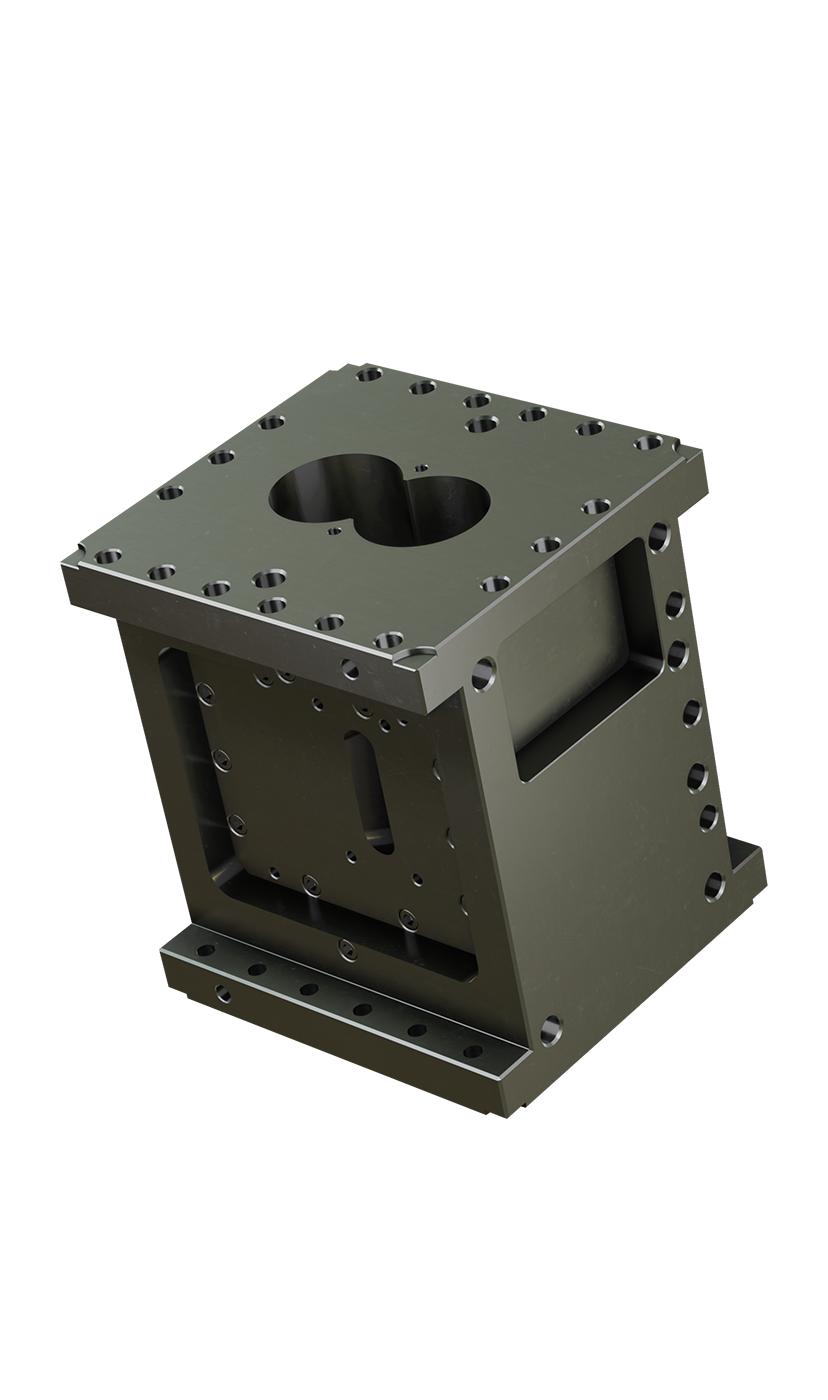

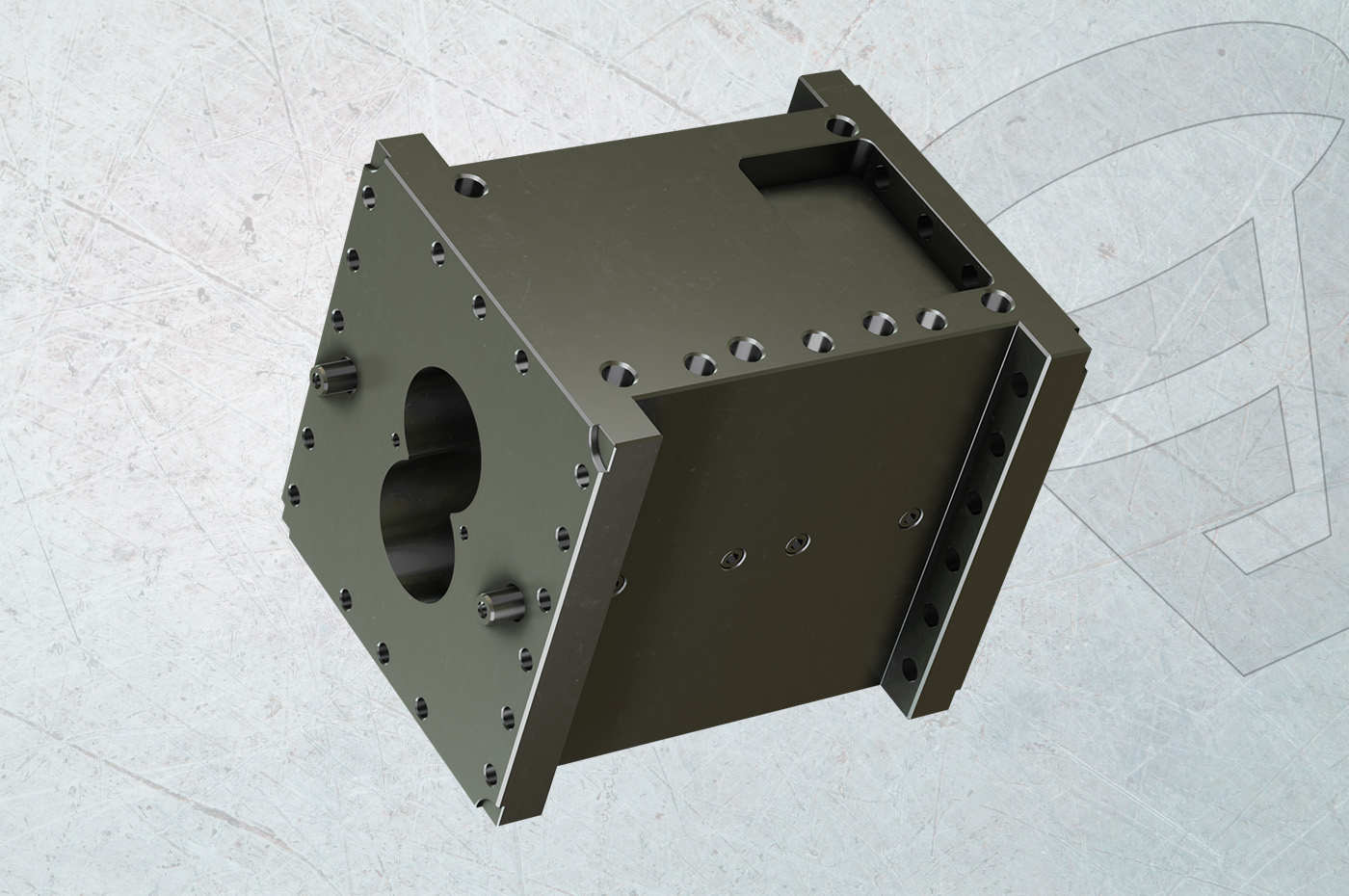

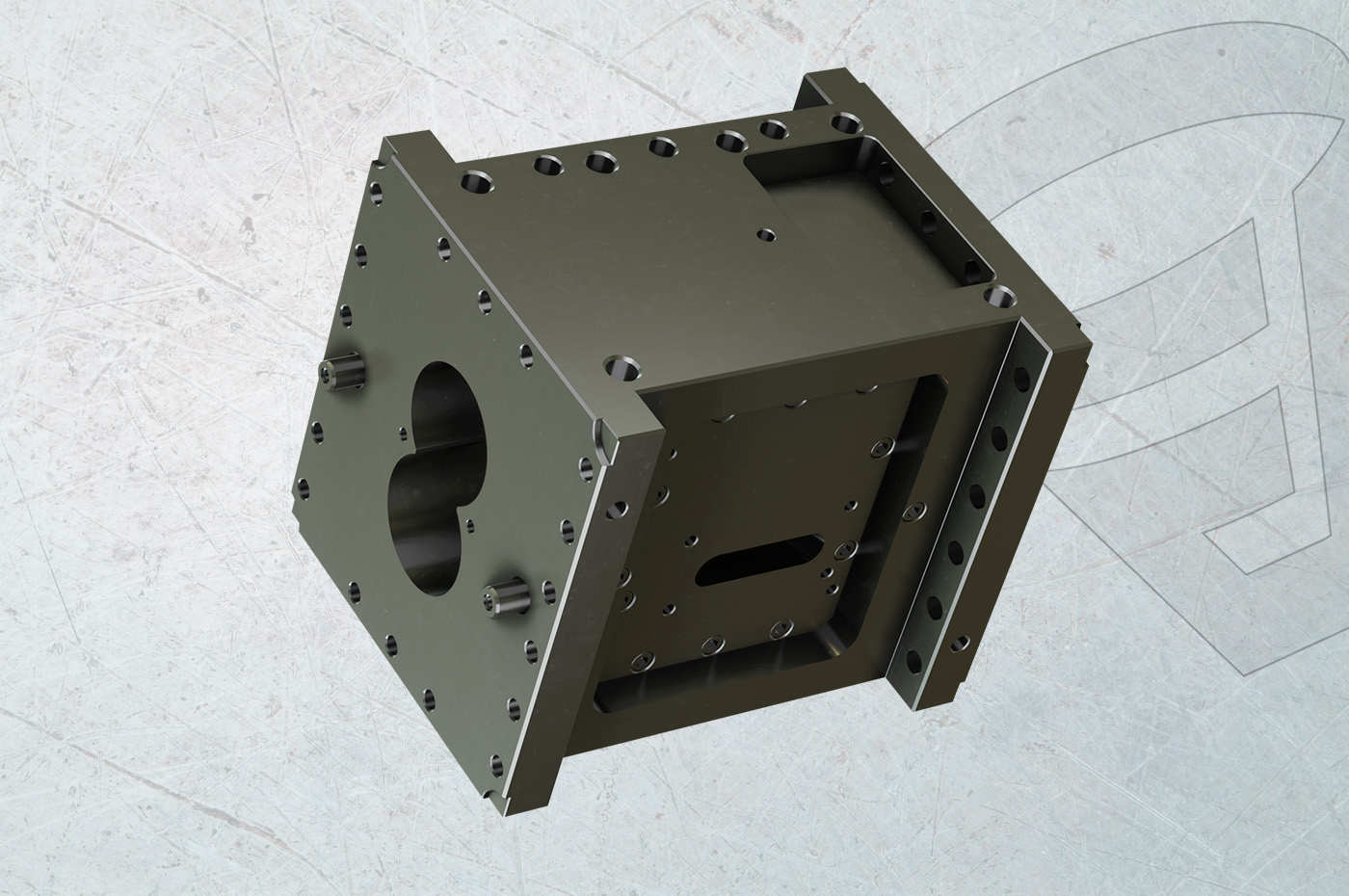

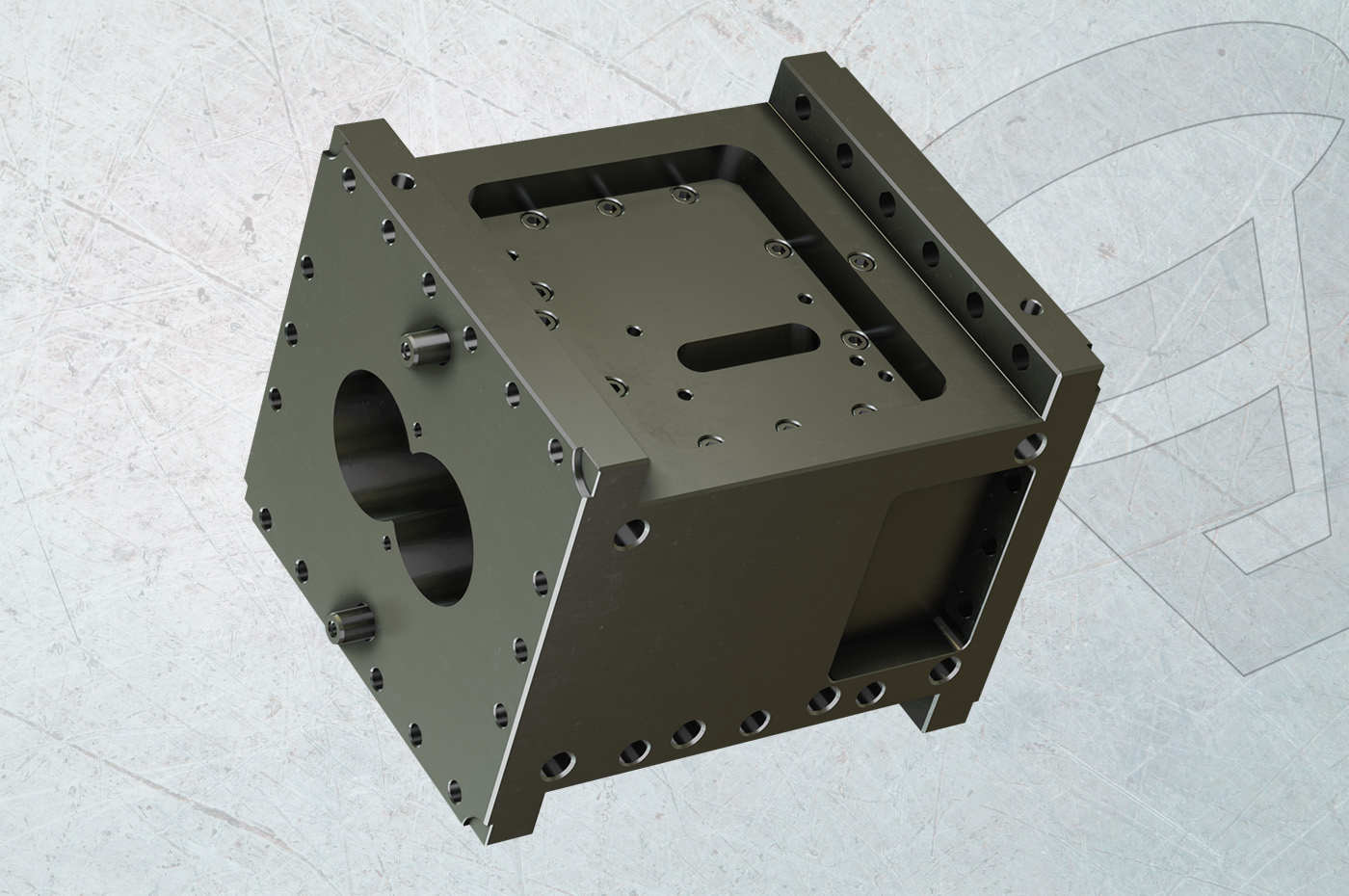

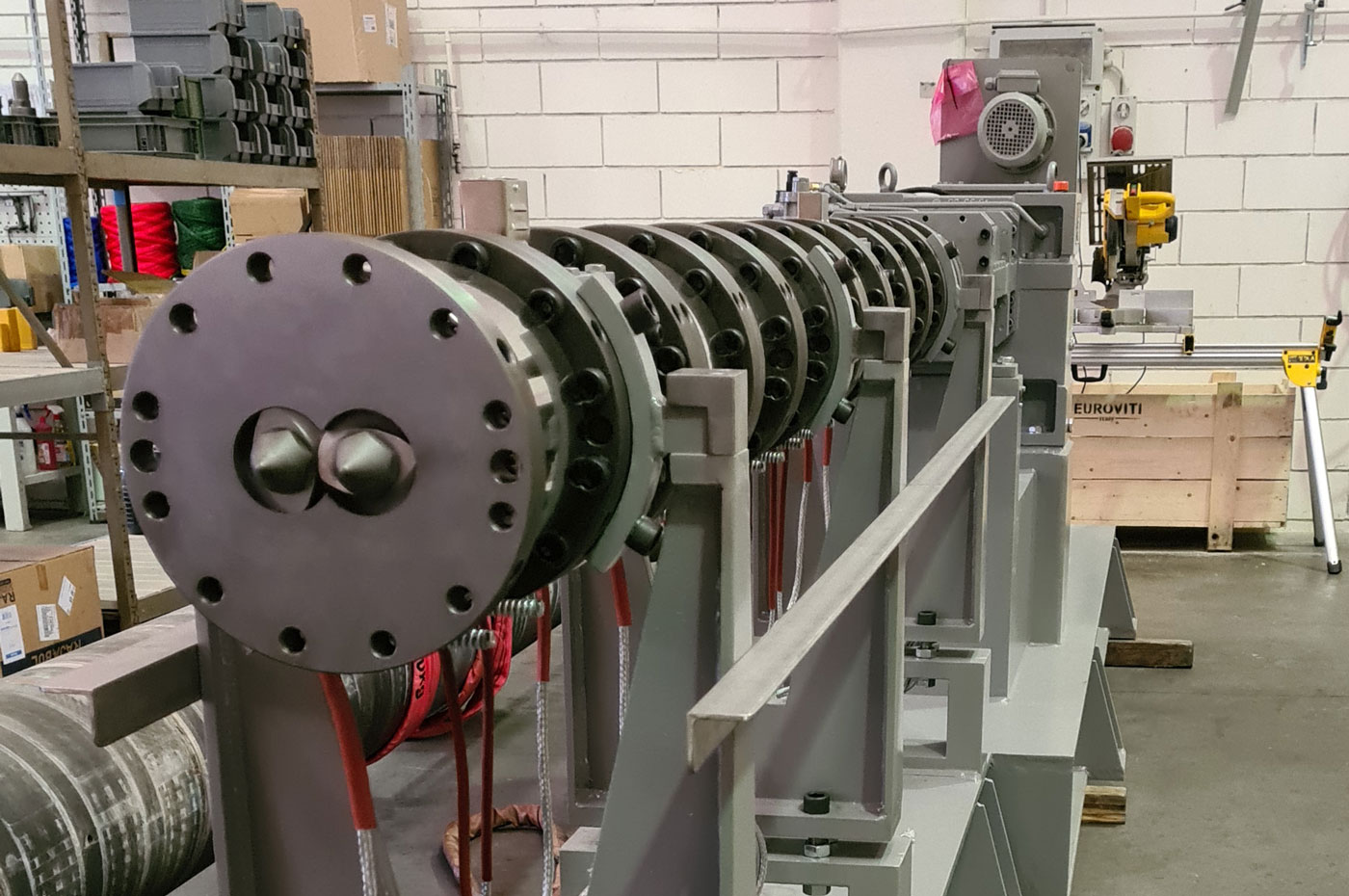

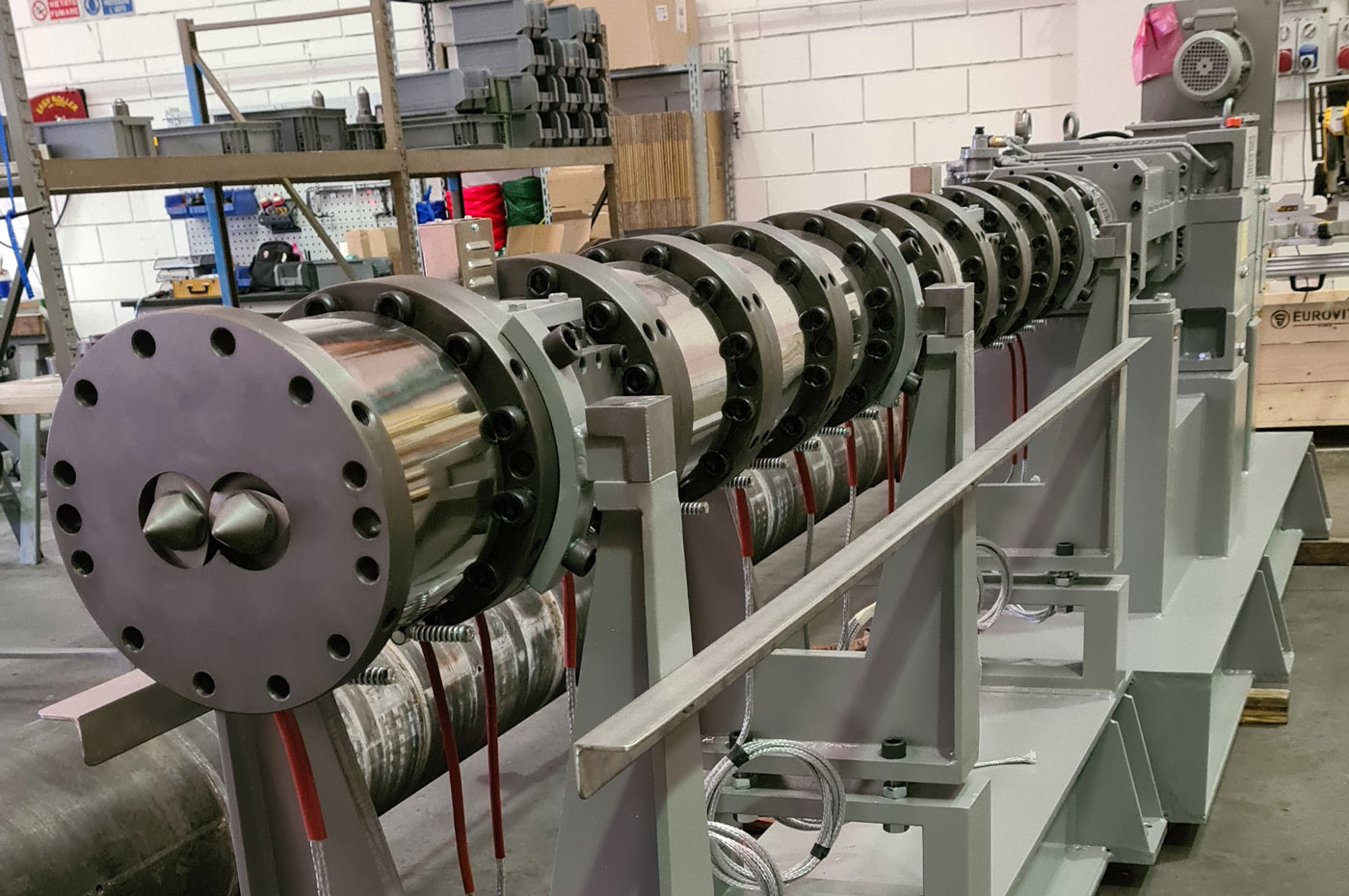

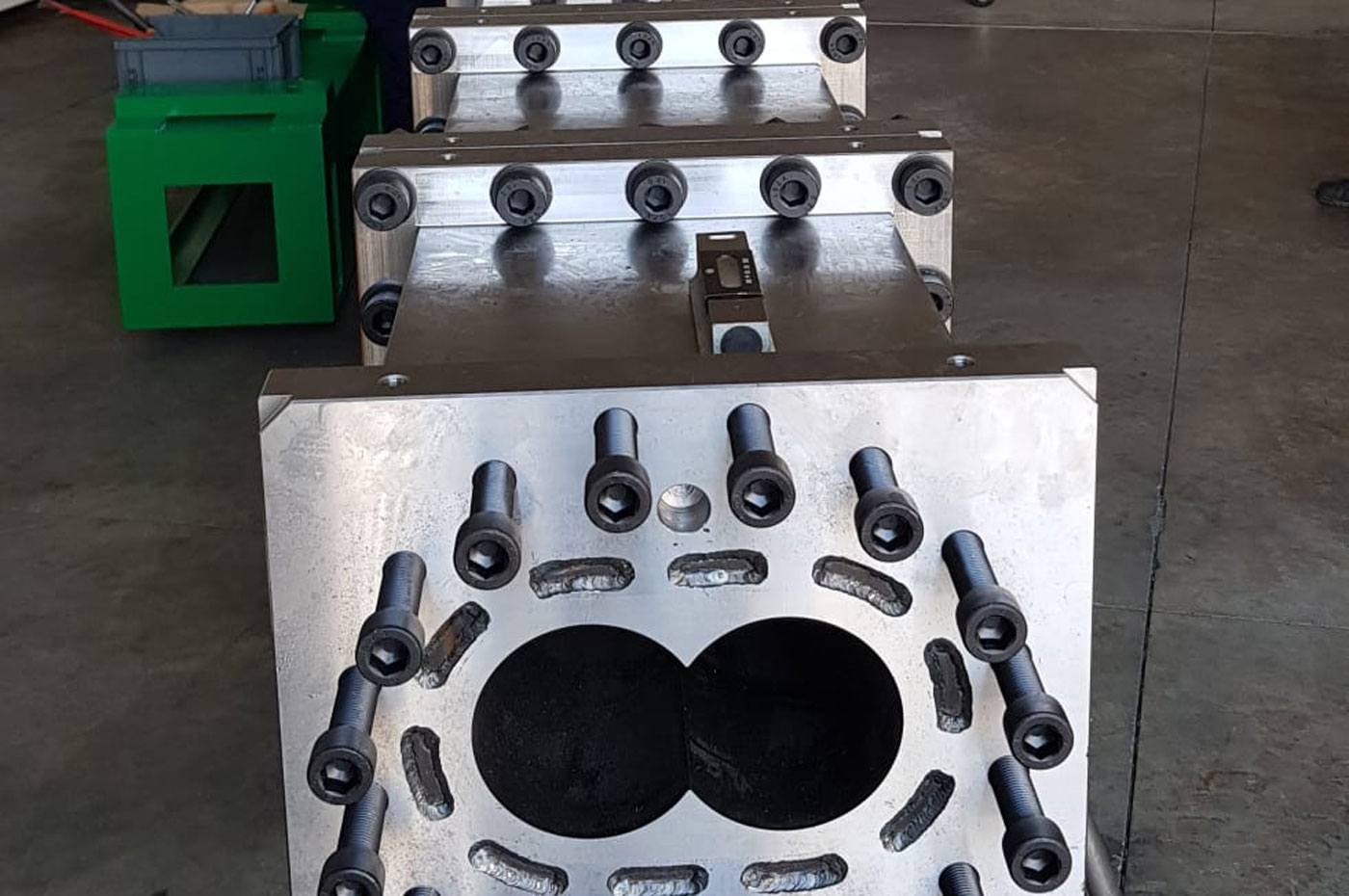

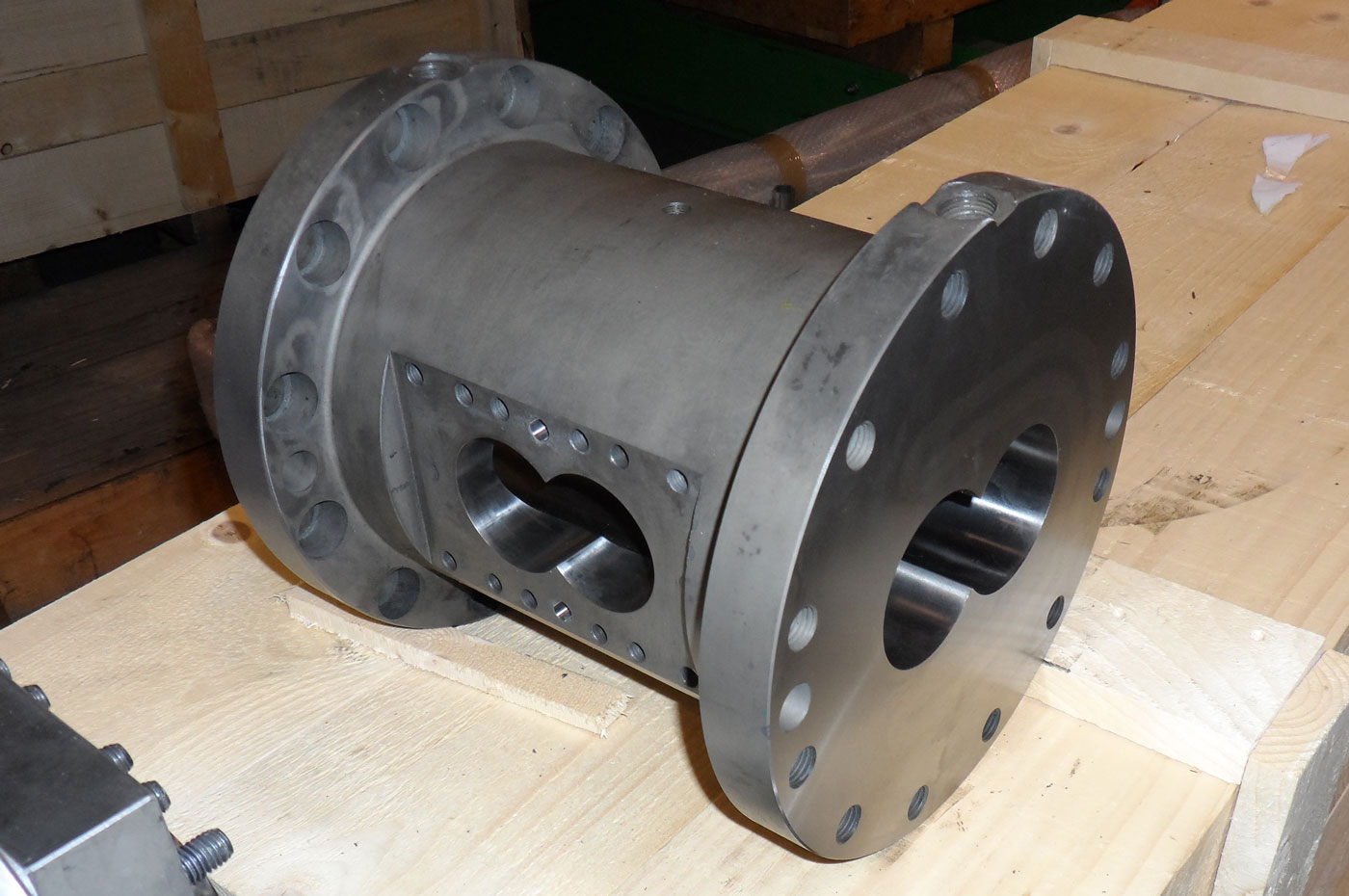

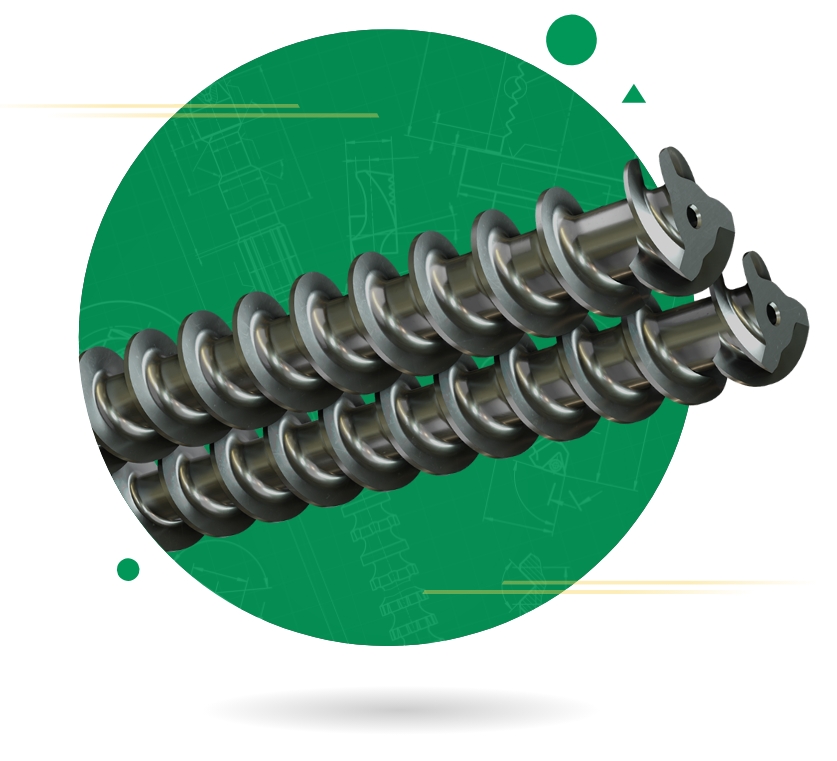

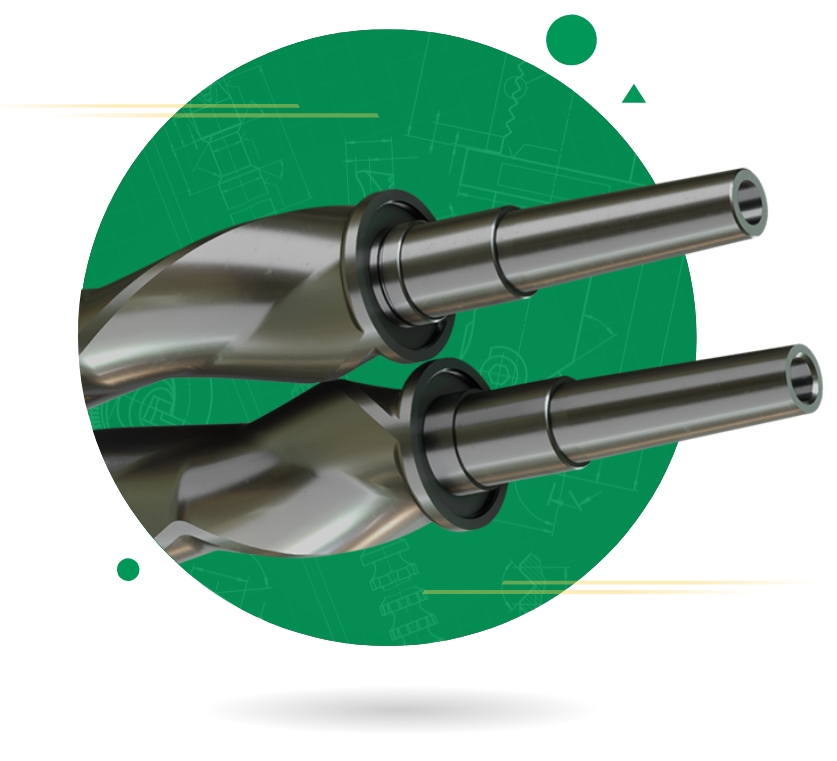

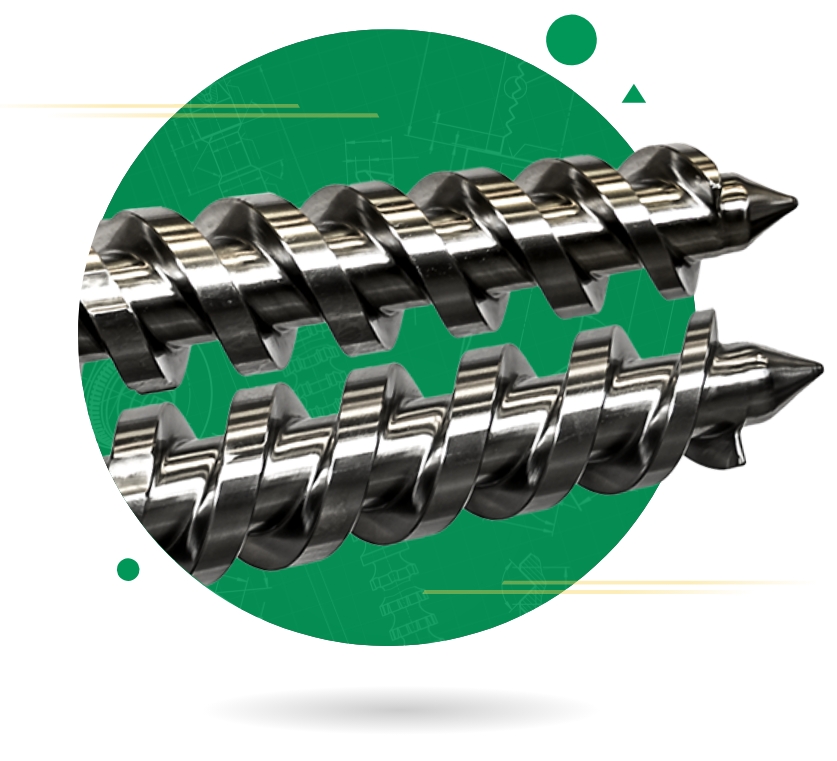

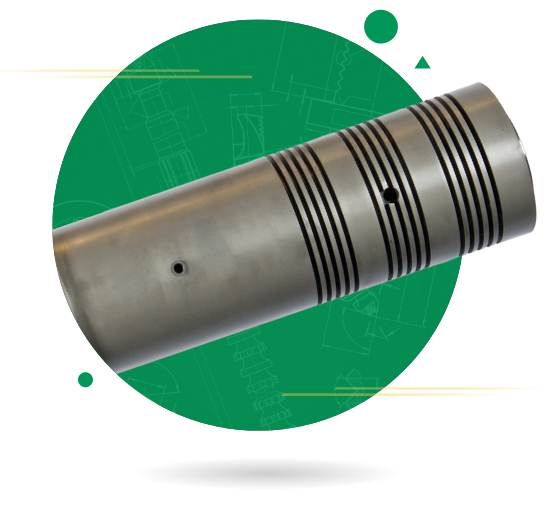

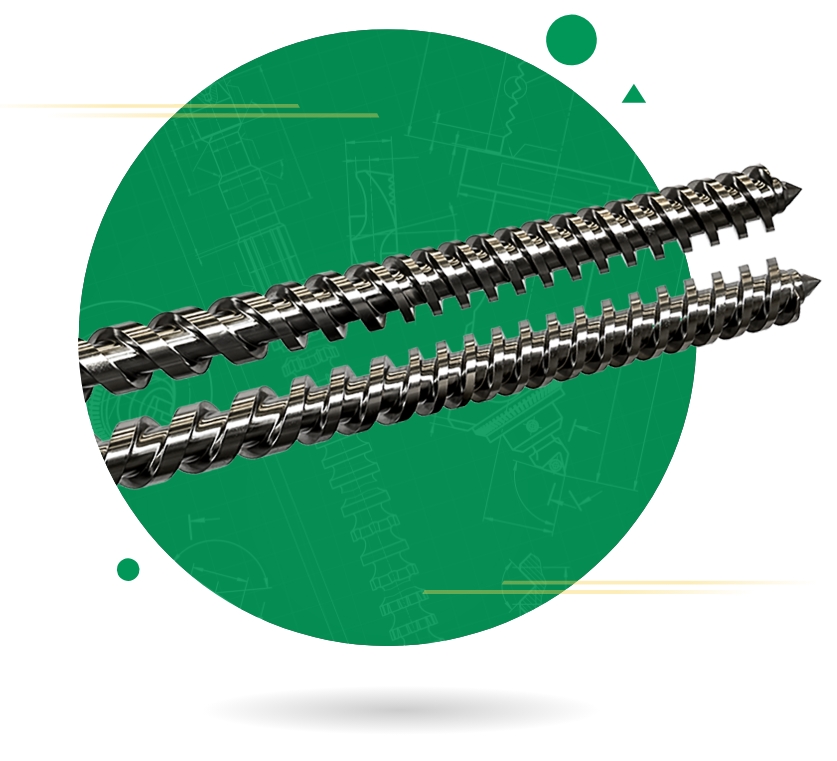

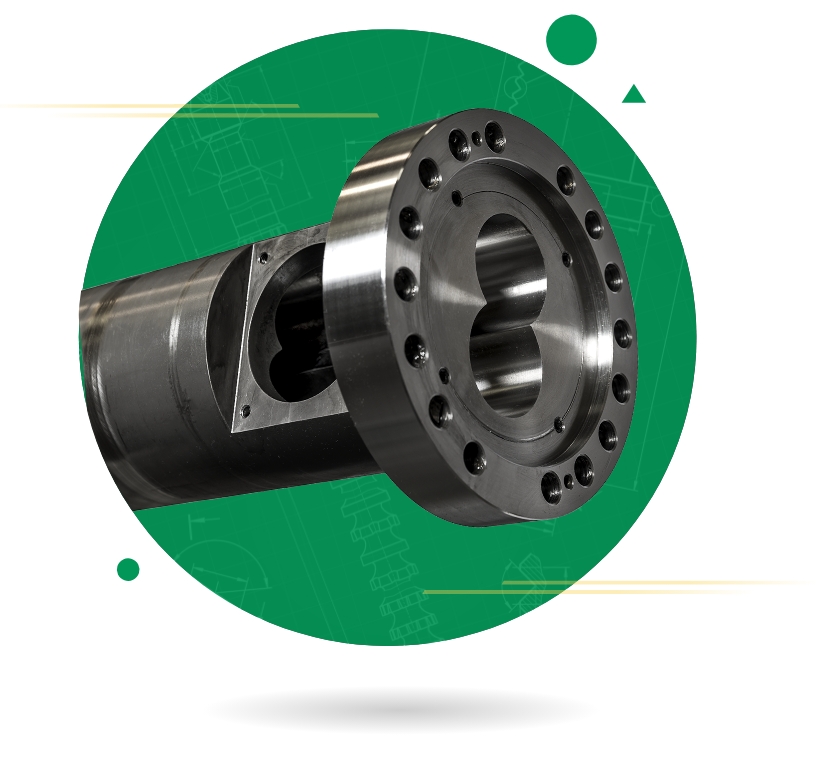

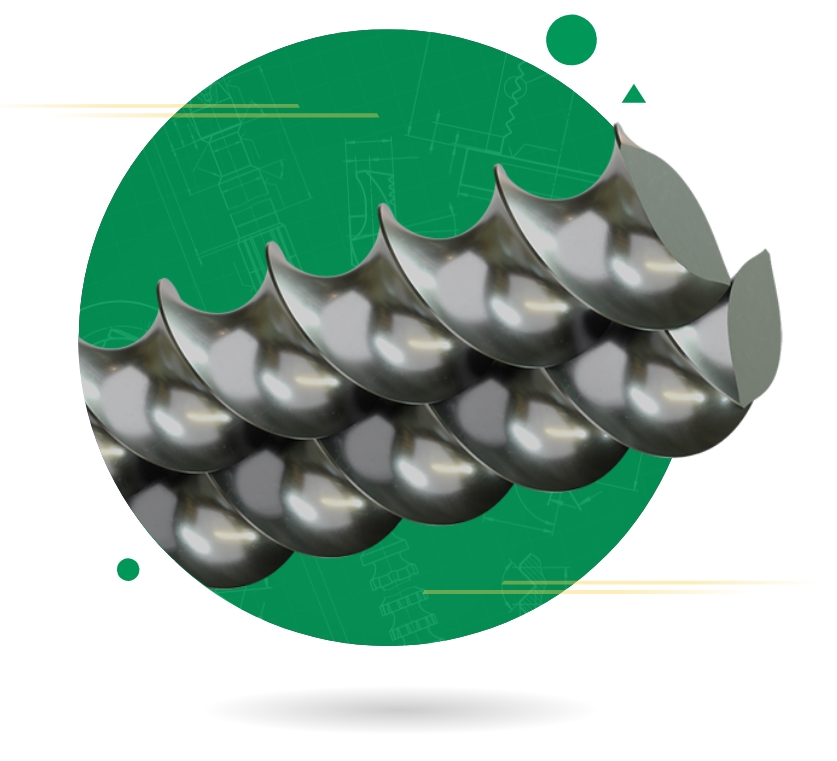

The bi-hole barrel for co-rotating extruders represents an advanced technological innovation. A crucial aspect is the cooling system, particularly important due to the high number of screw rotations during operation. The barrel is equipped with a sophisticated internal cooling system, specifically designed to manage the heat generated during the extrusion process.

The flexibility of this bi-hole barrel extends beyond cooling. The design varies according to the specific needs of the extrusion process. Some barrels can be supplied with a feed hole, others may be smooth or equipped with degassing holes. Additionally, some barrels include housing for a side feeder or a liquid injection system.

Each version of the bi-hole barrel has its unique features, adapting to different positions within the extruder configuration. This versatility makes it an essential component for a wide variety of extrusion operations, ensuring maximum effectiveness and performance.

Are you looking for information about Internal Sleeve?

Gallery

Discover the technical information about

Barrel

| PART | EUV CODES | TYPE | INLAY BASE ALLOY | THERMAL TREATMENT | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|---|

| Complete Part | EUV41 | Nitrided | Quenched and Tempered | Gas or Plasma Nitruration | 950÷1100HV | • | • |

| Main Body for Sleeve version | EUV40 | Carbon Steel | Quenched and Tempered | None | Not needed | Not subject to | Not subject to |

Related Products

CONTACT US

Tell us what you need

Follow us