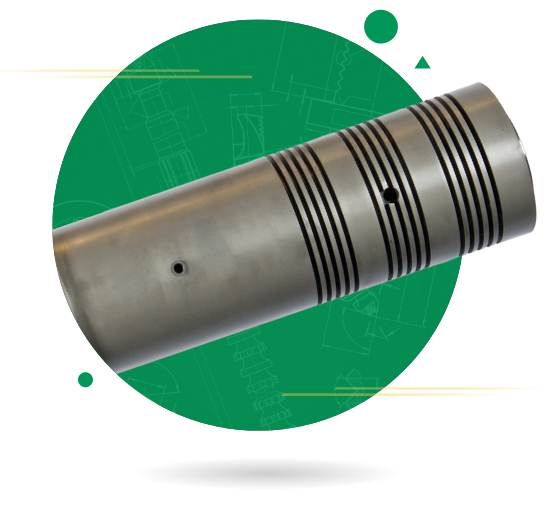

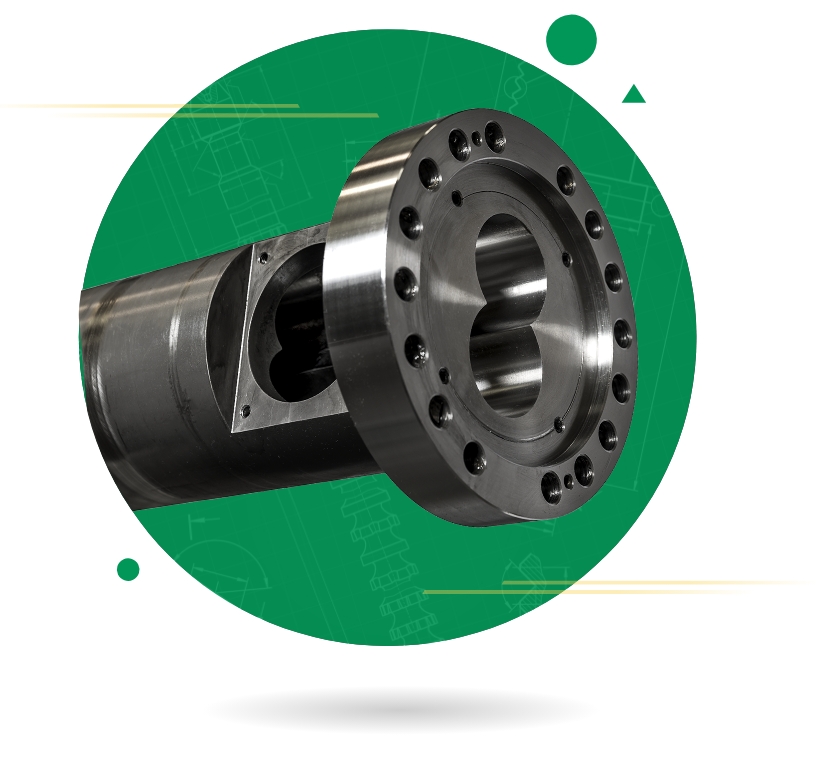

In more advanced and high-performance extrusion applications, the feeding zone of the extruder is divided into two main components: an outer casing or body and an insert or inner sleeve.

The outer body of the extruder is equipped with an integrated cooling circuit, a crucial feature to ensure a consistent and regular feed of the plastic material. The cooling circuit plays a key role in controlling the temperature of the extruder, ensuring that the plastic material does not overheat and remains in a suitable state for efficient and continuous processing.

Consequently, in a high-performance extrusion line, it’s essential not only to make the right choice of screw and extruder material but also to carefully design the feeding zone. This includes the integration of an effective cooling system within the outer casing to ensure an optimized and high-performing extrusion process.

Are you looking for information about Internal Sleeve?

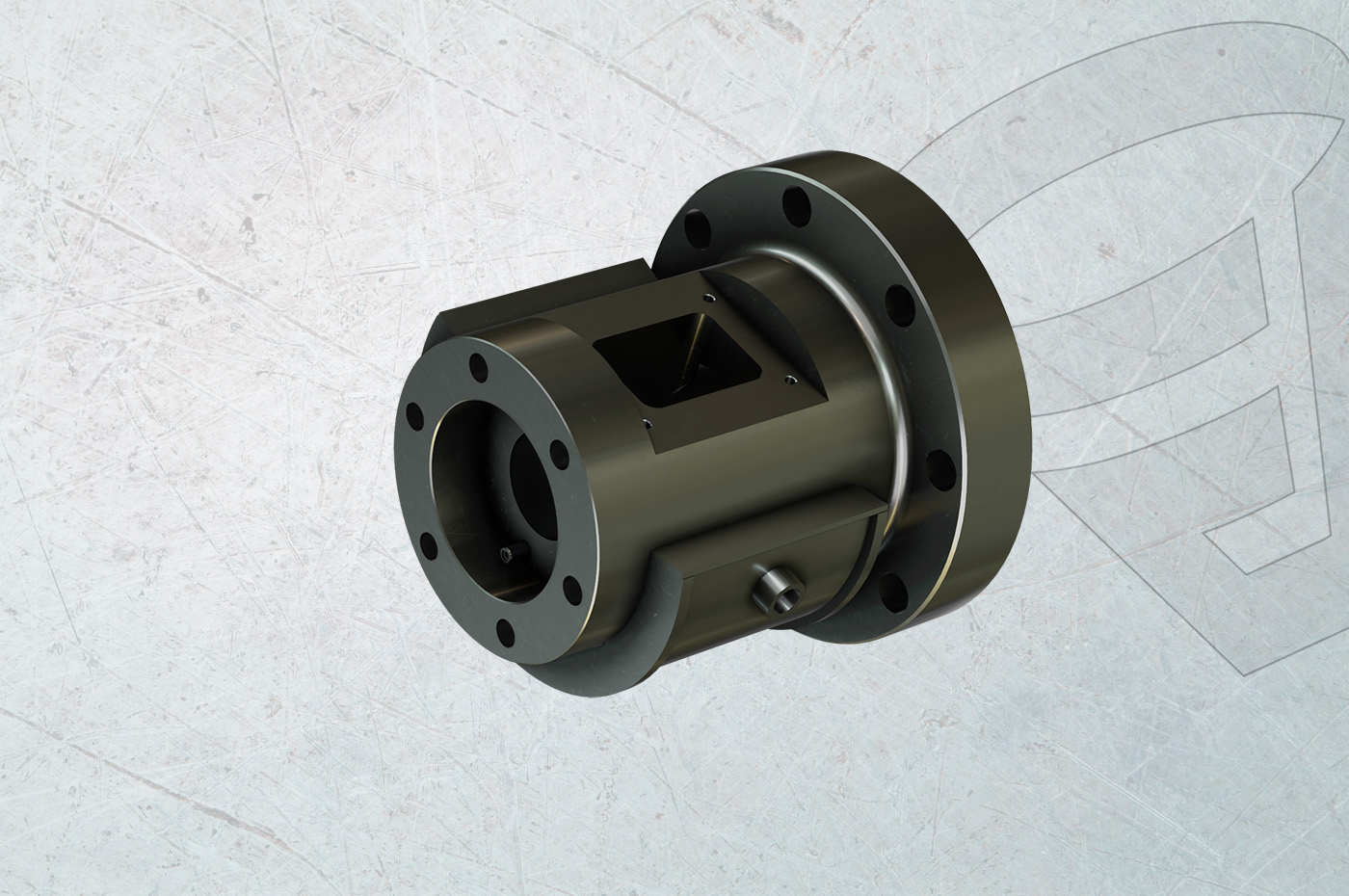

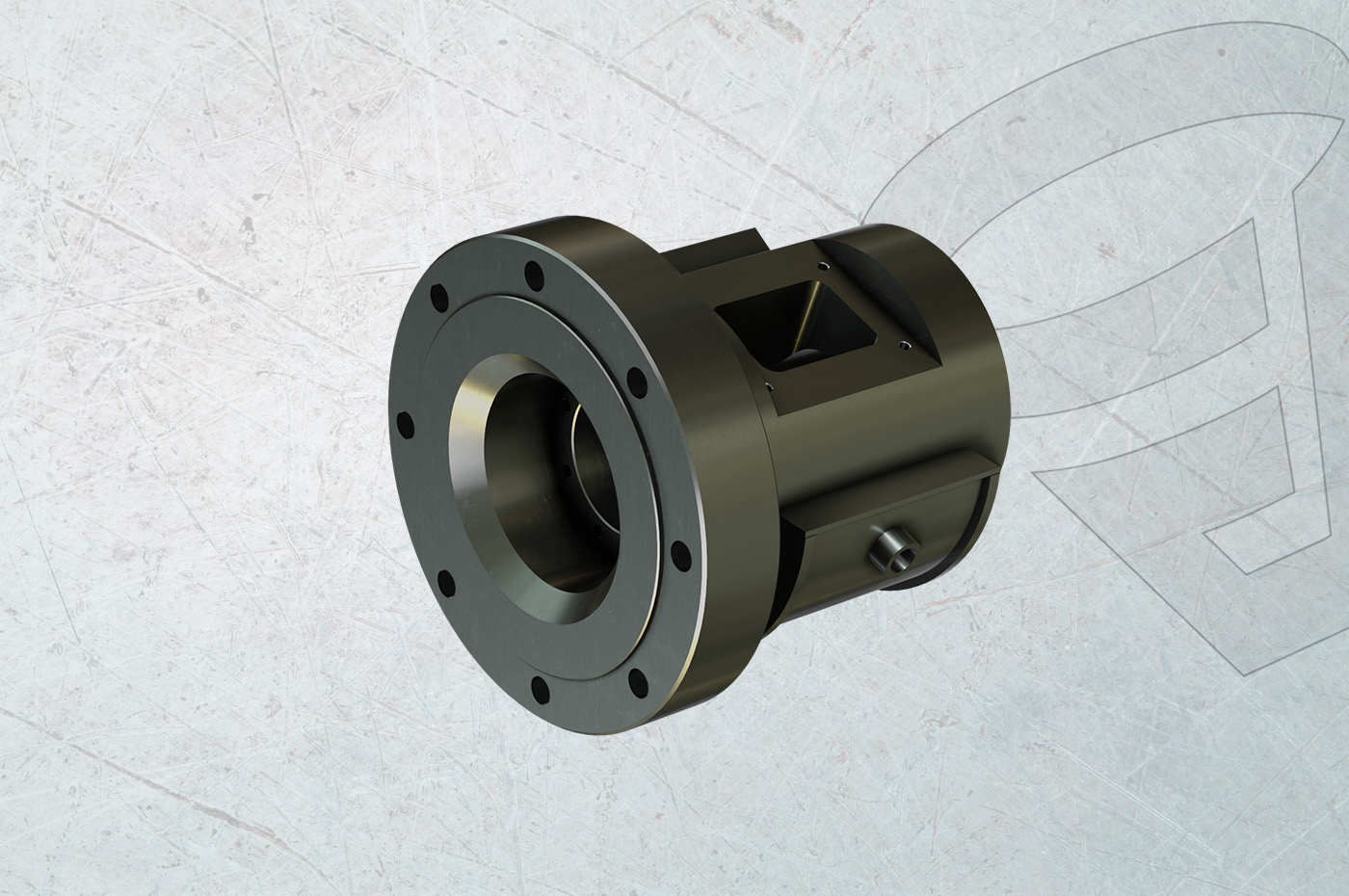

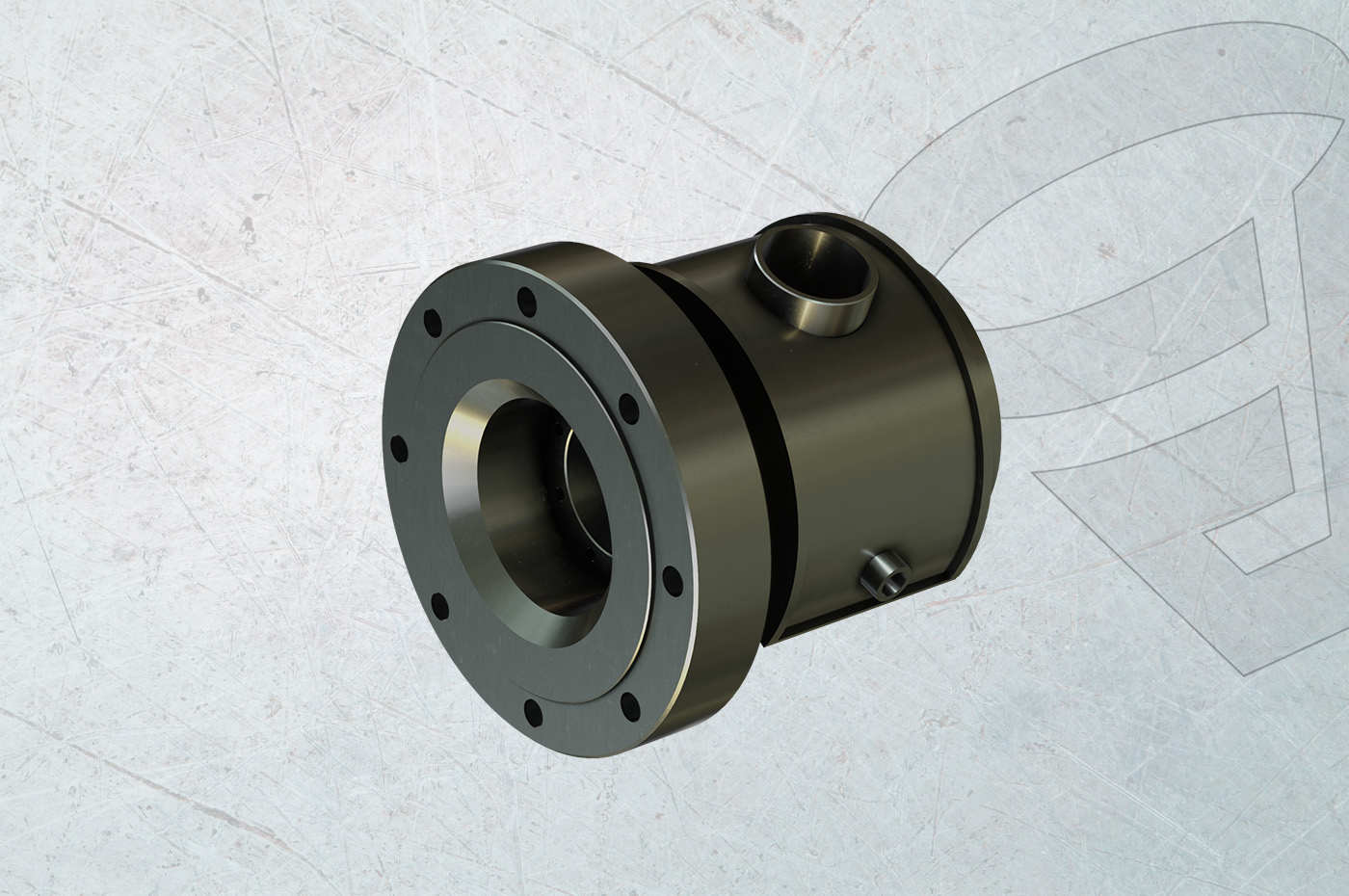

Gallery

Discover the technical information about

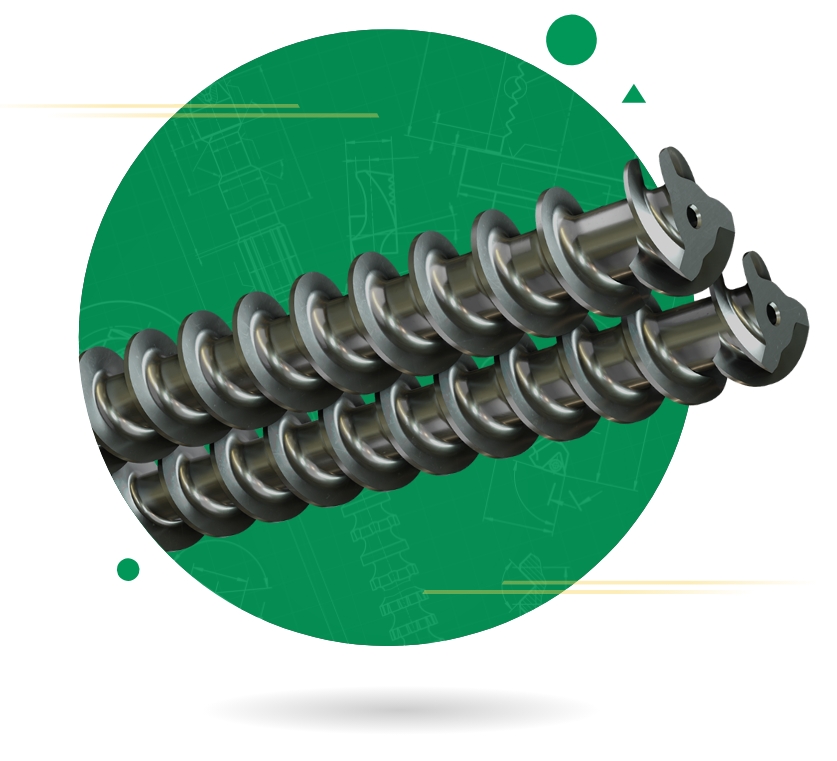

Feeding block

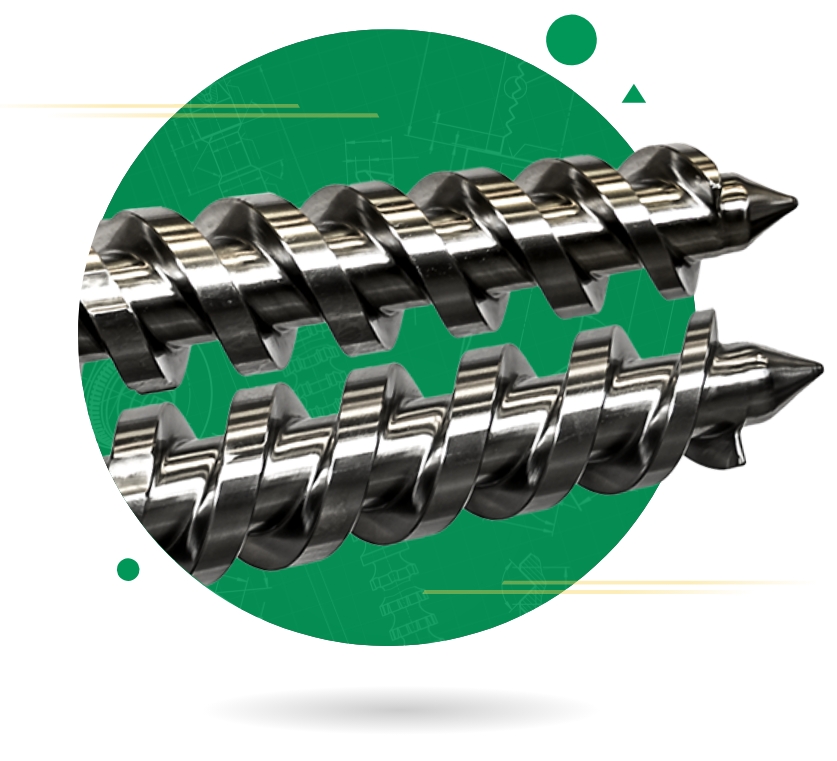

| PART | EUV CODES | TYPE | INLAY BASE ALLOY | THERMAL TREATMENT | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|---|

| Complete Part | EUV41 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV | • | • |

| Main Body for Sleeve version | EUV40 | Carbon Steel | Quenched and Tempered | None | Not needed | Not subject to | Not subject to |

Related Products

CONTACT US

Tell us what you need

Follow us